Patents

Literature

44results about How to "Not easy to drop paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Directly sprayed polypropylene material and preparation method thereof

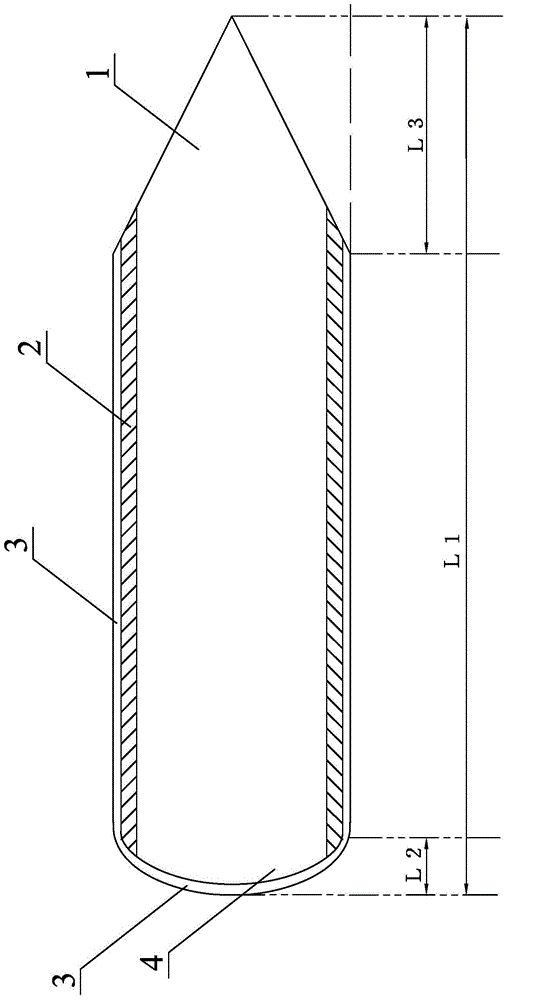

The invention relates to a directly sprayed polypropylene material and a preparation method thereof. The polypropylene material is prepared with the following materials: polypropylene, second component high polymer material, compatilizer, filler, lubricating agent and antioxidant. The preparation method includes the following steps: (1) the materials are weighed according to a ratio, and are uniformly mixed in a high-speed mixer at a high speed for 5 to 10 minutes; (2) the mixed material is added in a double-screw extruder, melted, extruded and granulated. The polypropylene material has high rigidity and good sprayability, cannot be easily scratched and chipped and cannot easily leave traces, and moreover, the preparation method has the advantages of simple technique, convenient operationand low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

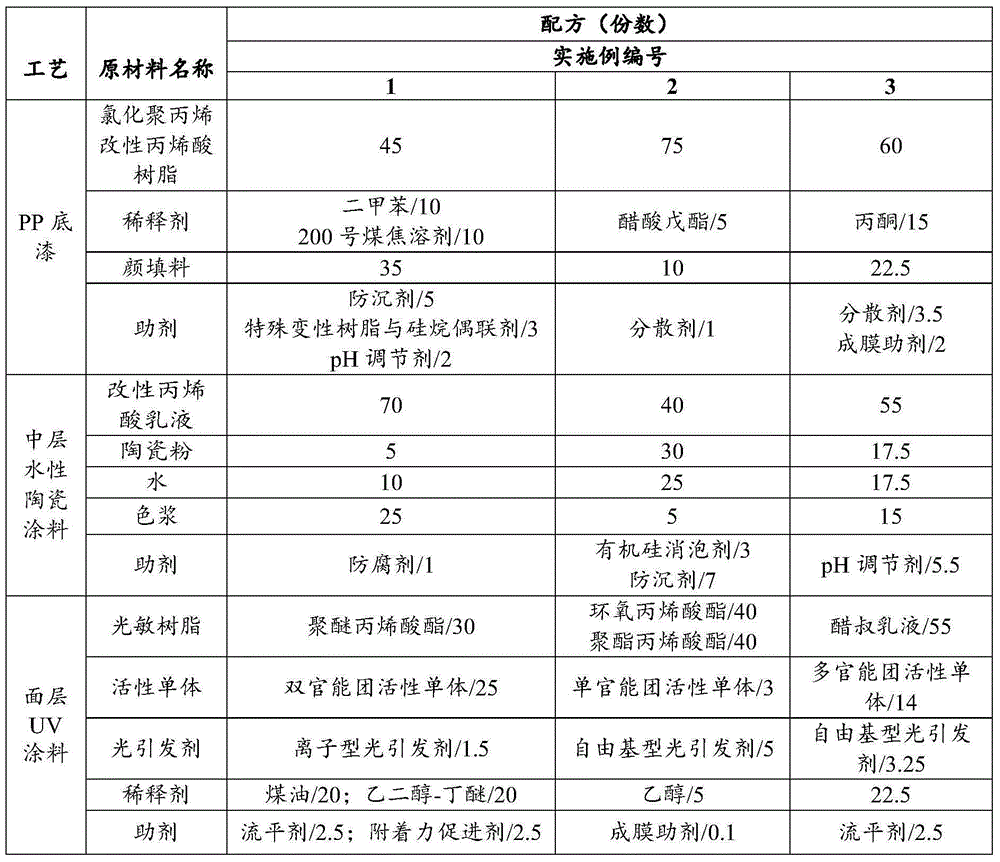

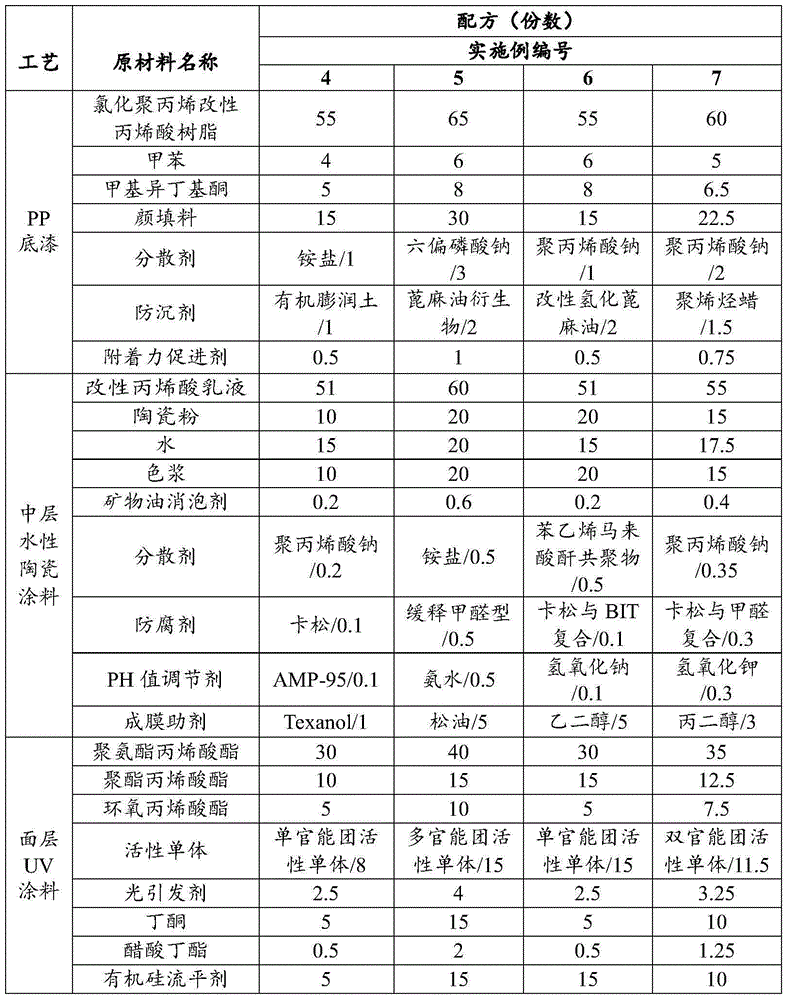

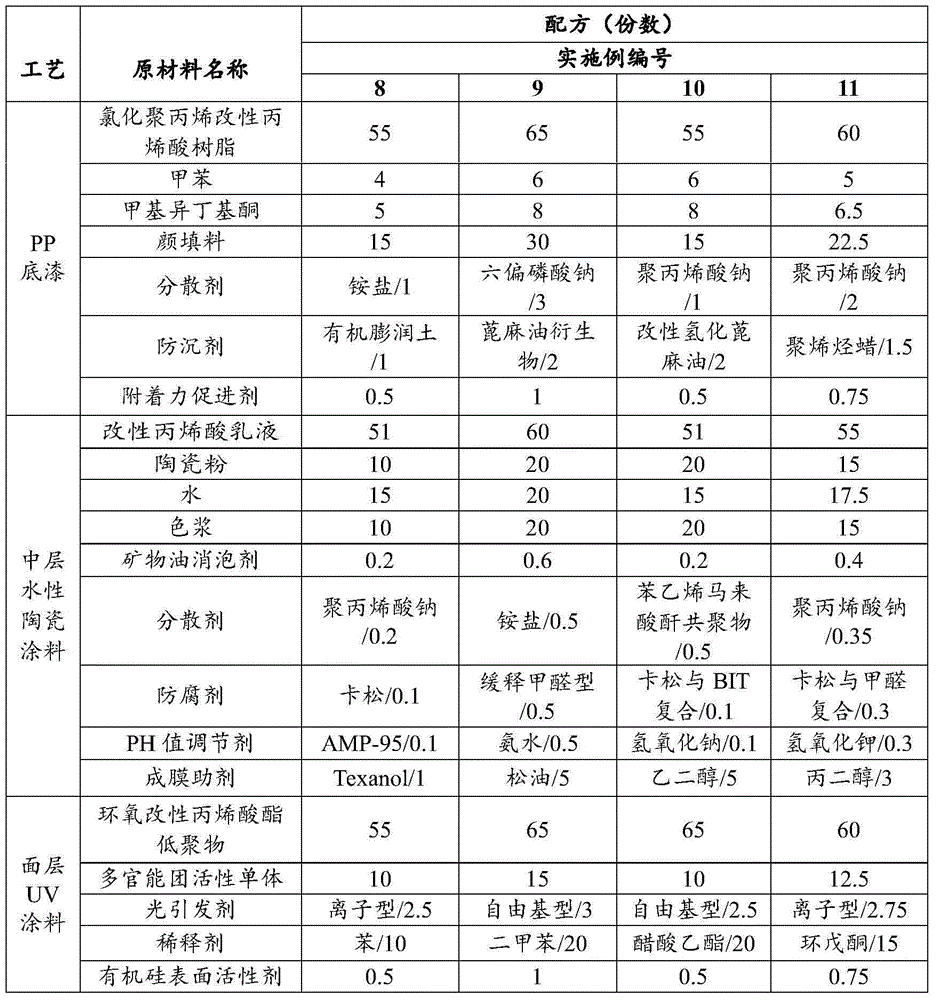

Porcelain imitation coating and spraying method thereof

ActiveCN105199515AImprove adhesionGood flexibilityPretreated surfacesPolyurea/polyurethane coatingsEnvironmental resistanceEmulsion

The invention relates to the fields of handicrafts and architectural decoration, and concretely relates to a porcelain imitation coating. The porcelain imitation coating comprises a PP primer, a middle layer aqueous porcelain imitation coating and a top layer UV coating; the PP primer comprises 45-75 parts of chlorinated polypropylene modified acrylic resin, 5-20 parts of a diluent, 10-35 parts of a pigment filler and 1-10 parts of an assistant; the middle layer aqueous porcelain imitation coating comprises 40-70 parts of a modified acrylic emulsion, 5-30 parts of ceramic powder, 10-25 parts of water, 5-25 parts of a color paste and 1-10 parts of an assistant; and the top layer UV coating comprises 30-80 parts of photosensitive resin, 3-25 parts of an active monomer, 1.5-5 parts of a photoinitiator, 5-40 parts of the diluent and 0.1-5 parts of an assistant. The coating primer difficulty cracks and strips, the middle layer coating has strong weather ability, ageing resistance and strong interlayer adhesion, and the top layer coating is environmentally friendly and has short air-drying solidification time. The invention also relates to a spraying method of the porcelain imitation coating. The method is easy to operate.

