Patents

Literature

207results about How to "Good voltage resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

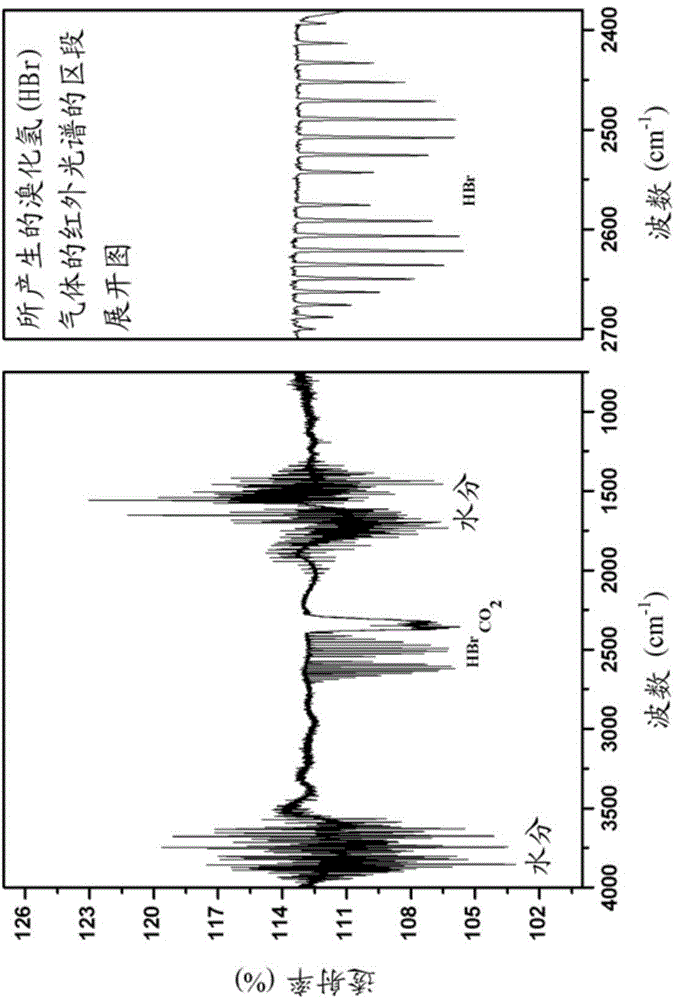

High voltage resistant electrolytic capacitor paper and preparation method thereof

ActiveCN104988809AHigh strengthSoft touchPlastic/resin/waxes insulatorsPaper coatingElectrolysisPaper production

The invention relates to electrolytic capacitor paper and a preparation method thereof. Raw paper pulp of the electrolytic capacitor paper is composed of insulation wood pulp, cotton pulp and hemp pulp; at least one of the cotton pulp and the hemp pulp is selected, papermaking is conducted on the cotton pump and / or the hemp pump, and raw paper is prepared by the processed cotton pump and / or hemp pump and the insulation wood pump in a composite mode. According to the technical scheme, high voltage resistant electrolytic capacitor paper is obtained through raw paper production and subsequent coating processing, the high voltage resistant electrolytic capacitor paper is better in strength, soft in hand feeling, good in water-absorbing capacity, low in loss value and excellent in voltage-resistance performance, and the voltage-resistance performance can be increased by over 100 V / mm.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +2

Preparing method of contact tip composite material of vacuum switch based on dispersed copper

InactiveCN101290838AExcellent withstand voltageExcellent resistance to welding and bondingContactsChromiumAluminium

The invention belongs to the alloy material technical field and provides a preparation technology method for a dispersion copper matrix vacuum switch contact composite material. The method adopts Cu-Al alloy powder with low solid solubility, the aluminum content of the Cu-Al alloy powder is not more than 1.00 wt percent, the balance is Cu, pure chromium metal powder and industrial Cu2O are taken as raw materials, wherein, the mixing proportion of the Cu-Al alloy powder and the oxidant Cu2O is (94-96)wt percent: (6-4)wt percent, and the mixing proportion of the total amount of the Cu-Al alloy powder and the oxidant Cu2O as well as Cr powder is (75-50)wt percent: (25-50)wt percent; the preparation technology comprises alloy melting, powder preparation, powder mixing, pressing, internal oxidation as well as hot extrusion and cold drawing molding; wherein, the inner oxidation and sintering are synchronously carried out, the sintering temperature is between 900 and 1050 DEG C, and the sintering time is between 4 and 10 hours; the obtained dispersion copper matrix vacuum switch contact composite material mainly comprises a dispersion copper matrix Cu-Al2O3 and Cr particles, the content of the Cu-Al2O3 is less than or equal to 1.50 wt percent, the diameters of particles are not more than 100nm, and the Cr content is between 25 and 50 wt percent.

