Dual-electrode plates of fuel cell

A fuel cell and bipolar plate technology, applied in battery electrodes, fuel cell components, circuits, etc., can solve the problems of overflowing to the surrounding, affecting the performance of the fuel cell, and easily blocking the plates, so as to improve the qualification rate and ensure Effects of reliability and tightness, reduced skill requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

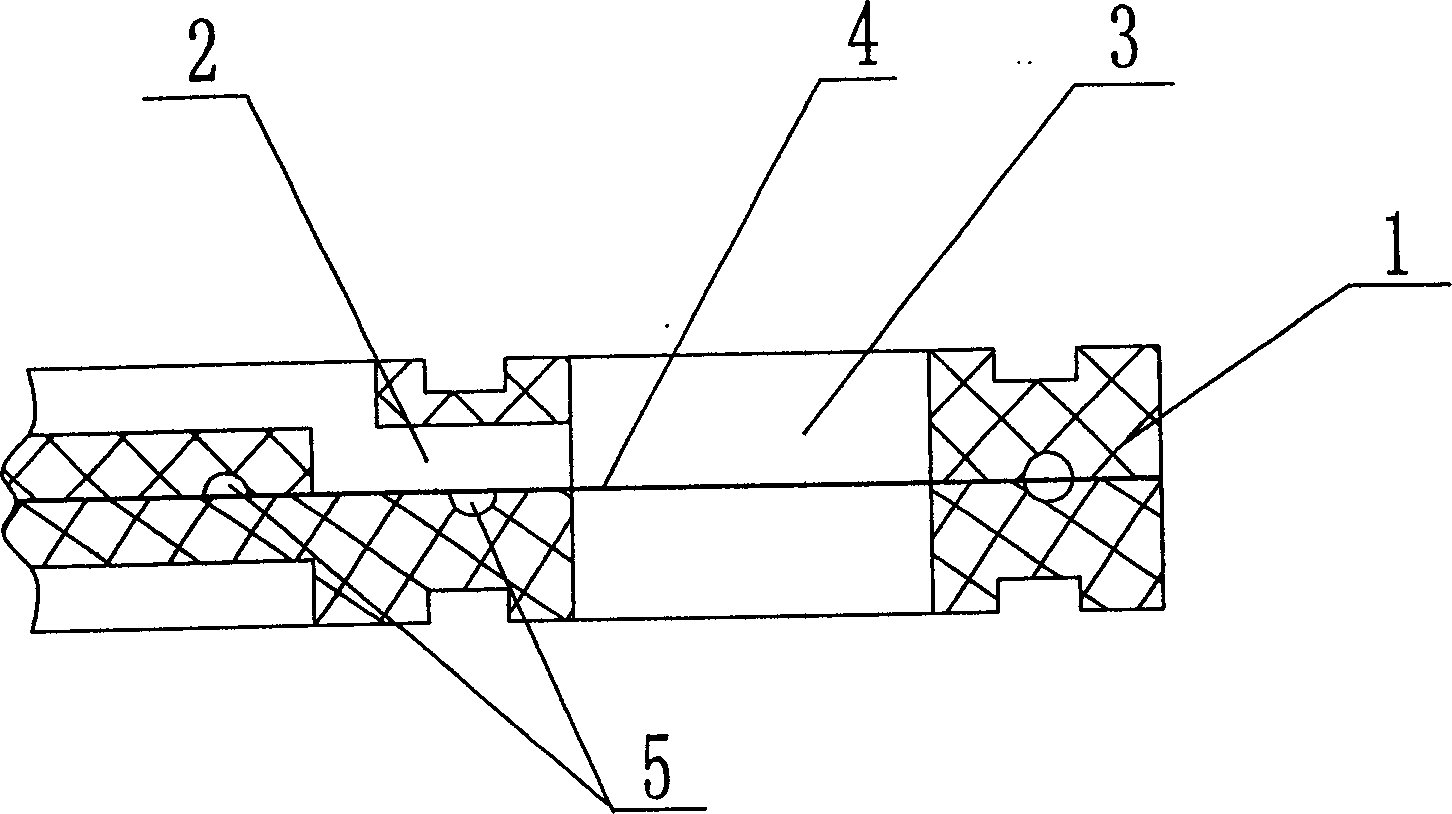

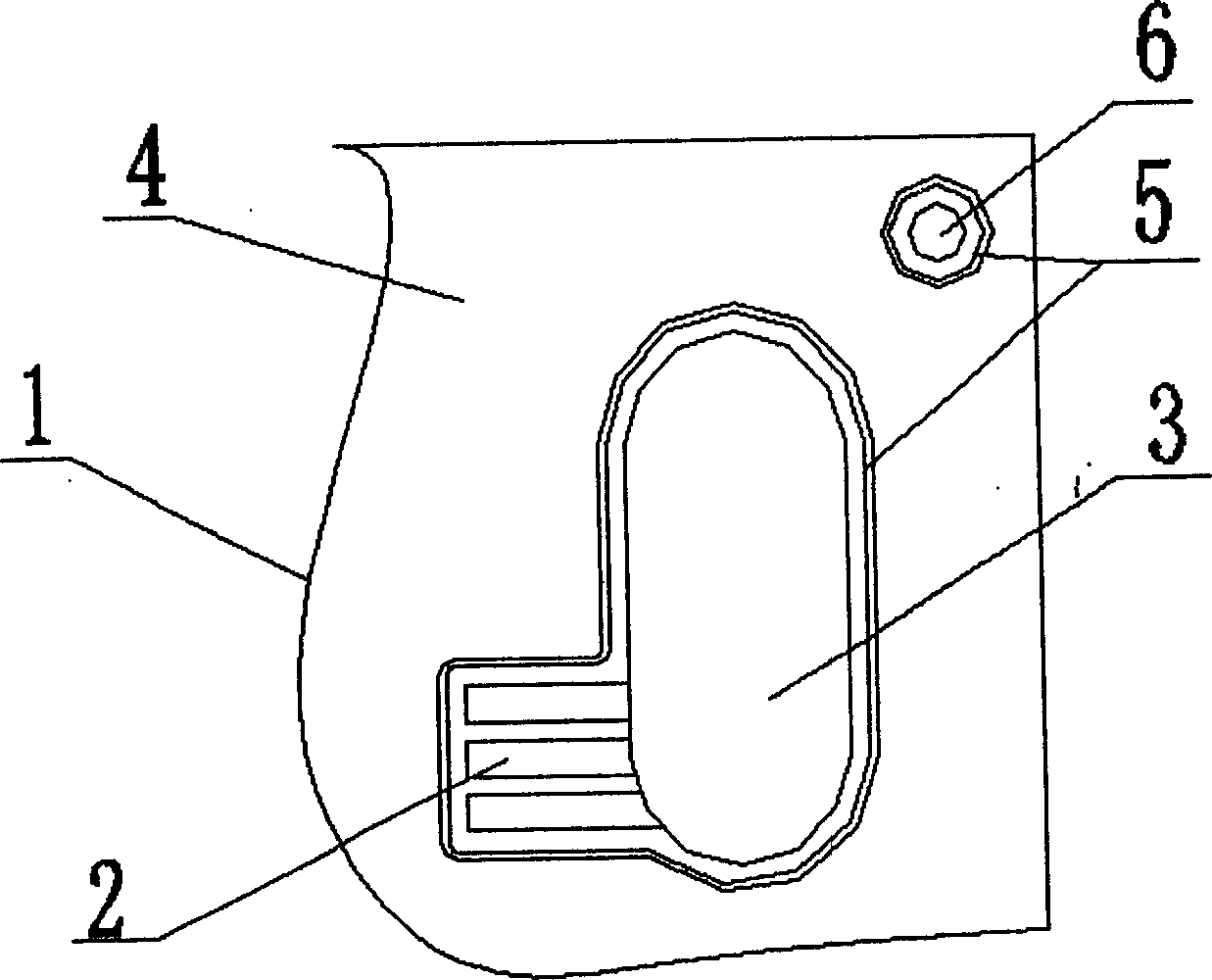

[0014] Such as figure 1 and figure 2 The fuel cell bipolar plate shown includes two upper and lower plate bodies 1 pasted together. On the pasting surface 4 of the two plates 1, a guide groove 2 and a guide groove passing through the two plate bodies 1 are provided. The orifice 3 and the positioning hole 6, the diversion groove 2 and the diversion hole 3 communicate and are used for circulating the reaction gas, and the positioning hole 6 is used for the installation and positioning of the bipolar plate. In order to prevent the viscose from overflowing and blocking the diversion groove 2, the diversion hole 3 and the positioning hole 6 when pasting the bipolar plate and affecting its normal operation, on the pasting surface 4 of the polar plate body 1, along the diversion groove 2, the diversion hole 3 and the periphery of the positioning hole 6 are provided with a groove 5 to prevent the glue from overflowing. The groove 5 adopts a closed annular structure, and is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com