Owner:HUIZHOU SHENGYUANHENG CRAFTS

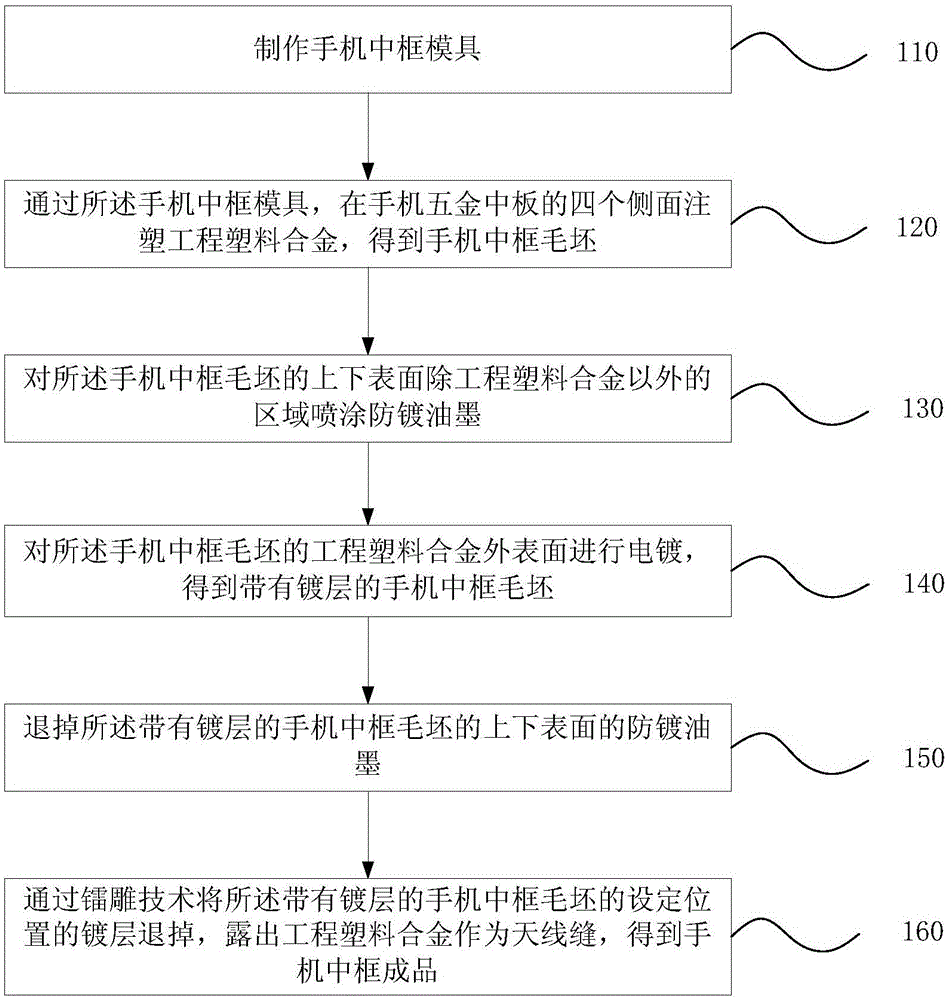

Method for manufacturing mobile phone middle frame and structure of mobile phone middle frame

ActiveCN105141725ANot easy to drop paintStrong adhesionTelephone set constructionsLaser etchingAgricultural engineering

The present invention discloses a method for manufacturing a mobile phone middle frame and a structure of the mobile phone middle frame. The method for manufacturing the mobile phone middle frame includes the steps as follows: manufacturing a mobile phone middle frame die; injecting an engineering plastic alloy into four side faces of a hardware middle plate of the mobile phone through the mobile phone middle frame die to obtain a mobile phone middle frame workblank; spraying the upper surface and the lower surface of the mobile phone middle frame workblank except for the engineering plastic alloy region with anti-electroplating printing ink; electroplating the outside surface of the engineering plastic alloy region of the mobile phone middle frame workblank to obtain the mobile phone middle frame workblank with an electroplating layer; rejecting the anti-electroplating printing ink on the upper surface and the lower surface of the mobile phone middle frame workblank with the electroplating layer; and rejecting the electroplating layer of a setting position of the mobile phone middle frame workblank with the electroplating layer through the laser etching technique to expose the engineering plastic alloy as an antenna slot so that the finished mobile phone middle frame is obtained. According to the present invention, the outside face of the finished mobile phone middle frame is not prone to painting peeling off and has the better adhesive force, and the plastic outer frame of the finished mobile phone middle frame is more aesthetically pleasing.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

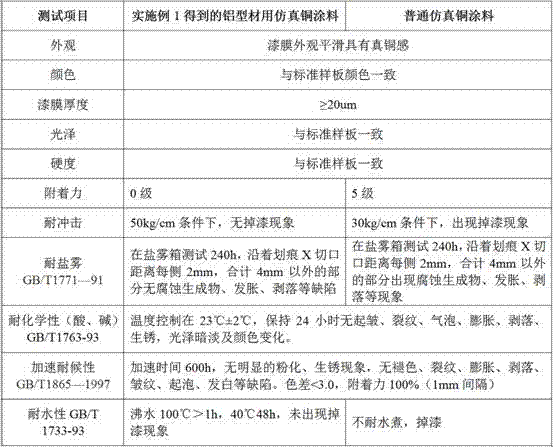

Artificial copper paint for aluminium profile and preparation method thereof

ActiveCN106883764ARealistic simulated copper effectRealistic imitation plating effectAnti-corrosive paintsCross-linkSolvent

The invention discloses an artificial copper paint for an aluminium profile. The artificial copper paint for the aluminium profile is prepared by the raw materials of electroplate silver resin for baking varnish, polyester resin, mixed solvent, cross-linked amino resin, oriented anti-settling agent, crystal pearlescent pigment, color mixing pigment and coupling agent; the electroplate silver resin for the baking varnish is obtained by combining solid electroplate silver resin and a mixed solvent according to a proportion. A preparation method for the artificial copper paint for the aluminium profile comprises the steps of adding the electroplate silver resin for the baking varnish and the polyester resin to a mixing tank to be uniformly mixed; adding 80-90% of the mixed solvent to the mixing tank during mixing; adding the cross-linked amino resin to the mixing tank during mixing and uniformly dispersing the cross-linked amino resin; adding the coupling agent and the oriented anti-settling agent to the mixing tank in sequence; stirring materials in the mixing tank till the materials are uniformly mixed; adding the crystal pearlescent pigment and the color mixing pigment to the mixing tank during mixing to mix the color; adding the rest mixed solvent to the mixing tank and adjusting the viscosity of the materials in the mixing tank; mixing the materials till the materials are uniformly mixed; cooling the materials to a room temperature; filtering and packaging the materials to obtain the artificial copper paint for the aluminium profile.

Owner:ZHEJIANG XIZERONG PAINT CO LTD

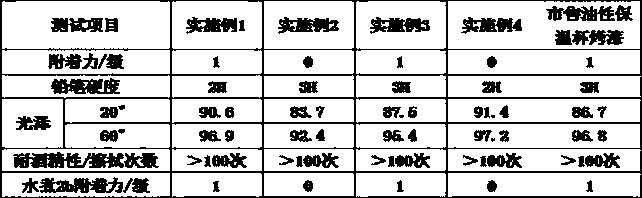

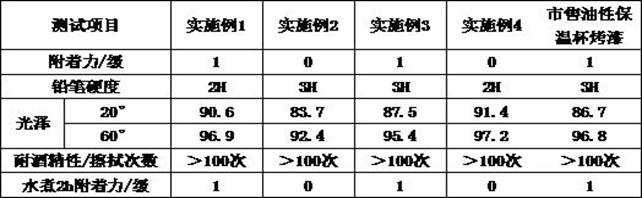

Waterborne amino stoving varnish for stainless steel vacuum cup and preparation method of waterborne amino stoving varnish

ActiveCN109401559AGood flickering decorative effectNot easy to drop paintEpoxy resin coatingsPolyester coatingsEpoxyPolyester

The invention relates to waterborne coating, in particular to waterborne amino stoving varnish for a stainless steel vacuum cup and a preparation method of the waterborne amino stoving varnish. The waterborne amino stoving varnish for the stainless steel vacuum cup has the characteristics that epoxy hybrid acrylic acid dispersion which has good adhesive force to stainless steel materials is selected as priming paint, and an adhesive promoter is added, so that the adhesive force of the priming paint is effectively improved; meanwhile, enclosed isocyanate ester and amino resin are introduced tobe mixed and cured, so that the problem of poor adhesive force after water boiling due to large quadric stress difference at the bottom of the stainless steel vacuum cup is effectively solved, and thestoving varnish coating the surface of the stainless steel vacuum cup is not likely to fall off; epoxy hybrid acrylic acid dispersion and polyester dispersion are matched to serve as finish paint, and the characteristic of high gloss of the polyester dispersion and the characteristics of high hardness, good flexibility and alcohol resistance of the epoxy hybrid acrylic acid dispersion are combined, so that the surface with the stoving varnish is not prone to abrasion, and the performance of high alcohol wiping resistance and water boiling resistance is achieved; and meanwhile, pearl powder isused to enable the vacuum cup to have a good flicker decoration effect.

Owner:江苏云湖新材料科技有限公司

Antirust paint processing transmission tower surface and preparation method thereof

InactiveCN104403512AGood flexibilityReduce brittlenessAnti-corrosive paintsEpoxy resin coatingsTransmission towerZinc phosphate

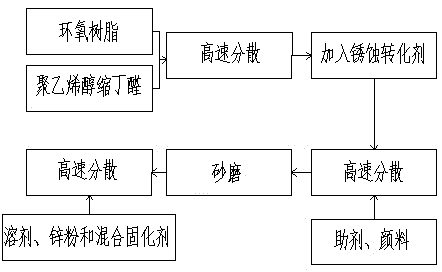

The invention discloses antirust paint processing a transmission tower surface and a preparation method thereof, and relates to the technical field of transmission tower surface protection. The antirust paint processing the transmission tower surface comprises, 15%-17% of epoxy resin E-44, 6%-9% of polyvinyl butyral, 5%-7% of zinc phosphate, 3%-6% of aluminum triphosphate, 1%-4% of zinc borate, 20%-40% of flake zinc powder, 1%-2% of organic bentonite, 4%-7% of a corrosion conversion agent, 20%-26% of a solvent, and 4%-7% of a mixed curing agent. The paint is excellent in corrosion resistance, strong in adhesive force with the transmission tower surface, not easy to fall off and long in protective life, the preparation technology is simple and easy to operate, and automatic production can be realized.

