Antirust paint processing transmission tower surface and preparation method thereof

A technology for surface treatment and transmission towers, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of increasing raw material costs and labor costs, affecting the protective effect of the coating system, and poor adhesion of coatings, etc., to achieve inhibition Corrosion process, improve protection effect, good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

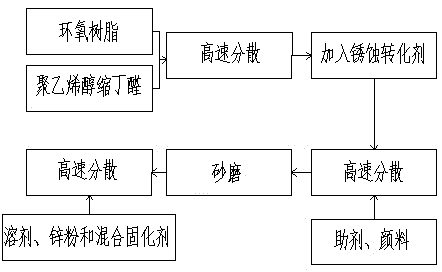

[0020] Example 1: A method for preparing an anti-rust coating for surface treatment of an electric transmission tower, comprising the following process steps:

[0021] (1) High-speed dispersion of film-forming resin: prepare raw materials, wherein the composition of the anti-rust paint for the surface treatment of transmission towers includes epoxy resin E-44 16%, polyvinyl butyral 7%, zinc phosphate 4%, aluminum tripolyphosphate 4%, zinc borate 2%, flaky zinc powder 35%, organic bentonite 1%, rust conversion agent 5%, solvent 21% and mixed curing agent 5%, then the prepared ring Put the oxygen resin and polyvinyl butyral into the high-speed disperser, turn on the high-speed disperser for high-speed dispersion, and make it into a powdery substance. During the high-speed dispersion, a phosphoric acid-tannic acid composite system is added as a rust conversion agent to control corrosion. The speed of the high-speed disperser is 845r / min, and the control dispersion time is 2min;...

Embodiment 2

[0028] Example 2: The rest are the same as in Example 1, except that in the step (1), the composition of the antirust paint for the surface treatment of the transmission tower includes 15% epoxy resin E-44, 6% polyvinyl butyral , 5% zinc phosphate, 4% aluminum tripolyphosphate, 2% zinc borate, 36% flaky zinc powder, 1% organic bentonite, 5% rust conversion agent, 21% solvent and 5% mixed curing agent, controlled high-speed disperser The rotation speed of the high-speed disperser is 850r / min, and the control dispersion time is 3min; in the step (2), the control speed of the high-speed disperser is 855r / min, and the control dispersion time is 7min; in the step (3), the sand milling time is controlled It is 8min; In the step (4), the rotating speed of the high-speed disperser is controlled to be 845r / min, and the dispersion time is controlled to be 7min; in the surface treatment method of the transmission tower, the thickness of the control coating layer is 80 .

Embodiment 3

[0029] Example 3: The rest are the same as in Example 1, except that in the step (1), the composition of the antirust coating for the surface treatment of the transmission tower includes 17% of epoxy resin E-44, 6% of polyvinyl butyral , 5% zinc phosphate, 4% aluminum tripolyphosphate, 2% zinc borate, 35% flaky zinc powder, 1% organic bentonite, 5% rust conversion agent, 21% solvent and 4% mixed curing agent, controlled high-speed disperser The rotation speed of the high-speed disperser is 855r / min, and the control dispersion time is 3min; in the step (2), the control speed of the high-speed disperser is 850r / min, and the control dispersion time is 8min; in the step (3), the sand milling time is controlled It is 6min; In the step (4), the rotating speed of the high-speed disperser is controlled to be 855r / min, and the dispersion time is controlled to be 8min; in the surface treatment method of the transmission tower, the thickness of the control coating layer is 85 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com