Flame-retardant encapsulating material and preparation method thereof

A potting material and flame-retardant technology, which is applied in the field of flame-retardant potting materials and its preparation, can solve the problems of poor fire-proof and flame-retardant properties and low flame-retardant levels, and achieve moisture-heat and atmospheric aging resistance and good dust-proof performance , good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

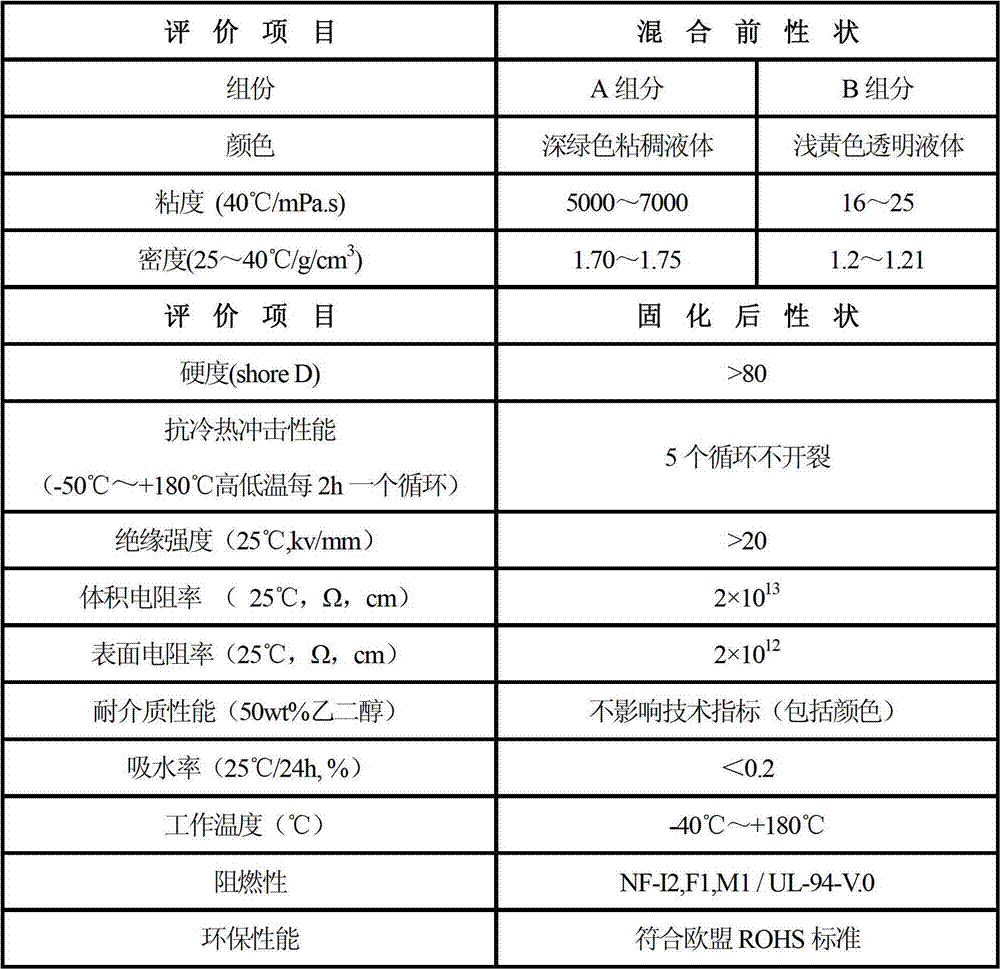

Image

Examples

Embodiment 1

[0047] In this embodiment, the flame retardant potting material includes A component and B component, wherein:

[0048] In terms of weight percentage, component A includes: base material bisphenol A epoxy resin 33%; thinner diethylene glycol dibenzoate 2.5%; toughening agent dioctyl phthalate 2%; pigment 1.9% % (carbon black 0.2%, medium chrome yellow 1.0%, phthalocyanine green 0.7%); organic silicon defoamer (KS-603) 0.1%; filler silicon powder 25%; flame retardant filler aluminum hydroxide weight accounted for 28%; liquid The flame retardant tris(chloroisopropyl) phosphate (TCPP) accounted for 7.5% by weight.

[0049] In terms of weight percentage, component B includes: curing agent methyltetrahydrophthalic anhydride 84%; curing agent tungalic anhydride 13%; accelerator 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30 ) 3%.

[0050] The weight ratio of A component and B component is 100:30.

[0051]The preparation method of the flame-retardant potting material comprises the ...

Embodiment 2

[0066] In this embodiment, the flame retardant potting material includes A component and B component, wherein:

[0067] In terms of weight percentage, component A includes: base material bisphenol A type epoxy resin 25%; thinner diethylene glycol dibenzoate 4%; toughening agent dioctyl phthalate 4%; pigment 3 % (carbon black 0.5%, medium chrome yellow 2%, phthalocyanine green 0.5%); organic silicon defoamer (KS-603) 0.15%; filler silicon powder 28%; flame retardant filler aluminum hydroxide weight accounted for 25.85%; liquid Flame retardant tris(chloroisopropyl) phosphate (TCPP) accounts for 10% by weight;

[0068] In terms of weight percentage, component B includes: curing agent methyltetrahydrophthalic anhydride 90%; curing agent tungalic anhydride 9%; accelerator 2,4,6-tris(dimethylaminomethyl)phenol )1%;

[0069] The weight ratio of A component and B component is 100:29.

[0070] The preparation method of the flame-retardant potting material comprises the following ste...

Embodiment 3

[0085] In this embodiment, the flame retardant potting material includes A component and B component, wherein:

[0086] In terms of weight percentage, component A includes: base material bisphenol A epoxy resin 35%; thinner diethylene glycol dibenzoate 1.5%; toughening agent dioctyl phthalate 1.5%; pigment 1.5% % (carbon black 0.1%, medium chrome yellow 1.0%, phthalocyanine green 0.4%); silicone defoamer (KS-603) 0.05%; filler silicon powder 24.95%; flame retardant filler aluminum hydroxide weight 30%; liquid Flame retardant tris(chloroisopropyl) phosphate (TCPP) accounts for 5.5% by weight;

[0087] In terms of weight percentage, component B includes: curing agent methyltetrahydrophthalic anhydride 80%; curing agent tungalic anhydride 15%; accelerator 2,4,6-tris(dimethylaminomethyl)phenol (DMP-30 ) 5%;

[0088] The weight ratio of A component and B component is 100:32.

[0089] The preparation method of the flame-retardant potting material comprises the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com