Painting method of square lead

A square, wire technology, applied in the direction of insulating conductors/cables, etc., can solve the problems of unqualified voltage withstand performance, paint peeling, easy cracking of narrow-edge paint films, etc., and achieve the effect of not easy cracking and uniform paint film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

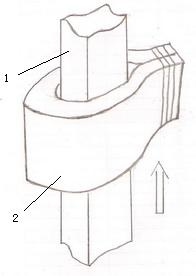

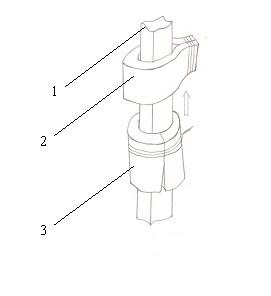

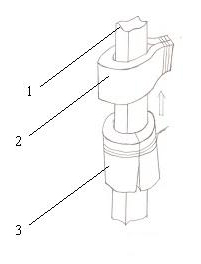

[0022] As shown in Figure 2: a method of painting a square wire, including the following steps:

[0023] 1) Bind the felt 3 and the square wire 1 together, and carry out the paint transfer and scraping of the varnish at the same time;

[0024] 2) Put the square wire 1 obtained in step 1) directly into the felt clip 2, and at the same time carry out the paint transfer and scraping of the varnish again;

[0025] 3) Baking the square wire 1 obtained in step 2).

[0026] The main factors affecting the amount of paint applied to the felt are: the degree of clamping of the felt, the temperature of the varnish, and the viscosity of the varnish. Due to the surface tension of the paint liquid, the adhesion of the paint liquid changes from uneven to basically uniform. To solve this problem, we must start from two aspects:

[0027] 1. Control the amount of paint on the narrow side so that it is basically the same as the amount of paint on the wide side;

[0028] 2. Increase the visco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com