Owner:WENZHOU TAICHANG TOWER MFG

Hydroxyl acrylic resin and preparation method thereof

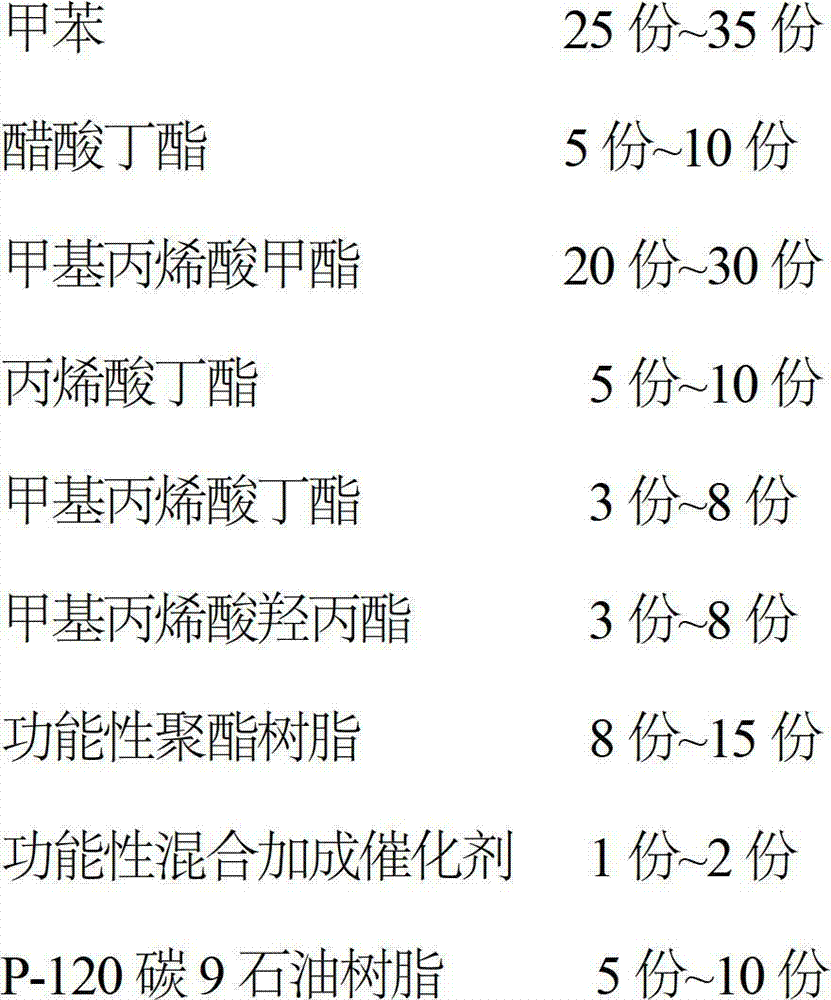

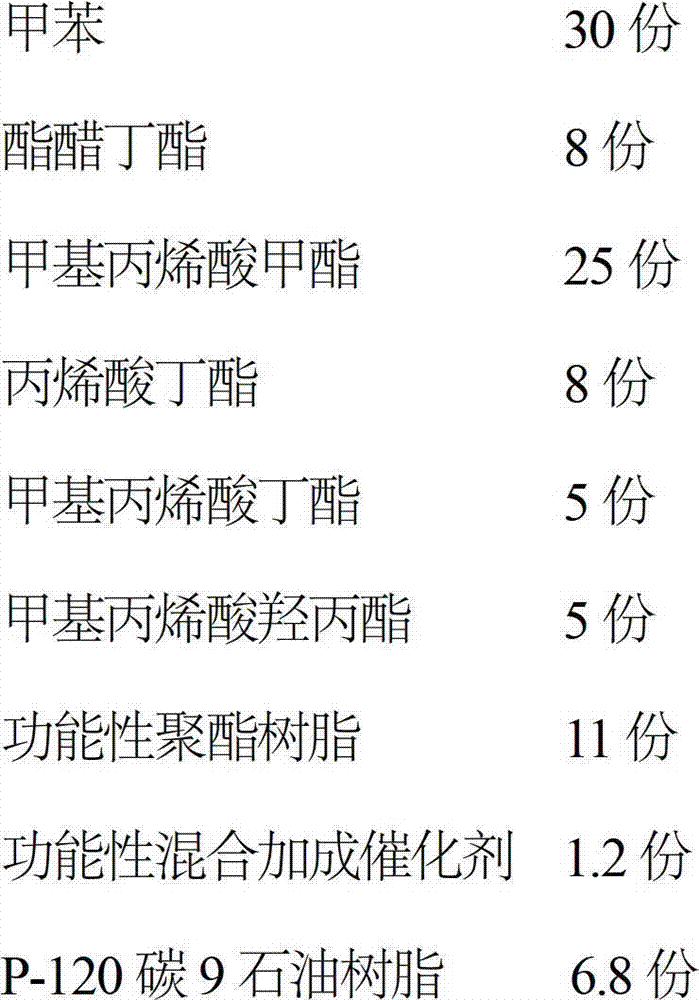

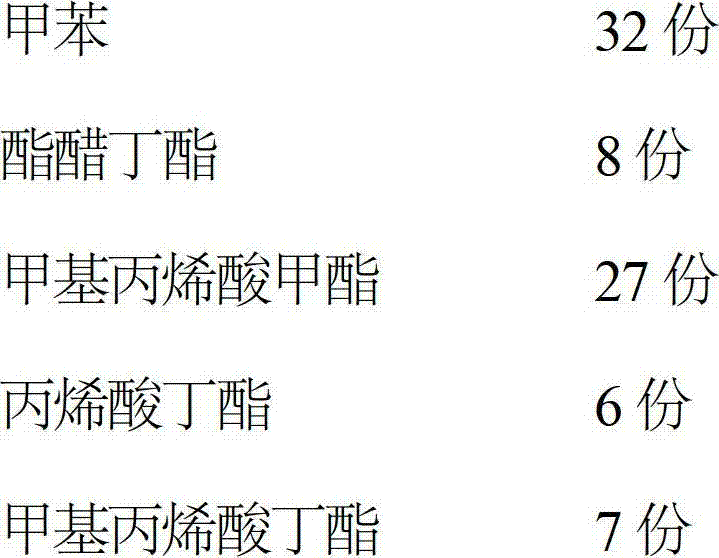

The invention discloses hydroxyl acrylic resin which comprises, by weight, 25-35 parts of toluene, 5-10 parts of butyl acetate, 20-30 parts of methyl methacrylate, 5-10 parts of butyl acrylate, 3-8 parts of butyl methacrylate, 3-8 parts of hydroxypropyl methacrylate, 8-15 parts of functionality polyester resin, 1-2 parts of functionality mixed addition catalyst and 5-10 parts of P-120 carbon 9 petroleum resin. The functionality polyester resin comprises, by weight, 5-10 parts of glycol, 30-40 parts of neopentyl glycol, 50-55 parts of adipic acid and 5-10 parts of fumaric acid and is obtained through esterification synthesis by using a high temperature melting method and diluted by using toluene. The functionality mixed addition catalyst is mixture of 8-12 parts of peroxide 2-ethylhexoic acid tert-butyl ester, 20-30 parts of azobisisobutyronitrile, 50-60 pats of peroxide teriary butyl and 10-15 parts of tert butyl perbenzoa. The hydroxyl acrylic resin has good adhesion when directly coated on nylon materials.