Owner:HENAN UNIV OF SCI & TECH

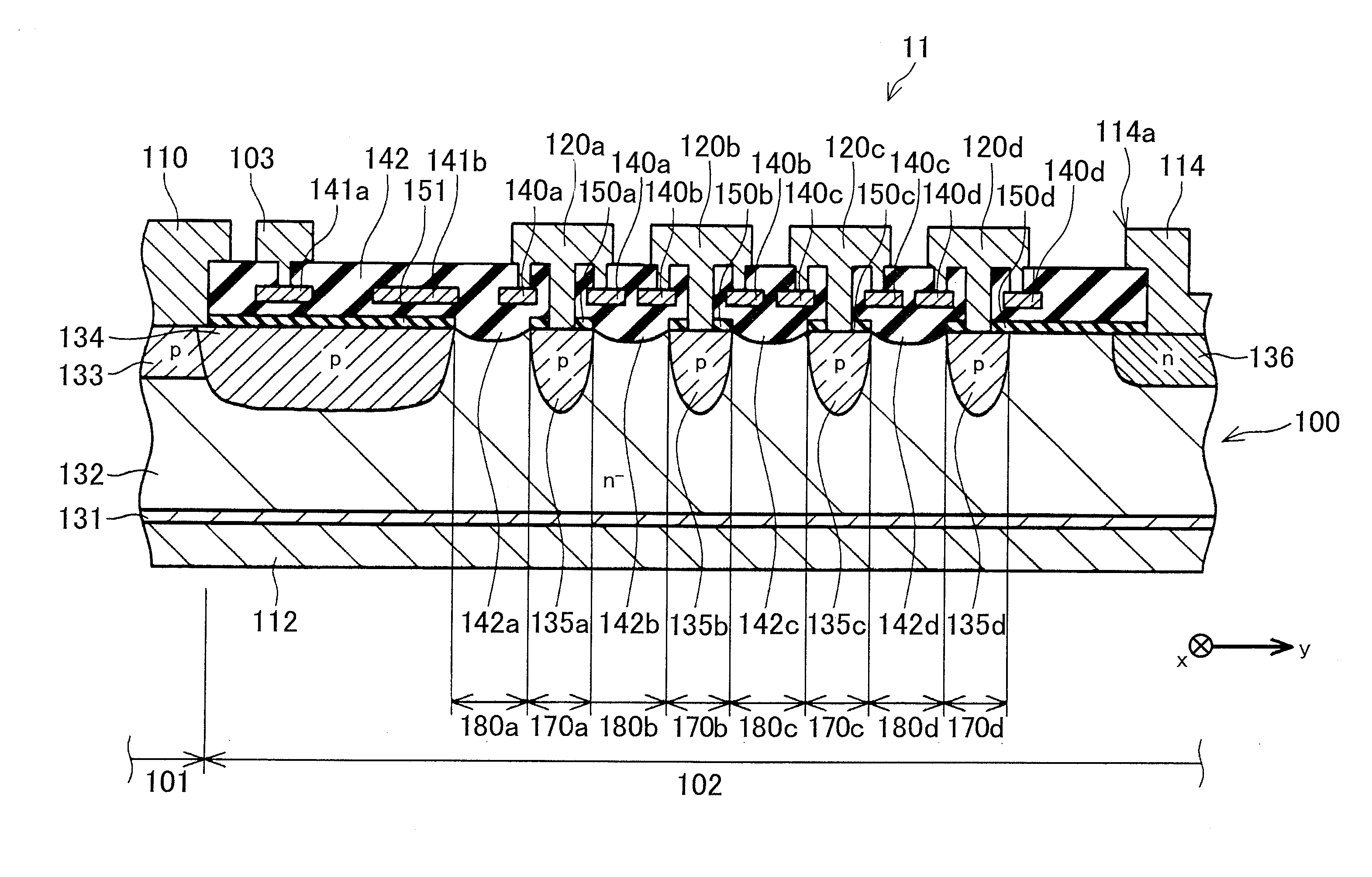

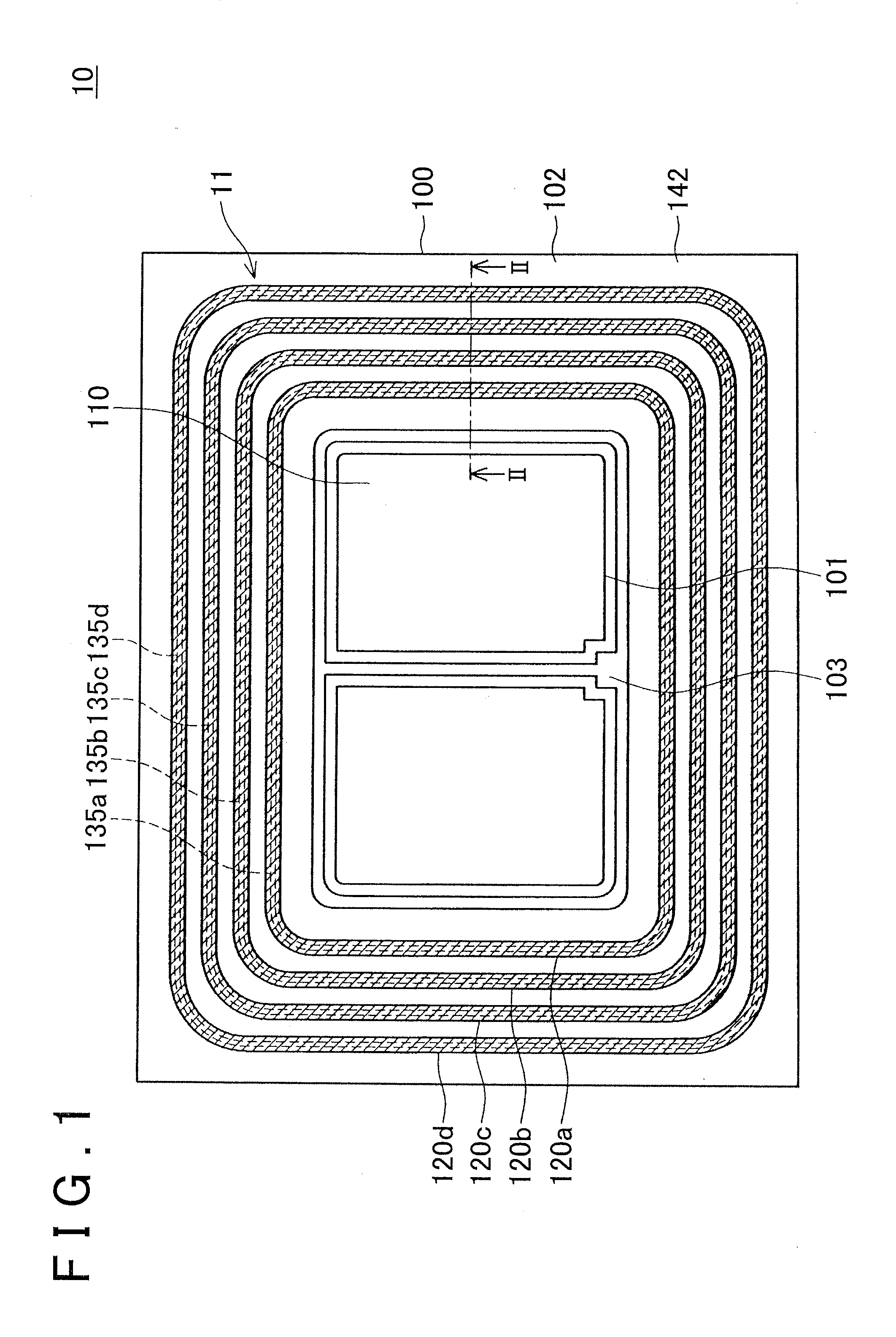

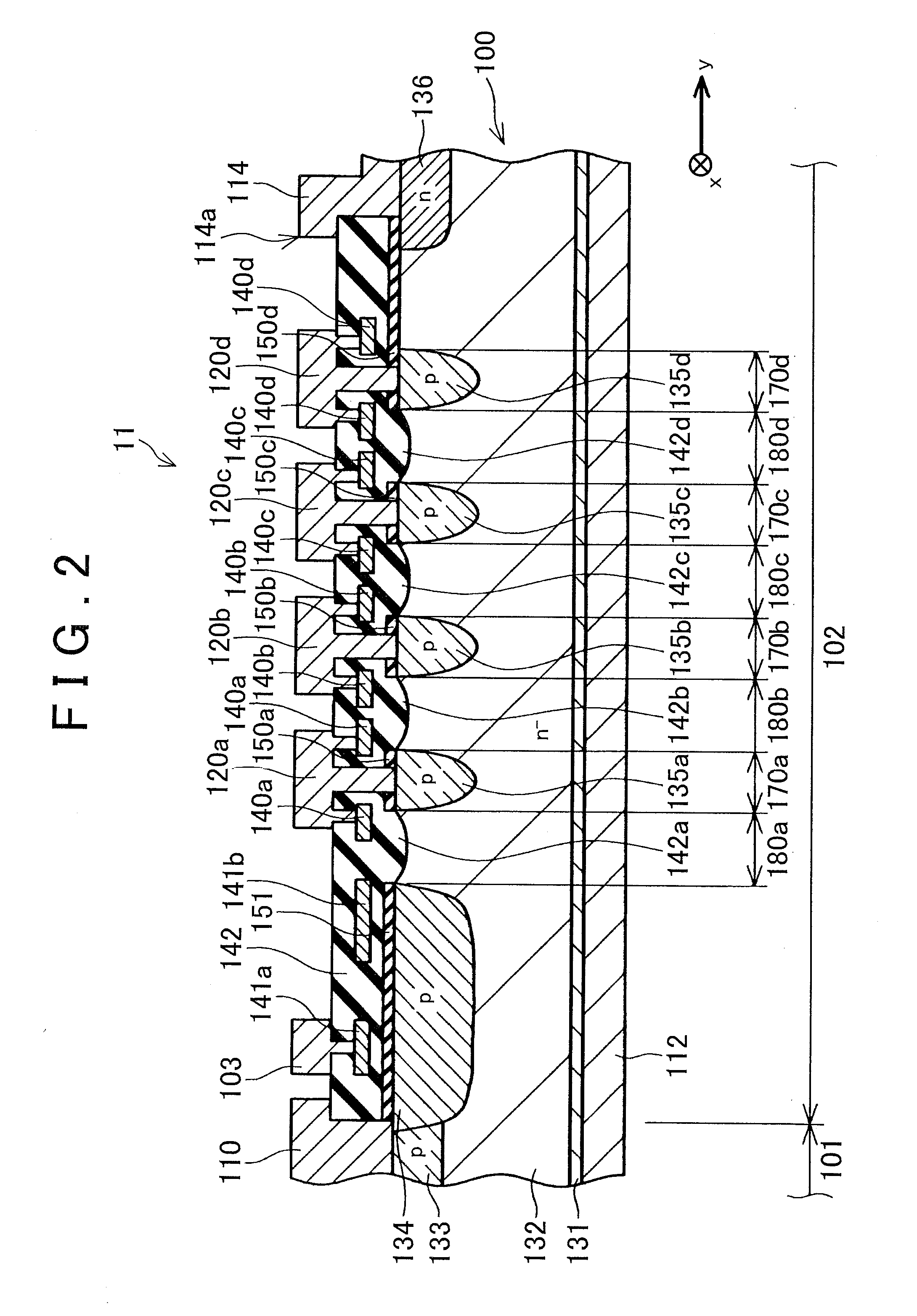

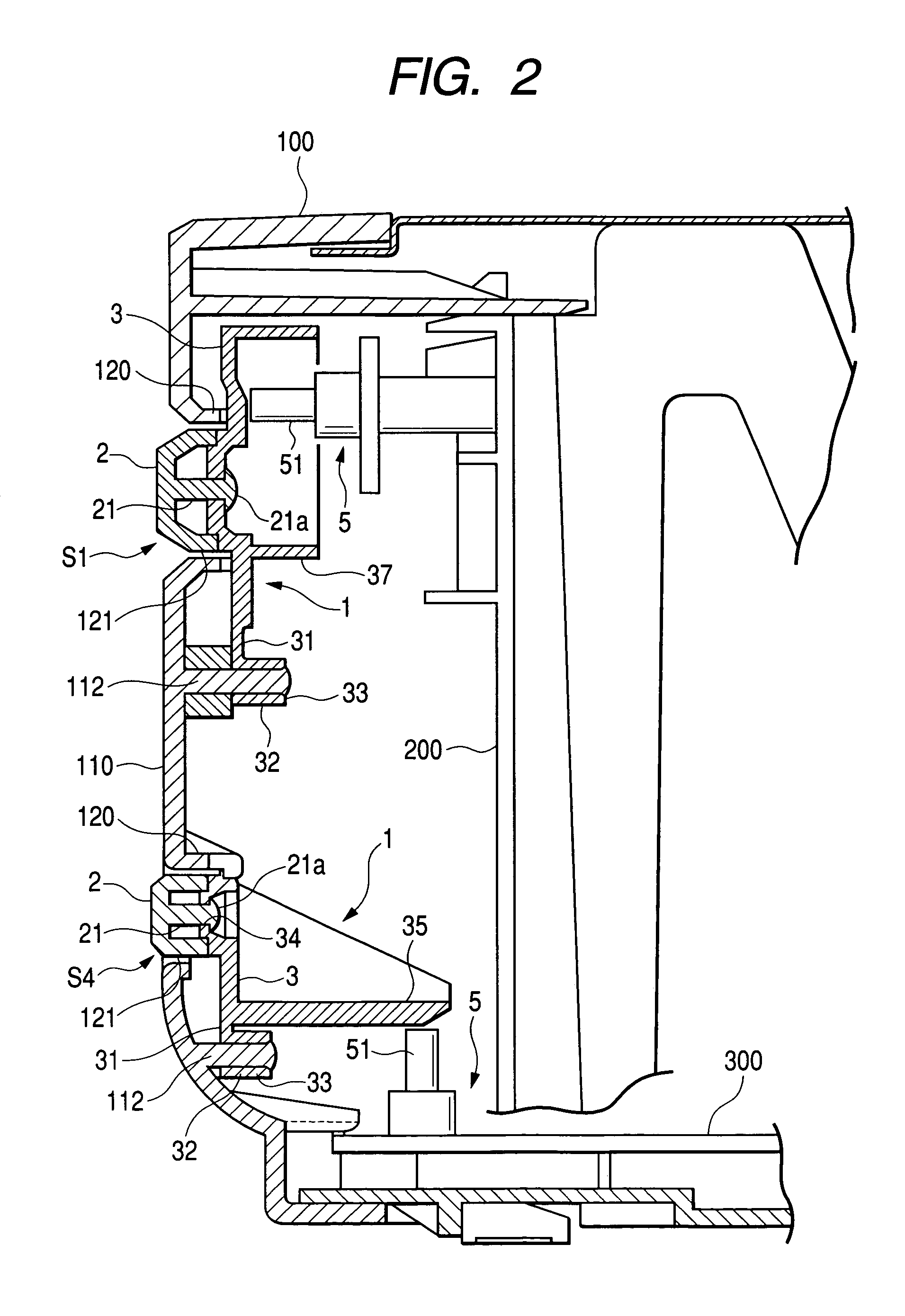

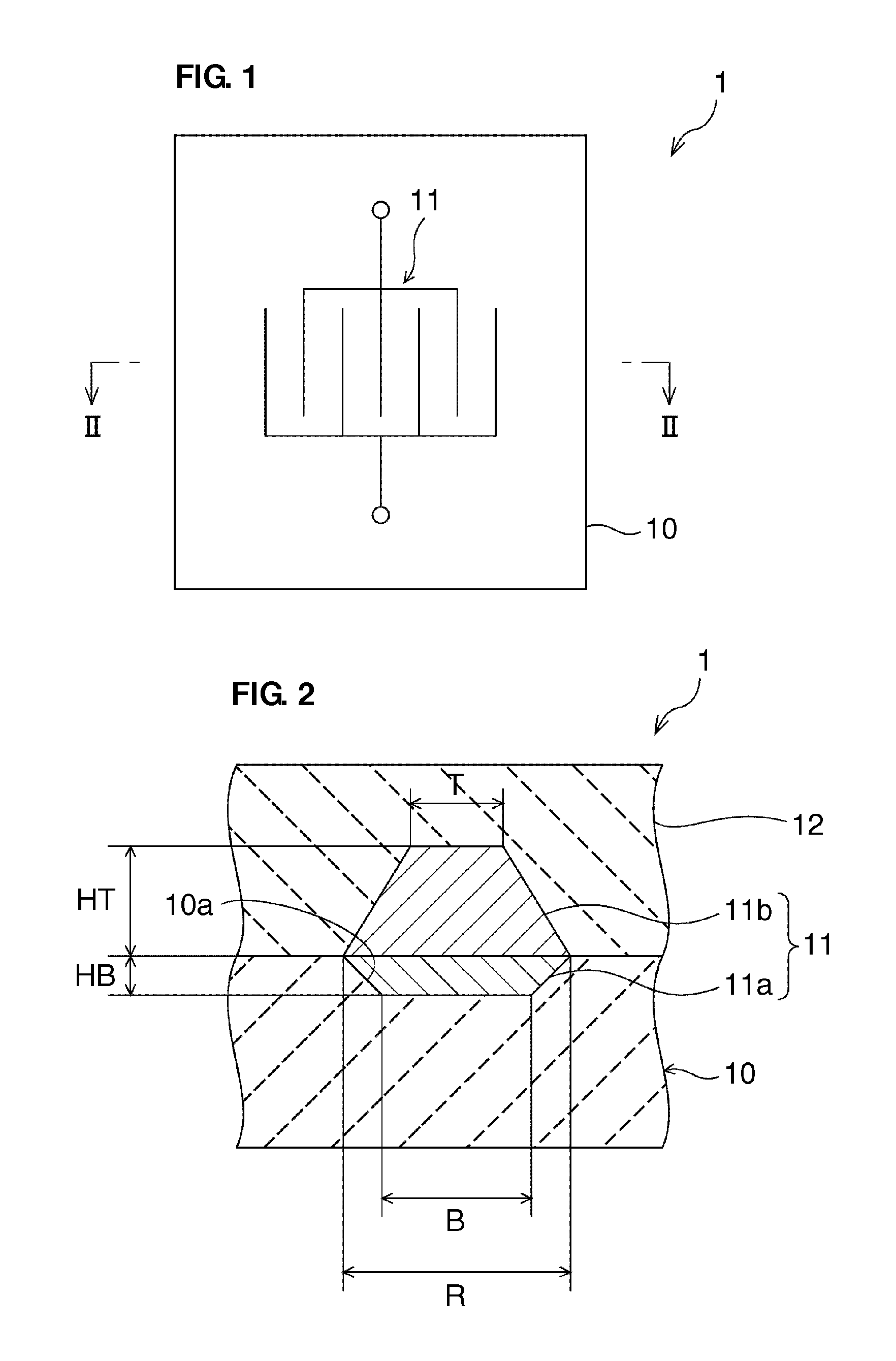

Semiconductor device

ActiveUS20130214394A1Improve reliabilityGood voltage resistanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialElectrical connection

A field plate of a semiconductor device is provided with i) an insulating film that is formed on a surface of the semiconductor substrate, and includes a plurality of first regions, one for each of a plurality of FLR layers, that contact the layers and are arranged at intervals in a radial direction, and a plurality of second regions, one for each of the first regions, that are adjacent to the first regions in the radial direction, and ii) a plurality of first conductive films that are formed, one for each of the layers, inside of the insulating film, are arranged at intervals in the radial direction along the layers when a semiconductor substrate is viewed from above, and that are electrically connected to the layers. A thickness of at least a portion of the second regions is thicker than a thickness of the first regions.

Owner:DENSO CORP

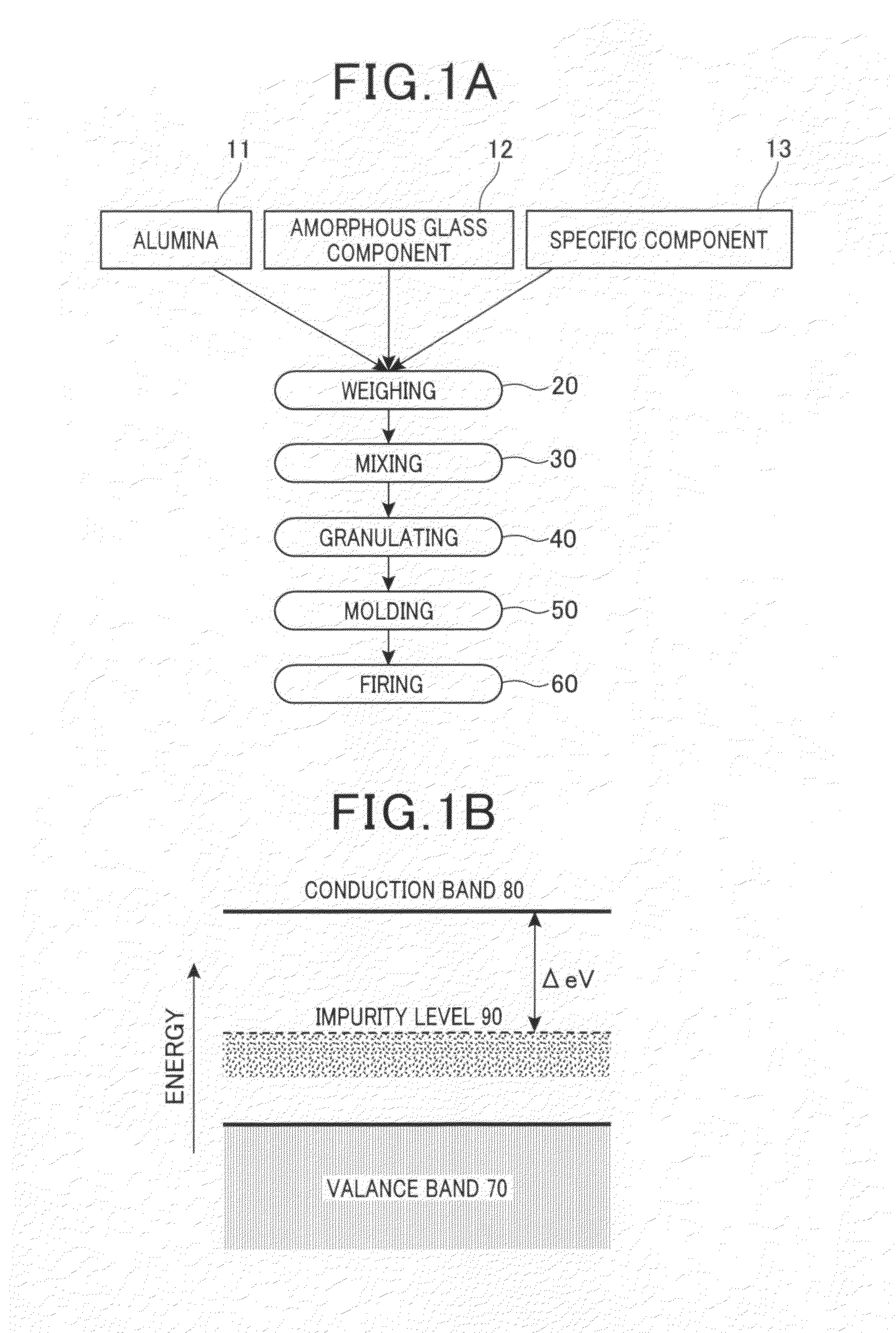

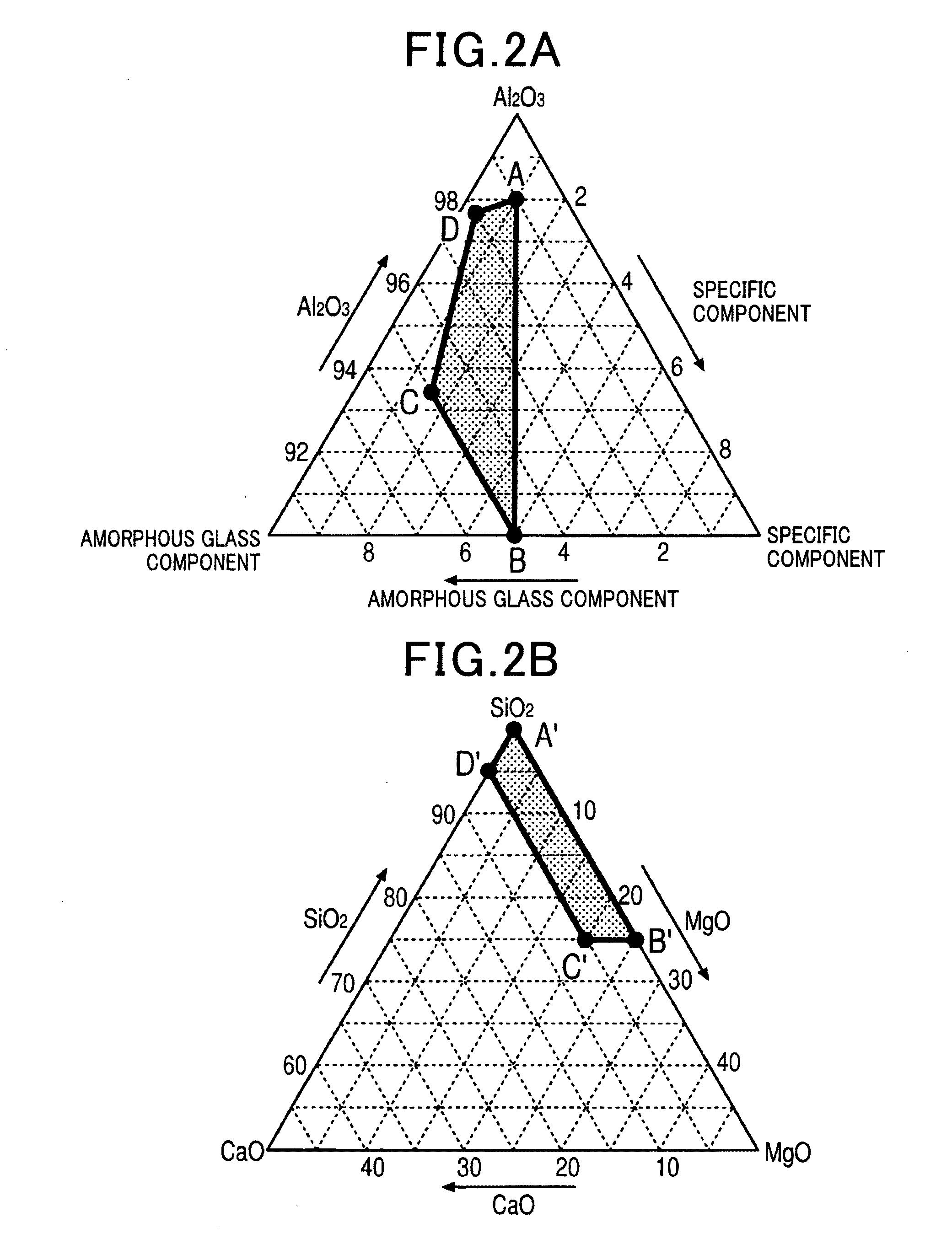

Alumina sintered body

An alumina sintered body of the present invention has alumina crystals as a main phase and an amorphous grain boundary glass phase. The amorphous grain boundary glass phase is a grain-boundary glass phase having an amorphous glass component in which at least one of either CaO or MgO is added to SiO2, and at least one type of oxide selected from rare-earth elements and elements in Group IV of the periodic table included in the amorphous glass component as a specific component. When a composition ratio of the main phase and the amorphous grain boundary glass phase is alumina:amorphous glass component:specific component=a:b:c (a+b+c=100% by weight), in a triangular coordinate of which peaks are alumina, the amorphous glass component, and the specific component, a point (a,b,c) is within a range surrounded by four points, A(98.0,1.0,1.0), B(90.0,5.0,5.0), C(93.5,5.0,1.5), and D(97.8,2.0,0.2).

Owner:DENSO CORP +1

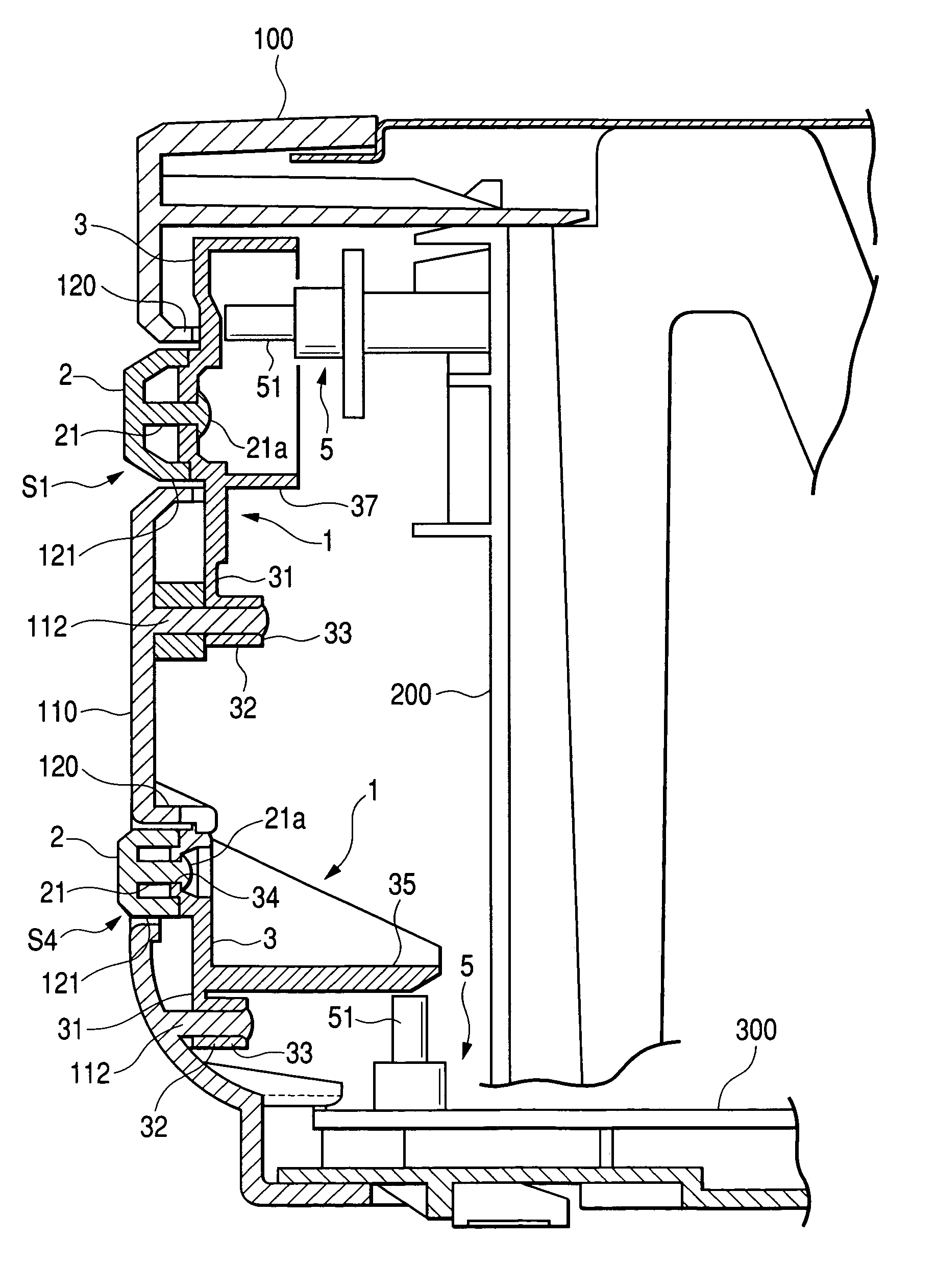

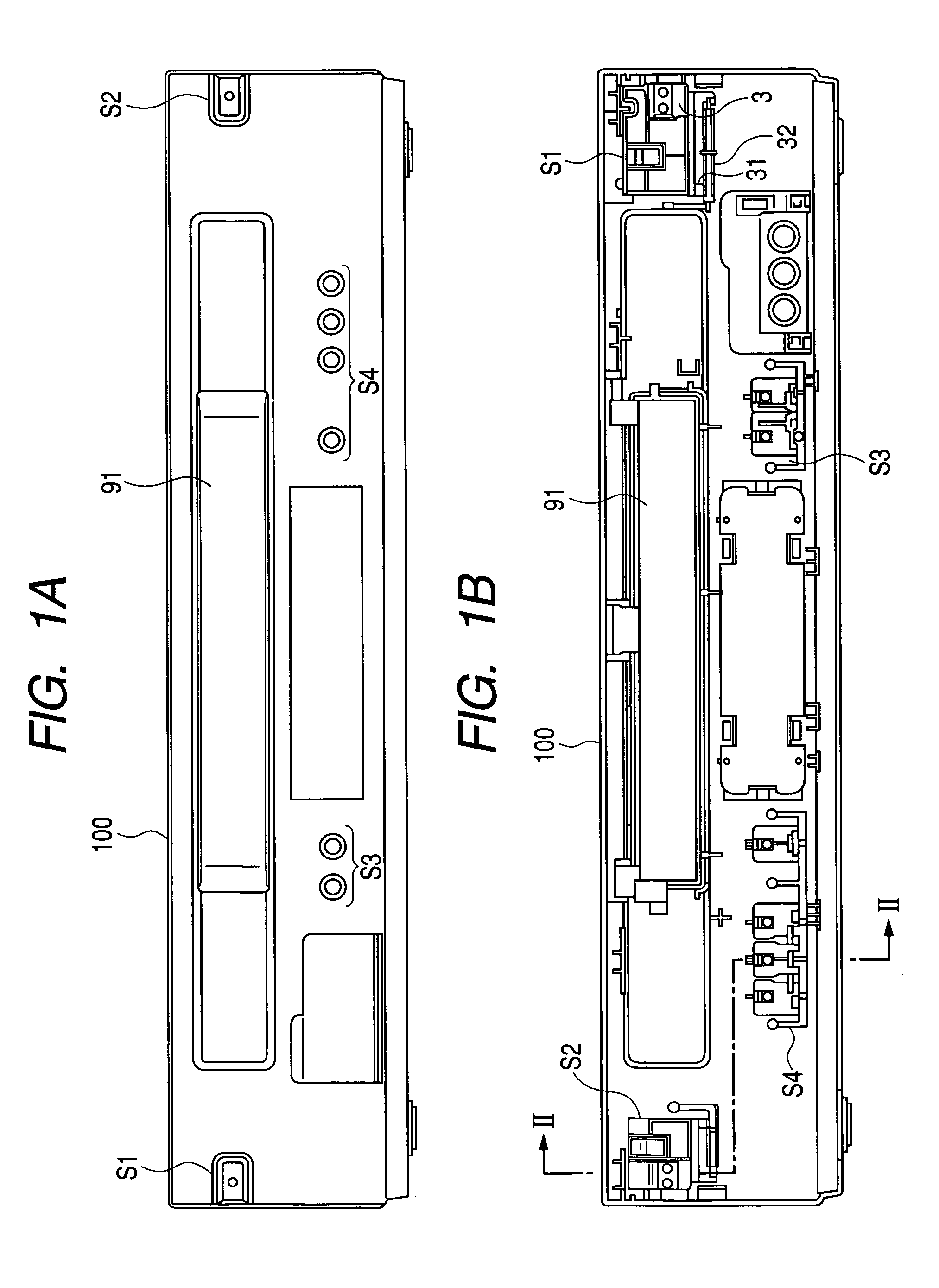

Switch device

InactiveUS7002086B2Improve pressure resistanceAvoid probabilityEmergency actuatorsContact operating partsEngineeringSynthetic resin

A switch device includes: an operating portion made of a synthetic resin and having a conductive plating layer formed thereon, the operating portion configured to be inserted into a hole formed on a housing of an apparatus; and a shielding portion made of a synthetic resin and having no conducive plating layer formed thereon, the shielding portion formed separately from the operating portion and covers a gap between the operating portion and the hole from an inner side of the housing. The shielding portion is provided to push a tact of a switch provided at a rear side of the shielding portion when the shielding portion is displaced by a pushing operation of the operating portion. The operating portion is fixed to the shielding portion in a state in which the plating layer thereof being not exposed to the rear side of the shielding portion.

