Process of producing plate with small size timber

A small-diameter, craft-based technology, applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, can solve the problems of insufficient veneer strength, affecting productivity, and cumbersome assembly of billets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

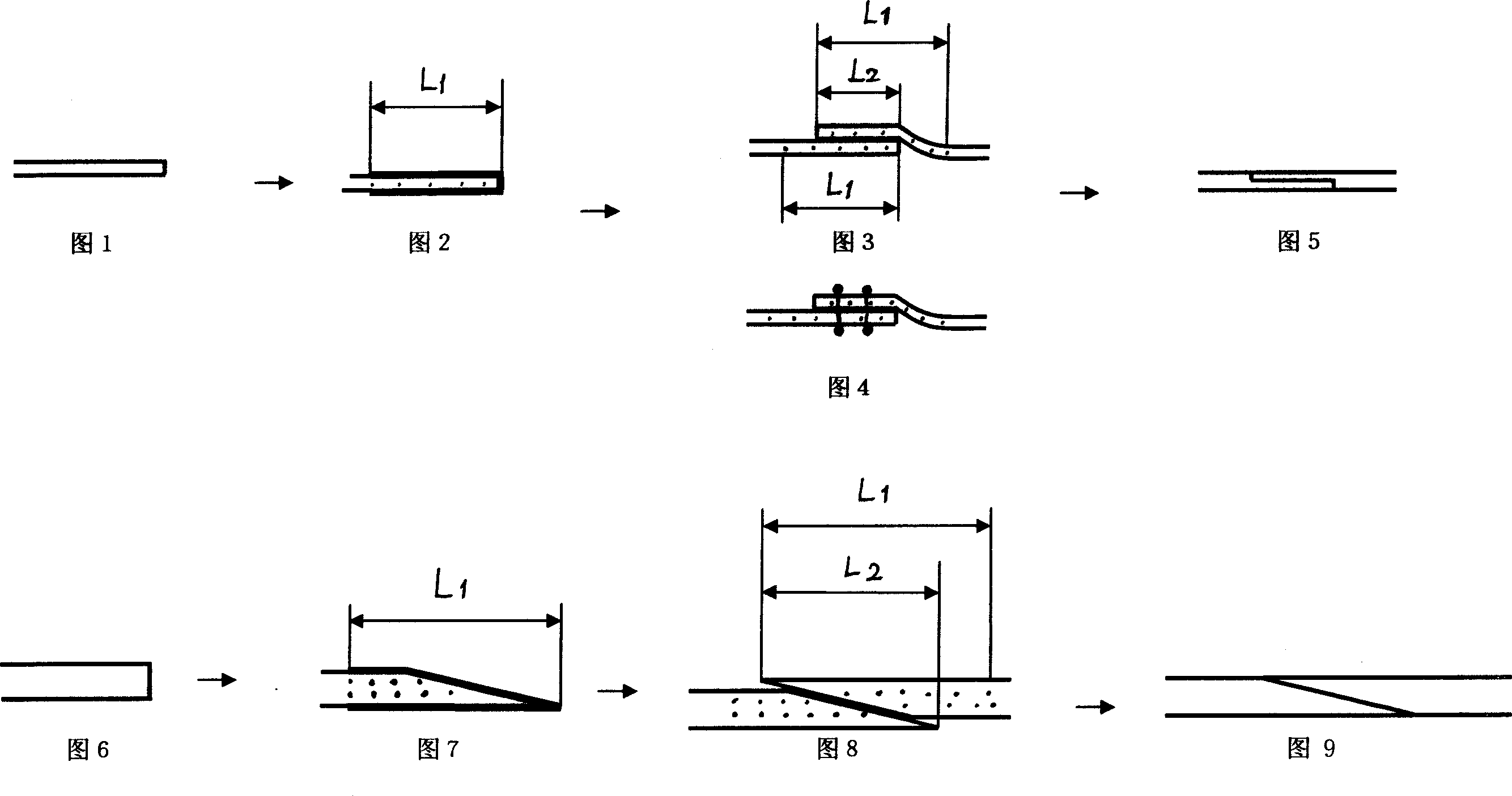

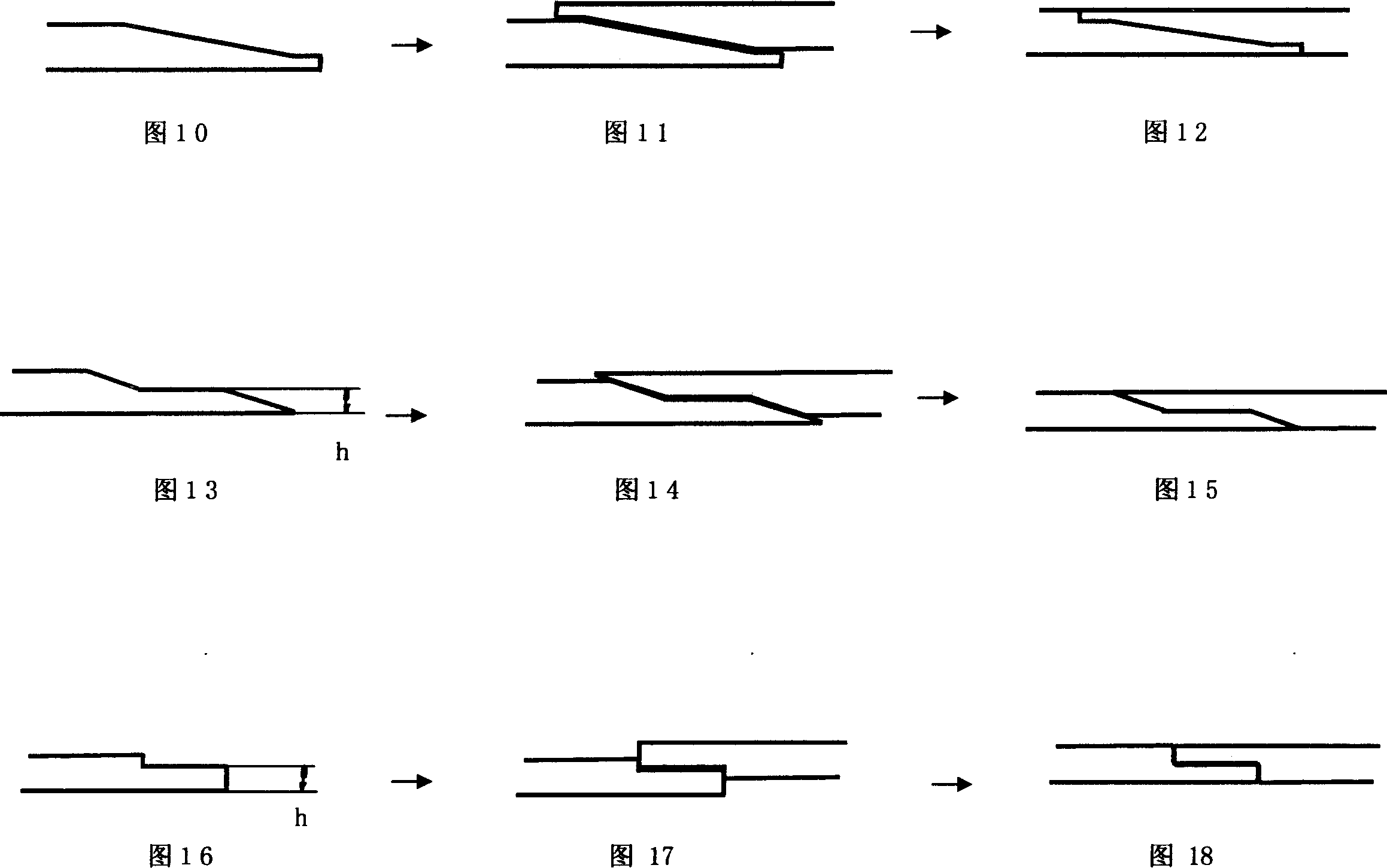

