Production method for colloid accumulator

A technology for colloidal batteries and manufacturing methods, which is applied in the direction of lead-acid batteries, lead-acid battery construction, and final product manufacturing. The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

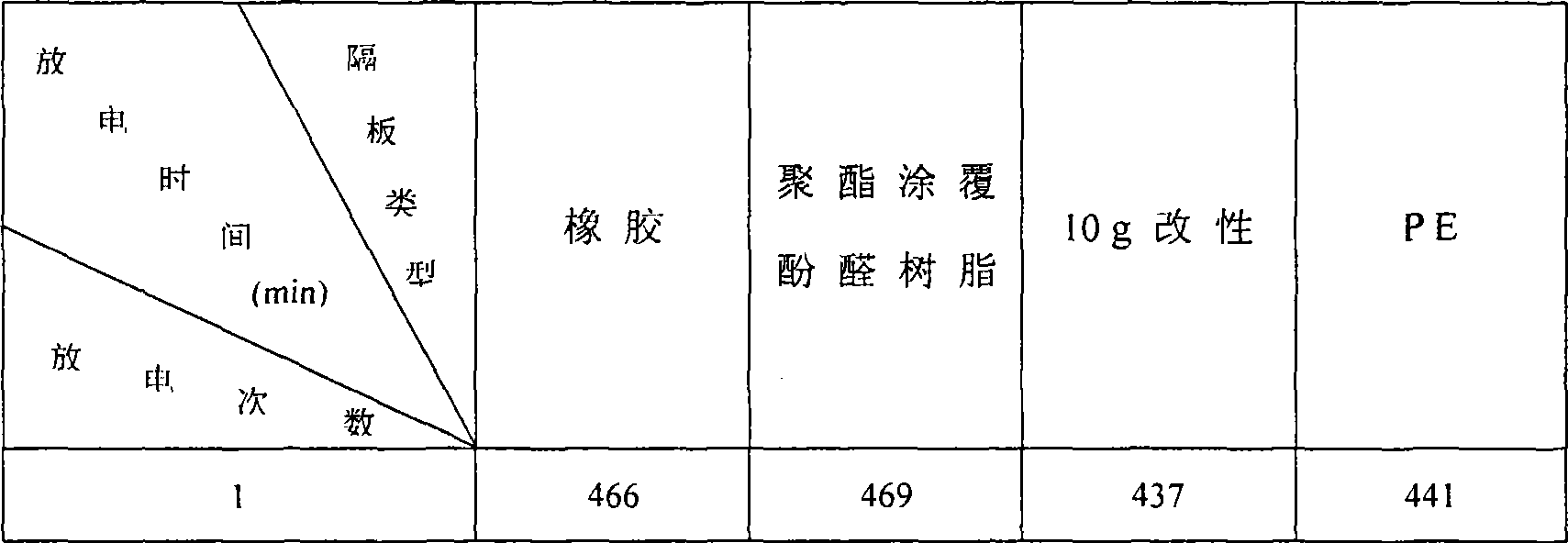

[0020] In addition to AGM, the present invention selected polyethylene (PE) separators, 10g modified separators, and rubber separators for making colloidal battery tests, and used DARAMIC's polyester-coated phenolic resin separators for comparison. The rubber separator used here is made of natural rubber and SiO 2 and sulfur by vulcanization, or natural rubber and SiO 2 It is made by electron radiation cross-linking, and its surface is corrugated, which is conducive to perfusion of colloid. Its resistivity≤0.003Ω / dm 2 , the porosity is about 60%. The rubber separator has high mechanical strength, can prevent the transfer of antimony between the positive and negative electrodes, prevent dendrite short circuit, and can be used to make long-life batteries 【2】 . The 10g modified separator here is modified by adding diatomaceous earth to polyethylene.

[0021] The specific preparation methods of the 4 test batteries are as follows:

[0022] 1. The grid is Pb-Ca alloy, and the...

Embodiment 2

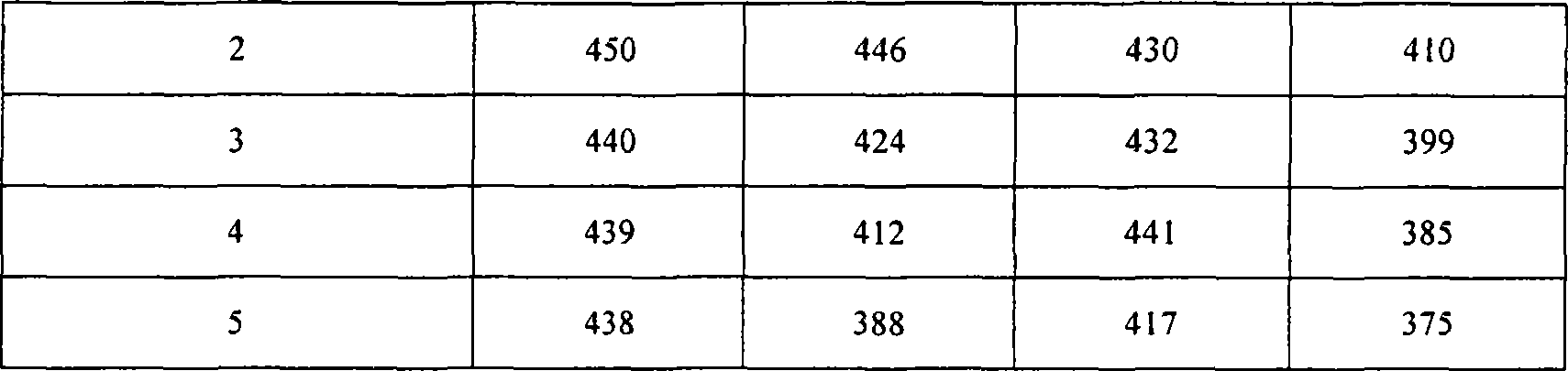

[0031] Test battery: 2 pcs of 6-DZMJ-10 electric vehicle battery, the external dimension is 152×98×94 (mm), the grid is Pb-Ca alloy, internalized, using AGM separator and rubber separator respectively, other processes are the same Example 1.

[0032] The test performances of the two separator gel batteries are listed in Table 2.

[0033] Table 2, AGM and rubber separator colloidal battery test performance comparison

[0034]

[0035] The test results show that the initial 5A discharge capacity of the gel battery with rubber separator is slightly lower than that of the AGM battery, but the battery capacity can reach the technical standard, and the other performances are better than the AGM battery. Its storage capacity is about 100g more, reaching the level of flooded batteries, which is very beneficial to increase capacity and prolong life. During constant current charging, the battery with rubber separator has low temperature, less water consumption, and slow corrosion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com