Owner:FUNAI ELECTRIC CO LTD

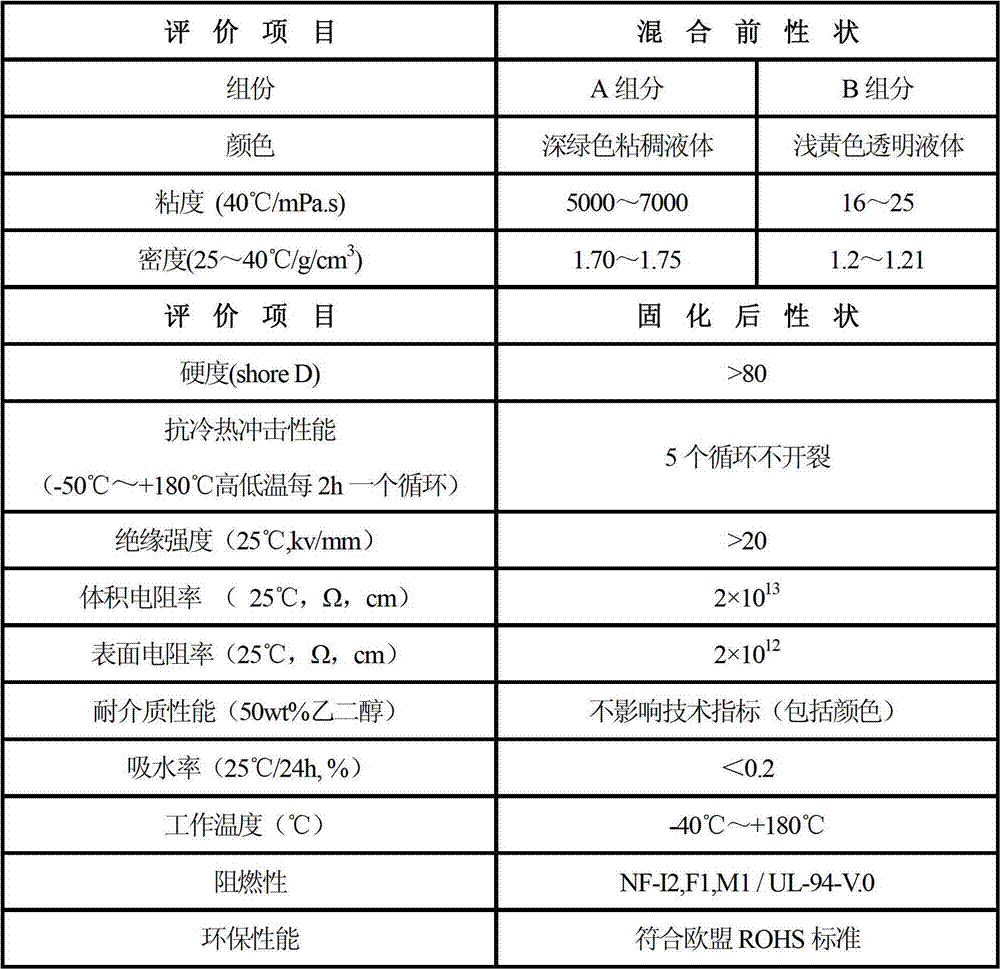

Flame-retardant encapsulating material and preparation method thereof

The invention relates to the field of encapsulation of electronic component, in particular relates to a flame-retardant encapsulating material applicable to electronic and electric product and a preparation method of the flame-retardant encapsulating material, solving the problems of the prior art that the fire-proofing and flame retardant performance is poor, and relatively high flame-retardant rating cannot be obtained. The material comprises a component A and a component B; in percentage by weight, the component A comprises base stock bisphenol-A epoxy resin, fire retardant, diluent diethylene glycol dibenzoate, flexibilizer dioctyl phthalate, pigment, organic silicon defoaming agent and filler silica micropowder; the component B comprises curing agent phthalic anhydride or methyl tetrahydrophthalic anhydride, curing agent eleostearate anhydride, and accelerator 2, 4, 6-tri(dimethylamino methyl) phenol; before the flame-retardant encapsulating material is used, the component A is pre-heated in an oven and then uniformly agitated in an up-to-bottom way; and the component A and the component B are uniformly mixed, so as to obtain flame-retardant encapsulating material; and then the encapsulating can be carried out. The flame-retardant encapsulating material provided by the invention is mainly applicable to insulating packaging of various electronic components such as power engine, rail transit, war industry, spaceflight, car and power.

Owner:大连宝津科技发展有限公司 +1

High-dielectric constant composite material

The invention relates to a high-dielectric constant composite material. Bismaleimide resin monomer, maleic anhydride, octamethylcyclotetrasiloxane, pentaerythritol tetraacrylate, phenoxy resin, iso-tridecanol polyoxyethylene ether, polycaprolactam resin, filler and ethylene glycol are taken as materials, a resin-based compound system is prepared; the resin-based compound system is then put into a mold and hot-pressed, and thereby the high-dielectric constant composite material is obtained. The high-dielectric constant composite material has excellent mechanical property and heat resistance, and the development and application of high-dielectric constant composite materials can be met.

Owner:苏州凯欧曼新材料科技有限公司

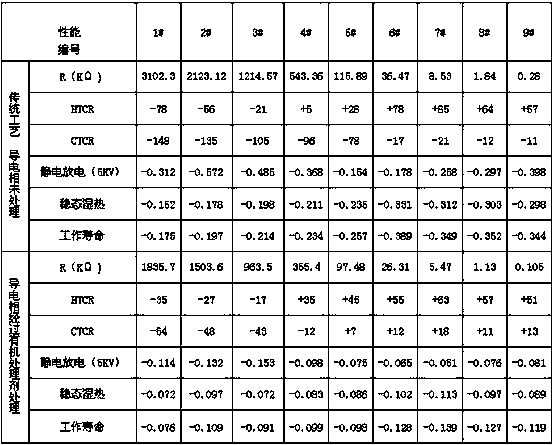

High-performance thick-film resistor paste composition

InactiveCN109637695AGood resistance reproducibilityImprove stabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureElectrical resistance and conductancePhosphate

The invention discloses a high-performance thick-film resistor paste composition. The composition comprises 12-44 parts of conductive powder, 20-60 parts of lead borosilicate glass powder, 0.5-5 partsof inorganic additive and 35-45 parts of organic carrier based on 100 parts in total; the conductive powder is one or a mixture of two of ruthenium dioxide or lead ruthenate subjected to surface-treatment by using a phosphate ester organic treating agent. The conductive powder comprises the components: 40-100% of ruthenium dioxide and 20-100% of lead ruthenate. According to the high-performance thick-film resistor paste composition disclosed by the invention, the materials of ruthenium dioxide with extremely low resistivity and lead ruthenate with high resistivity are adopted as main conductive powder, the resistor paste is guaranteed to have excellent resistance value stability, excellent voltage resistance and power resistance characteristics at different resistance values; and the resistor has good compactness after being sintered.

Owner:西安宏星电子浆料科技股份有限公司

Halogen-free combustion-proof thermoplastic engineering plastics

InactiveCN101077928AImprove flame retardant performanceGood voltage resistanceThermoplasticPhosphate

The present invention relates to one kind of no-halogen fire retardant thermoplastic engineering plastic, which is prepared with nylon-66 200-700 weight portions, glass fiber 100-500 weight portions, fire retarding system comprising phosphate-containing fire retardant 50-300 weight portions and mineral fire retardant 10-300 weight portions, and antioxidant with hindered phenol as main component 1-10 weight portions. Compared with available technology, the present invention has the advantages of high CTI, low smoking amount, low toxicity, environment friendship, etc.

