Preparation method and application of hot-mixed epoxy tack coat oil for steel bridge deck pavement

A hot-mix epoxy adhesive layer oil, hot-mix epoxy adhesive technology, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of insufficient durability, insufficient waterproof performance, and epoxy adhesive layer bonding. Insufficient strength and other problems, to achieve good waterproof effect, improve epoxy flexibility, and excellent shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of hot-mix epoxy adhesive layer oil for steel bridge deck paving, said hot-mix epoxy adhesive layer oil for steel bridge deck paving is composed of epoxy resin component A and curing agent component B, said The raw material of epoxy resin component A comprises the following components according to the proportioning in parts by mass:

[0034] Bisphenol A epoxy resin NPEL128 100 parts

[0035] Thinner PEGGE 205 (polyethylene glycol diglycidyl ether) 3 parts

[0036] Coupling agent A-151 1 part

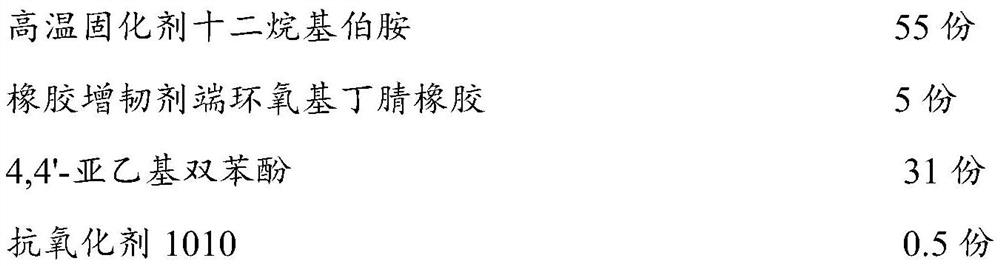

[0037] The raw materials of curing agent component B are proportioned in parts by mass, including:

[0038]

[0039] Preparation method of epoxy resin component A: heat each component in epoxy resin component A to 60°C, mix and stir according to the above ratio, and stir at a speed of 500r / min for 30min to prepare epoxy resin component A;

[0040] Preparation method of curing agent component B: After heating each component in curing agent component B to ...

Embodiment 2

[0049] A preparation method of hot-mix epoxy adhesive layer oil for steel bridge deck paving, said hot-mix epoxy adhesive layer oil for steel bridge deck paving is composed of epoxy resin component A and curing agent component B, said The raw material of epoxy resin component A comprises the following components according to the proportioning in parts by mass:

[0050]Bisphenol A epoxy resin E511 100 parts

[0051] Thinner AGE 748 (C12-14) alcohol glycidyl ether 13 parts

[0052] Silane coupling agent A-172 3 parts

[0053] The raw materials of curing agent component B are proportioned in parts by mass, including:

[0054]

[0055] Preparation method of epoxy resin component A: heat each component in epoxy resin component A to 60°C, mix and stir according to the above ratio, and stir at a speed of 500r / min for 30min to prepare epoxy resin component A;

[0056] Preparation method of curing agent component B: After heating each component in curing agent component B to 80°C...

Embodiment 3

[0065] A preparation method of hot-mix epoxy adhesive layer oil for steel bridge deck paving, said hot-mix epoxy adhesive layer oil for steel bridge deck paving is composed of epoxy resin component A and curing agent component B, said The raw material of epoxy resin component A comprises the following components according to the proportioning in parts by mass:

[0066] Bisphenol A epoxy resin E44 100 parts

[0067] Thinner PPGDGE207 (polypropylene glycol diglycidyl ether) 6 parts

[0068] Silane coupling agent KH-540 2.5 parts

[0069] The raw materials of curing agent component B are proportioned in parts by mass, including:

[0070]

[0071] Preparation method of epoxy resin component A: heat each component in epoxy resin component A to 60°C, mix and stir according to the above ratio, and stir at a speed of 500r / min for 30min to prepare epoxy resin component A;

[0072] Preparation method of curing agent component B: After heating each component in curing agent compone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com