Directly sprayed polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of polypropylene material and its preparation, can solve the problems of soft, scratch-prone, sticky products, etc., and achieve the effects of convenient operation, not easy to scratch, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

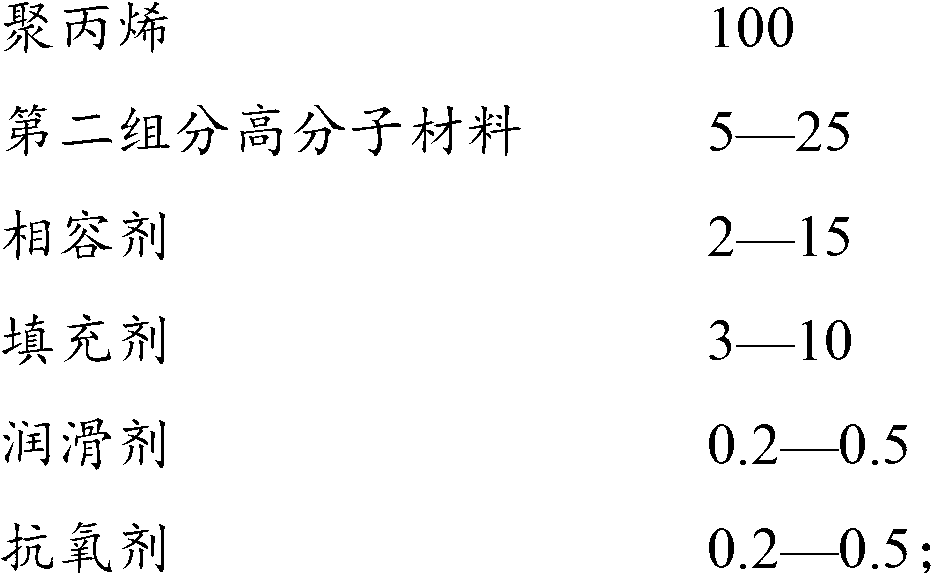

Method used

Image

Examples

Embodiment 1

[0038] Preparation of PP / ABS alloy. In this example, the polypropylene material used is homopolypropylene, and the typical grade is T30S of Maoming Petrochemical; the selected second component polymer material is ABS; the compatibilizer used is PP-g-ABS; the filler used The agent is talcum powder; the lubricant is stearamide lubricant; Phosphate tris(2,4-di-tert-butylphenyl ester) auxiliary antioxidant is compounded at a ratio of 1:1. Embodiment 1 formula is as follows (mass parts):

[0039] Polypropylene 100

[0040] ABS 5

[0041] PP-g-ABS 2

[0042] filler 3

[0043] Lubricant 0.2

[0044] Antioxidant 0.2.

[0045] Preparation:

[0046] 1) Weigh the raw materials according to the proportion, and stir in a high-speed mixer for 5-10 minutes at high speed to mix evenly;

[0047] 2) Add the mixed raw materials into a twin-screw extruder, melt extrude, and granulate.

[0048] Twin-screw extruder temperature: the temperature of the first zone is 170-210°C; the temperatu...

Embodiment 2

[0050] Preparation of PP / SAN alloy. In this example, the polypropylene material used is homopolypropylene, the typical grade is T30S of Maoming Petrochemical; the selected second component polymer material is SAN; the compatibilizer used is PP-g-SAN; the filler used The agent is calcium carbonate; the lubricant is stearic acid lubricant; Phosphate tris(2,4-di-tert-butylphenyl ester) auxiliary antioxidant is compounded at a ratio of 1:2. Embodiment 2 formula is as follows (mass parts):

[0051] Polypropylene 100

[0052] SAN 10

[0053] PP-g-SAN 4

[0054] filler 5

[0055] Lubricant 0.25

[0056] Antioxidant 0.3.

[0057] Preparation:

[0058] 1) Weigh the raw materials according to the proportion, and stir in a high-speed mixer for 5-10 minutes at high speed to mix evenly;

[0059] 2) Add the mixed raw materials into a twin-screw extruder, melt extrude, and granulate.

[0060] Twin-screw extruder temperature: the temperature of the first zone is 170-210°C; the tempe...

Embodiment 3

[0062] Preparation of PP / PMMA alloy. In this example, the polypropylene material used is copolymerized polypropylene, and the typical grade is AW564 of Singapore polyolefin; the selected second component polymer material is PMMA; the compatibilizer used is PP-g-MAH; The filler is barium sulfate; the lubricant is PE wax; the antioxidant is tetrakis [3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol main antioxidant and phosphite tri( 2,4-di-tert-butylphenyl ester) secondary antioxidant compounded at a ratio of 1:2. Embodiment 3 formula is as follows (mass parts):

[0063] Polypropylene 100

[0064] PMMA 15

[0065] PP-g-MAH 6

[0066] filler 7

[0067] Lubricant 0.3

[0068] Antioxidant 0.3.

[0069] Preparation:

[0070] 1) Weigh the raw materials according to the proportion, and stir in a high-speed mixer for 5-10 minutes at high speed to mix evenly;

[0071] 2) Add the mixed raw materials into a twin-screw extruder, melt extrude, and granulate.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com