Owner:广东迪爱生彤德树脂有限公司

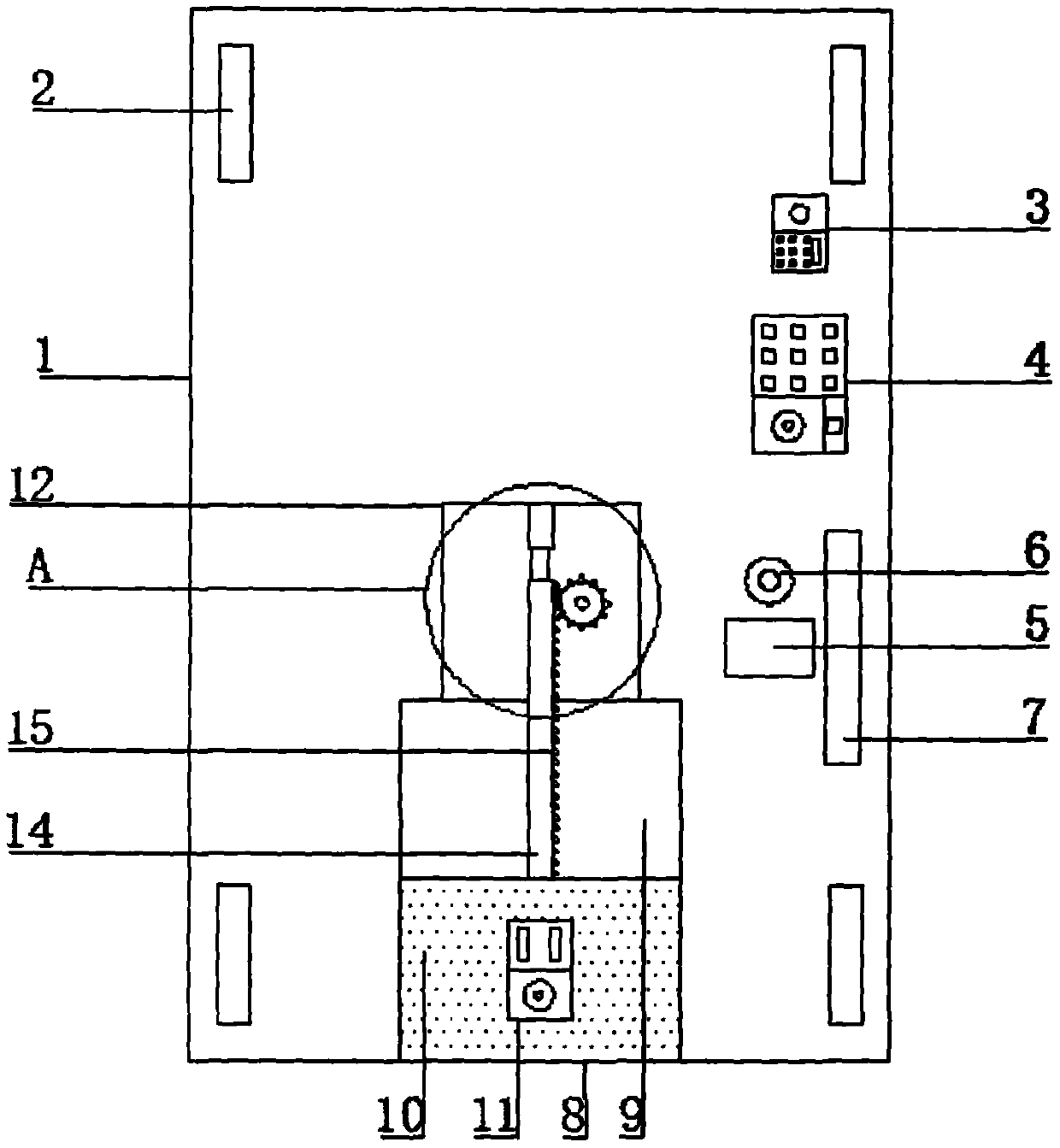

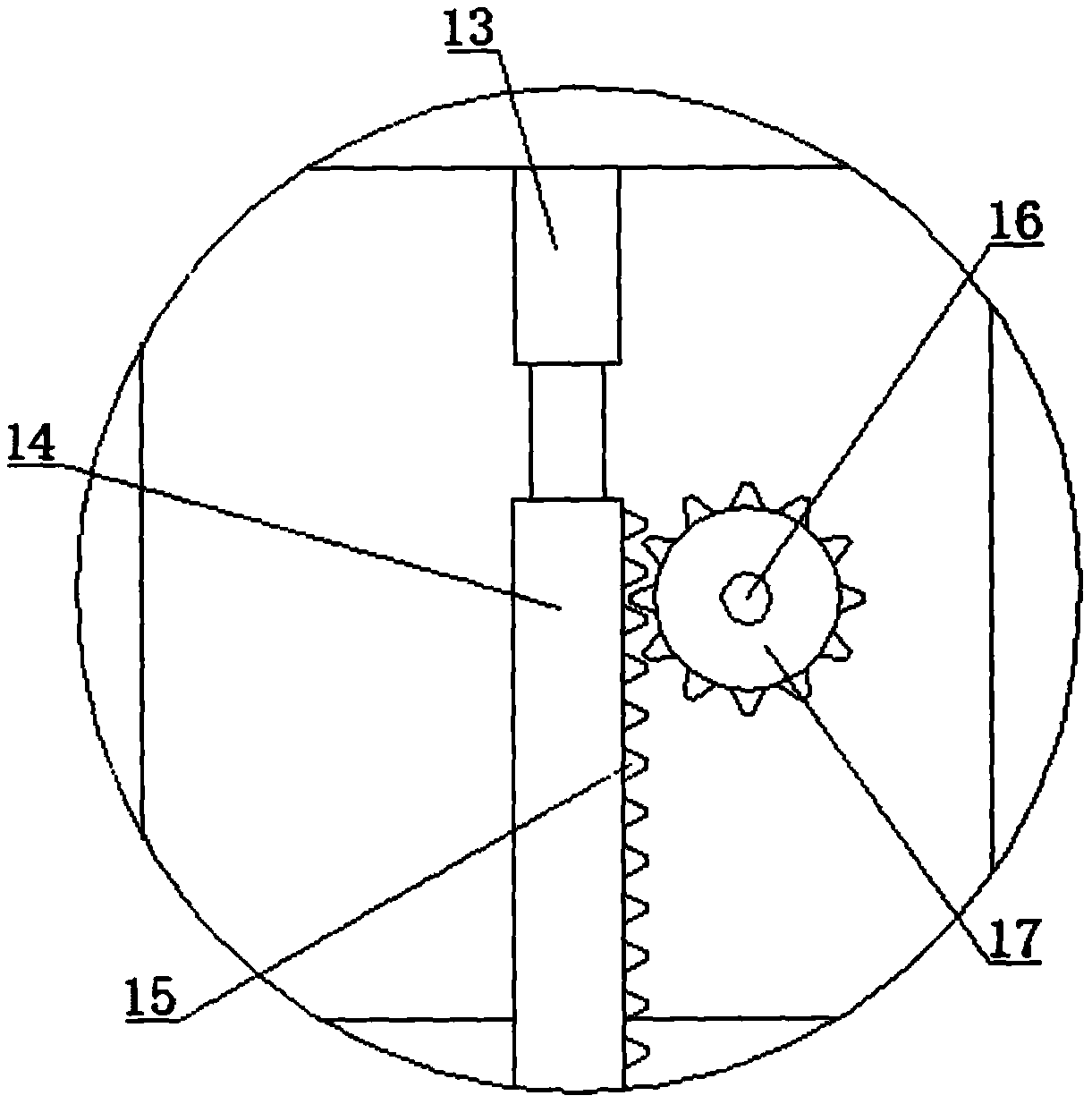

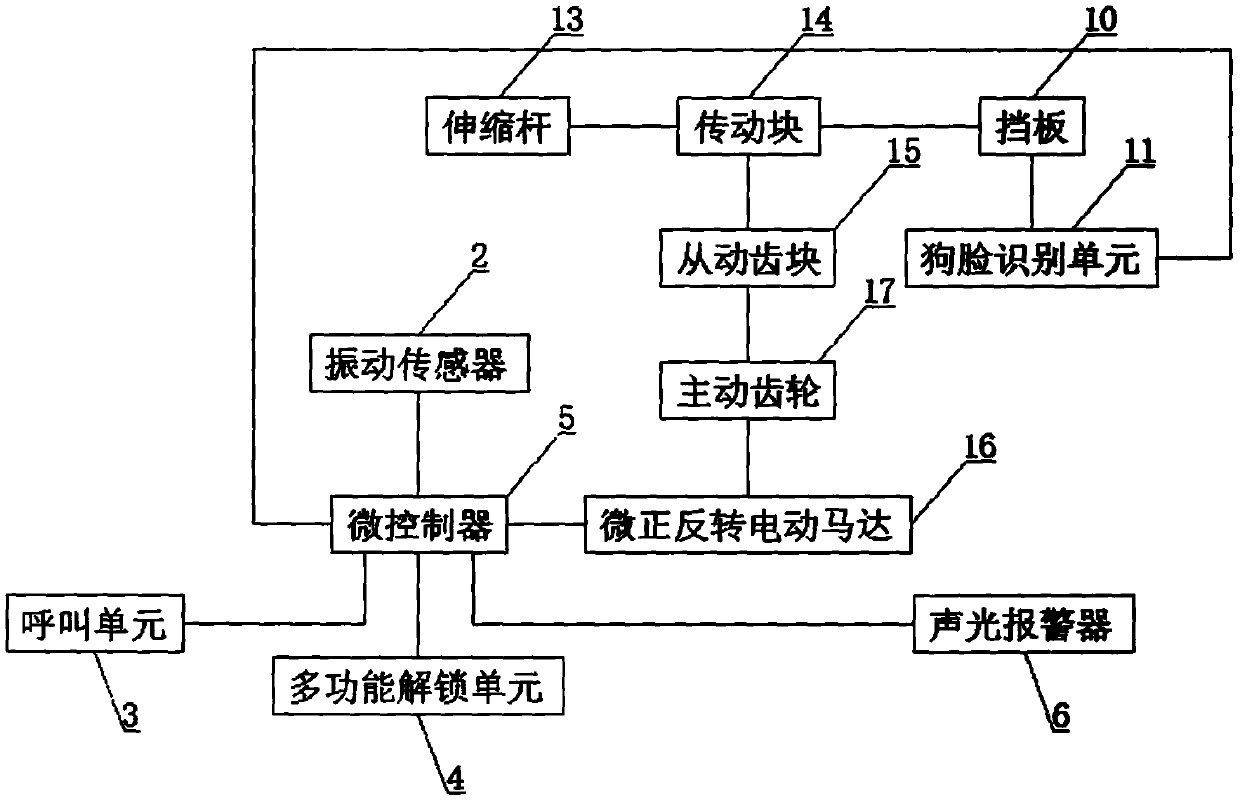

Novel entrance door for villa

InactiveCN111335792AKeep it neat and cleanGood security and anti-theft performanceBurglary protectionWing handlesGear driveGear wheel

The invention discloses a novel entrance door for a villa, and belongs to the field of doors and windows. The novel entrance door comprises a door body, an opening is dug in the front end of the doorbody, a sliding groove is dug in the inner top end of the opening, a storage groove is dug in the bottom end of the sliding groove, a telescopic rod is fixedly connected to the bottom end of the storage groove, a transmission block is fixedly connected to the lower end of the telescopic rod, the lower end of the transmission block is fixedly connected with a baffle, the rear inner end of the storage groove is fixedly connected with a micro forward and reverse rotation electric motor, the output end of the micro forward and reverse rotation electric motor is fixedly connected with a driving gear, the right end of the transmission block is fixedly connected with a plurality of evenly-distributed driven tooth blocks, the front end and the rear end of the baffle are fixedly connected with a dog face recognition unit, the dog face recognition unit comprises a dog face camera, a dog face processing module, a dog face storage module, a dog face comparison module and an infrared detection switch, a dog face can be automatically recognized, a dog can enter and exit a house at will, the nature of the dog face can be effectively released, meanwhile, tidiness and cleanness in a villa house areeffectively guaranteed, and the safety and anti-theft performance are good.

Owner:安徽维卡门窗股份有限公司

Paint-immersion process for motor coil of washing machine

InactiveCN106026568APerfect immersion environmentStable immersion environmentPretreated surfacesManufacturing dynamo-electric machinesLacquerEngineering

The invention discloses a paint-immersion process for a motor coil of a washing machine. The paint-immersion process comprises the following steps of S1: preparing materials and tools; S2: preparing an immersion solution; S3: starting the general power supply of an automatic immersion machine, setting the voltage, choosing an automatic working mode, regulating the pitch time, and setting a preheating temperature; S4: starting a heater, an air heater and a circulating fan, enabling the automatic immersion machine to perform preheating and cooling operations, and putting a coil-inserting stator on the station of the automatic immersion machine after the cooling operation is finished; S5: performing operations of paint immersion, paint dripping, curing and workpiece taking-out; S6: removing residual paint by a scraper knife; S7: performing examination; and S8: switching off the power supply after the obtained workpiece is qualified through examination. The paint-immersion process provided by the invention is complete, and simple to operate; the surface of the immersed paint film is uniform without causing phenomena of cracks, wrinkles and exposed wires; and in addition, the paint film is firm and the paint does not fall off easily, so that high safety is achieved.

Owner:ANHUI JINSHUAI WASHING MACHINE

Aluminum alloy stamping part stoving varnish

InactiveCN105062261AMeet special needsFast dryingAnti-corrosive paintsEpoxy resin coatingsEpoxyOXALIC ACID DIHYDRATE

The invention discloses an aluminum alloy stamping part stoving varnish, and relates to the technical field of stoving varnishes. The formula of the stoving varnish comprises 22-34wt% of butyl acetate, 11-23wt% of n-butanol, 30-40wt% of acrylic resin, 4-7wt% of xylene, 13-19wt% of epoxy resin, 6-11wt% of light calcium carbonate, 9-17wt% of oxalic acid, 2-4wt% of a cosolvent, 1-3wt% of an antifoaming agent, 2-4wt% of a dispersant, and the balance of water. The stoving varnish has high hardness, adhesion and corrosion resistance, is more economic and suitable for general stoving varnishes, meets special demands of aluminum alloy on stoving varnishes, can bear special working environment, and also has the advantages of fast drying speed, difficult peeling, wear resistance and long service life.

Owner:LUAN MICRO & SPECIAL MOTOR

Multi-functional composite floor

PendingCN109483961AExtended service lifeControl releaseCovering/liningsSynthetic resin layered productsEnvironmental resistanceEngineering

The invention discloses a multi-functional composite floor. The multi-functional composite floor comprises multiple wood board bodies. The wood board body successively comprises a base layer, a core veneer and a decoration layer. The side face of the base layer is provided with multiple bulges and grooves. The bulges and the grooves can be mutually buttoned with the grooves and the bulges on the neighboring wood board body. A damp-proof layer is installed below the base layer. A reinforcing rib is installed below the damp-proof layer. A damping layer is installed between the core veneer and the base layer. A plurality of cavities is uniformly arranged in the damping layer. A wear-resisting protective layer is installed above the decoration layer. The multi-functional composite floor is simple in structure, convenient to install. Compared with a traditional wooden floor, the multi-functional composite floor further has the effects of wear resistance, waterproofness, insect prevention, firmness, shock absorption, and more difficult deformation, and is comfortable in foot feeling during a using process, simpler in daily maintenance, economic and environment-friendly, difficult to become white and peel off paint in edge, stable in texture, difficult to expand and shrink, and long in floor service life. In addition, the floor can be layered and re-processed after recovered and can be circularly used, requirements of people in multiple aspects are satisfied, and market competiveness is enhanced.

Owner:JIANGSU KENTIER WOOD

Aluminum profile cleaning, spraying and curing process

InactiveCN107841753AWash thoroughlySpray thoroughlyAnodisationPretreated surfacesMetallurgyHigh pressure water

The present invention is a cleaning and spraying curing process for aluminum profiles, which is characterized in that it comprises the following steps: (1) degreasing; (2) high-pressure water washing; (3) anodic oxidation; (5) high-pressure water washing; (6) spraying; (7) ) solidified. The cleaning, spraying, and curing process for aluminum profiles according to the invention has the advantages of thorough cleaning, uniform spraying, good curing effect, not easy to drop paint, and good surface smoothness.

Owner:天津佰亿铝业有限公司

Finishing paint coating construction process of high-elasticity UV closed sheet having matte effect

InactiveCN107583838AImprove adhesionFast dryingPretreated surfacesGrinding machinesPuttyComposite material

The invention discloses a finishing paint coating construction process of a high-elasticity UV closed sheet having a matte effect. The finishing paint coating construction process comprises the following steps that the sheet is treated, high-elasticity UV putty is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; a high-elasticity UV primer is coated in a rolling mode, and the coating amount is 60-70 g / m<2>; a high-elasticity UV sanding primer is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; sanding and dust removal treatment is performed; a high-elasticityUV matte surface is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; bending treatment is performed; a protective film is attached, and detection and package are performed. Accordingto the finishing paint coating construction process of the high-elasticity UV closed sheet having the matte effect, the sheet is firstly subjected to coating of the high-elasticity putty, the high-elasticity primer and the sanding primer and then coating of the high-elasticity UV matte surface in the rolling mode, the primer is ground, and then bending is performed, so that an obtained paint filmis uniform and flat in coating, the thickness of the paint film is greatly improved, the problems of crocodile skin and cracking are not likely to occur, and an attachment force is strong.

Owner:惠州市摩彩装饰材料有限公司

Charcoal pencil for art painting and making method of charcoal pencil

InactiveCN104725937ANot easy to fall offNot easy to drop paintPencil leadsHazardous substanceGraphite

The invention discloses a charcoal pencil for art painting. The charcoal pencil consists of the following components in parts by mass: 10-15 parts of clay powder, 35-45 parts of charcoal, 35-45 parts of graphite powder, 10-15 parts of high-color carbon black and 3-8 parts of a sterilizing material. The invention discloses a making method of the charcoal pencil for art painting; the making method comprises the following steps: making a charcoal pencil refill, soaking the charcoal pencil refill in an ethyl acetate solution which is 85% in concentration for 2h, coating a primer, milling top, coating UV paint and milling tip. According to the charcoal pencil for art painting disclosed by the invention, the UV paint layer is not easy to fall off and the problem of paint peeling off due to poor bonding between the primer and the charcoal pencil refill in a painting process is avoided; and meanwhile, the charcoal pencil has certain functions of inhibiting bacteria, sterilizing as well as adsorbing and decomposing harmful and toxic substances.

Owner:NANYANG INST OF TECH

Primer coating construction process for high-elasticity UV opening-effect thin plate

InactiveCN107639012AImprove adhesionFast dryingOther plywood/veneer working apparatusPretreated surfacesFilm-coated tabletUV coating

The invention discloses a primer coating construction process for a high-elasticity UV opening-effect thin plate. The primer coating construction process includes: processing the thin plate; using roller coating to coat high-elasticity UV first sanding primer, wherein coating quantity is 10-15g / m<2>; using roller coating to coat high-elasticity UV elastic primer, wherein coating quantity is 15-20g / m<2>; using roller coating to coat high-elasticity UV second sanding primer, wherein coating quantity is 10-15g / m<2>; performing sanding and dust removing; bending; testing and packaging. The primercoating construction process has the advantages that the thin plate is subjected to the UV coating of the high-elasticity first sanding primer, the elastic primer and the second sanding primer, the primer is polished, then the bending is performed, even and smooth paint film coating is achieved, paint film thickness is improved greatly, the problems of orange peel and cracking cannot occur easily,and high adhesive force is achieved.

Owner:惠州市摩彩装饰材料有限公司

Water-based amino baking varnish for stainless steel thermos cup and preparation method thereof

ActiveCN109401559BGood flickering decorative effectNot easy to drop paintEpoxy resin coatingsPolyester coatingsEpoxyPolyester

Owner:江苏云湖新材料科技有限公司

Painting method of square lead

InactiveCN101901648ASame degree of roastingAvoid crackingInsulating conductors/cablesEngineeringVarnish

The invention relates to a painting method of a square lead, which comprises the following steps: (1) binding a felt and the square lead together, and simultaneously, conveying and scraping varnish; (2) enabling the square lead obtained in the step (1) to directly enter a felt clamp, and simultaneously, conveying and scraping the varnish again; and (3) baking the square lead obtained in the step (2). In the invention, the film painting method of the square lead manufactured in a secondary felt mode has good voltage resistance and ensures that the films painted at the wide edge and the narrow edge of the square lead are uniform and can not crack easily, and the paint can not fall off easily.

