Method for fixing copper sleeve on notebook computer panel

A notebook computer, copper sleeve fixing technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of copper sleeve drawing strength reduction, copper sleeve fixing hole deformation, etc., to increase the amount of glue, improve the diameter The effect of expanding outward and increasing the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

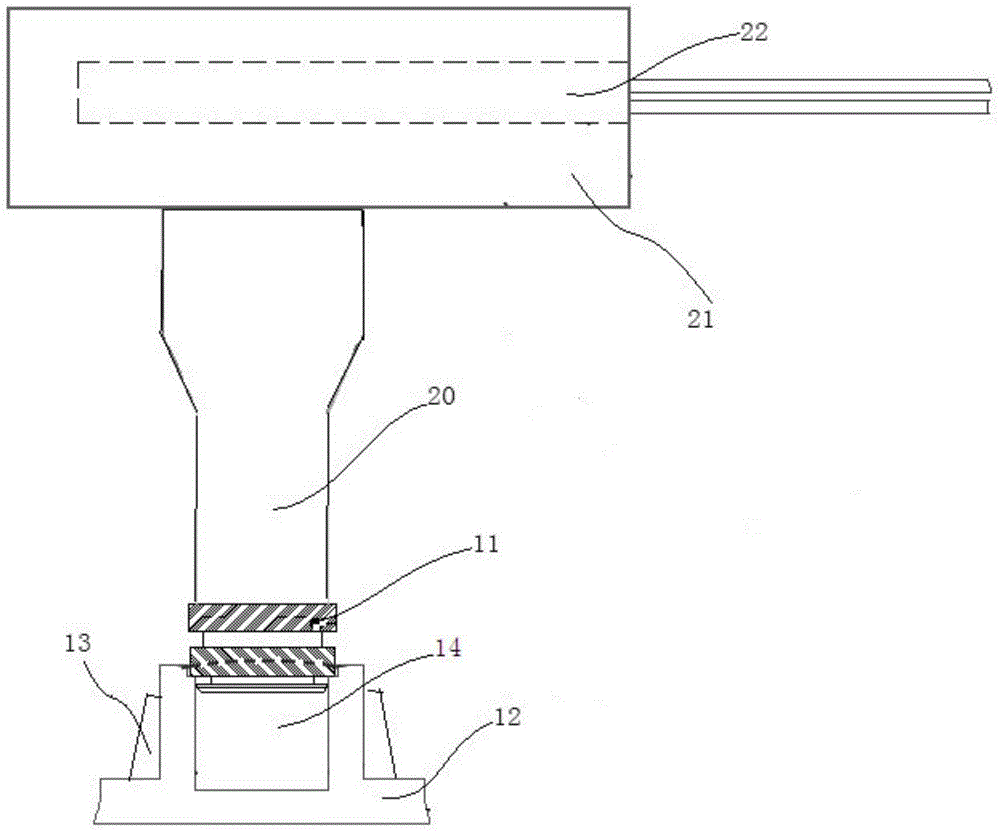

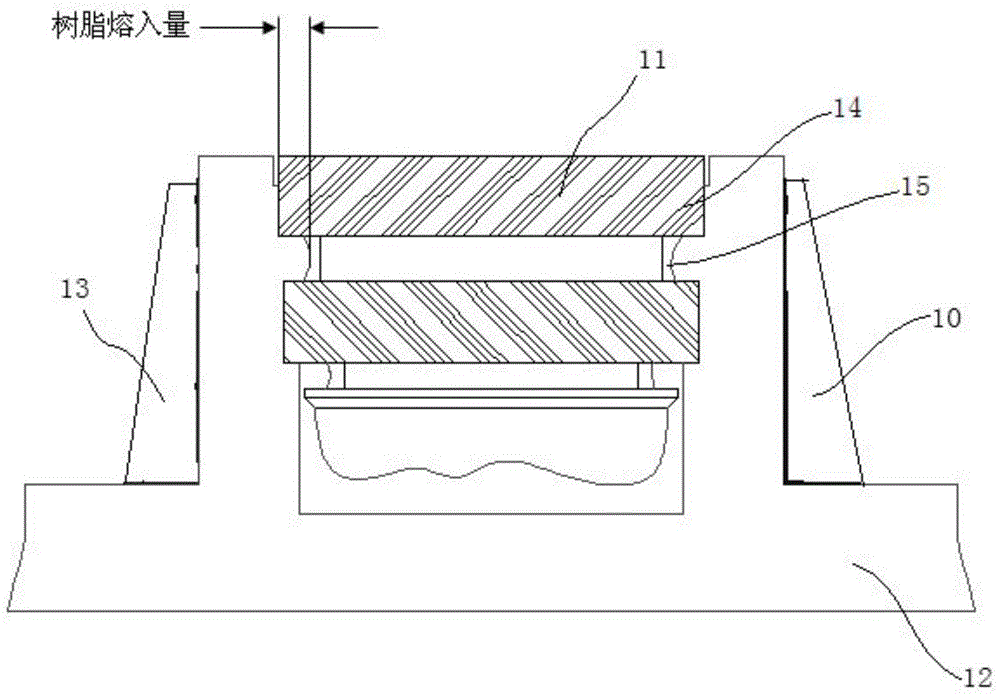

[0012] Below in conjunction with embodiment and attached Figure 1-2 The present invention is further described.

[0013] The invention provides a method for fixing a copper sleeve on a notebook computer panel, the method comprising the following steps: setting the diameter of a fixing hole corresponding to hot pressing into the copper sleeve at least 0.4 cm smaller than the maximum diameter of the copper sleeve; At least one pair of reinforcing ribs is arranged on the outer periphery of the fixing hole; the copper sleeve is hot-pressed into the fixing hole by means of high temperature and pressure for fixing.

[0014] figure 1 It is an assembly diagram of the method for fixing the copper sleeve on the notebook computer panel of the present invention. The hot-pressed copper rod 20 is fixed on the fixing block 21 of the machine, and the thermocouple 22 heats the hot-pressed copper rod 20 to about 200 ° C, so that the temperature of the copper sleeve 11 raised. The hot-presse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com