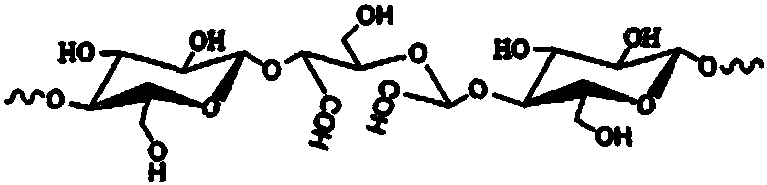

Adhesive for non-formaldehyde impregnated film paper and preparation method thereof

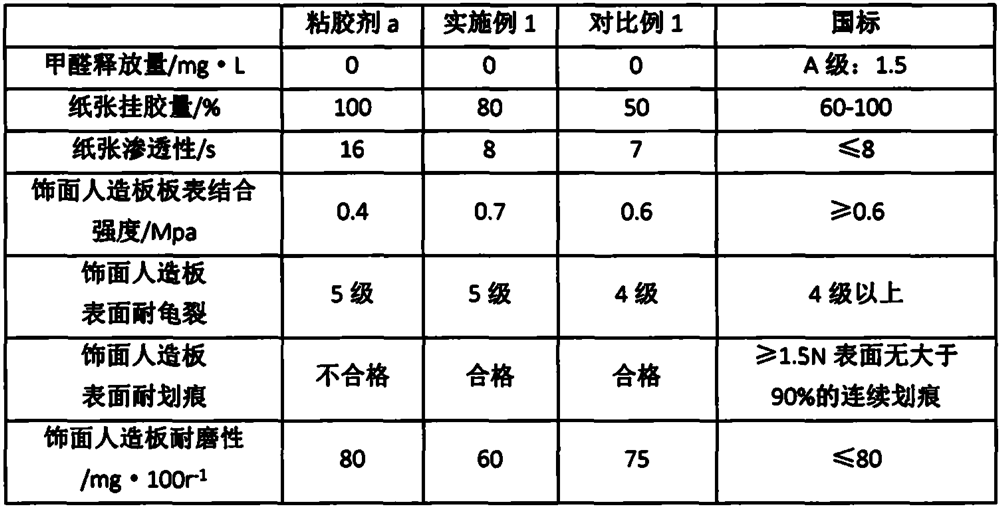

A technology of impregnating film paper and adhesive, applied in papermaking, paper, textiles and papermaking, etc., can solve the problems of poor scratch resistance, high degree of cross-linking, unattainable gloss and fullness, etc. Scratch resistance, solve the damage between paper, improve the effect of glue hanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Add polyethylene glycol (molecular weight 200) and isophorone diisocyanate into a reaction kettle with a stirring and reflux device according to a molar ratio of 0.8, and carry out a prepolymerization reaction under the protection of high-purity nitrogen. The temperature is 40°C, and the reaction time is 1h to obtain a polyurethane prepolymer.

[0028] 2) The temperature of the prepolymer was raised to 65° C., and 1,4-butanediol was added dropwise to the prepolymer for 20 minutes. The chain extension reaction lasted 1.5 hours, and the stirring speed was 50 r / min. Then the temperature was lowered to 40°C, and the hydrophilic agent was added, and the addition was completed within 30 minutes, and the reaction time of this step was 0.5 hours.

[0029] 3) Cool to room temperature, add glacial acetic acid for neutralization, and reduce viscosity with appropriate amount of acetone. After the viscosity is suitable, add water and high-speed shearing. The shearing speed is 200...

Embodiment 2

[0038] 1) Add polyester diol CMA-1024 and isophorone diisocyanate into a reaction kettle with a stirring and reflux device according to a molar ratio of 2, and carry out a prepolymerization reaction under the protection of high-purity nitrogen, and the reaction temperature The temperature is 60°C, the reaction time is 0.5h, and the polyurethane prepolymer is obtained.

[0039]2) The temperature of the prepolymer was raised to 80°C, and ethylene glycol was added dropwise to the prepolymer for 10 min, the chain extension reaction time was 0.5 h, and the stirring speed was 100 r / min. Then the temperature was lowered to 60°C, and the hydrophilic agent was added, and the addition was completed within 30 minutes, and the reaction time of this step was 1.5 hours.

[0040] 3) Cool to room temperature, add glacial acetic acid for neutralization, and reduce viscosity with appropriate amount of acetone. After the viscosity is suitable, add water and high-speed shearing. The shearing spee...

Embodiment 3

[0049] 1) Add polyester diol CMA-1024, Polyethylene Glycol (both molar ratio 1: 1) and hexamethylene diisocyanate into the reactor with stirring and reflux device according to molar ratio 1.3, in Under the protection of high-purity nitrogen, a prepolymerization reaction was carried out at a reaction temperature of 50° C. and a reaction time of 0.7 h to obtain a polyurethane prepolymer.

[0050] 2) The temperature of the prepolymer was raised to 75° C., and propylene glycol was added dropwise to the prepolymer for 15 minutes, the chain extension reaction time was 0.8 hours, and the stirring speed was 80 r / min. Then the temperature was lowered to 50°C, and the hydrophilic agent was added, and the addition was completed within 30 minutes, and the reaction time of this step was 1 hour.

[0051] 3) Cool to room temperature, add glacial acetic acid for neutralization, and reduce viscosity with appropriate amount of acetone. After the viscosity is suitable, add water and high-speed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com