Owner:SUZHOU XINDI ELECTRICAL

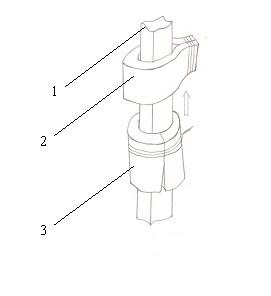

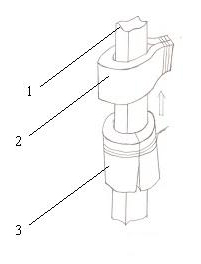

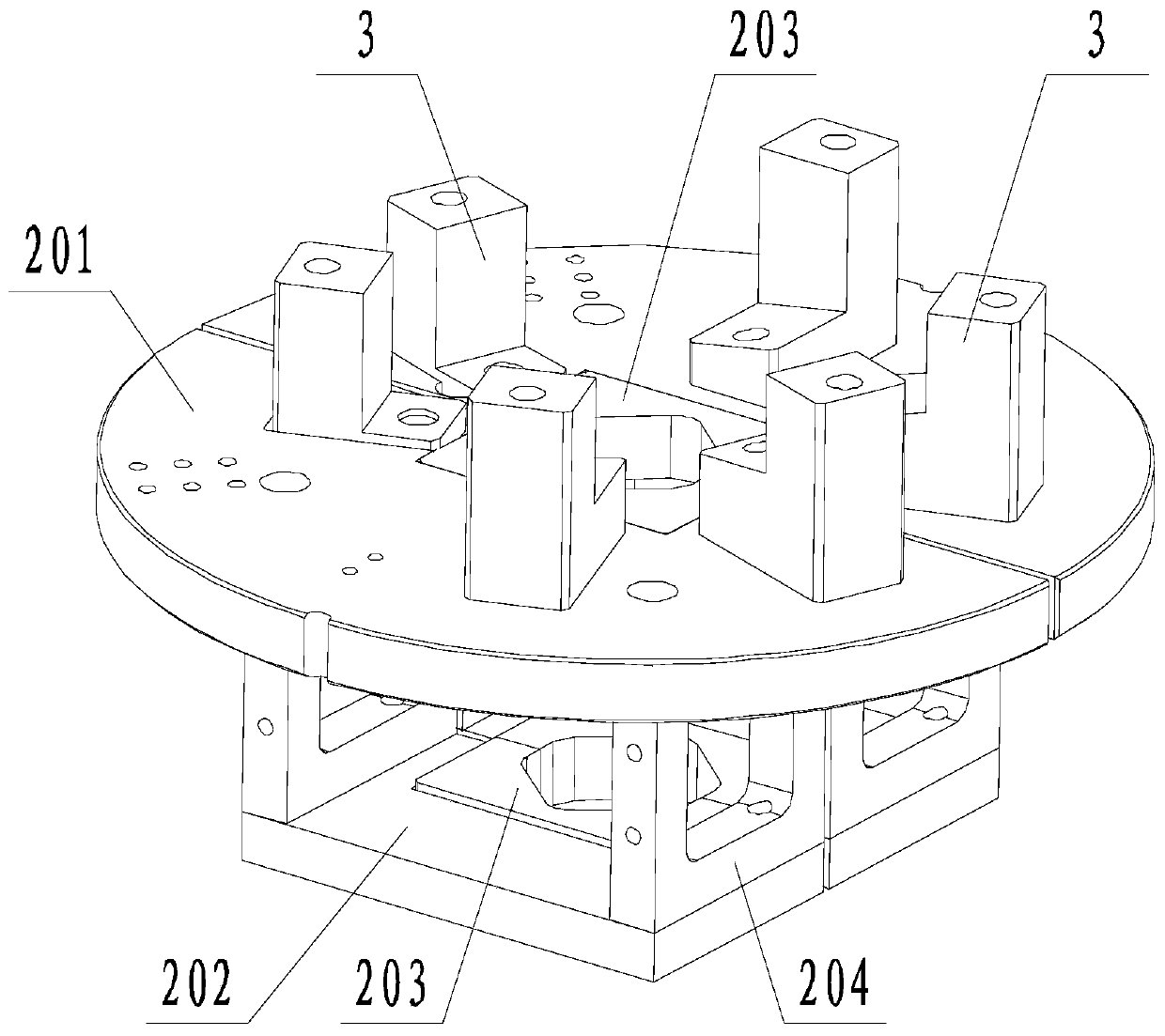

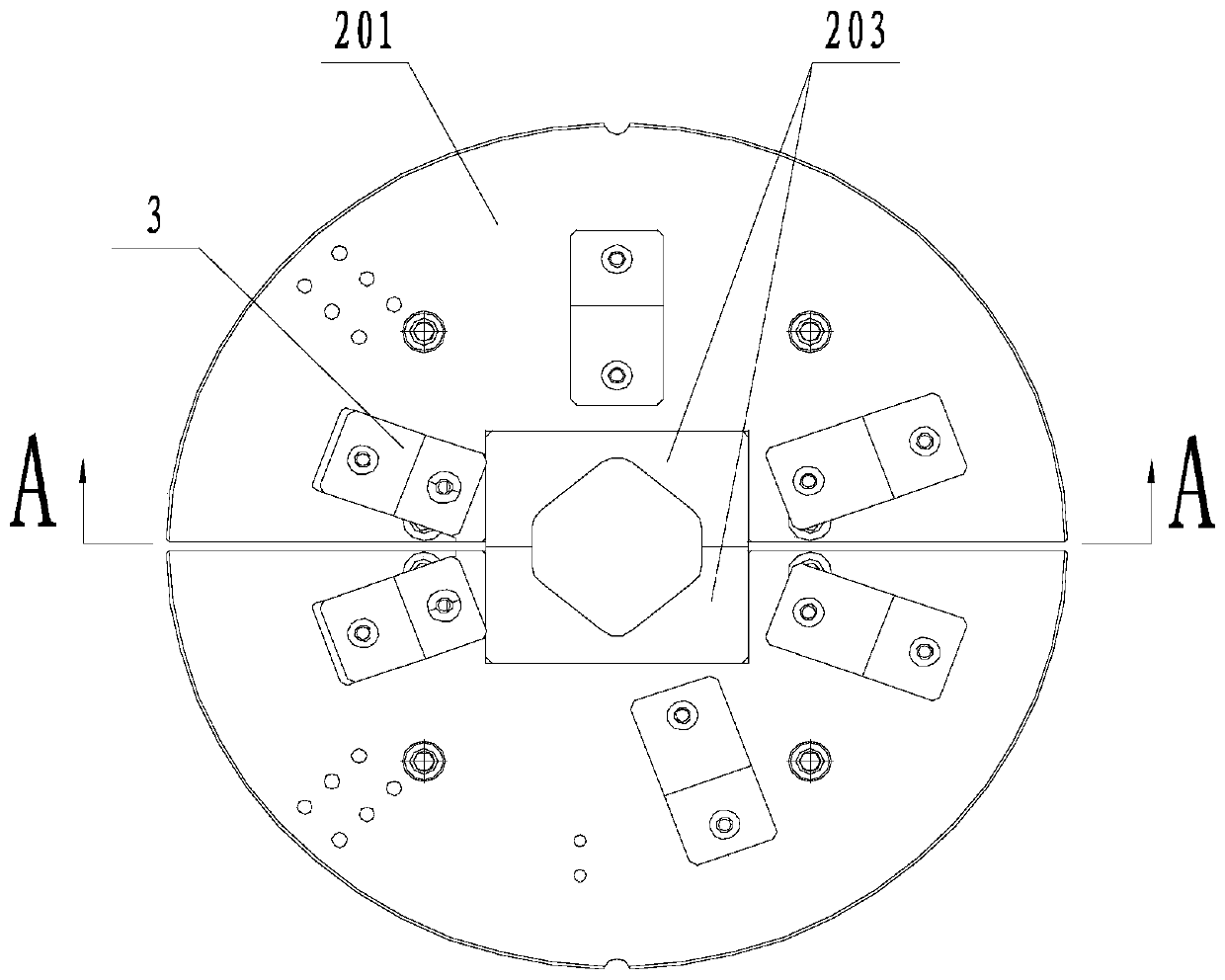

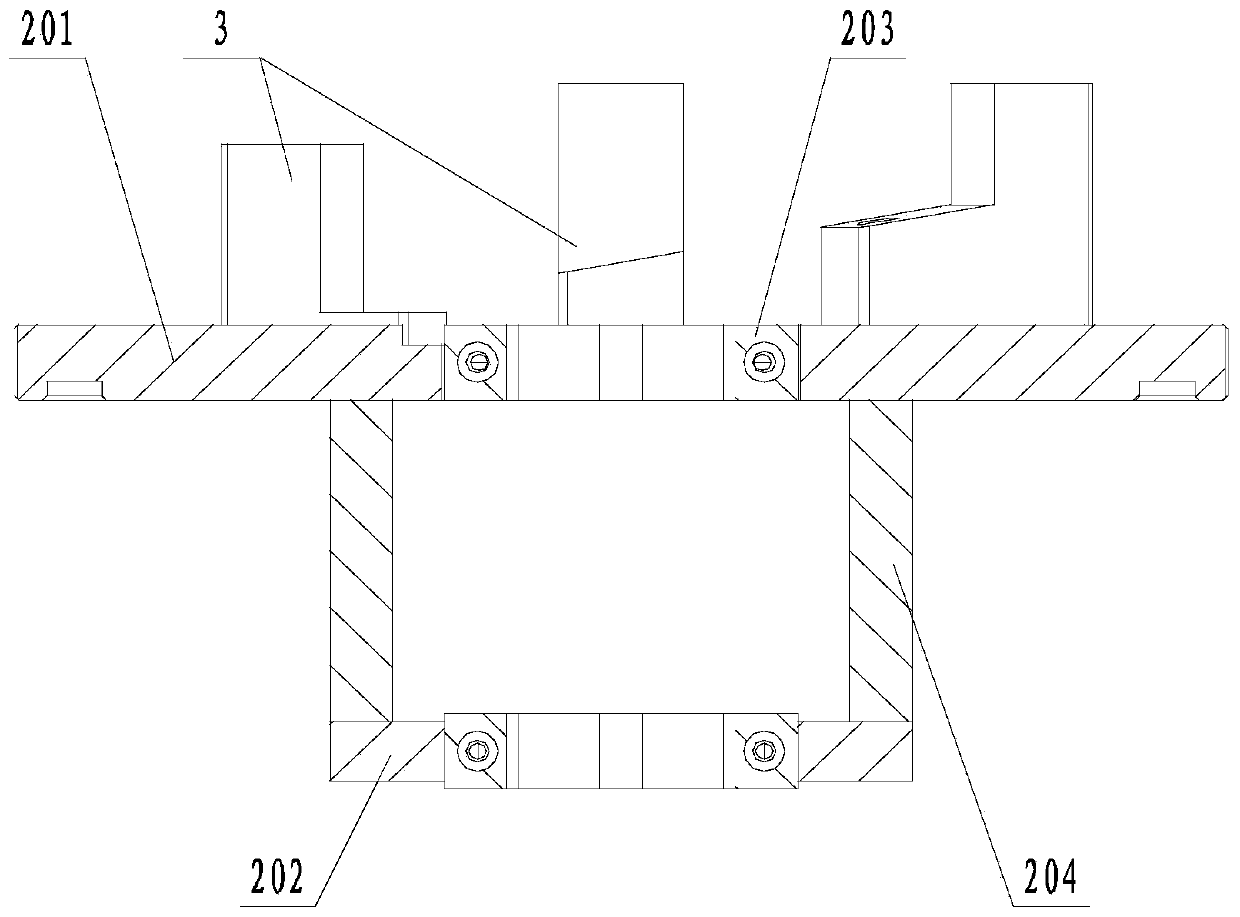

Spring mounting tooling of semi-automatic spring mounting machine for shock absorber and spring mounting method of spring mounting tooling

PendingCN111113005AShorten the timeIncreased press strokeMetal working apparatusSemi automaticEngineering

The invention discloses a spring mounting tooling of a semi-automatic spring mounting machine for a shock absorber and a spring mounting method of the spring mounting tooling. The spring mounting tooling comprises an upper spring compressing tooling, and further comprises a lower spring compressing tooling positioned below the upper spring compressing tooling, wherein the lower spring compressingtooling is used for limiting a spring and compressing the spring to a working part; and a spring disc positioning tooling is arranged on the upper surface of the lower spring compressing tooling and used for positioning a spring disc. In order to solve the problem that in the prior art, the spring head in-place rate is low, the spring mounting and compressing stroke is limited, the spring mountingefficiency is low, the spring mounting tooling of the semi-automatic spring mounting machine for the shock absorber and the spring mounting method of the spring mounting tooling are provided; and thepurposes of ensuring the one-time in-place of a spring head, enlarging the spring mounting and compressing stroke, and improving the spring mounting efficiency can be fulfilled.