Owner:上海耐特复合材料制品有限公司

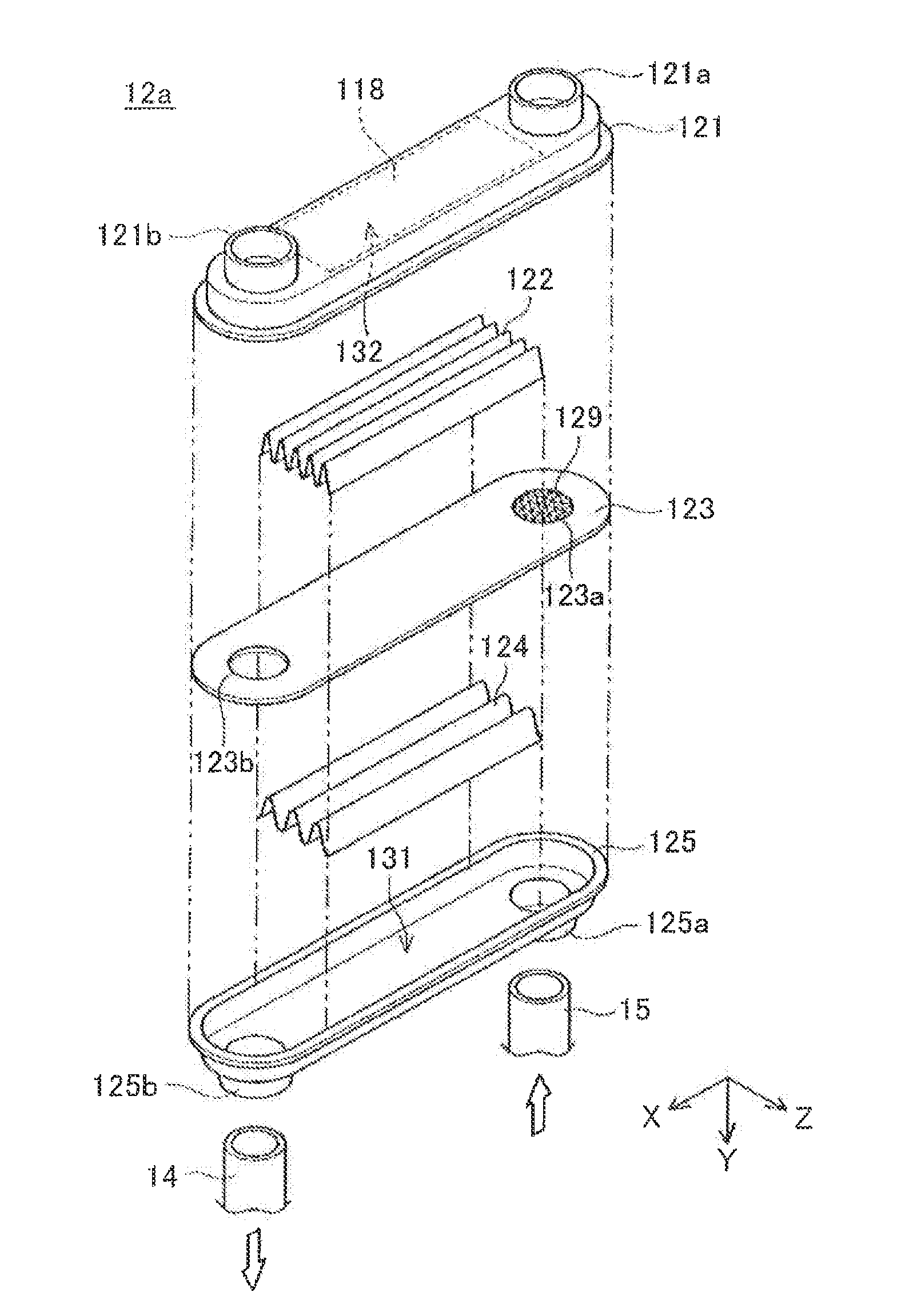

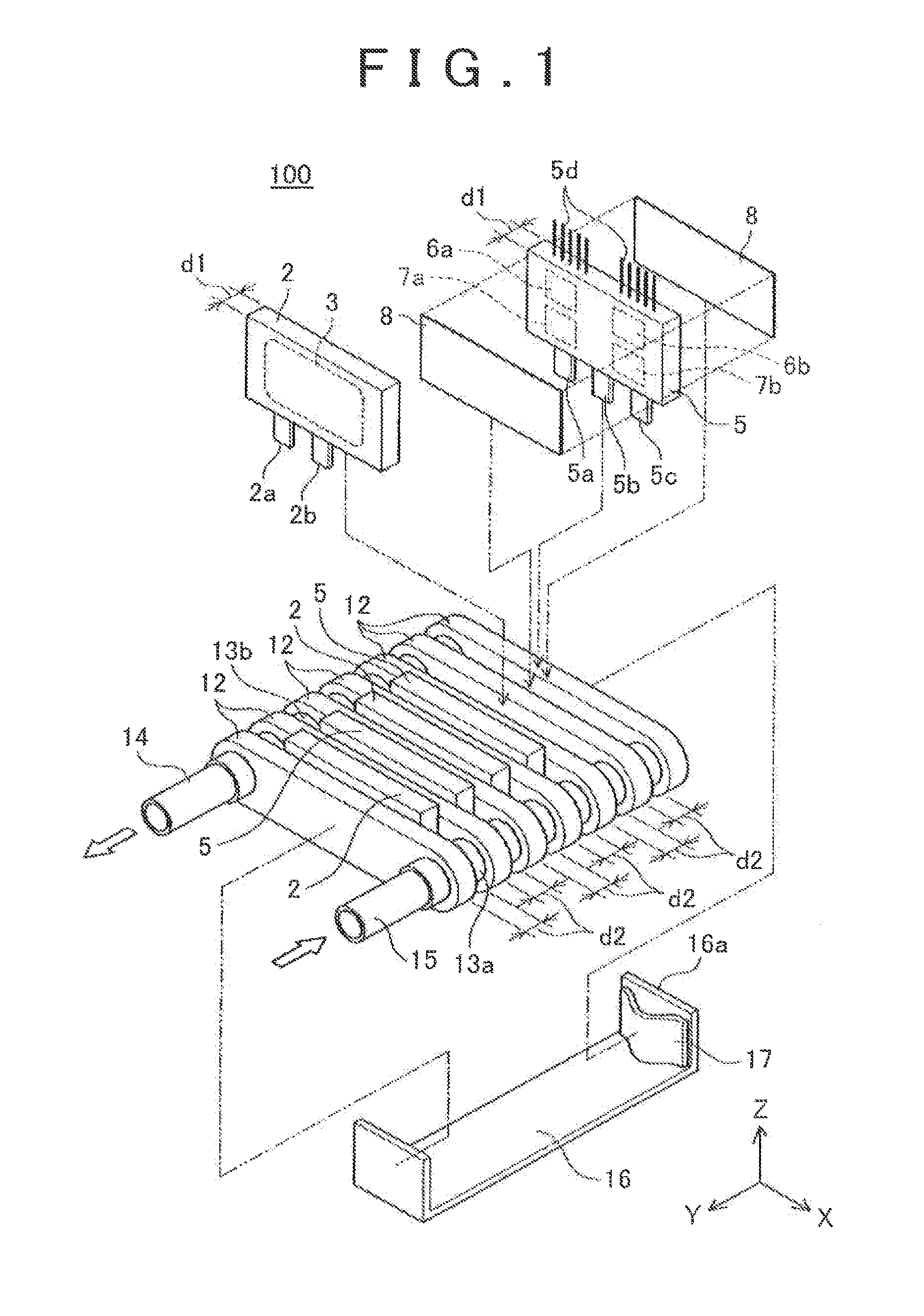

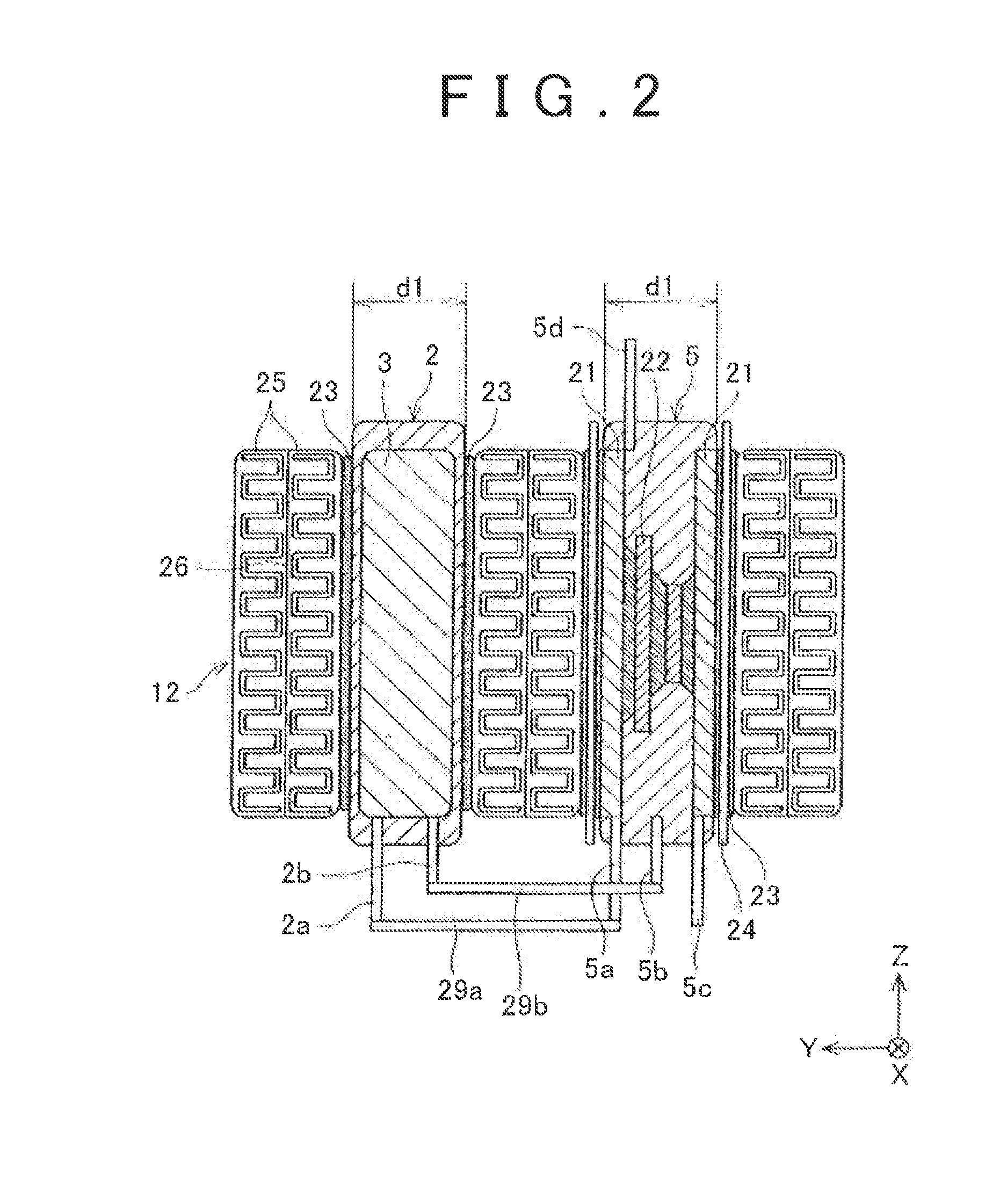

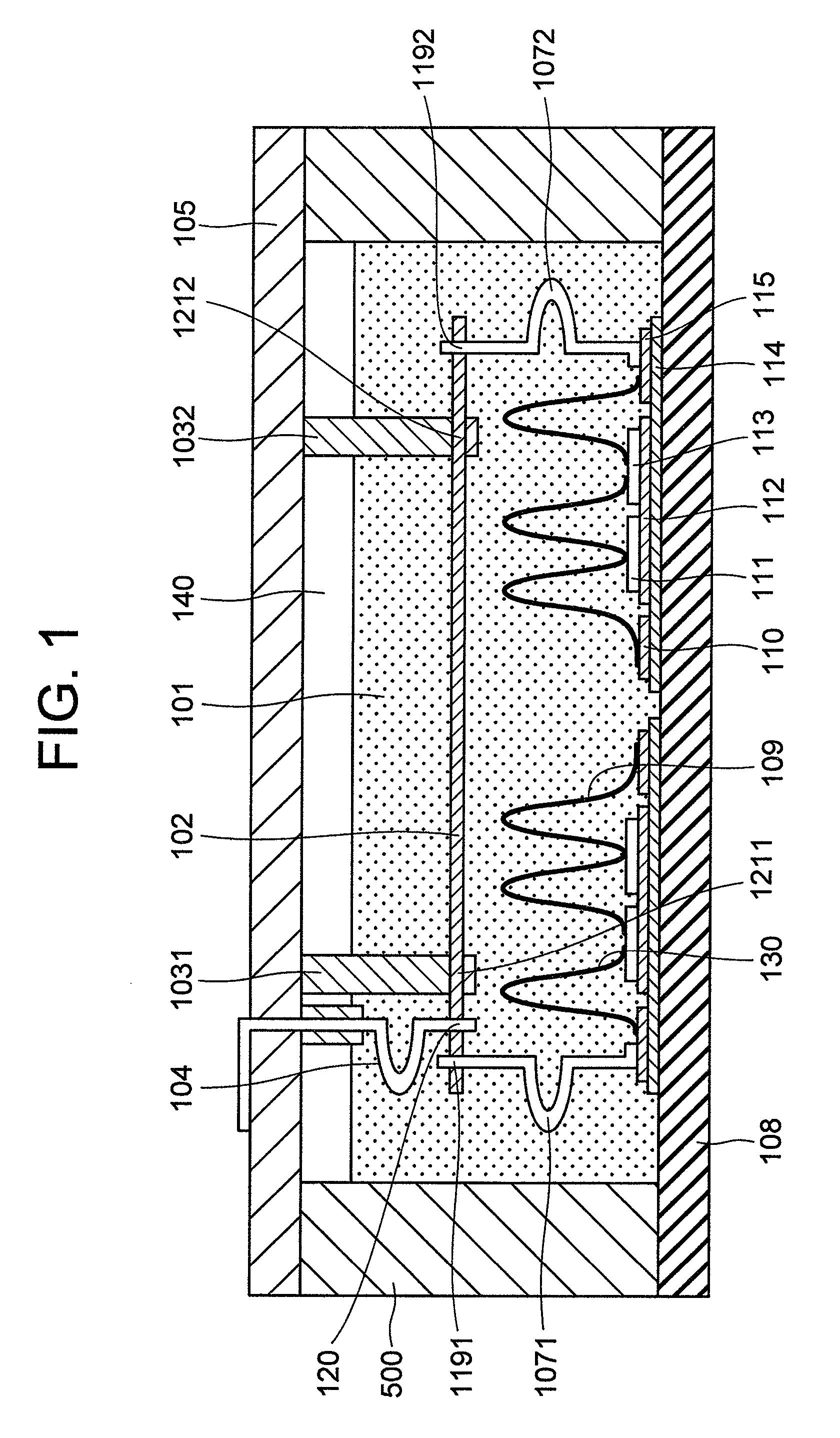

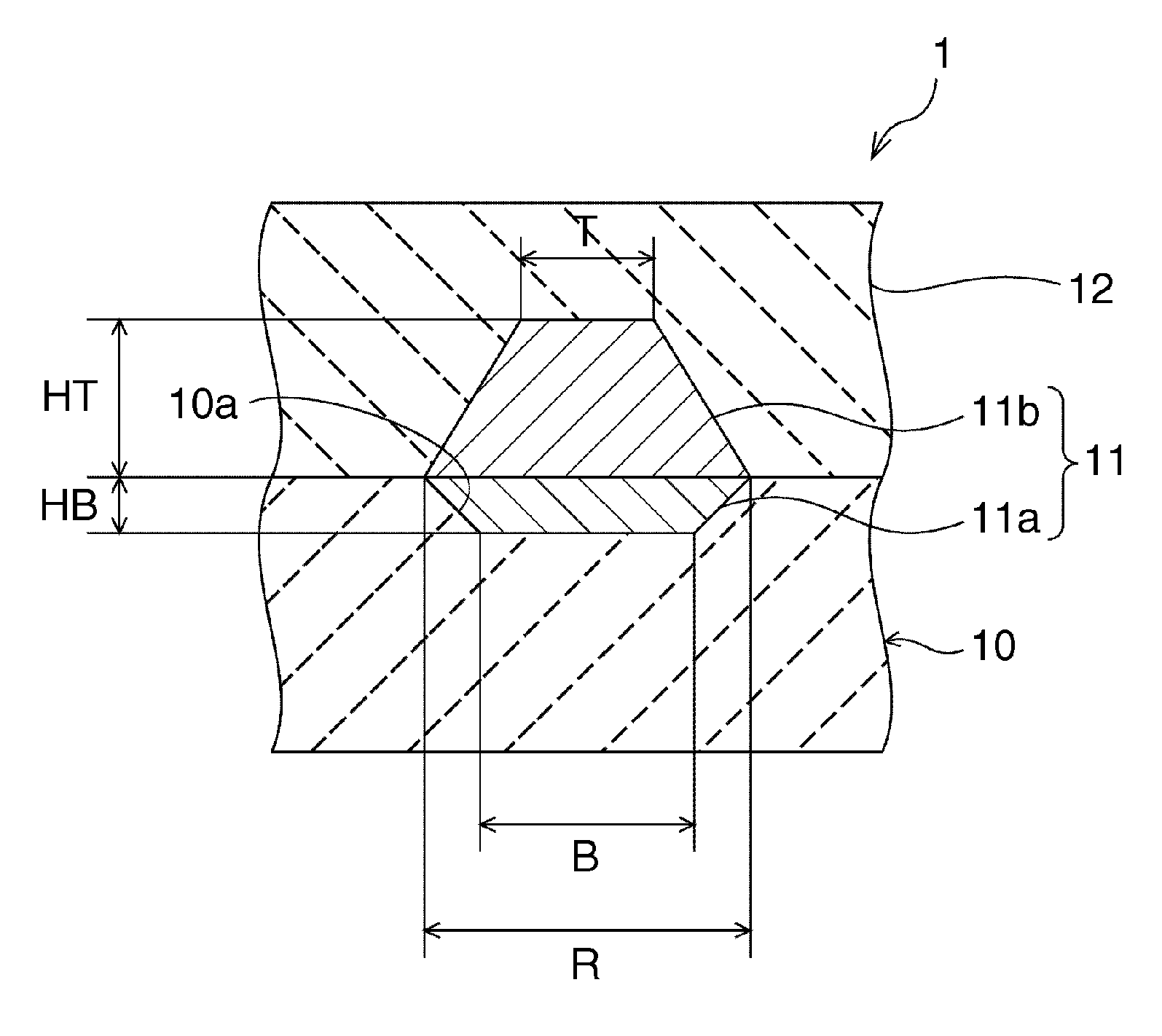

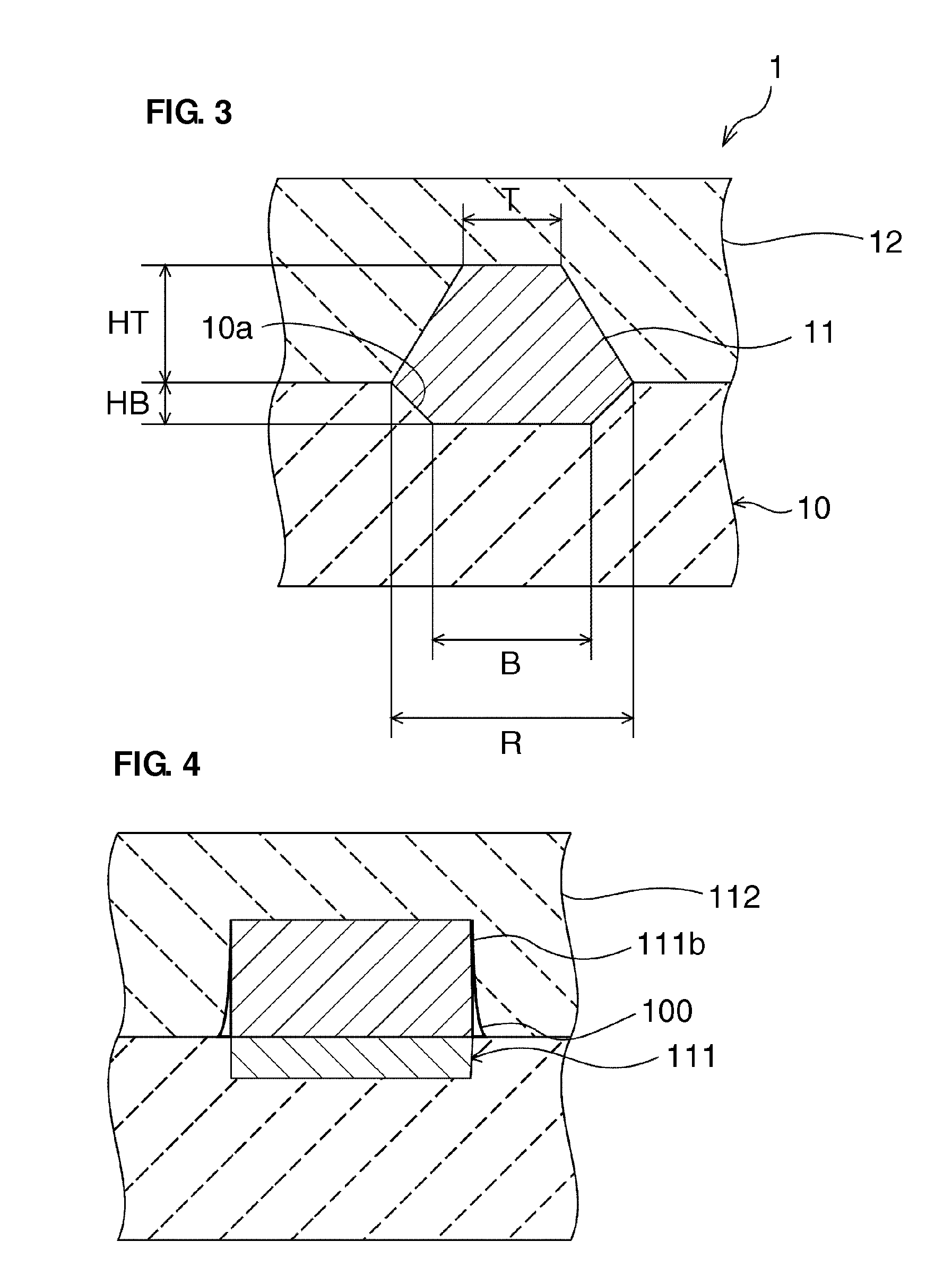

Semiconductor module

InactiveUS20140339693A1Improve moisture resistanceExcellent in voltage enduranceTransistorSemiconductor/solid-state device detailsSemiconductor packageEngineering

Provided is an improved cooler-integrated semiconductor module.A semiconductor module (100) includes a plurality of cooling plates (12), and a plurality of flat-plate semiconductor packages (5) and flat-plate device packages (2). The semiconductor packages (5) each include a semiconductor element housed therein. The device packages (2) each include an electronic component housed therein, the electronic component being different in type from the semiconductor element housed in the semiconductor elements. The cooling plates (12) are laminated alternately with the semiconductor packages (5) or the device packages (2). Connecting tubes (13a, 13b) having refrigerant flowing therein are provided between the cooling plates (12) adjacent to each other.

Owner:TOYOTA JIDOSHA KK

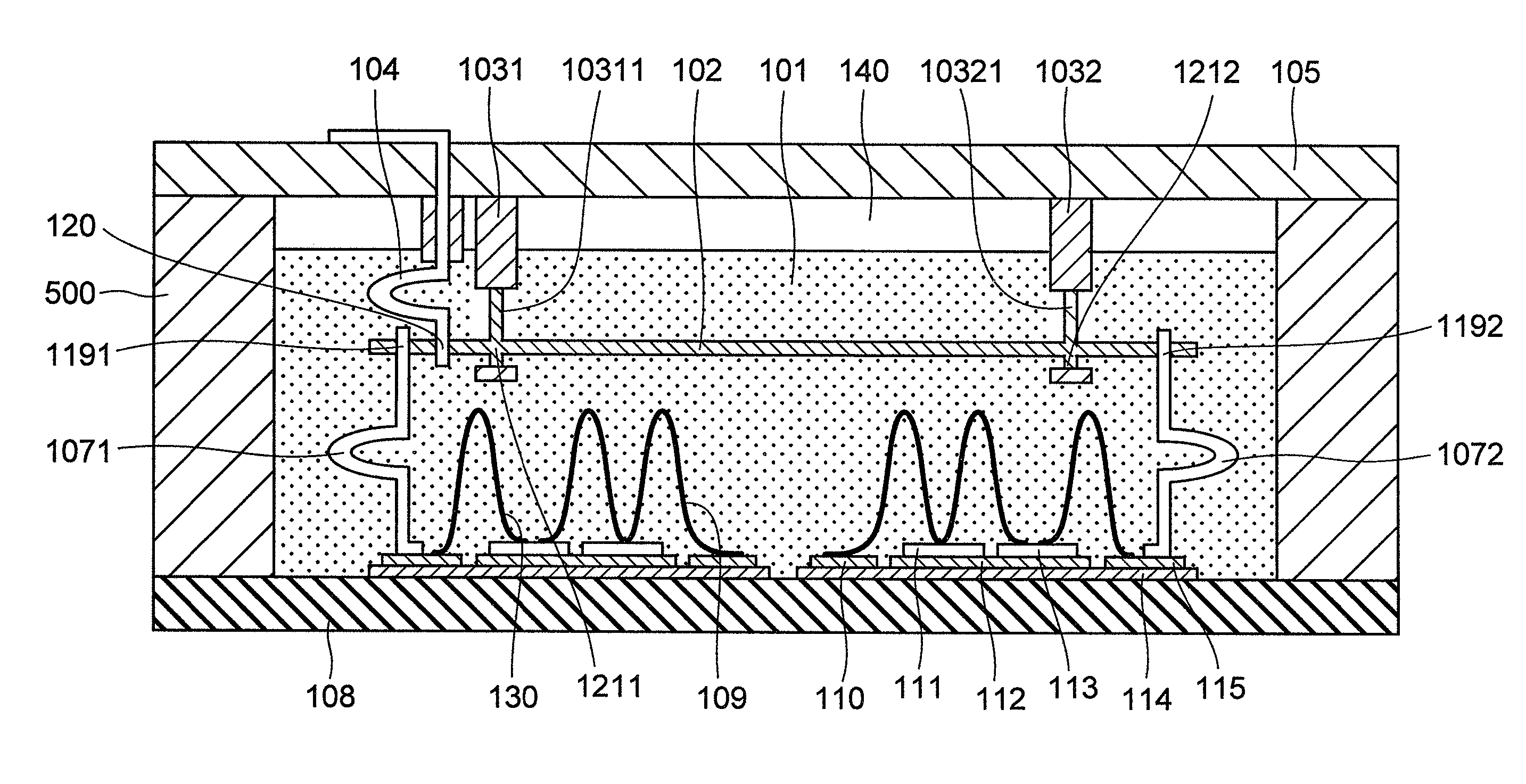

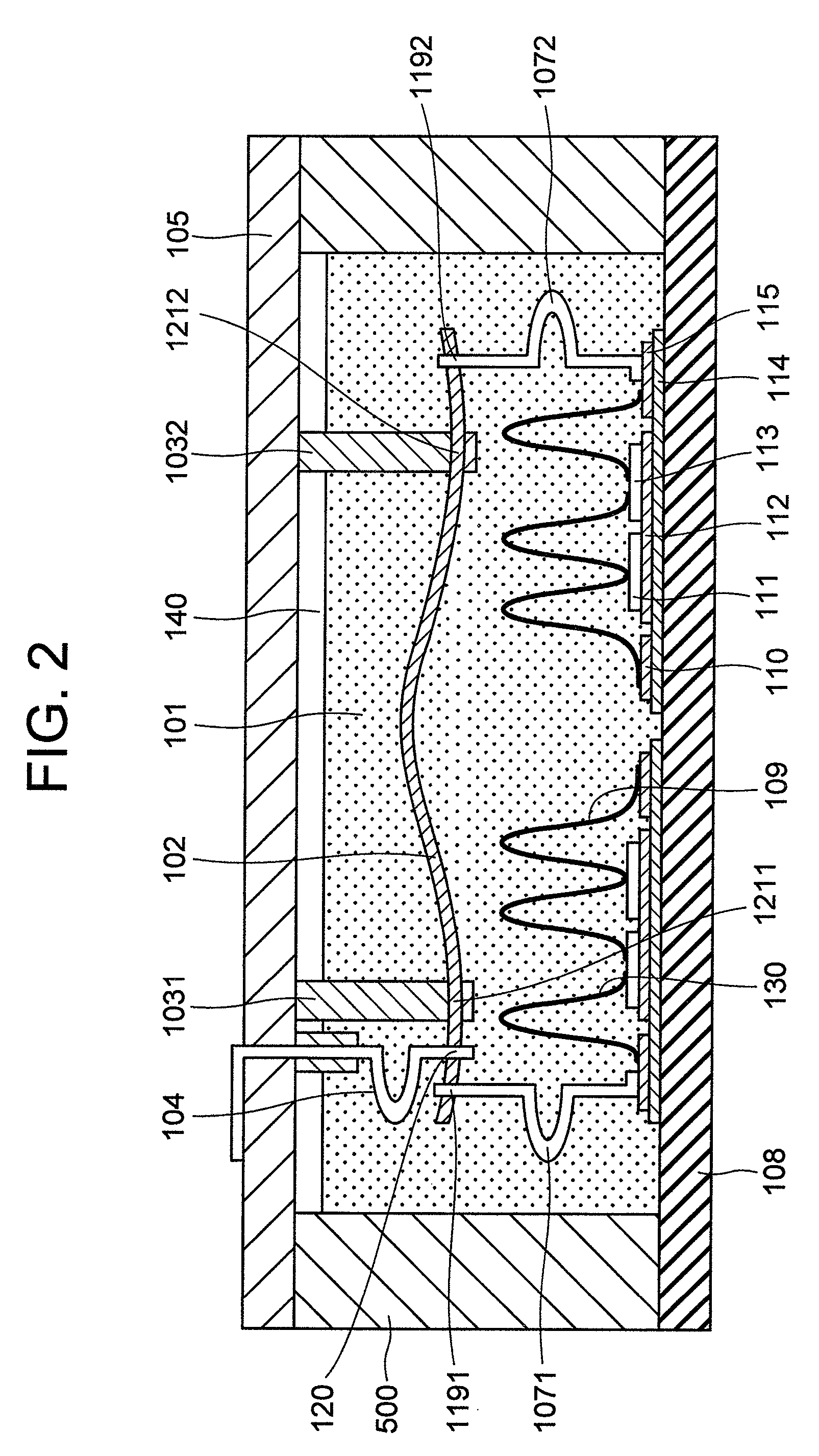

Power Semiconductor Module and Fabrication Method Thereof

ActiveUS20070290305A1Good voltage resistanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesMoistureContamination

An elastic printed board is provided so that stress applied by the silicon gel is absorbed by the printed board. Further, the printed board is formed to be so narrow that the stress may be escaped. On the other hand, the wires on which a high voltage is applied are patterned on respective printed boards. This serves to prevent discharge through the surface of the same printed board served as current passage. This design makes it possible to hermetically close the power module, prevent intrusion of moisture or contamination as well as displacement, transformation and crack of the cover plate.

