Novel water surface salvage cable robot built-in connecting mechanism

A technology of connecting mechanism and robot, which is applied in the directions of underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of increased driving resistance, sudden changes in structure, and increased cross-sectional size of robots, and achieves reduced resistance, simple operation, The effect of reducing the self-weight of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

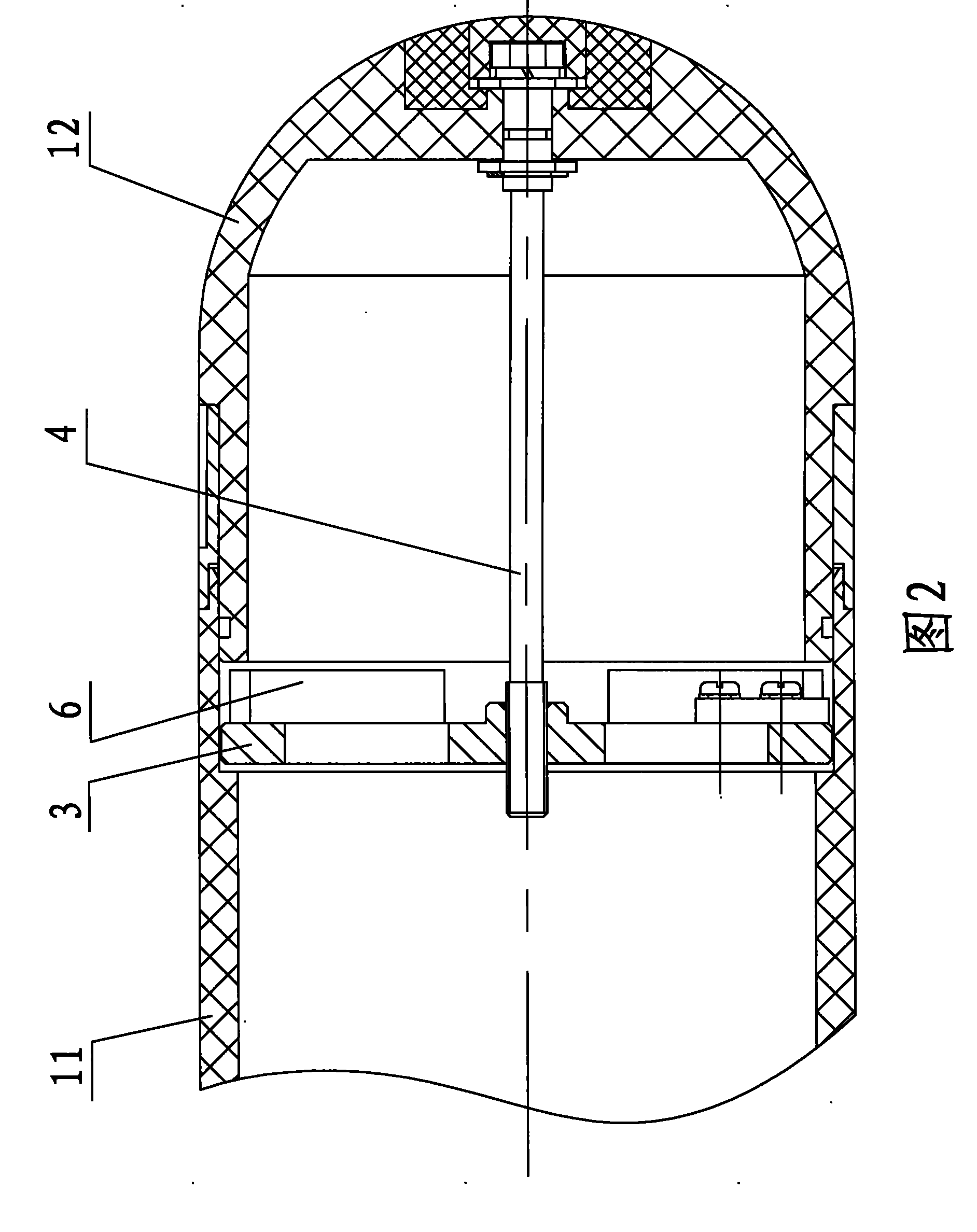

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

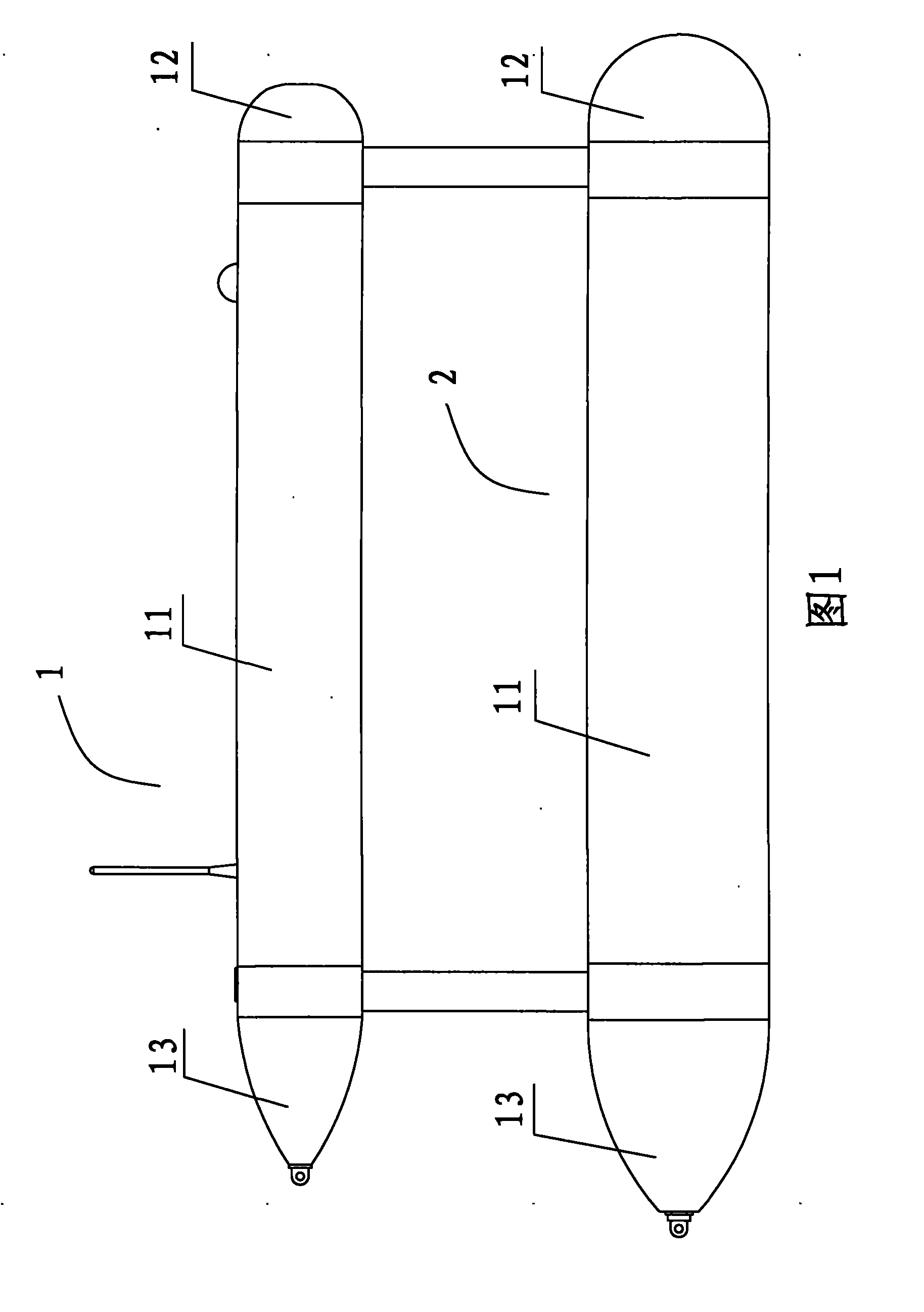

[0020] The present invention can connect the cylinder body and the ball head of the surface rescue cable robot or connect the cylinder body and the tail cone.