Owner:SICHUAN NINGJIANG SHANCHUAN MACHINERY

Shell injection molding process for bluetooth sound equipment

InactiveCN110328804AImprove aging resistanceImprove impact resistanceDomestic articlesCoatingsAntioxidantEngineering

The invention relates to the technical field of bluetooth sound equipment, and particularly relates to a shell injection molding process for the bluetooth sound equipment. The shell injection moldingprocess comprises the following steps of designing a mold; granulating modified plastics, wherein 90-95 parts of synthetic resin, 3-5 parts of anti-aging agents, 2-3 parts of antioxidants, 4-7 parts of flame retardants, 3-5 parts of toughening agents and 1-2 parts of stabilizing agents are uniformly mixed by mass; drying plastic particles; carrying out injecton molding, conducting preheating on injection molding equipment and the mold, then setting parameters, and putting plastic master batches into the injection molding equipment for injection molding, wherein the injection molding step includes injection, pressure maintaining and cooling; demoulding and shaping; polishing and removing dust and static electricity; spraying an accelerant, conducting degreasing treatment on a semi-finishedshell through a degreasing agent, then spraying a nylon accelerant on the surface, and blow-drying the surface; and conducting product testing process flow. According to the shell injection molding process for the bluetooth sound equipment, the problem of insufficient existing spraying adhesive force in the shell surface of the bluetooth sound equipment can be solved, and anti-aging performance, anti-impact capacity and flame retardation performance of the shell are improved as well.

Owner:安顺智森电子科技有限公司

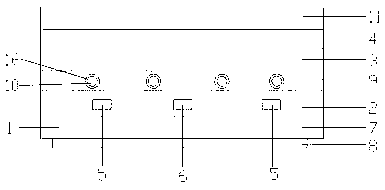

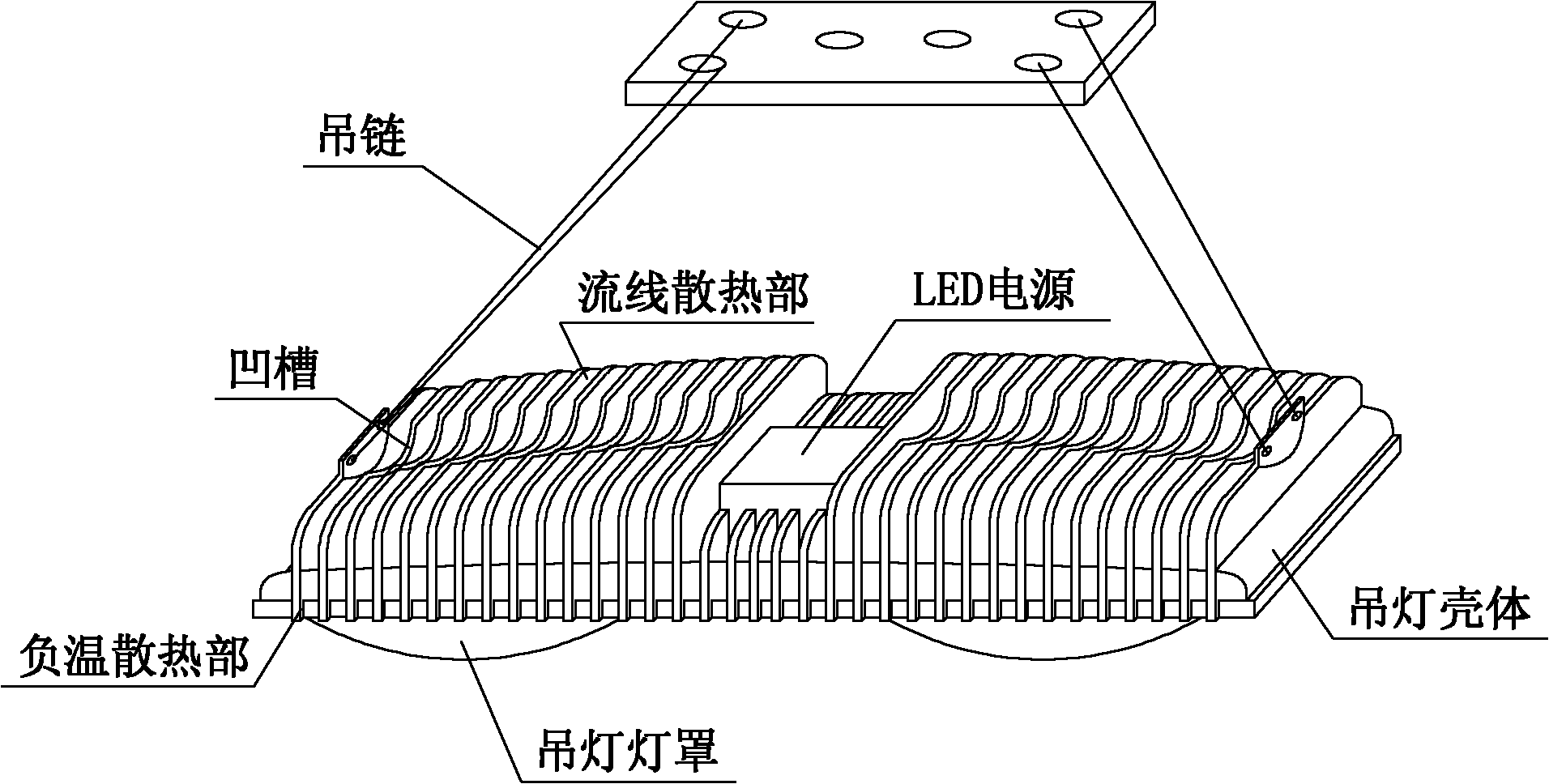

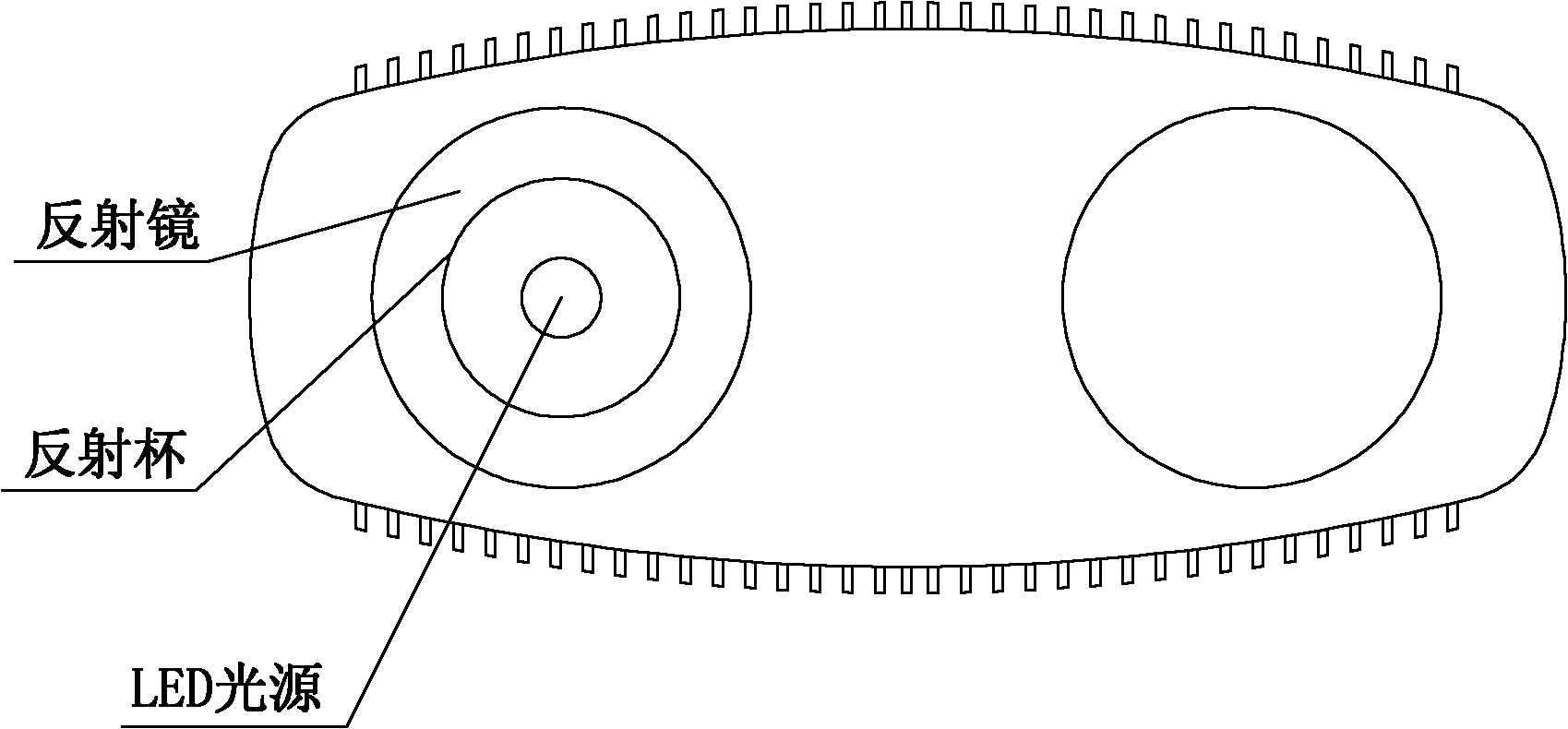

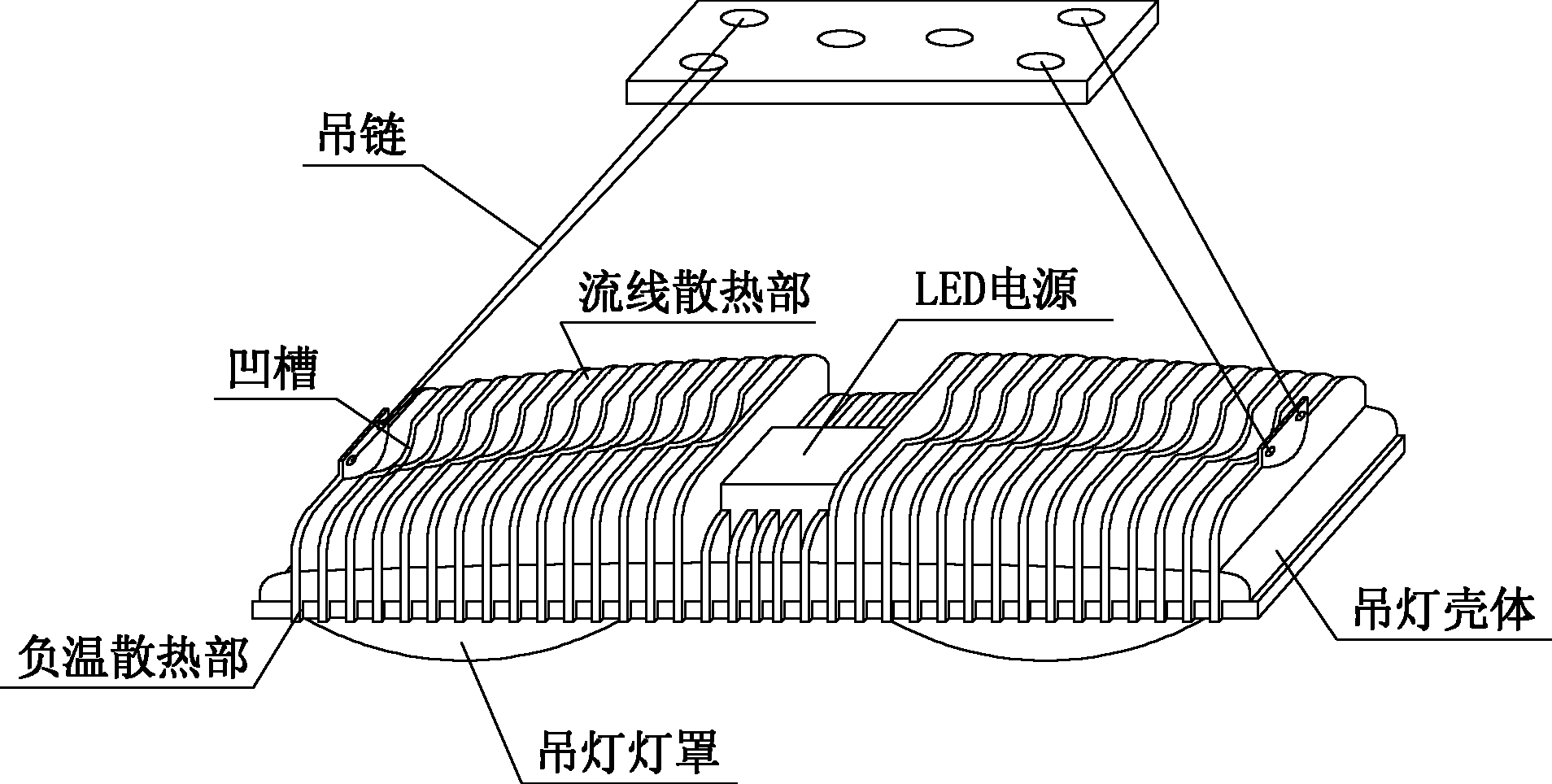

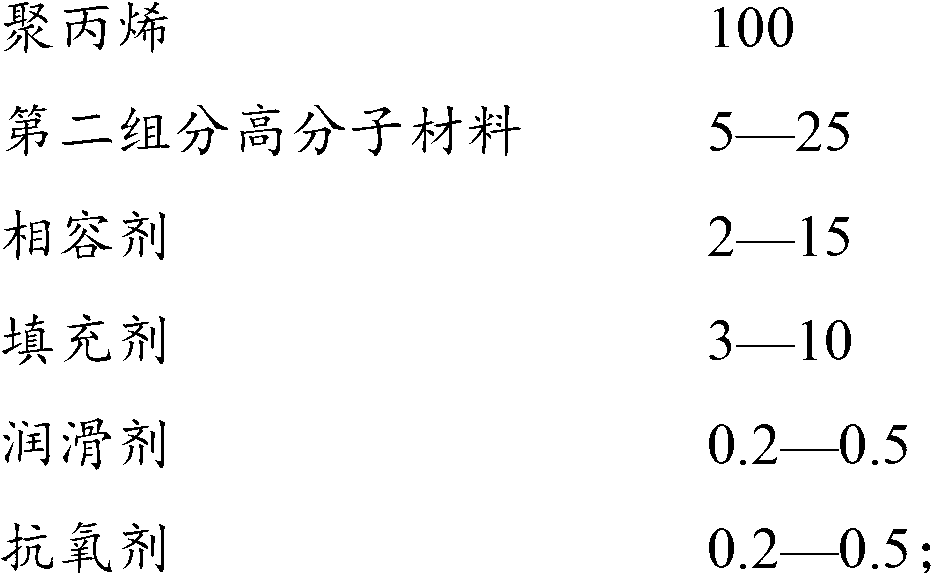

Uniform light radiating type photoelectric separation LED (Light Emitting Diode) droplight with sling chains and groove