Owner:HITACHI POWER SEMICON DEVICE

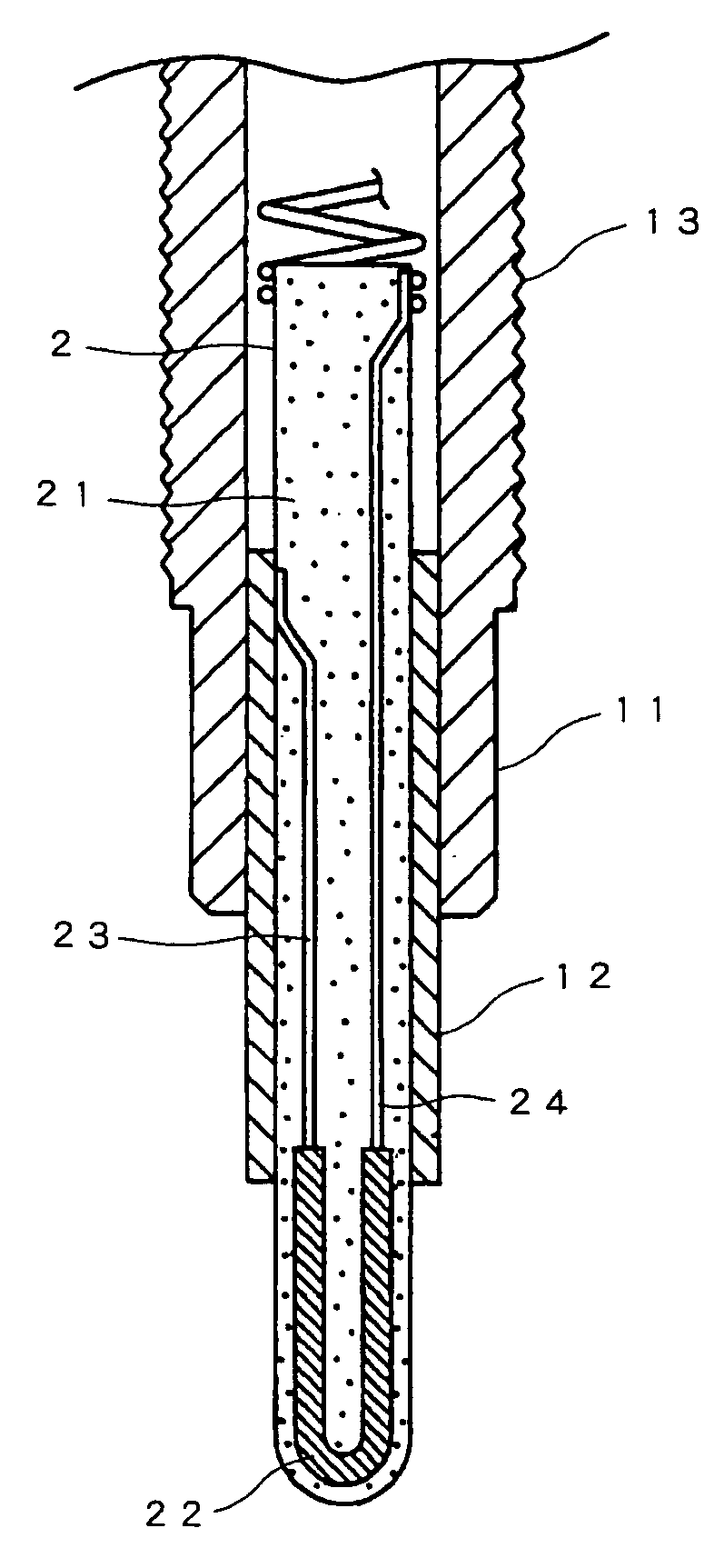

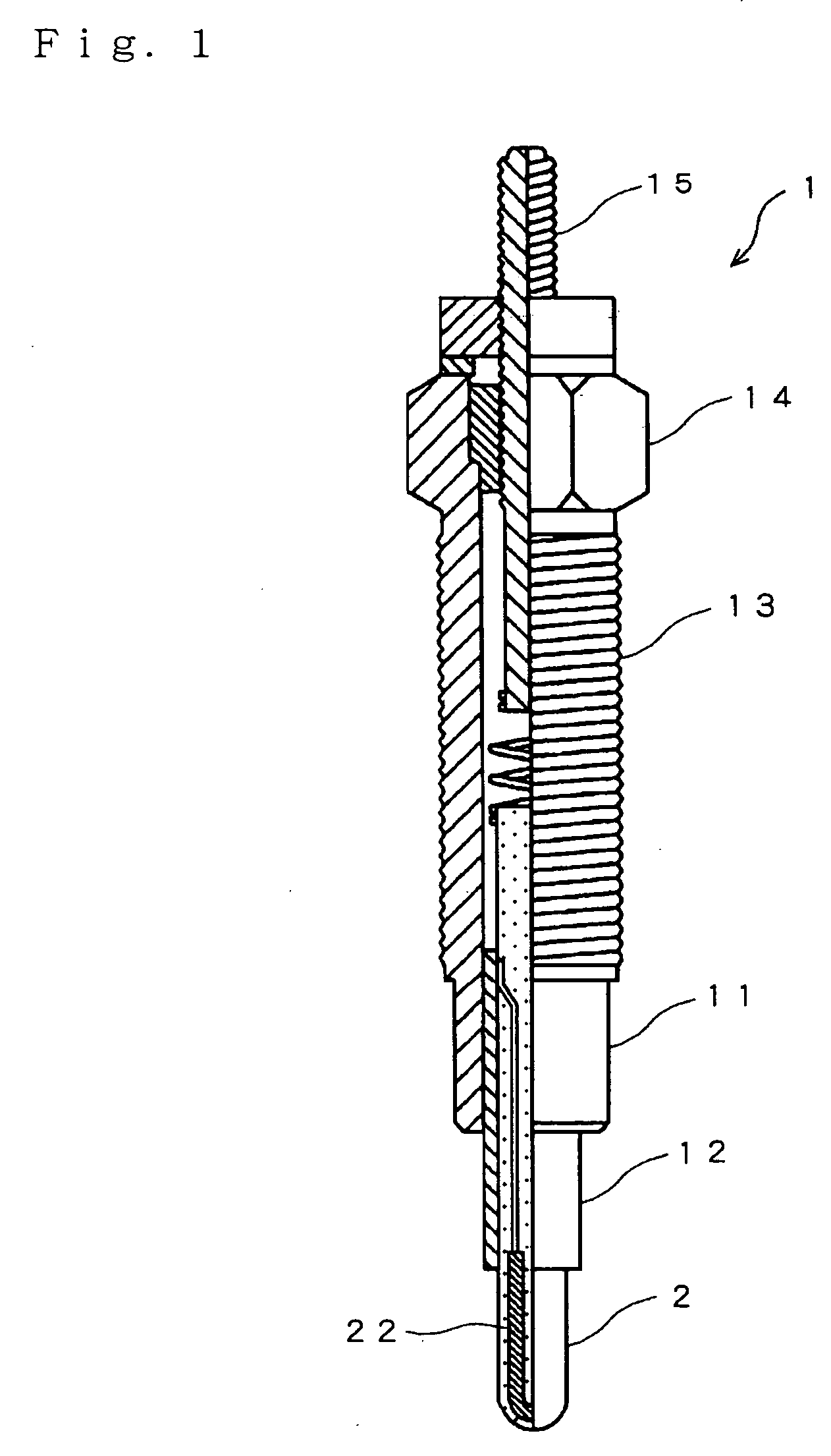

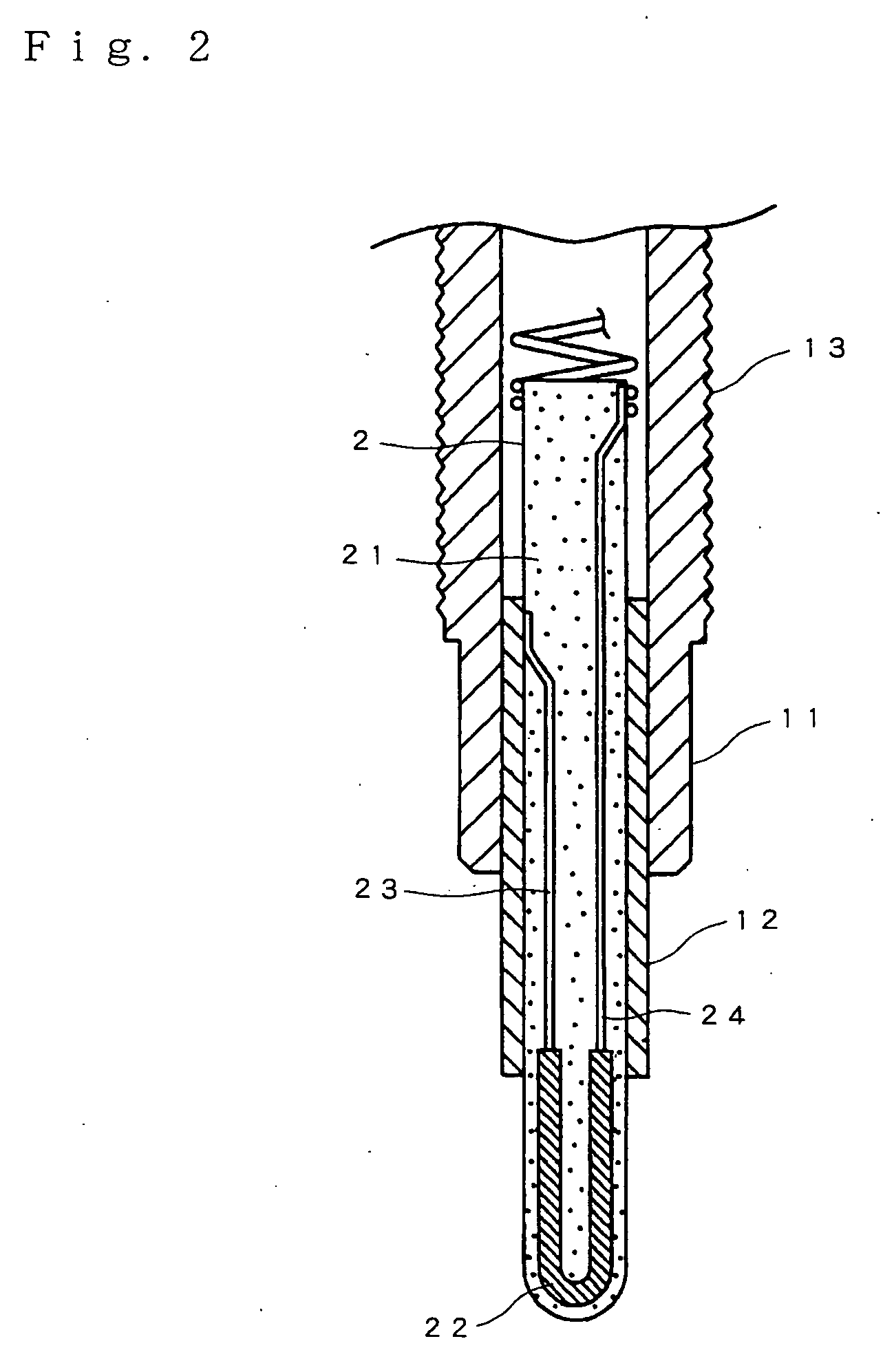

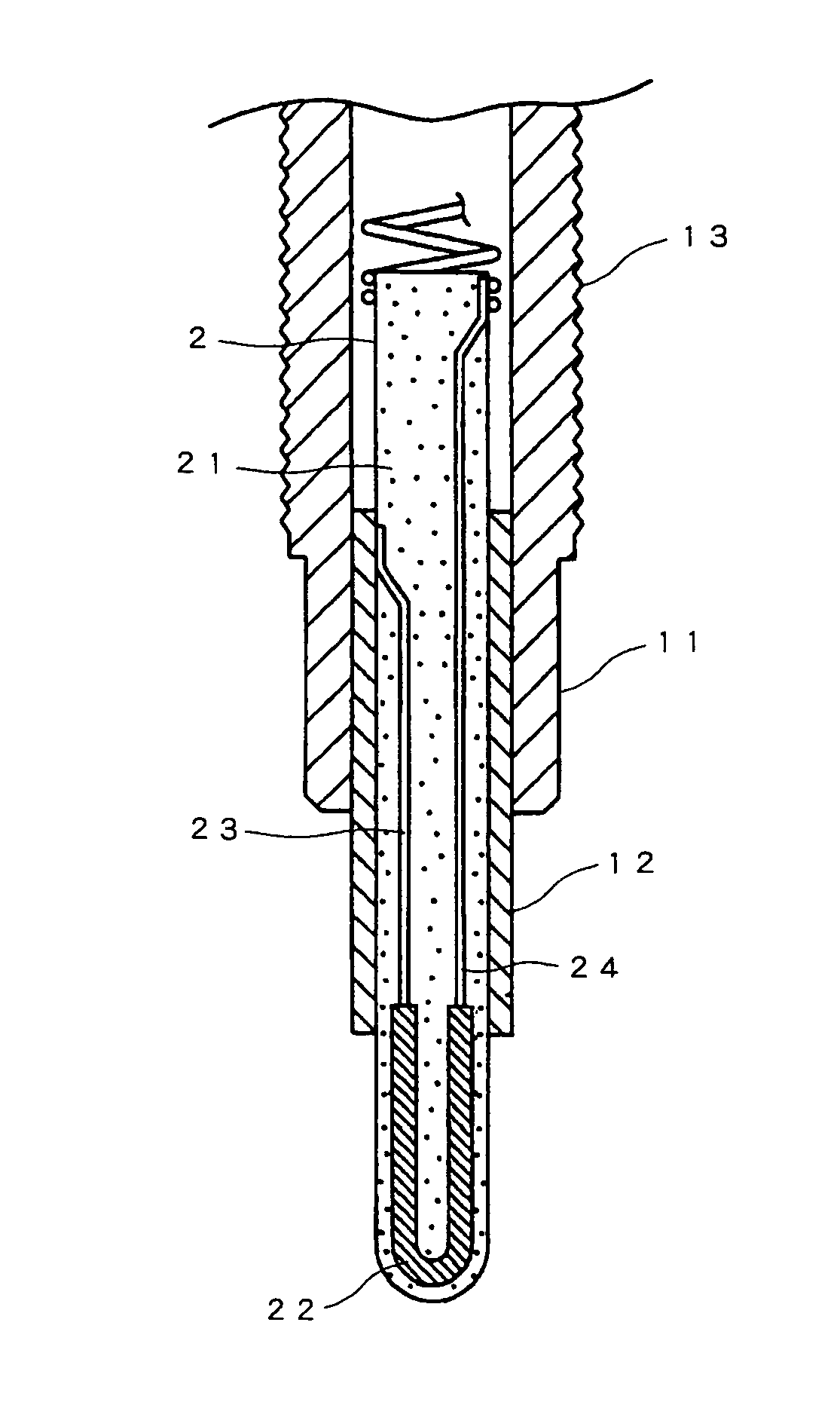

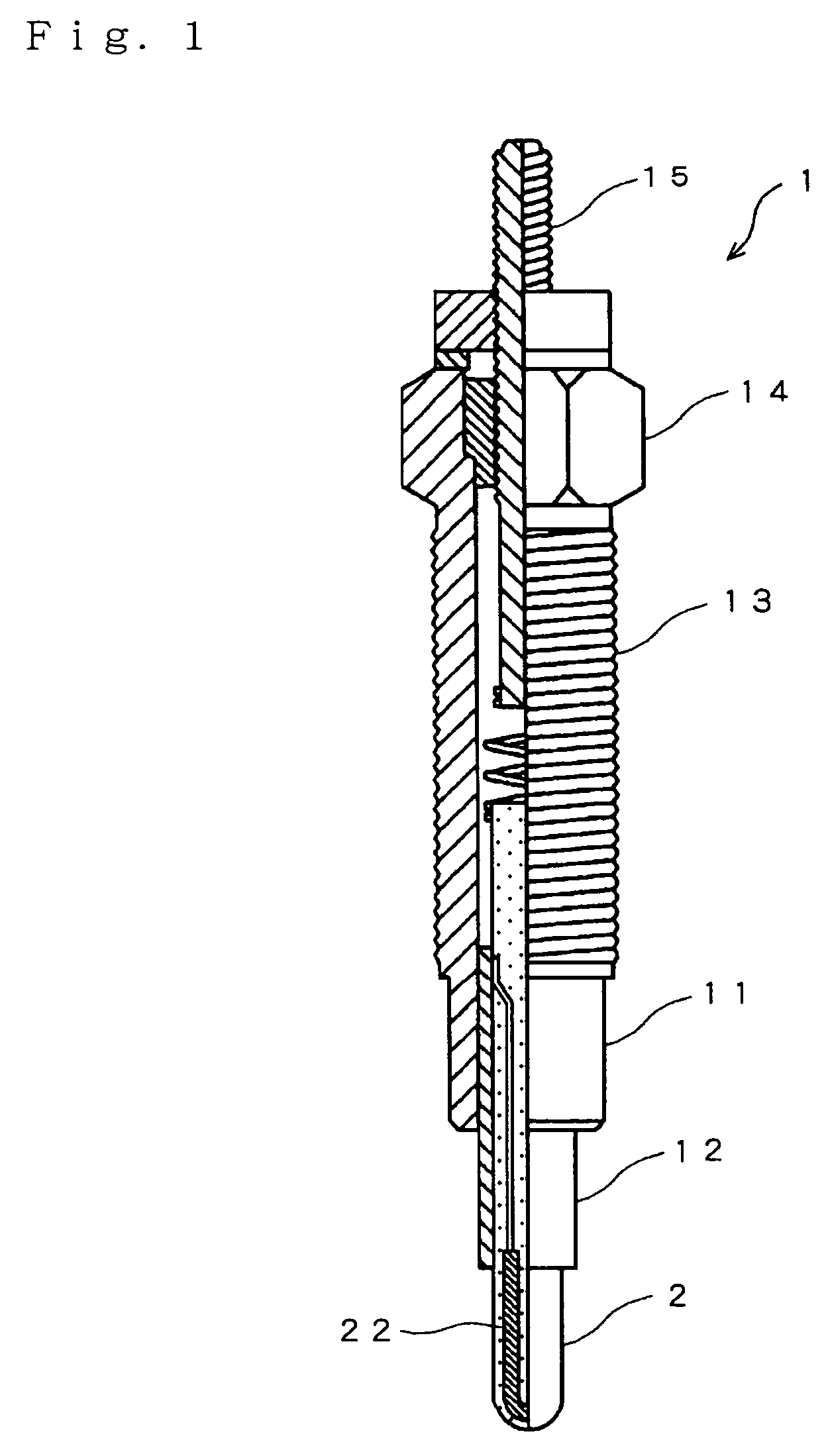

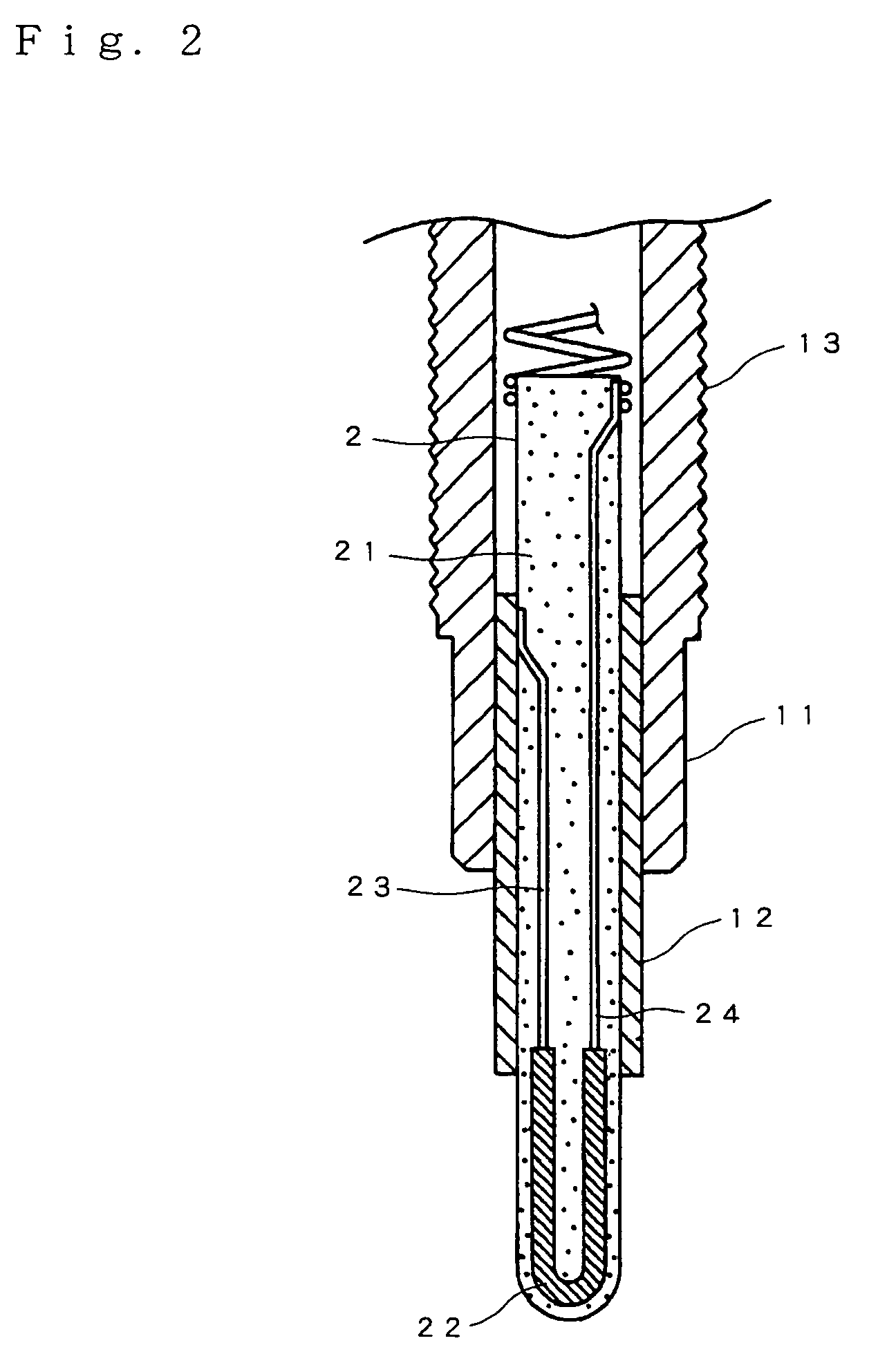

Ceramic heater and glow plug having the same

ActiveUS20050274707A1Voltage endurance can be enhancedSmall differenceIncandescent ignitionHeating element materialsRare-earth elementSilicon dioxide

The present invention relates to a ceramic heater which is capable of preventing an electric conduction defect of a heat-generating resistor from being caused by a supplied current, thus being excellent in voltage endurance, and a glow plug containing the ceramic heater. The ceramic heater 2 contained in the glow plug 1 has an insulative ceramic base material 21 and the heat-generating resistor 22 embedded in the insulative ceramic base material. The heat-generating resistor 22 has, as main components, an electrically conductive compound, silicon nitride and a grain boundary amorphous glass phase. The amount of the rare earth element contained in the heat-generating resistor is less than 2% by volume in terms of its oxide and, further, a molar ratio R=(A / A+B) of the mol number A of the amount of the rare earth element in terms of its oxide to a total of the mol number A and a mol number B, which is the amount of excess oxygen in terms of silicon dioxide, is 0.3 or less. By achieving such a constitution, the heat-generating resistor is capable of preventing electric conduction defects and of being excellent in voltage endurance.