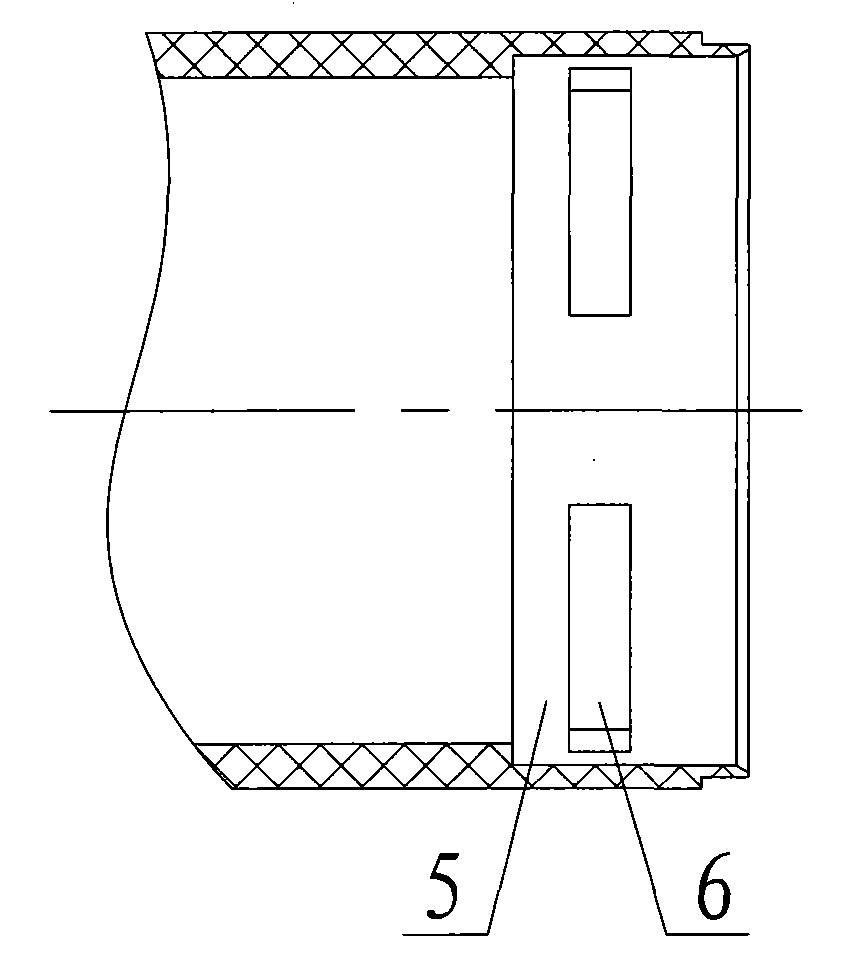

[0021] As shown in Figures 1 to 3, the present invention includes a connecting ring plate 3, and four flanges 9 are evenly distributed on its outer wall, so that the center line of the connecting ring plate 3 is symmetrical in pairs; Screw holes 10. On one side of the connecting ring plate 3, two symmetrical flanges are respectively provided with a stop key 8 through screws. Four protrusions 6 are evenly distributed on the inner wall of the connecting end of the cylinder 11, and an axial insertion groove 7 corresponding to the flange 9 is formed between two adjacent protrusions, and the flange 9 connecting the ring plate 3 passes through the axial insertion groove 7Insert into the end of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com