Film and method for producing same

A manufacturing method and polymer film technology, which can be used in the manufacture/assembly of flat products, piezoelectric/electrostrictive devices, and other household appliances, can solve the problems of reduced electrical insulation and reduced voltage resistance, and achieve excellent The effect of voltage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0125] Process A (preparation process of liquid composition)

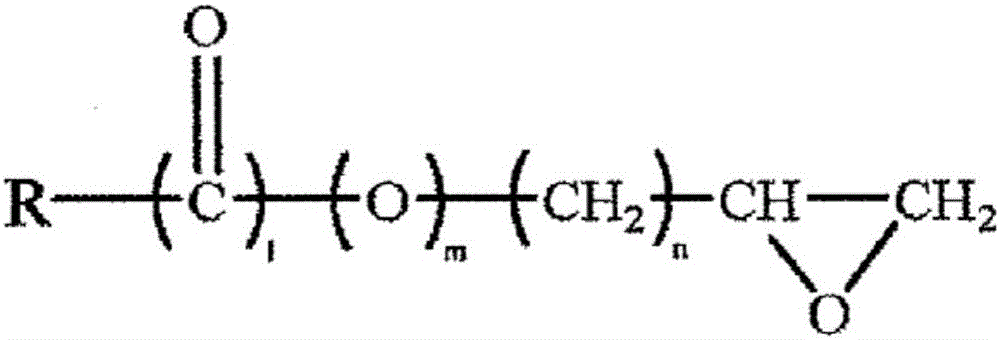

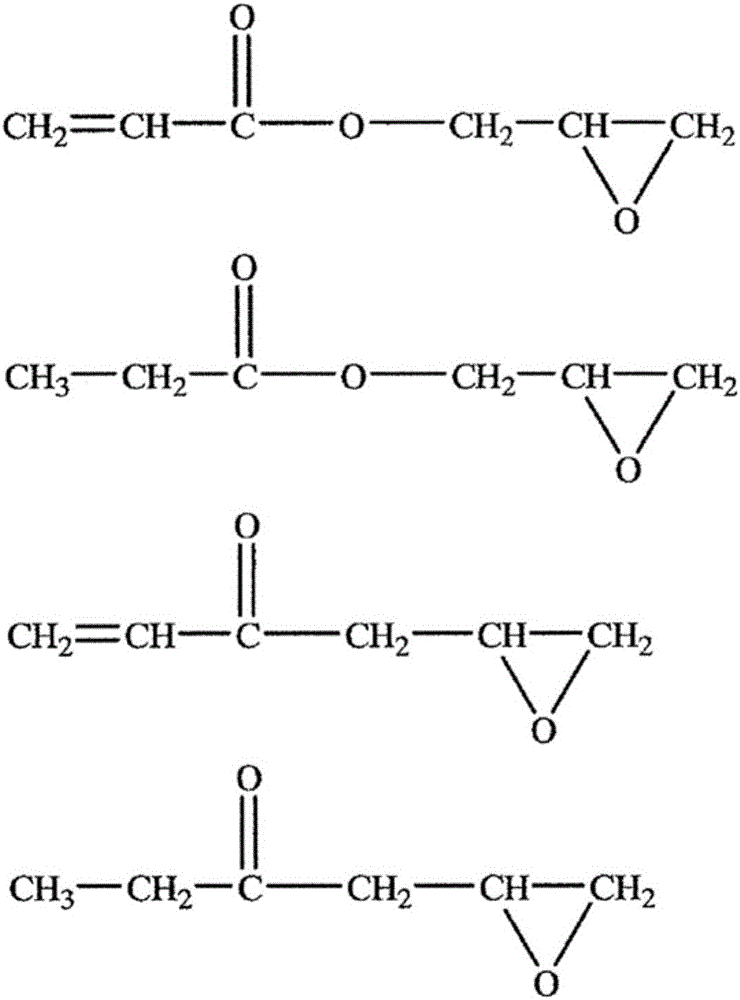

[0126] In step A, a liquid composition (paint) containing a vinylidene fluoride polymer and a solvent is prepared. For example, a vinylidene fluoride polymer and desired components (for example, polymers other than the above polymers, inorganic oxide particles, and affinity enhancer) are dissolved or dispersed in a solvent to prepare a liquid composition.

[0127] The dissolution temperature at the time of preparation of the liquid composition is not particularly limited, but it is preferable to increase the dissolution temperature because dissolution can be accelerated. However, if the dissolution temperature is too high, the obtained film tends to be colored, so the dissolution temperature is preferably room temperature or higher and 80° C. or lower.

[0128] In addition, in the sense of preventing such coloring, preferable examples of the above-mentioned solvents include ketone-based solvents (for example, me...

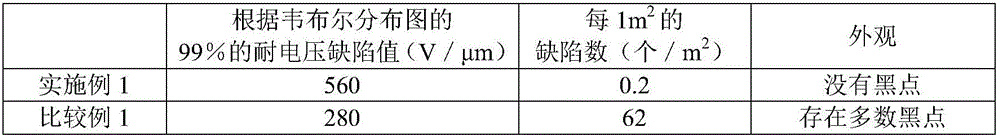

Embodiment 1

[0228] Example 1 (Example as Piezoelectric Film)

[0229] (1) Dissolve vinylidene fluoride / tetrafluoroethylene copolymer (TFE / VDF=20 / 80) in methyl ethyl ketone (MEK) to prepare a coating with a solid content of 25 wt%, and then use the coating with a pore size of 3 μm A deep pleated filter (ROKITECHNO Co., Ltd. DIAII series) was used to obtain a filtrate.

[0230] (2) Next, apply the above-mentioned filtrate on the PET film with a die coater, and further dry it, so that a vinylidene fluoride / tetrafluoroethylene copolymer film (film thickness of the copolymer film: 25 μm) is produced on the PET film. ). At this time, the above-mentioned drying is carried out as follows: in a drying oven with the drying temperatures of 4 zones (2m per zone) set to 50°C / 80°C / 120°C / 150°C, respectively, at a peripheral speed of 8m / min conduct.

[0231] (3) Next, the above-mentioned copolymer film is peeled off from the PET film, and the above-mentioned copolymer film is sandwiched from the upp...

Embodiment 2

[0255] Example 2 (Example as film for film capacitor)

[0256] (1) 90 parts by mass of a vinylidene fluoride / tetrafluoroethylene copolymer (TFE / VDF=7 / 93) and 10 parts by mass of carboxybutyl cellulose were mixed.

[0257] (2) Next, with respect to a mixed solvent of N-methylpyrrolidone (NMP) and methyl ethyl ketone (MEK) (NMP:MEK=3:7 (mass ratio)), the solid content is 20 wt%. The above-mentioned copolymer and carboxybutyl cellulose were dissolved, thereby preparing a dope.

[0258] (3) Next, the above-mentioned paint was filtered with a deep pleated filter (ROKITECHNO Co., Ltd. DIAII series) with a pore diameter of 3 μm to obtain a filtrate.

[0259] (4) Next, apply the above-mentioned filtrate on the PET film with a die coater, and further dry it, thereby producing a film capacitor film (film film) containing a vinylidene fluoride / tetrafluoroethylene copolymer on the PET film. Thickness: 3 μm). At this time, the above-mentioned drying is carried out at a peripheral spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com