Owner:NGK SPARK PLUG CO LTD

Aluminum member or aluminum alloy member with excellent corrosion resistance

InactiveUS20090233113A1Improve the immunityImprove adhesionAnodisationSemiconductor/solid-state device manufacturingHardnessCorrosion resistant

To provide an aluminum alloy or aluminum member having an anodic oxide coating formed thereon, the coating having excellent resistance to gaseous corrosion and resistance to plasma and excellent adhesion, and a member for a vacuum apparatus formed of such an aluminum alloy or aluminum member having excellent corrosion resistance. Moreover, a member having a sufficient voltage resistance is provided to stably keep a plasma state in a process using plasma.The object is substantialized by providing the following:(1) An aluminum alloy or aluminum member, wherein the anodic oxide coating has impedance of at least 107Ω at a frequency of 10−2 Hz, and hardness of at least 400 in Vickers hardness (Hv); or(2) An aluminum alloy or aluminum member, wherein the anodic oxide coating has impedance of at least 108Ω at a frequency of 10−2 Hz, and hardness of at least 350 in Vickers hardness (Hv).

Owner:KOBE STEEL LTD

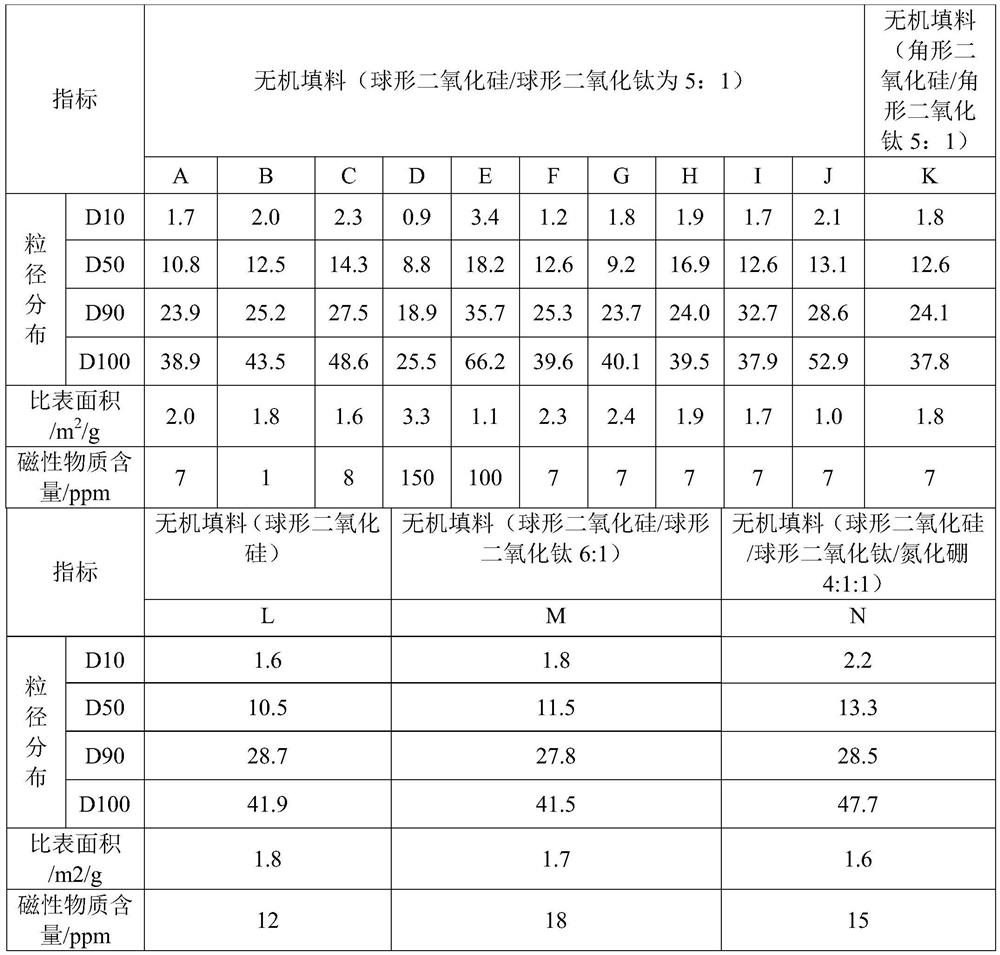

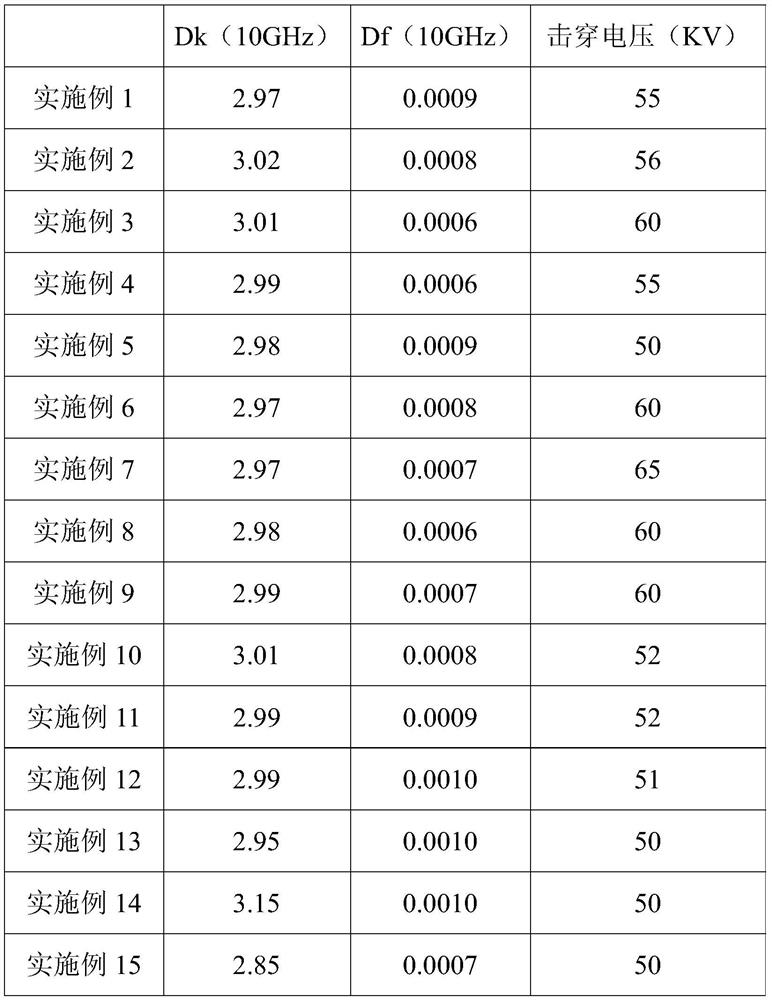

Fluorine-containing resin composition, resin glue solution containing fluorine-containing resin composition, fluorine-containing dielectric sheet, laminated board, copper-clad board and printed circuit board

ActiveCN112574521AExcellent dielectric propertiesGood voltage resistanceSynthetic resin layered productsPrinted circuit aspectsPolymer scienceFluoropolymer

The invention relates to a fluorine-containing resin composition, and a resin glue solution containing the fluorine-containing resin composition, a fluorine-containing dielectric sheet, a laminated board, a copper-clad board and a printed circuit board. The fluorine-containing resin composition comprises the following components: 30wt%-70wt% of a fluorine-containing polymer and 30wt%-70wt% of an inorganic filler; the inorganic filler comprises the following particle size distribution: D10 is greater than 1.5 microns, and D50 is 10-15 microns. By selecting the inorganic filler with specific particle size distribution, even if the addition amount of the inorganic filler is large, the plate prepared from the fluorine-containing resin composition has excellent dielectric property and voltage resistance.

Owner:GUANGDONG SHENGYI SCI TECH

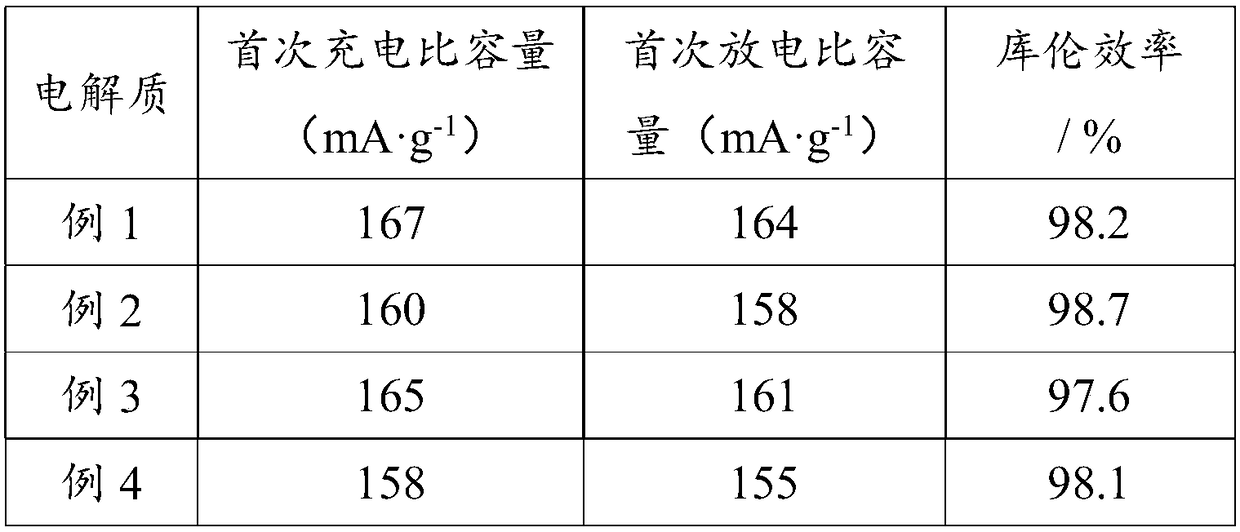

Composite, preparation method and application thereof in lithium battery electrolyte

InactiveCN109004278AHigh flash pointImprove securityFinal product manufactureElectrolyte accumulators manufactureOrganic solventEther

The invention belongs to the field of chemical power supplies, in particular to a composite, a preparation method and an application thereof in a lithium battery electrolyte. The invention provides acomposite, which includes an electrolyte lithium salt, an ether-based functionalized pyrrolidine ionic liquid and a non-aqueous organic solvent; the ether-based functionalized pyrrolidine ionic liquidis composed of cations and anions, and the cations are ether-based functionalized pyrrolidine cations. The invention also provides a preparation method of the composite and an application of the composite or a product obtained by the preparation method in a lithium battery electrolyte. In the invention, the composite is non-flammable and has high safety performance; at the same time, it is determined by experiments that the composite has good withstand voltage performance; and the composite solves the technical defects of poor withstand voltage performance, poor temperature tolerance, flammability and explosiveness of lithium ion batteries in the prior art.

Owner:GUANGDONG UNIV OF TECH

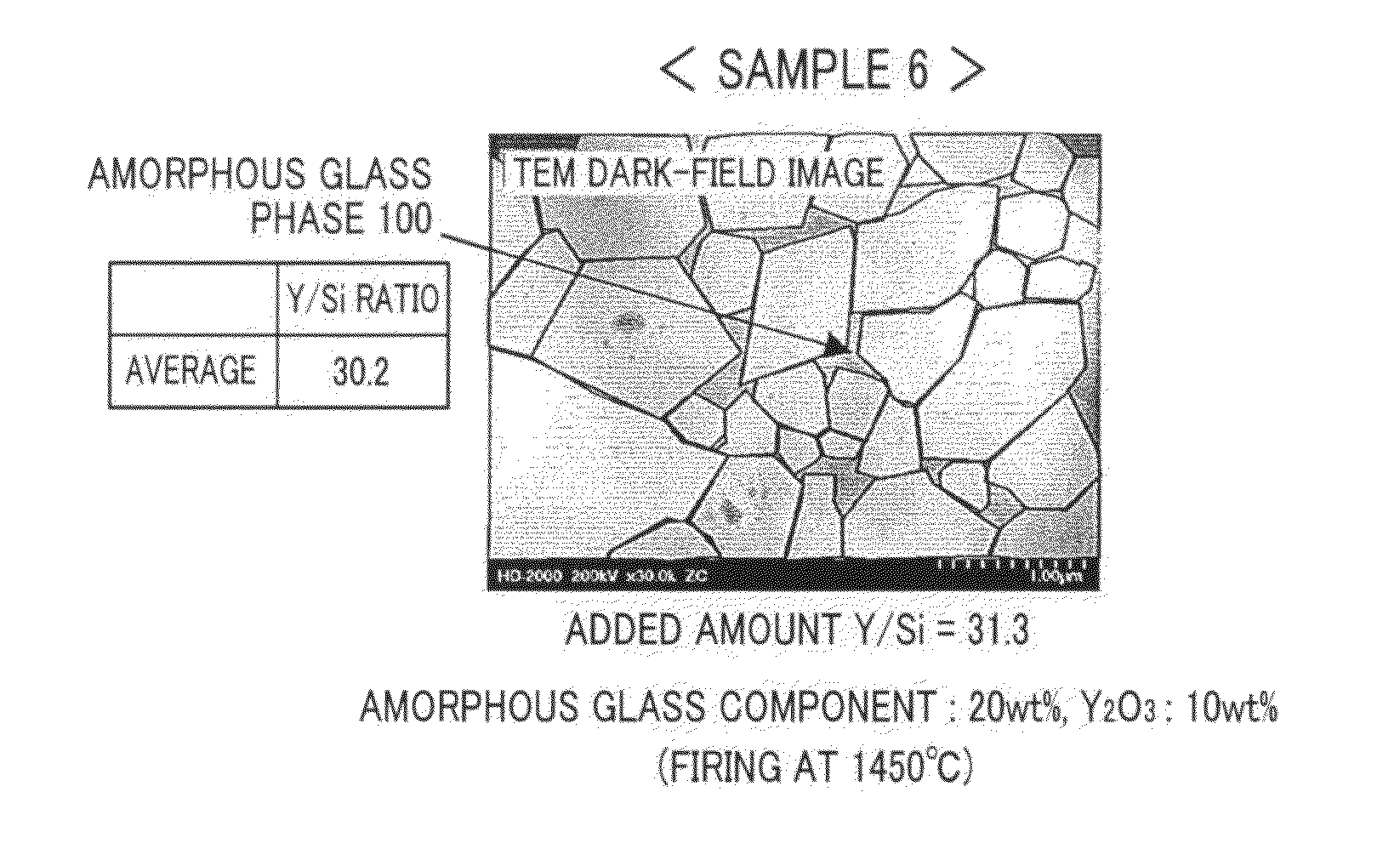

Ceramic heater and glow plug having the same

ActiveUS7282670B2Good voltage resistanceSmaller thermal expansion coefficientIncandescent ignitionHeating element materialsRare-earth elementExcess oxygen

The present invention relates to a ceramic heater which is capable of preventing an electric conduction defect of a heat-generating resistor from being caused by a supplied current, thus being excellent in voltage endurance, and a glow plug containing the ceramic heater. The ceramic heater 2 contained in the glow plug 1 has an insulative ceramic base material 21 and the heat-generating resistor 22 embedded in the insulative ceramic base material. The heat-generating resistor 22 has, as main components, an electrically conductive compound, silicon nitride and a grain boundary amorphous glass phase. The amount of the rare earth element contained in the heat-generating resistor is less than 2% by volume in terms of its oxide and, further, a molar ratio R=(A / A+B) of the mol number A of the amount of the rare earth element in terms of its oxide to a total of the mol number A and a mol number B, which is the amount of excess oxygen in terms of silicon dioxide, is 0.3 or less. By achieving such a constitution, the heat-generating resistor is capable of preventing electric conduction defects and of being excellent in voltage endurance.

Owner:NGK SPARK PLUG CO LTD

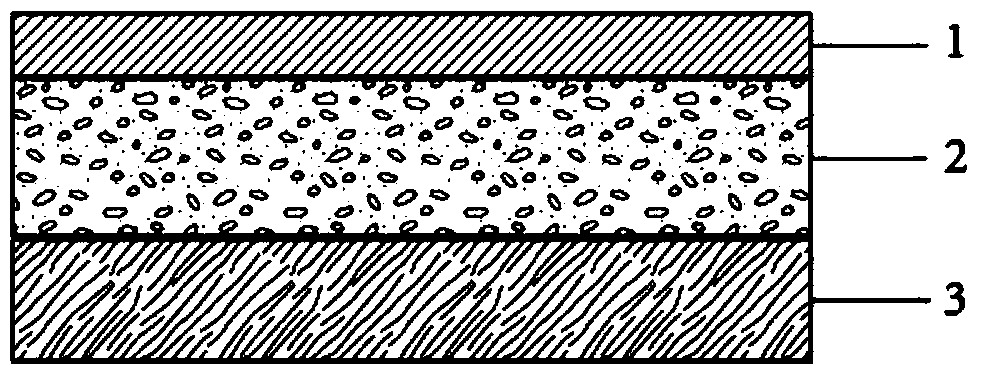

Heat dissipation circuit board and method for fabricating same

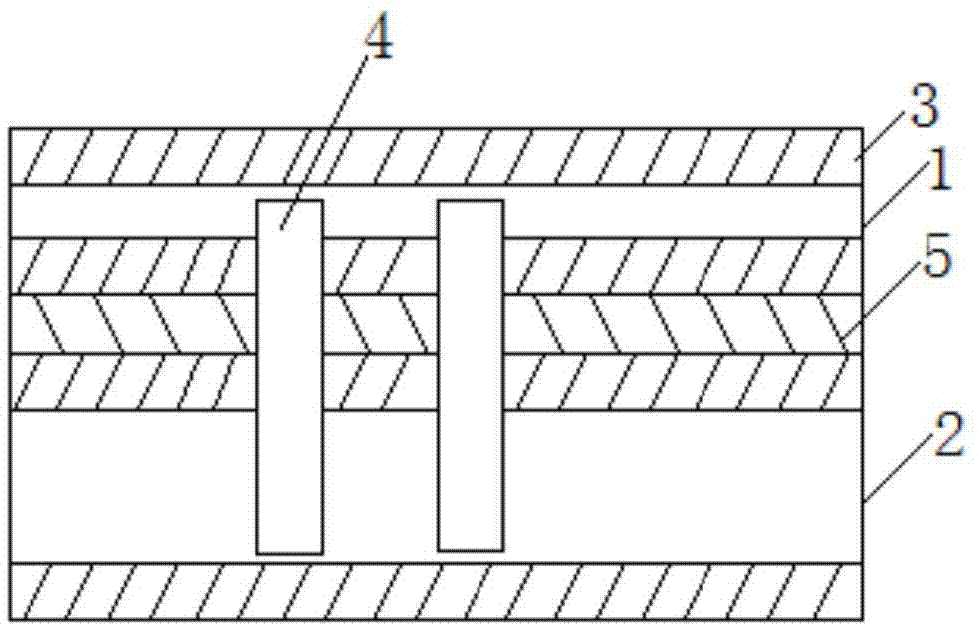

PendingCN107623986AExcellent voltage resistanceImprove thermal stabilityPrinted circuit detailsMultilayer circuit manufactureInsulation layerMetal

The invention provides a heat dissipation circuit board and a method for fabricating the same. In an embodiment, the heat dissipation circuit board comprises a substrate and a heat dissipation body, wherein the substrate is provided with a first metal layer and a second metal layer, the first metal layer is formed on an upper surface of the substrate, the second metal layer is formed on a lower surface of the substrate, the first metal layer forms a conductive pattern layer, the heat dissipation body is arranged in the substrate and penetrates through the substrate, the heat dissipation body comprises a metal body, a first heat conduction insulation layer, a third metal layer, a second heat conduction insulation layer and a fourth metal layer, the first heat conduction insulation layer isformed on the upper surface of the metal body, the third metal layer is formed on the first heat conduction insulation layer, the second heat conduction insulation layer is formed on a lower surface of the metal body, the fourth metal layer is formed on the second heat conduction insulation layer, outer surfaces of the first metal layer and the third metal layer are flush with each other, and outer surfaces of the second metal layer and the fourth metal layer are flush with each other. The heat dissipation circuit board has favorable voltage resistance and heat dissipation performance, and islow in cost and excellent in thermal reliability.

