C35 self-compacting concrete adopting machine-made sand and preparation method thereof

A technology for self-compacting concrete and machine-made sand, applied in the field of concrete, can solve the problems of poor concrete strength, poor compactness, irregular shape, etc., and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

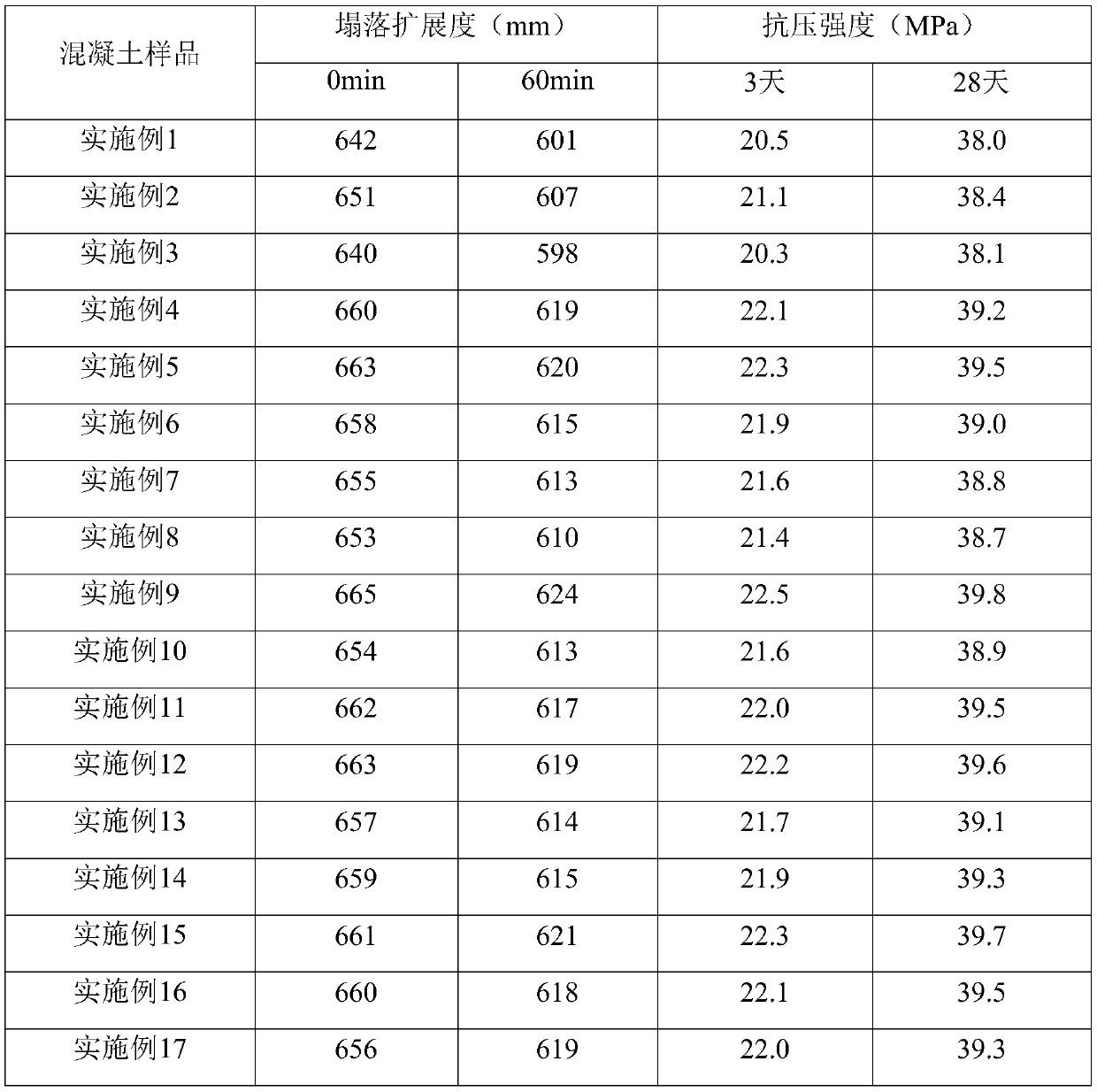

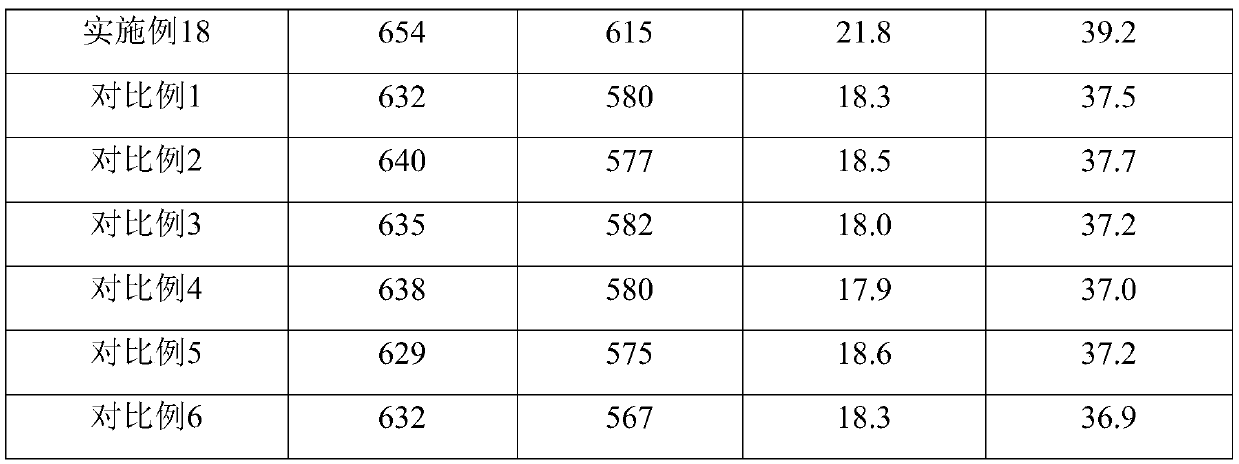

Examples

Embodiment 1

[0038] A C35 self-compacting concrete using machine-made sand, including the following components in parts by weight: 250 parts of cement, 80 parts of fly ash, 80 parts of mineral powder, 680 parts of machine-made sand with a fineness of 3.1-3.5, fine 160 parts of natural fine sand with a degree of 0.5-0.8, 350 parts of 5-16mm continuously graded natural crushed stone, 500 parts of 5-20mm continuously graded natural crushed stone, 210 parts of water, 10.0 parts of polycarboxylate superplasticizer , wherein, the ratio by weight of machine-made sand and natural fine sand is 1:0.235;

[0039] The preparation method of the C35 self-compacting concrete using machine-made sand includes the following steps: uniformly mixing cement, fly ash, mineral powder and water, then adding machine-made sand with a fineness of 3.1-3.5, fineness of 0.5-0.8 Natural fine sand, 5-16mm continuous graded natural gravel, 5-20mm continuous graded natural gravel are mixed evenly, and then polycarboxylate ...

Embodiment 2

[0041] A C35 self-compacting concrete using machine-made sand, including the following components in parts by weight: 280 parts of cement, 60 parts of fly ash, 100 parts of mineral powder, 620 parts of machine-made sand with a fineness of 3.1-3.5, fine 205 parts of natural fine sand with a degree