InactiveCN102705764AEfficient use ofUniform outgoing lightLighting support devicesPoint-like light sourceNegative temperatureLight spot

The invention provides a uniform light radiating type photoelectric separation LED (Light Emitting Diode) droplight with sling chains and a groove, which mainly solves the problems that the sling chains of the existing droplight are unreasonably distributed, the balance is poor, light intensity in light spots formed by emergent light are not uniformly distributed, energy is easily wasted, the heat dissipation performance is poor and cannot be balanced with weight, a light source of the droplight and a power supply are arranged in same positions on different sides of a housing of the droplight, heat is intensively radiated by the light source and the power supply, and the light spots cannot be adjusted. The uniform light radiating type photoelectric separation LED droplight with the sling chains and the groove comprises four sling chains, a reflecting mirror and a reflecting cup, wherein the reflecting mirror and the reflecting cup are positioned in a light cover of the droplight, a radiating device which comprises a negative temperature radiating part and a streamline radiating part is arranged on the back side of the housing of the droplight, two LED light sources are symmetrically arranged on the light source side of the housing of the droplight, and the groove is arranged in the middle of the radiating device.

Owner:XIAN ZHIHAI POWER TECH

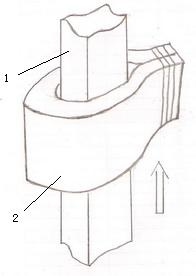

A kind of drawing pencil without charcoal drawing core and preparation method thereof

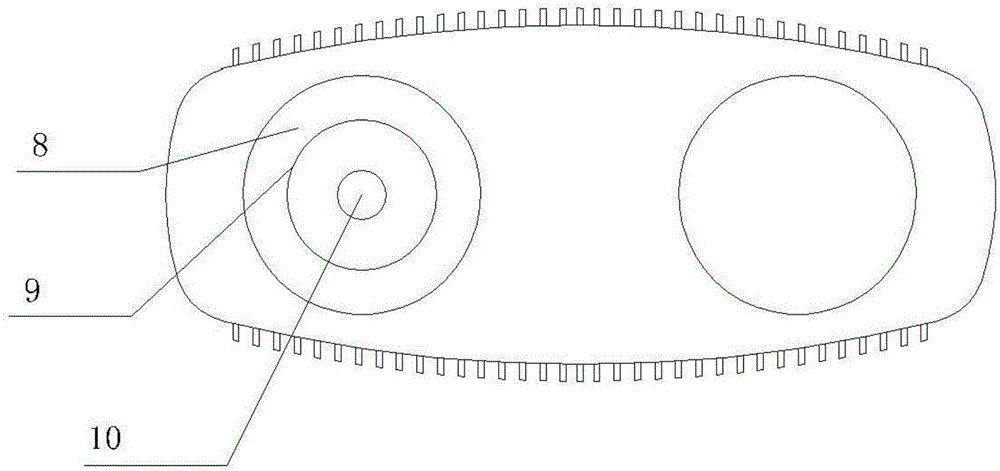

ActiveCN104015524BNot easy to fall offAvoid breakingNon-propelling pencilsOrganic solventEngineering

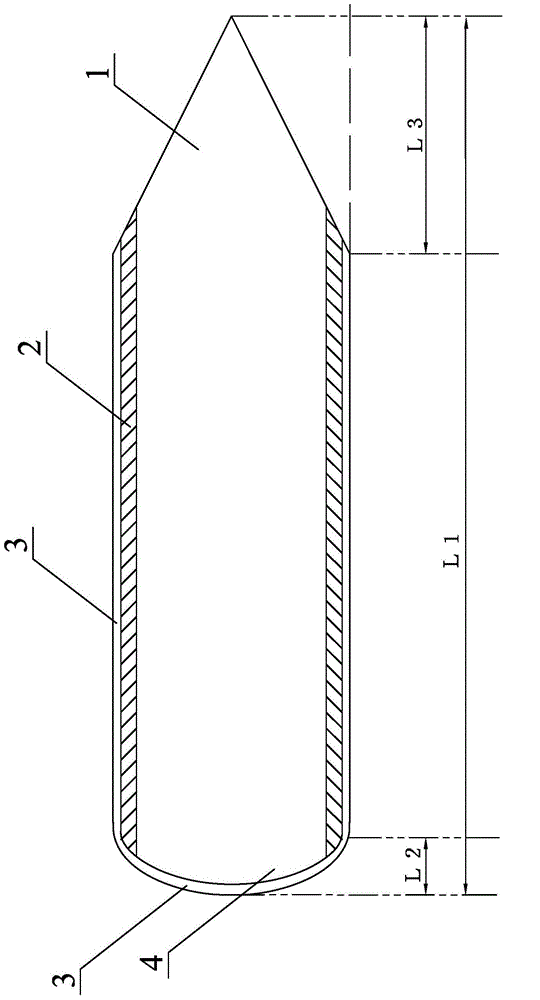

The invention discloses a wood-free charcoal drawing core drawing pencil and a preparation method thereof. The wood-free charcoal drawing core drawing pencil comprises a charcoal drawing core (1), the side face of the charcoal drawing core (1) is coated with a base coat (2), and the base coat is coated with a UV paint layer (3). One end of the charcoal drawing core is provided with an arc-shaped top (4), the other end of the charcoal drawing core is provided with a conical sharp part, and the surface of the arc-shaped top (4) is coated with the UV paint layer (3). The method for preparing the wood-free charcoal drawing core drawing pencil comprises the steps that (A) the charcoal drawing core (1) is prepared; (B) an organic solvent is used for soaking the charcoal drawing core (1); (C) the base coat is coated, top grinding is conducted, UV paint is coated, sharp grinding is conducted, and the wood-free charcoal drawing core drawing pencil is manufactured. The wood-free charcoal drawing core drawing pencil manufactured by the preparation method has the advantages of being saving in wood, low in cost, high in gloss, plump and flat in ink layer, attractive, good in levelling property, environmentally friendly, good in surface anticorrosion performance, not prone to painting peeling off, assistant to scratch and capable of being widely applied to production.

Owner:LONGKOU YIYOU STATIONERY IND

A kind of preparation method of wood-free graphite drawing pencil

The invention discloses a woodless graphite drawing pencil and a preparation method thereof. The woodless graphite drawing pencil comprises a graphite core (1), a base coat layer (2) coats the lateral surface of the graphite core (1), a UV paint layer (3) coats the base coat layer, one end of the graphite core is an arc-shaped top (4) while the other end is a conical point, and the UV paint layer (3) coats the surface of the arc-shaped top (4). The method for preparing the woodless graphite drawing pencil includes that: (A), preparing the graphite core (1); (B) soaking the graphite core (1) in organic solvent; (C) coating the base coat, grinding the top, coating the UV paint and grinding the point to obtain the woodless graphite drawing pencil. The woodless graphite drawing pencil prepared by the preparation method has advantages of wood material conservation, low cost, high gloss, plump and flat graphite layer, beautiful shape, good leveling property, environment friendliness, good surface corrosion resistance, difficulty in paint losing and scratch resistance and can be broadly used for production.

Owner:LONGKOU YIYOU STATIONERY IND

Directly sprayed polypropylene material and preparation method thereof

The invention relates to a directly sprayed polypropylene material and a preparation method thereof. The polypropylene material is prepared with the following materials: polypropylene, second component high polymer material, compatilizer, filler, lubricating agent and antioxidant. The preparation method includes the following steps: (1) the materials are weighed according to a ratio, and are uniformly mixed in a high-speed mixer at a high speed for 5 to 10 minutes; (2) the mixed material is added in a double-screw extruder, melted, extruded and granulated. The polypropylene material has high rigidity and good sprayability, cannot be easily scratched and chipped and cannot easily leave traces, and moreover, the preparation method has the advantages of simple technique, convenient operationand low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Benzene-free flame-retardant resin

InactiveCN103554336AMeet performance requirementsGood compatibilityFireproof paintsAcrylic resinSolvent

The invention relates to benzene-free flame-retardant resin comprising the components of: 10 parts of methacrylic acid, 12 parts of methyl methacrylate, 30 parts of ethylene glycol, 7 parts of butyl acetate, 5 parts of butyl acrylate, 1 part of hydroxypropyl methacrylate, 4 parts of acrylic resin, 9 parts of pentaerythritol, 3 parts of methyl methacrylate, 2 parts borax, and 4 parts of mica powder. According to the benzene-free flame-retardant resin, low-smell alcohol, ether, and ester are used as a mixed solvent. The resin is suitable for coating of outdoor large-scale steel structures and indoor woodenware. The resin has good adhesion performance, and is prevented from paint falling. With the resin, during paint coating, processing steps can be saved, processing cost can be reduced, and market application requirement can be satisfied.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

Hydroxyl acrylic resin fire-retardant paint

The invention relates to a hydroxyl acrylic resin fire-retardant paint which comprises the following components: 40-65 parts of acrylic resin, 10-15 parts of pentaerythritol, 5-15 parts of phthalic anhydride, 1-3 parts of aluminum tripolyphosphate, 8-13 parts of methyl methacrylate, 4-6 parts of borax, and 5-8 parts of a mica powder. The content of aluminum tripolyphosphate is 2 parts. The hydroxyl acrylic resin fire-retardant paint can retain the acrylic resin advantages of color retention, light retention, quick drying and high weatherability, has the fullness advantage of alkyd resin, also has a flame retardant effect, is suitable for coating large outdoor steel structures and indoor woodware, has quite good adhesiveness, allows the paint not to be easily peeled off, can save treatment processes and reduce treatment costs when the paint is coated, and meets market operating requirements.

Owner:QINGDAO XUANWEI COATING MATERIAL

Special oil paint for motorcycle

InactiveCN106752479ABright colorNot easy to drop paintPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyCarbamate

The invention relates to the field of oil paint, in particular to special oil paint for a motorcycle. The special oil paint consists of the following substances in parts by weight: 45-55 parts of emulsion type acrylic resin, 25-35 parts of carbamate resin, 25-32 parts of cellulose acetate, 25-35 parts of emulsion type maleic acid, 20-30 parts of tert-amino epoxy resin, 55-70 parts of an ester solvent, 50-60 parts of an ether solvent, 15-20 parts of organic siloxane, 10-15 parts of an anti-settling agent, 10-15 parts of a flattening agent and 15-20 parts of a dispersed pigment. The special oil paint for the motorcycle, provided by the invention, is bright in color, can mutually penetrate and is unlikely to fall off; with the adoption of the dispersed pigment and organic bentonite, oil paint particles can be uniformly dispersed and uniformly and smoothly colored; the special oil paint has good high temperature resistance, good wear resistance and good stability.

Owner:QINGDAO HUANAN SHENGYUAN FRUIT IND CO LTD

Coating process of high-pressure cleaning machine

InactiveCN109967325AWash thoroughlySpray evenlyPretreated surfacesCoatingsSocial benefitsHigh pressure water

The invention discloses a coating process of a high-pressure cleaning machine. The coating process comprises the following steps of S1, grinding; S2, degreasing; S3, high-pressure water washing; S4, anodic oxidation; S5, high-pressure water washing; S6, spraying; S7, curing; and S8, warehousing. The coating process overcomes the defects in the prior art, and has the advantages of being thorough incleaning, uniform in spraying, good in curing effect, not prone to paint falling, good in surface flatness and the like, and meanwhile, the process has the characteristics of being scientific, reasonable, professional and the like, so that the coating efficiency is greatly improved, the social benefit is obvious, and the coating process is suitable for popularization.