Owner:许明杰

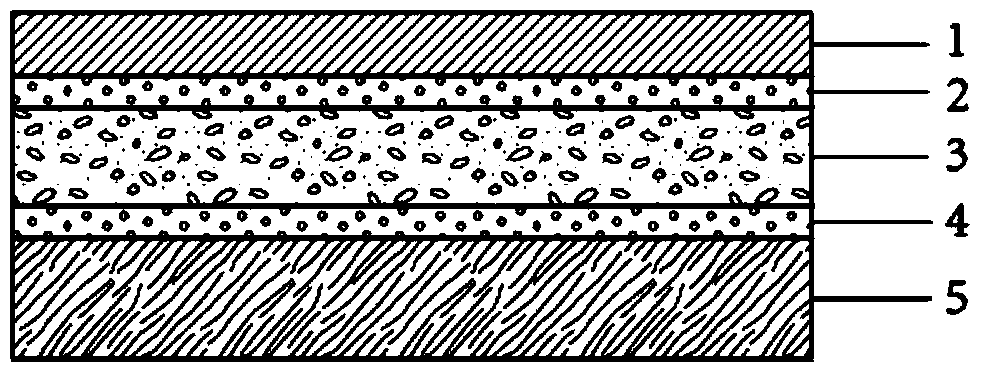

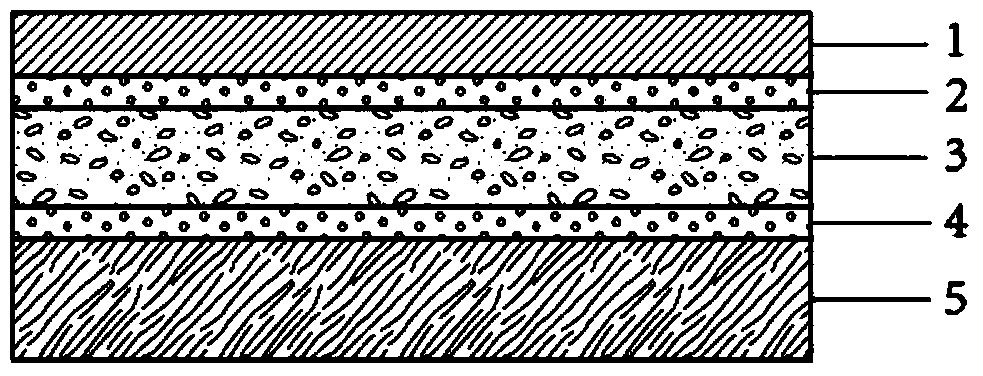

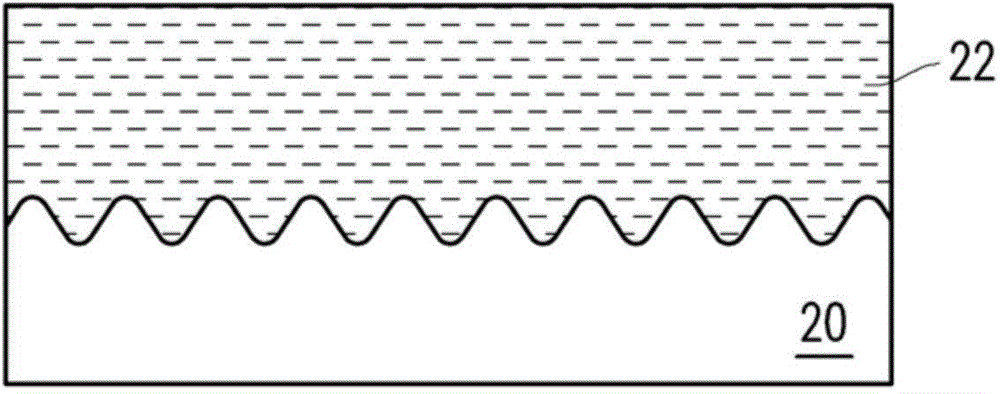

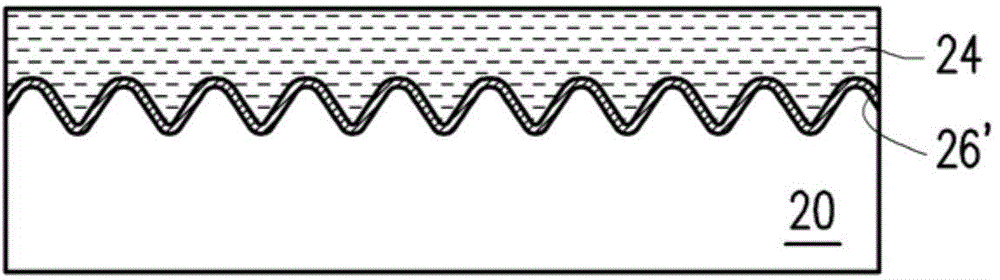

Highly thermal-conductive aluminum-based copper-clad plate

ActiveCN103722805AImprove liquidityFully contactedLaminationLamination apparatusCopper foilUltimate tensile strength

The invention relates to a highly thermal-conductive aluminum-based copper-clad plate. Three layers of glue are arranged between a copper foil and an aluminum plate, namely a copper foil, a first layer of glue, a second layer of glue, a third layer of glue and the aluminum plate are arranged, wherein the content of a filler in the second layer of glue is greater than that of a filler in the first layer of glue or the third layer of glue; the grain size of the filler in the second layer of glue is greater than that of the filler in the first layer of glue or the third layer of glue. The three layers of glue are skillfully combined together; the advantages of the three layers of glue are fully displayed; the aluminum-based copper-clad plate manufactured by using the method not only has ultrahigh thermal conductivity but also has high peeling strength and excellent thermal stress and voltage resistance.

Owner:GUANGDONG SHENGYI SCI TECH

Surface acoustic wave device

ActiveUS20130069481A1Good voltage resistanceImproving frequency-temperature characteristicPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic wavePiezoelectric substrate

A surface acoustic wave device includes a piezoelectric substrate including a groove located in a surface thereof, an IDT electrode, and a dielectric film. The IDT electrode includes a first electrode layer located in the groove and a second electrode layer located outside the groove. The dielectric film is arranged on the piezoelectric substrate so as to cover the IDT electrode. The second electrode layer is tapered toward a side opposite to the piezoelectric substrate.

Owner:MURATA MFG CO LTD

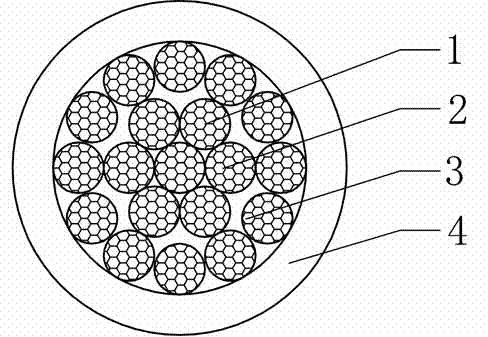

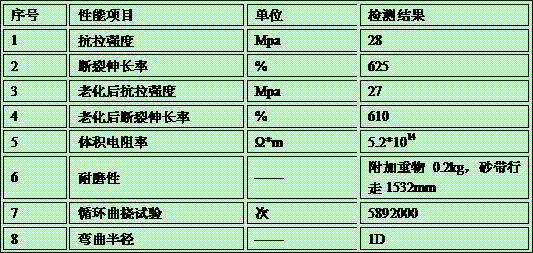

Preparation method of super-soft cable and external coating material of super-soft cable

ActiveCN104761909AWill not deformSmall bending radiusFlexible cablesCable/conductor manufactureYarnSesquioxide

The invention discloses a preparation method of a super-soft cable and an external coating material of the super-soft cable. The super-soft cable comprises a conductive core stranded by 7-61 groups of folded yarns and the external coating material of the conductive core, wherein each of the folded yarns is stranded by a plurality of tinned copper wires; the conductive core is coated with super-soft high-strength silicon rubber for insulation; the high-strength silicon rubber comprises the following components: methyl vinyl silicone rubber, precipitated white carbon, iron sesquioxide, chlorinated paraffin, magnesium hydrate, an anti-aging agent N-isopropyl benzene-N'-phenyl p-phenylenediamine, hydroxyl silicone oil, silicone oil containing hydrogen, dioctyl phthalate, a surfactant gamma-thiopropyl triethoxy silane, a silane coupling agent and a bis-2, 5 vulcanizing agent. The super-soft cable has the characteristics of bending resistance, corrosion resistance, wear resistance and the like, is relatively high in using temperature and relatively long in service life, and can be used for various types of equipment which is small in cable laying space and great in number of round trips.

Owner:西安飞机工业(集团)亨通航空电子有限公司

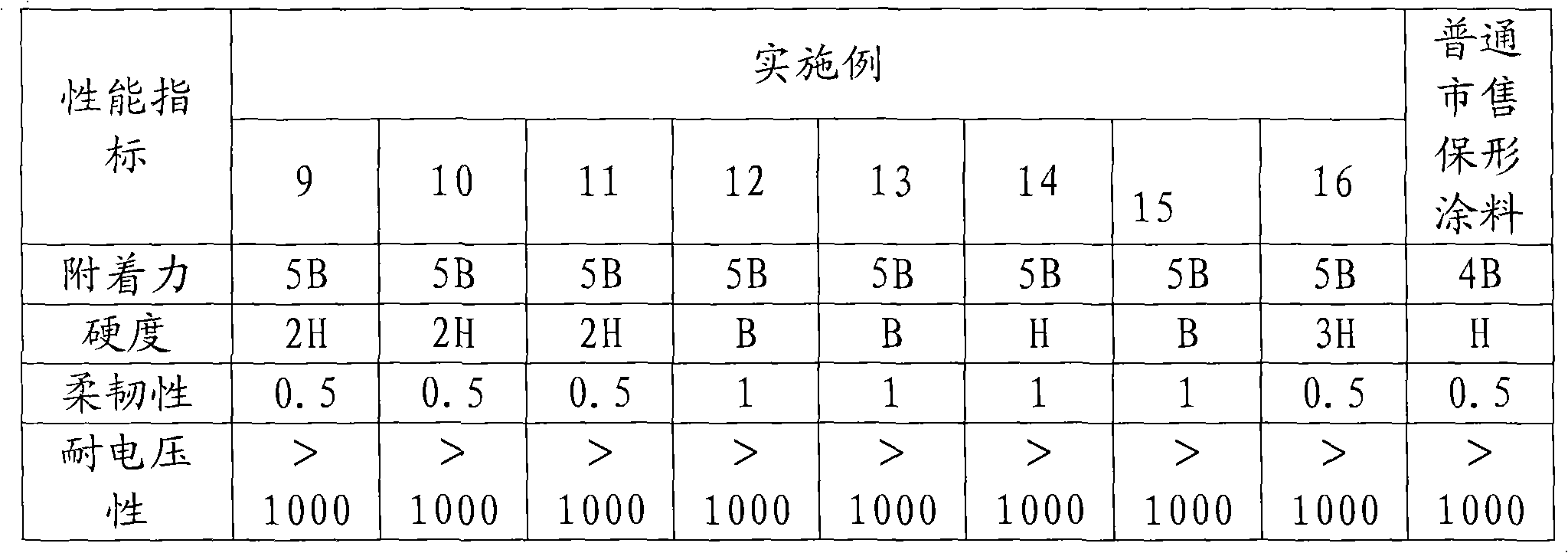

Flame retardant polyurethane resin and preparation method thereof and flame retardant polyurethane conformal coating

InactiveCN102040725ACuring Rate ControlRaw materials are easy to getPolyurea/polyurethane coatingsConformal coatingSolvent

The invention relates to flame retardant polyurethane resin and a preparation method thereof and flame retardant polyurethane conformal coating. The preparation method of the flame retardant polyurethane resin comprises alcoholization of grease and synthetization of the flame retardant polyurethane resin, and the flame retardant polyurethane resin is prepared by the method; and the flame retardant polyurethane conformal coating comprises the following ingredients in percentage by weight: 60-80wt% of flame retardant polyurethane resin, 15-35wt% of solvent; 0.01-2wt% of catalyst, 0-2wt% of leveling agent, 0-1.5wt% of defoaming agent, and 0-1wt% of fluorescent powder.

Owner:YANTAI DARBOND TECH

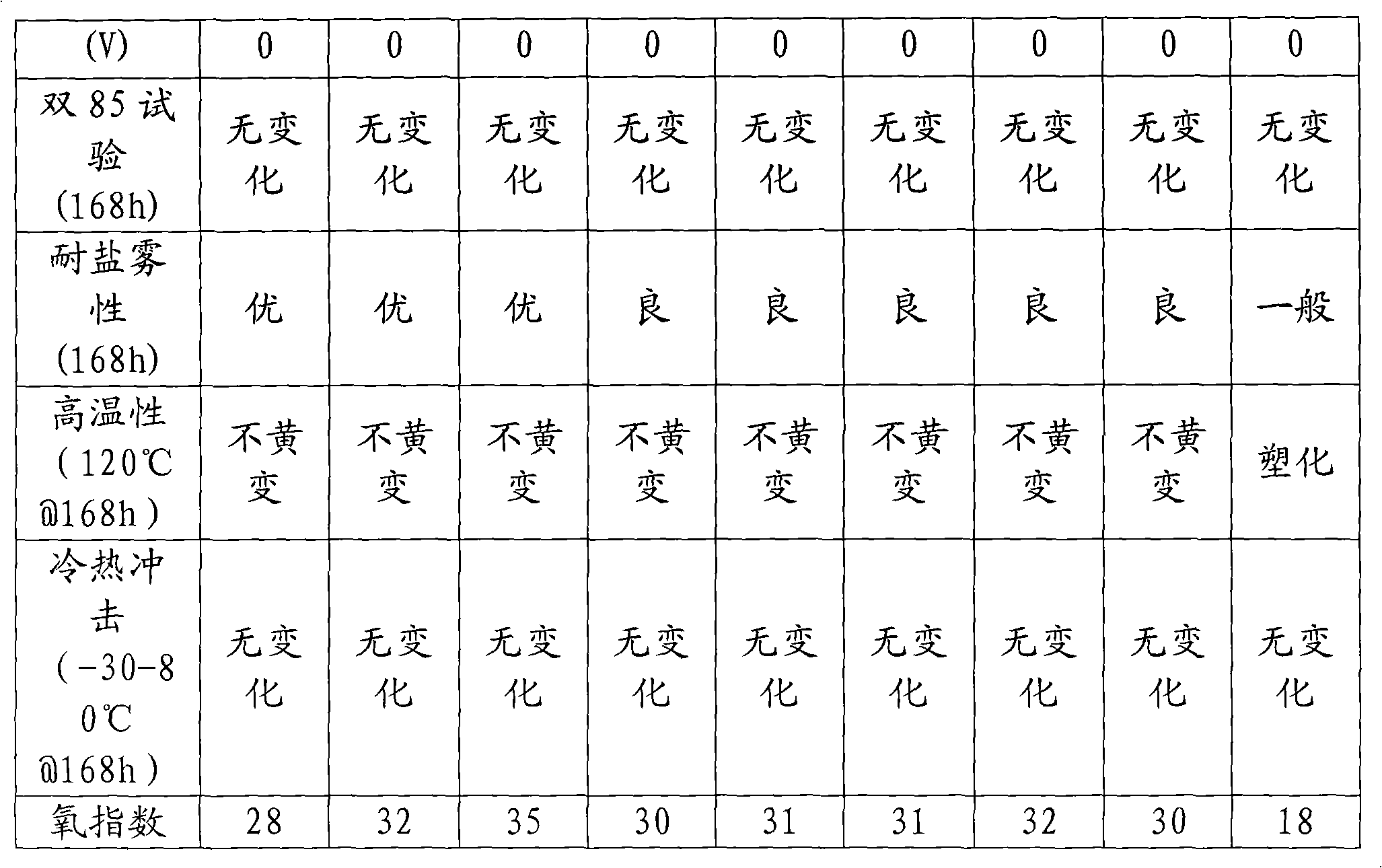

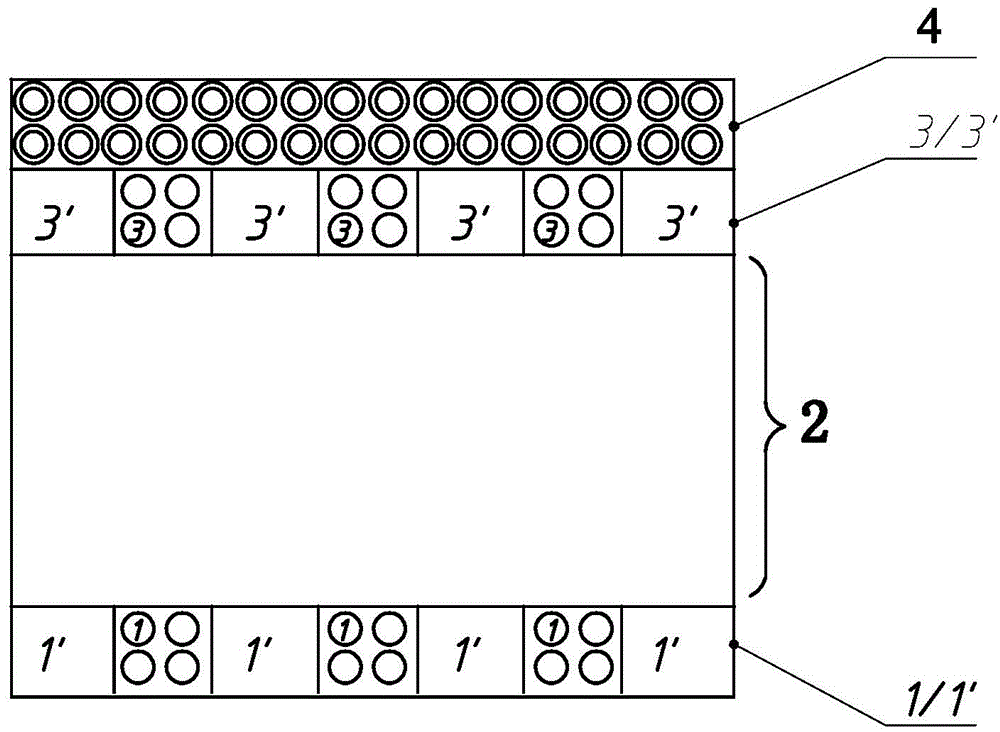

High-stable low-loss microwave diode of nanocrystalline embedded single crystal epitaxial silicon carbide

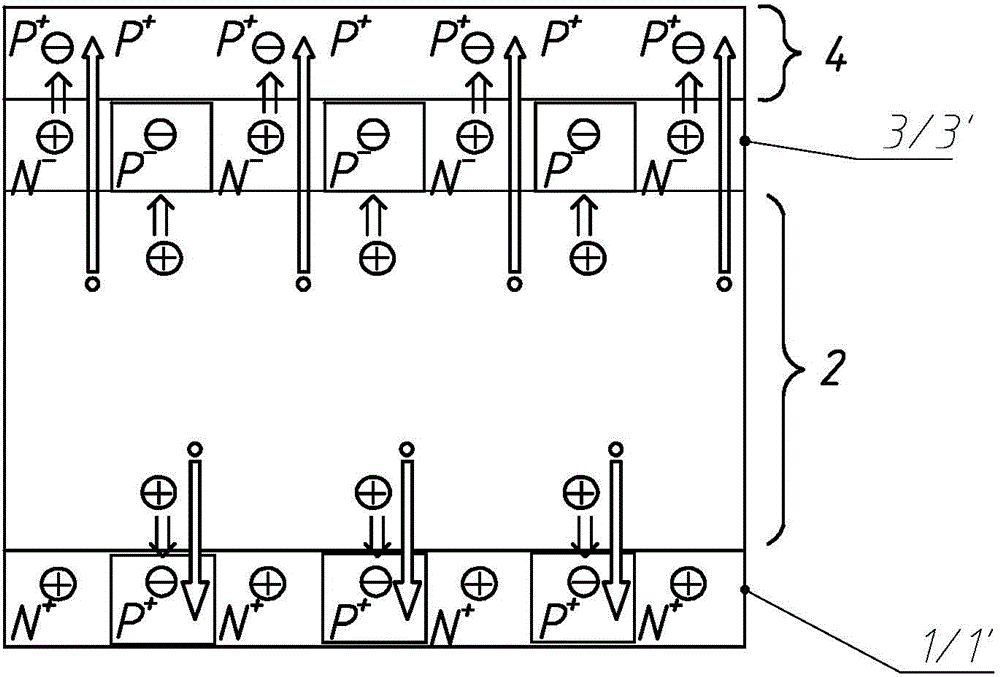

ActiveCN104701385AReduce the impactLinear relationship is stableSemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalReactive-ion etching

The invention discloses a high-stable low-loss microwave diode of nanocrystalline embedded single crystal epitaxial silicon carbide and a technique. The structure of the high-stable low-loss microwave diode is: (P+)4H-nc-SiC / [(P-)4H-nc-SiC / (N-)6H-c-SiC] / (N-)6H-c-SiC / [(P+)4H-nc-SiC / (N+)6H-c-SiC]; the high-stable low-loss microwave diode comprises a (P+)4H-nc-SiC / (N+)6H-nc-SiC composite cathode, a (N-)6H-c-SiC base zone, a (P-)4H-nc-SiC / (N-)6H-c-SiC composite transition layer, and a (P+)4H-nc-SiC anode. The high-stable low-loss microwave diode is researched by magnetic control sputtering, RIE (reactive ion etching) and PECVD (plasma enhanced chemical vapor deposition) technologies. The P / N border local area is used up, junction capacity in the appliance is reduced; the diode is applicable to the microwave frequency section; temperature stability and voltage withstanding ability are improved; the reverse process time is shortened and loss is reduced.