of 0.5-0.8, 250 parts of 5-16mm continuously graded natural crushed stone, 650 parts of 5-20mm continuously graded natural crushed stone, 195 parts of water, 11 parts of polycarboxylate superplasticizer , wherein, the weight ratio of machine-made sand and natural fine sand is 1:0.33;

[0042]The preparation method of the C35 self-compacting concrete using machine-made sand includes the following steps: uniformly mixing cement, fly ash, mineral powder and water, then adding machine-made sand with a fineness of 3.1-3.5, fineness of 0.5-0.8 Natural fine sand, 5-16mm continuous graded natural gravel, 5-20mm continuous graded natural gravel are mixed evenly, and then polycarboxylate water ...

Embodiment 3

[0044] A C35 self-compacting concrete using machine-made sand, including the following components in parts by weight: 320 parts of cement, 40 parts of fly ash, 120 parts of mineral powder, 580 parts of machine-made sand with a fineness of 3.1-3.5, fine 250 parts of natural fine sand with a degree of 0.5-0.8, 150 parts of 5-16mm continuously graded natural crushed stone, 750 parts of 5-20mm continuously graded natural crushed stone, 180 parts of water, 12.0 parts of polycarboxylate superplasticizer , wherein, the ratio by weight of machine-made sand and natural fine sand is 1:0.43;

[0045] The preparation method of the C35 self-compacting concrete using machine-made sand includes the following steps: uniformly mixing cement, fly ash, mineral powder and water, then adding machine-made sand with a fineness of 3.1-3.5, fineness of 0.5-0.8 Natural fine sand, 5-16mm continuous graded natural gravel, 5-20mm continuous graded natural gravel are mixed evenly, and then polycarboxylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com