Owner:安徽屹盛机电科技有限公司

A uniform photoelectric separation led pendant lamp with hanging chain and mounting plate

InactiveCN102966895BReasonable distributionImprove connection strengthLighting support devicesPoint-like light sourceEngineeringChandelier

The invention provides a light-equalizing photoelectric separated type LED (Light Emitting Diode) pendant lamp with pendant chains and a mounting plate. The light-equalizing photoelectric separated type LED pendant lamp is mainly used for solving the problems of the present pendant lamp that the pendant chain distribution is unreasonable, the equilibrium is poor, the reliability is low, the height and the angle cannot be adjusted, the light intensity distribution in faculae formed by emergent light is uneven, the energy waste is easily caused, the pendant lamp cannot be used for a long time, a pendant lamp light source and a power supply are arranged in same positions on different sides of a pendant lamp shell, the light source and the power supply heat in a concentrated form and the faculae are nonadjustable. The light-equalizing photoelectric separated type LED pendant lamp with the pendant chains and the mounting plate is connected with the four pendant chains, is mounted in a mounting position through the mounting plate and further comprises a reflecting mirror and a reflecting cup, wherein two LED light sources are arranged.

Owner:XIAN ZHIHAI POWER TECH

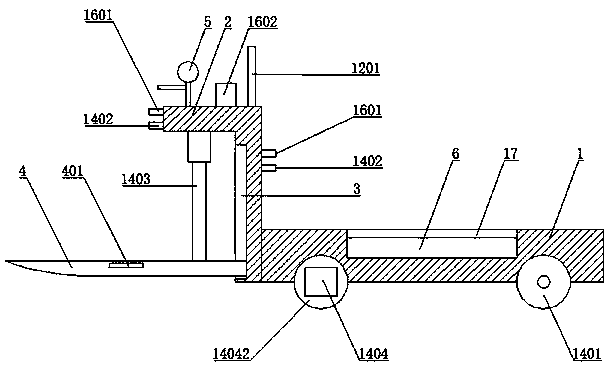

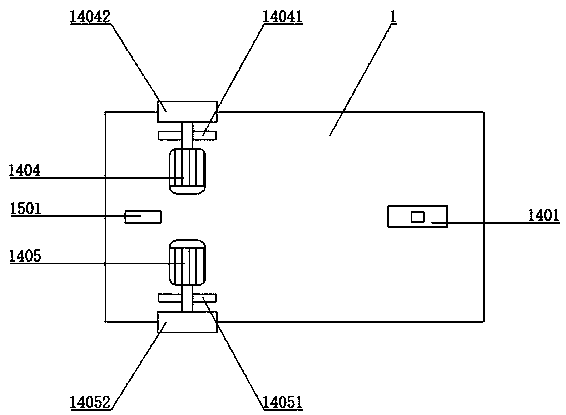

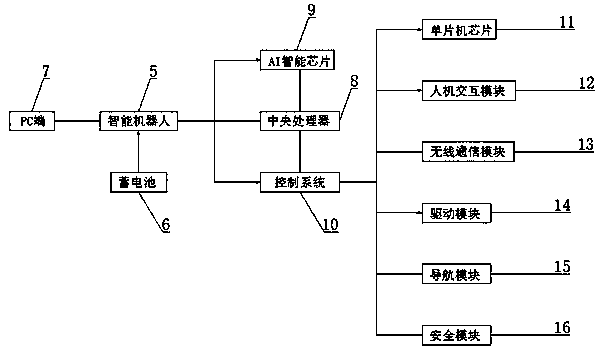

Unmanned forklift for intelligent warehouse

InactiveCN111320103ALow costImprove efficiencySafety devices for lifting equipmentsControl systemControl engineering

The invention discloses an unmanned forklift for an intelligent warehouse, and belongs to the field of forklifts. The unmanned forklift comprises the intelligent warehouse, a trolley bottom plate anda vehicle head, a sliding chute is formed in the inner wall of the vehicle head, a forklift block is slidably connected to the chute bottom end of the sliding chute, and a pressure sensor is embeddedin the position, close to the interior of the upper end, of the forklift block. A battery container is formed in the upper end of the trolley bottom plate, a storage battery is connected to the innerend of the battery container in a clamping mode, an intelligent robot is fixedly connected to the upper end of the vehicle head, the intelligent robot is in signal connection with a PC terminal, a central processing unit and an AI intelligent chip are installed in the intelligent robot, and the central processing unit is electrically connected with the AI intelligent chip. The intelligent robot isconnected with a control system, and the control system comprises a single chip microcomputer chip, a human-computer interaction module, a wireless communication module, a driving module, a navigation module and a safety module. The intelligence degree is high, the forklift can be autonomously, manpower and material sources are greatly saved, the labor strength is low, the enterprise cost is reduced, and the enterprise benefits are improved.

Owner:黎越智能技术研究(广州)有限公司

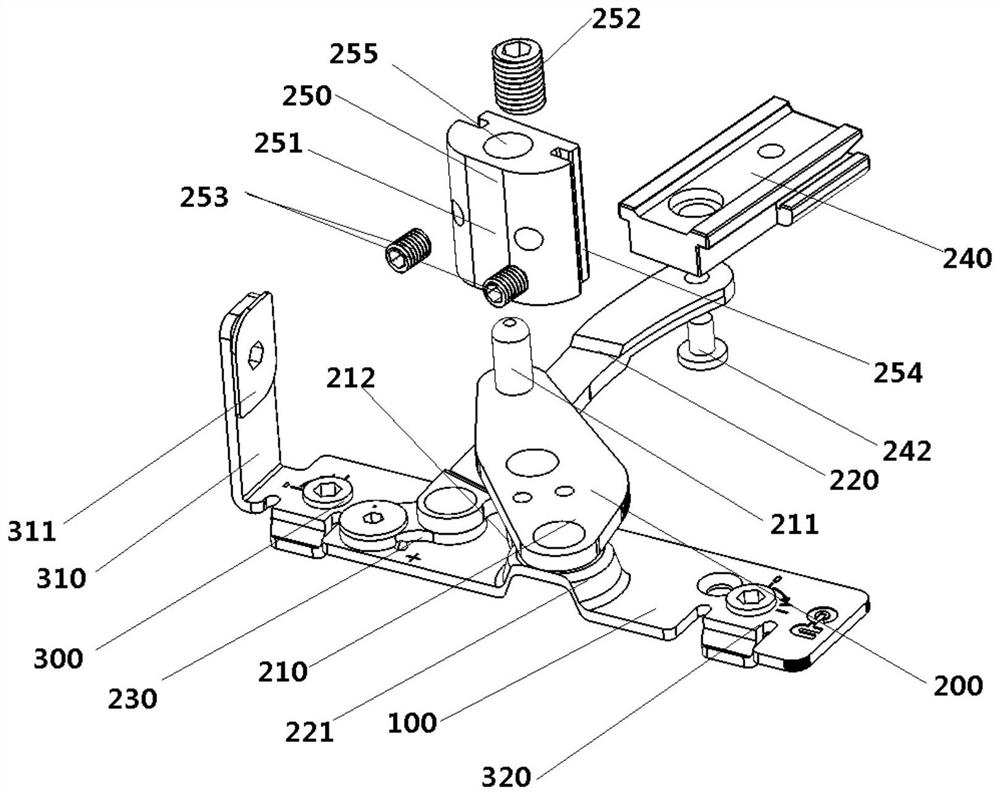

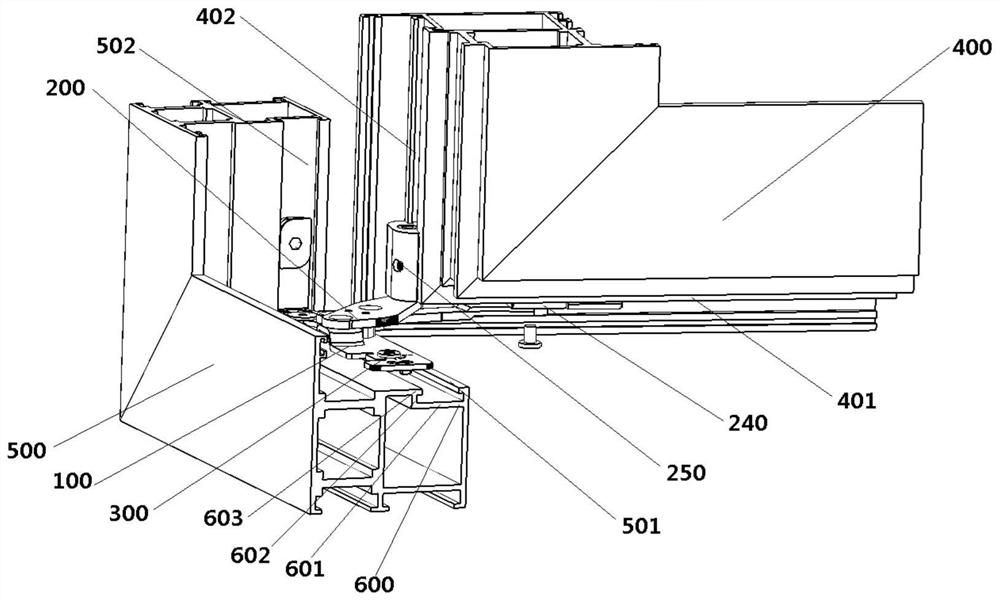

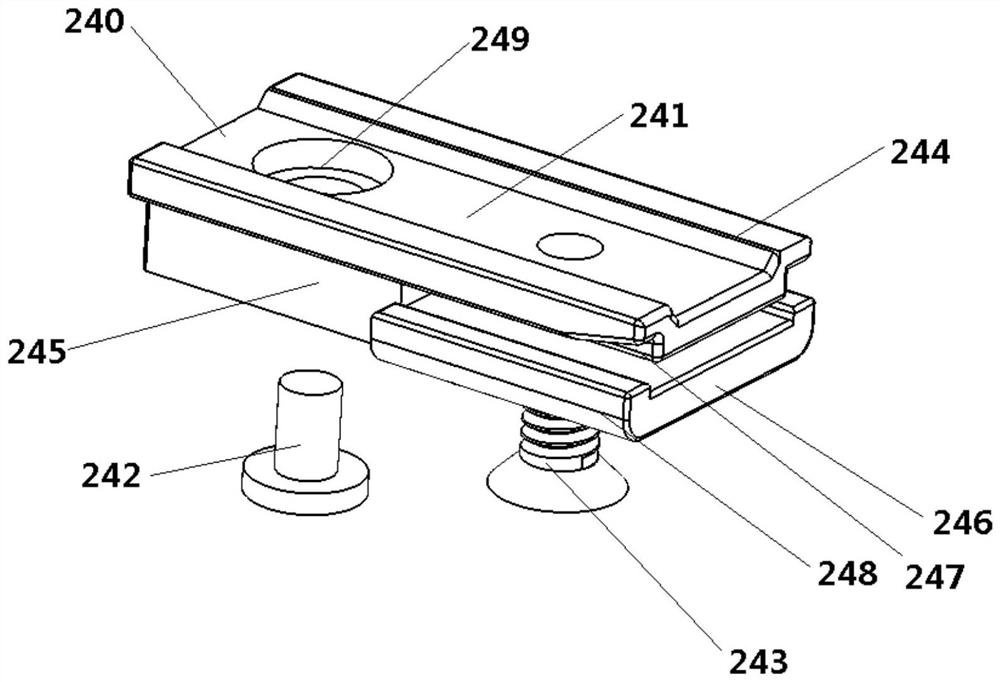

Installation method of side-hung hinge

The invention provides an installation method of a side-hung hinge. The side-hung hinge comprises fixed plates used for being fixed to a window frame and connecting rod mechanisms which are arranged on the fixed plates and used for installing a window sash, window sash fixing blocks and window sash sliding blocks are arranged on the connecting rod mechanisms, and the window sash fixing blocks andthe window sash sliding blocks are detachably fixed to the connecting rod mechanisms. The installation method comprises the following steps that the two window sash fixing blocks are installed at theupper end and the lower end of a same vertical window sash notch; the two window sash sliding blocks are correspondingly installed in horizontal window sash notches located on the upper part and the lower part of the window sash; the fixed plates are installed in horizontal window frame notches of the upper end and the lower end of the inner wall of the window frame; and the window sash fixing blocks and the window sash sliding blocks on the window sash are installed on the connecting rod mechanisms located on the fixed plates. By adopting the installation method, compared with an existing installation method, the installation is more convenient, and meanwhile, the situation that the aesthetics is affected due to paint removal caused by scratching of the side-hung hinge and the window frame cannot exist.

Owner:格屋(上海)安防产品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com