Owner:宁波致鼎新材料科技有限公司

Modified polytetrafluoroethylene wire enamel and preparation method thereof

The invention discloses modified polytetrafluoroethylene wire enamel which is characterized by being prepared from raw materials in parts by weight (kilogram) as follows: 13-17 parts of dimethylaminoethyl methacrylate, 5-8 parts of benzoyl peroxide, 1-2 parts of triethanolamine, 5-8 parts of ethanediol, 12-15 parts of nylon 12, 10-12 parts of neopentyl glycol, 1-2 parts of polytetrafluoroethylene, 5-7 parts of beryllium oxide, 1-2 parts of dibutyltin dilaurate, 2-4 parts of aluminum hydroxide, 12-14 parts of polypropylene random copolymers, 2-4 parts of nano pottery clay, 7-9 parts of an assistant, 100-120 parts of m, p-cresol and 70-80 parts of xylene. The modified polytetrafluoroethylene wire enamel has good adhesive force, high flexibility and excellent heat resistance, elasticity, toughness resistance, voltage resistance and solvent resistance.

Owner:铜陵天河特种电磁线有限公司

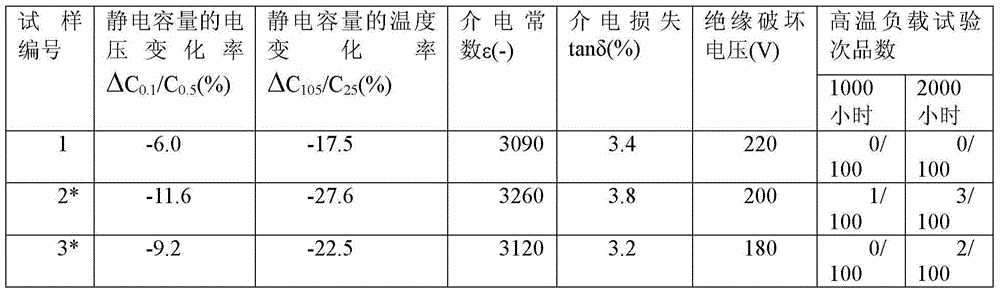

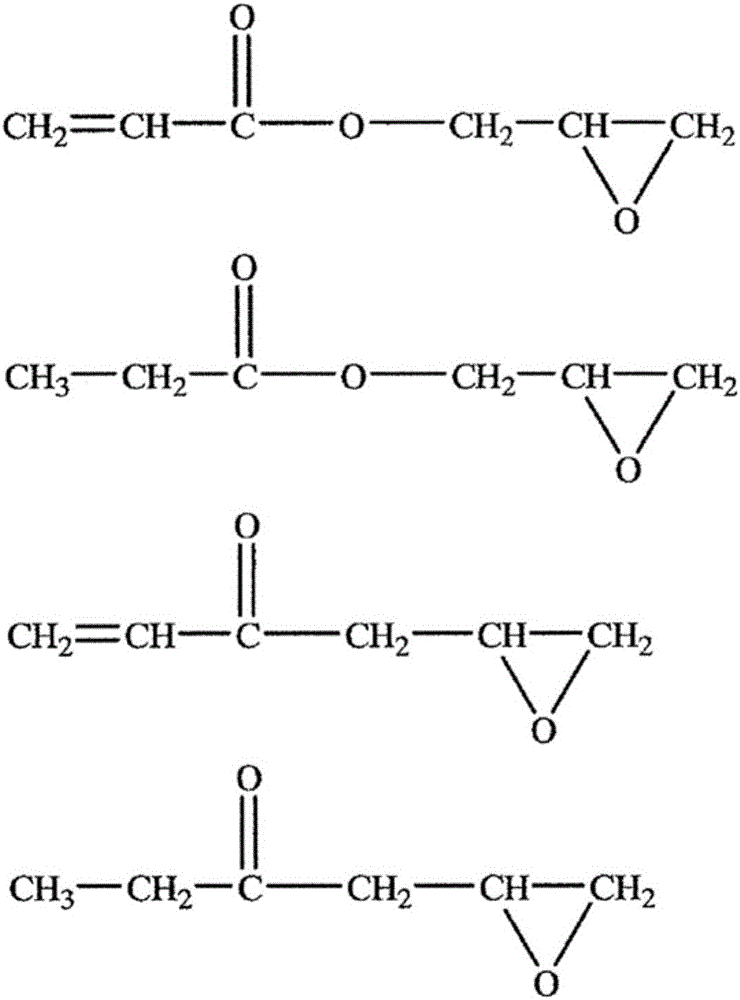

Composition and method for forming electroactive coating comprising conjugated heteroaromatic polymer, capacitor and antistatic object comprising the electroactive coating, and solid electrolytic capacitor and method for fabricating the same

ActiveCN105295008ALong application lifeReduce contentSolid electrolytic capacitorsElectrically-conductive paintsActive polymerLeaving group

A composition for forming an electroactive coating is described, including an acid as a polymerization catalyst, at least one functional component, and at least one compound of formula (1) as a monomer: wherein X is selected from S, O, Se, Te, PR2 and NR2, Y is hydrogen (H) or a precursor of a good leaving group Y- whose conjugate acid (HY) has a pKa of less than 30, Z is hydrogen (H), silyl, or a good leaving group whose conjugate acid (HY) has a pKa of less than 30, b is 0, 1 or 2, each R1 is a substituent, and the at least one compound of formula (1) includes at least one compound of formula (1) with Z=H and Y<>H.

Owner:POLYM TECH

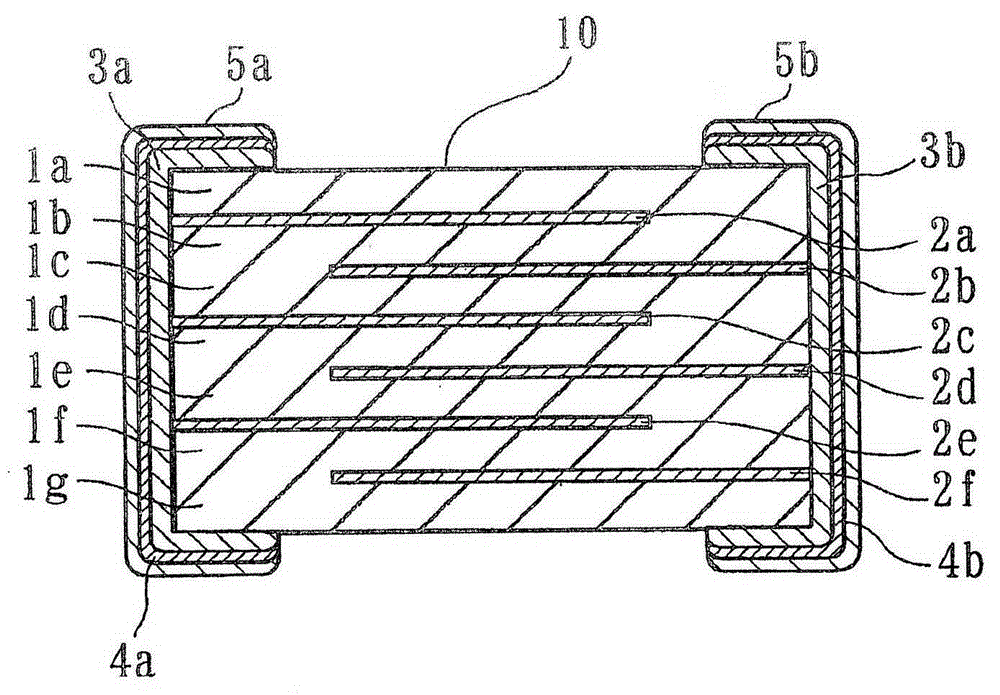

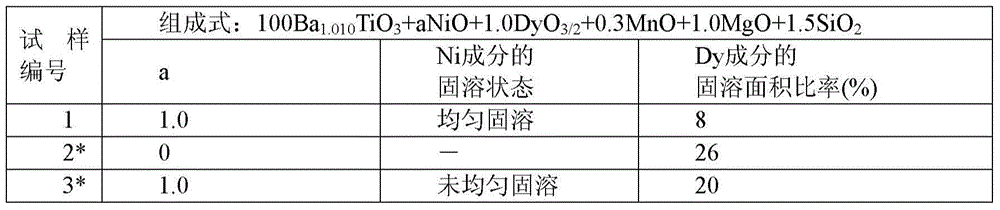

Dielectric ceramics, and laminated ceramic capacitor

InactiveCN105130422ASolid solution inhibitionImproved AC voltage characteristicsStacked capacitorsCeramicsRare-earth elementElectricity

A dielectric ceramic contains a BaTiO3-based compound as a main ingredient, and can be represented by the general formula: 100AmBO3+aNiO+bROn+cMOv+dMgO+eXOw where R represents a rare earth element such as Dy, M represents a metal element such as Mn, and X represents a sintering aid component containing Si. Ni is uniformly solid-solved in crystal grains, and the solid-solution region of the rare earth element in the crystal grains is an average 10% or less in terms of a cross section ratio. 0.96≰m≰1.030, 0.05≰a≰3, 0.1≰b≰1.5, 0.1≰c≰1.0, 0.1≰d≰1.5, and 0.05≰e≰3.5 are satisfied. A laminated ceramic capacitor has dielectric layers formed of the dielectric ceramic. As a result, a dielectric ceramic, and a laminated ceramic capacitor having excellent AC voltage characteristics, capable of keeping desired dielectric characteristics and excellent temperature characteristics, and having excellent withstand voltage and capable of ensuring reliability can be realized.

Owner:MURATA MFG CO LTD

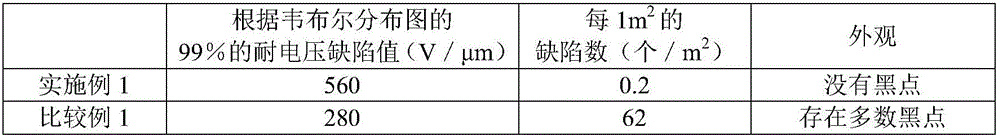

Film and method for producing same

ActiveCN105683265AImprove insulation performanceGood voltage resistanceThin/thick film capacitorFixed capacitor dielectricPolymerVoltage

The primary problem addressed by the present invention is to provide a film exhibiting high electrical insulation properties and exhibiting superior voltage resistance, and a method for producing the film. As a means of solving the problem, the present invention provides a fluorinated vinylidene polymer film of which the 99% voltage failure resistance value in a Weibull plot is at least 300 V / mum.

Owner:DAIKIN IND LTD

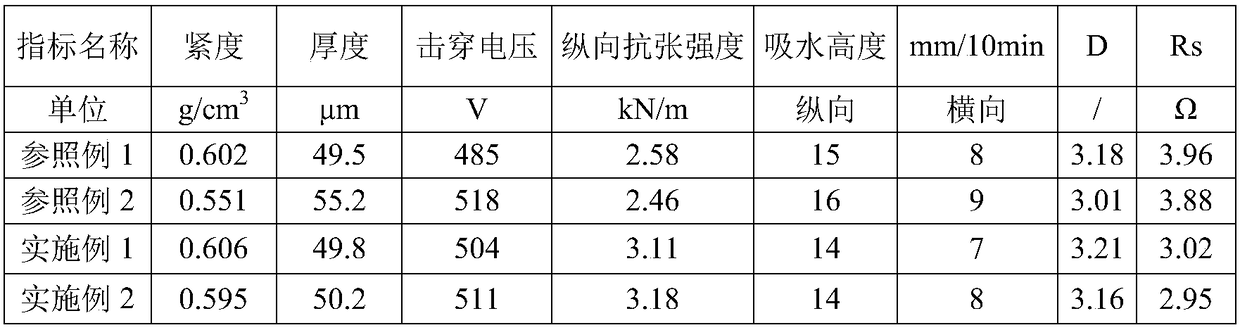

Low-tightness high-strength electrolytic capacitor paper and preparation method therefor

InactiveCN108203893ALow tightnessLow tightness high tightnessHybrid capacitor separatorsPlastic/resin/waxes insulatorsElectrolysisCylinder mold

The invention relates to electrolytic capacitor paper and a preparation method therefor. According to the low-tightness high-strength electrolytic capacitor paper, raw paper pulp of the electrolytic capacitor paper is made from hemp pulp, wherein the hemp pulp has the mass concentration of 2% to 5%, the degree of beating of 30 degree SR to 60 degree SR and the wet weight of 2g to 16g; and the rawpaper pulp is subjected to molding and laminating through double cylinder molds and is subjected to squeezing and drying, then, the surface of paper is coated with coating liquid by an amount of coating of 0.1g / m<2> to 1.0g / m<2>, and the coating liquid is prepared from polycarboxylic acid and PVA which are in the mass ratio of (1: 1) to (1: 5). According to the low-tightness high-strength electrolytic capacitor paper and the preparation method therefor, the low-tightness high-strength electrolytic capacitor paper is obtained through raw paper production and in-line coating and has relatively good strength, good water absorbency, a good loss value and excellent voltage resistance, and the tensile strength is improved by 0.4kN / m or more.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +1

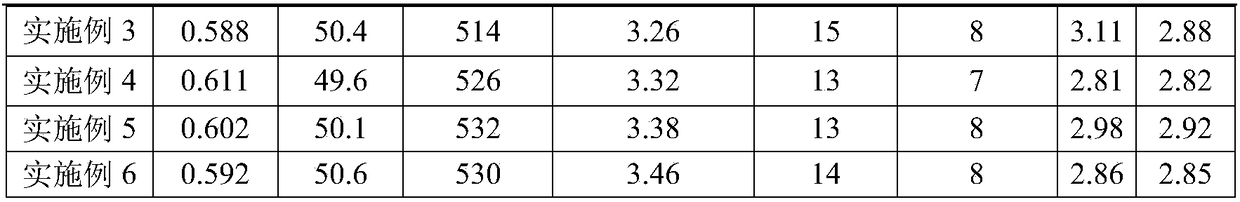

Enhanced electrolytic condenser paper and preparation method thereof

InactiveCN108179652ALow tightnessLow tightness high strengthSpecial paperPaper/cardboardElectrolysisSlurry

The invention relates to enhanced electrolytic condenser paper and a preparation method thereof. The base paper slurry of the enhanced electrolytic condenser paper is prepared from low beating degreesisal hemp pulp and high beating degree sisal hemp pulp, and the mass ratio of the low beating degree sisal hemp pulp to the high beating degree sisal hemp pulp is (20-40):(80-60); the beating degreeof the low beating degree sisal hemp pulp is 20-60 degrees SR, the wet weight is 2-16 g, the beating degree of the high beating degree sisal hemp pulp is 60-98 degrees SR, and the wet weight is 2-10 g; the base paper slurry is formed through twin cylinders and composited, after squeezing and drying are conducted, the surface of a paper sheet is coated with coating fluid, the coating weight is 0.1-1.0 g / m<2>, and the coating fluid is a polycarboxylic acid wet strength agent. The electrolytic condenser paper has the good water absorbing property, low loss value, excellent voltage resistance andexcellent mechanical property, and the tensile strength is increased by 0.5 kN / m or above.

Owner:ZHEJIANG KAN SPECIAL PAPER CO LTD +1

Manufacturing method for circuit board with embedded magnetic core

InactiveCN105451465AImproving the situation vulnerable to frackingImprove production yieldPrinted circuit assemblingPrinted circuit aspectsCoated surfaceControl manner

The invention discloses a manufacturing method for a circuit board with an embedded magnetic core. The manufacturing method comprises the following steps: S1, performing a front process, and cutting a copper-coated core plate and a prepreg; S2, etching a copper foil, wherein the copper foil, close to the inner side of the circuit board, of the copper-coated core plate where the magnetic core is positioned is etched off; S3, milling a magnetic core slot in the copper-coated core plate in a depth-control manner, wherein the section of the magnetic core slot adopts a circular ring shape; S4, windowing the prepreg; S5, laminating; and S6, performing a back process. The laminating structure is adjusted; the magnetic core slot is milled from the copper-coated surface to the etching surface in the step of milling the magnetic core slot in the copper-coated core plate in a depth-control manner, so that the depth of the slot is accurate, and the condition that the magnetic core is fractured easily is reduced; and meanwhile, the inner circle diameter of the section circular ring of the magnetic core slot is less than the inner diameter of the magnetic core while the outer circle diameter of the section circular ring of the magnetic core slot is larger than the outer diameter of the magnetic core, so that a movable space is reserved for the magnetic core, and the limitation causing the condition that magnetic core is fractured easily is further reduced.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Dry-type transformer and reactor casting process

InactiveCN102623163AGood voltage resistanceEasy to wrapInductances/transformers/magnets manufactureEpoxyPositive pressure

The invention relates to the manufacture of both a transformer and a reactor, in particular to a dry-type transformer and reactor casting process. The casting process comprises the steps of fixing, curing, casting, pressurizing, heating and testing, and products successfully passing the test are accepted products. The invention has the characteristics that firstly, as epoxy resin is cured in the positive pressure state, that the epoxy resin can wrap the products according to the design requirements is effectively ensured, the voltage resisting strength of the products is improved, meanwhile, the partial discharge of the products is remarkably reduced, and the appearances of the products are improved; secondly, as the epoxy resin is cured in constant-temperature state, setting can be performed according to the optimal curing temperature of the adopted epoxy resin, on one hand, the wrapping performance of the epoxy resin to the products is improved, on the other hand, the curing time is effectively shortened, and the qualification rate and the production efficiency of the products are greatly improved.

Owner:NINGXIA YINLI ELECTRICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com