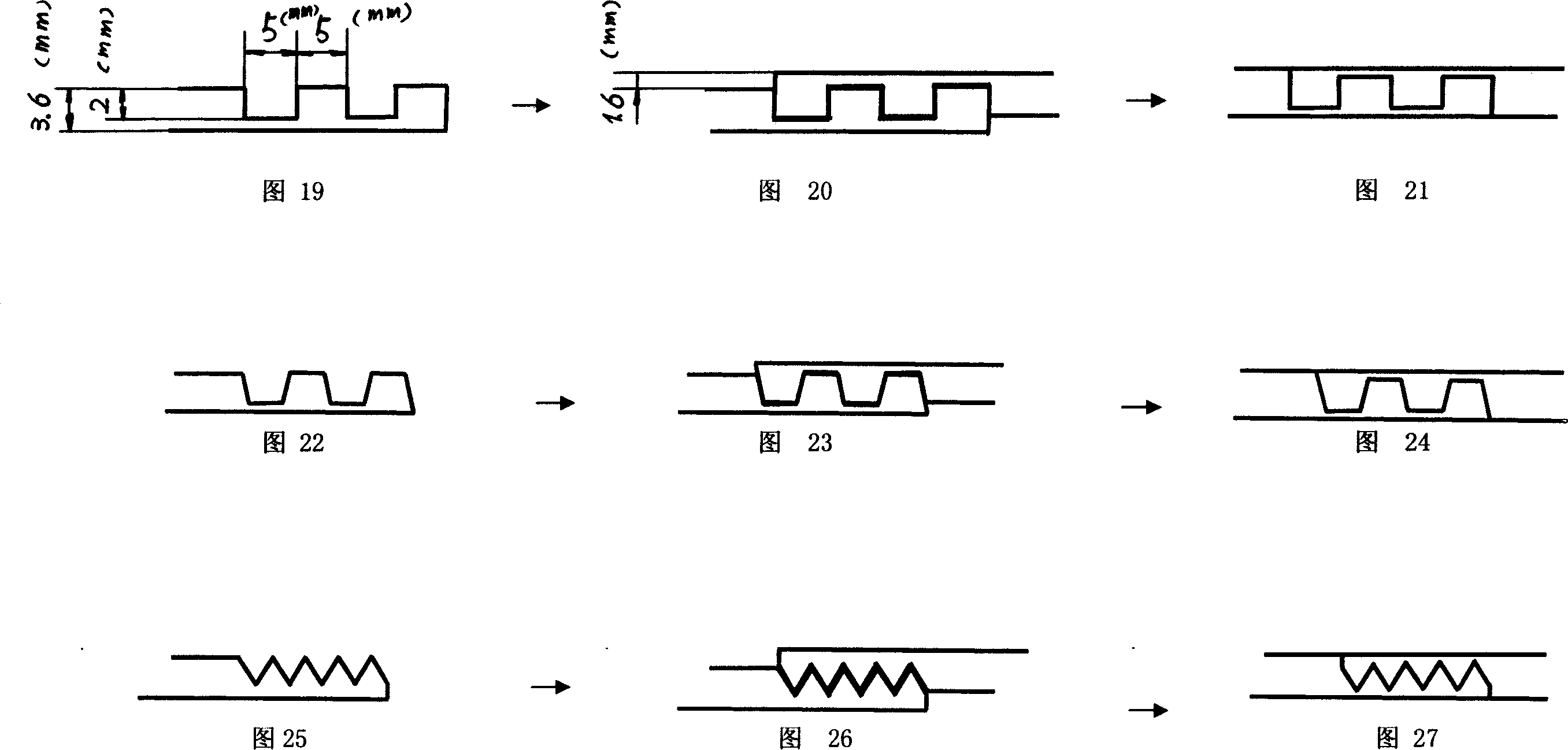

[0046] Whole method of thick poplar veneer:

[0047] The poplar wood section is about 650mm long, cut into veneers with a thickness of 3.6mm, and dried;

[0048] The end is processed into rectangular teeth, the specific dimensions are shown in Figure 19 and Figure 20;

[0049] Use phenolic resin glue, dip the joints of the veneers with glue, the dipping amount is about 20%, and dry the veneers at 90°C until the moisture content is about 10%. The rectangular tooth butt joint blanks are shown in Figure 20;

[0050] Hot-pressing parameters, hot-pressing temperature 170°C, 3.6mm thickness gauge controls the thickness of the veneer joint, the compression rate is 31%, after three connections, the length of the whole large veneer is 2520mm (650×4-3×30 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com