Patents

Literature

263 results about "Diethylene glycol dibenzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethylene glycol dibenzoate, a glycol benzoate ester, is a clear liquid with chemically stable properties and high boiling point. It is slightly soluble in water and very soluble in polymers. It is used as a has an excellent compatibility with polyvinyl acetates and polyvinyl chloride.

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Environmental-friendly white emulsion

InactiveCN103725229AOptimal temperature timeImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDioxyethylene EtherBenzioc acid

The invention discloses an environmental-friendly white emulsion. The environmental-friendly white emulsion is prepared from the components in percentage by weight: 1.8-2.5 percent of polyvinyl alcohol PVA, 23-27 percent of vinyl acetate VAC, 0.3-0.8 percent of acrylic acid AA, 0.8-1.5 percent of acryl amide AM, 0.1-0.15 percent of ammonium persulfate, an anionic emulsifier A-102, alkyl polyoxyethylene ether LCN-287, a nonionic emulsifier, 5-7 percent of corn starch, a transparent powder, a plasticizer, 2.5-4 percent of diethylene glycol dibenzoate, 0.2-0.3 percent of preservative KSG-201, 0.1-0.2 percent of sodium hydroxide NaOH, 0.3-0.5 percent of methanol, 3-6 percent of functional filler, 0.15-0.3 percent of compound emulsifier and 56-58 percent of water. The environmental-friendly white emulsion is strong in the adhesive force and the adhesive strength, is low in the production cost and is good in the environmental protection performance.

Owner:GUANGZHOU YIJIANG CHEM CO LTD

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

Owner:EASTMAN SPECIALITIES HLDG CORP

Liquid benzoate ester compositions and aqueous polymer compositions containing same as plasticizers

InactiveUS20030050372A1Antifouling/underwater paintsOther chemical processesPolymer scienceDiethylene glycol

The addition of at least about 30 weight percent of diethylene glycol (DEG) monobenzoate or dipropylene glycol (DPG) monobenzoate to diethylene glycol (DEG) dibenzoate, which is a solid at 28° C., results in a mixture that is unexpectedly a liquid at this temperature. The resultant mixtures are effective plasticizers for aqueous polymer compositions, including adhesives and caulks.

Owner:EASTMAN SPECIALITIES HLDG CORP

Environment-friendly composite plasticizer and preparation method

The invention discloses a plasticizer and a preparation method, in particular an environment-friendly composite plasticizer which is based on a diethylene glycol dibenzoate type plasticizer and di(2-ethylhexyl) terephthalate and can comprise epoxy compounds, adipate compounds, dicaprate compounds and trimellitate compounds. The environment-friendly composite plasticizer can be used as a main plasticizer of polyvinyl chloride resin and other resins. The invention also relates to a preparation method of the environment-friendly composite plasticizer and ingredients thereof, namely the diethylene glycol dibenzoate type plasticizer and the di(2-ethylhexyl) terephthalate. The environment-friendly composite plasticizer has the characteristics of high intermiscibility, plasticizing efficiency, cold resistance, heat resistance, pollution resistance, extraction resistance, migration, electric insulation, light and heat stability and the like, and is widely applied in plasticizing industry.

Owner:浙江嘉澳环保科技股份有限公司

Montmorillonite/isotactic polypropylene/polylactic acid composite sound absorbing cotton and preparation method thereof

InactiveCN103696127ASimple production processRaw materials are cheap and easy to getSynthetic resin layered productsNon-woven fabricsAdditive ingredientPolypropylene

The invention discloses montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton, which consists of a top surface layer, a back surface layer and a fiber cotton layer, wherein the fiber cotton layer is clamped and arranged between the top surface layer and the back surface layer, and the top surface layer and the back surface layer are made of non-woven fabric materials. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton is characterized in that the non-woven fabric is prepared form the following ingredients in parts by weight by a melt blowing method: 100 parts of isotactic polypropylene, 10 to 12 parts of polylactic acid, 10 to 12 parts of montmorillonite powder, 5 to 7 parts of dilauryl thiodipropionate, 2 to 3 parts of zinc oxide, 12 to 15 parts of diethylene glycol dibenzoate, 4 to 6 parts of triethyl citrate, 2 to 3 parts of zinc chloride, 5 to 7 parts of chitosan, 2 to 3 parts of molecular sieves, 12 to 15 parts of yellow cinnamon leaf, 2 to 3 parts of rhizoma gastrodiae, 2 to 3 parts of mint, 2 to 3 parts of radix angelicae pubescentis and 4 to 5 parts of auxiliary agents. The montmorillonite / isotactic polypropylene / polylactic acid composite sound absorbing cotton has the advantages that the montmorillonite, the isotactic polypropylene and the polylactic acid are compounded for preparing the sound absorbing cotton by the melt blowing method, the production process is simple, the raw materials are easy to obtain, the cost is low, and the prepared product has the advantages that the air permeability and the oxygen permeability are good, the tensile strength and the extension degree are high, the sound absorbing effect is obvious, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

PVC gloves production method using non-o-benzene plasticiser

The invention provides a PVC glove production method by using a non-o-benzene plasticizer. The method is mainly used on the improvement of the materials that are used. The materials that are used are as follows: 100 portions of PVC powder, 20 to 40 portions of dipropylene glycol dibenzoate, 10 to 15 portions of epoxidized soybean oil, 10 to 35 portions of diethylene glycol dibenzoate, 5 to 20 portions of C8-C12 higher fatty alcohol benzoic ether, 1.5 to 3 portions of calcium-zinc stabilizer as well as 20 to 35 portions of viscosity reducer. The PVC gloves produced by the PVC glove production method by using a non-o-benzene plasticizer provided by the invention has the advantages of no poison, environment protection, better quality and lower cost.

Owner:郑建明

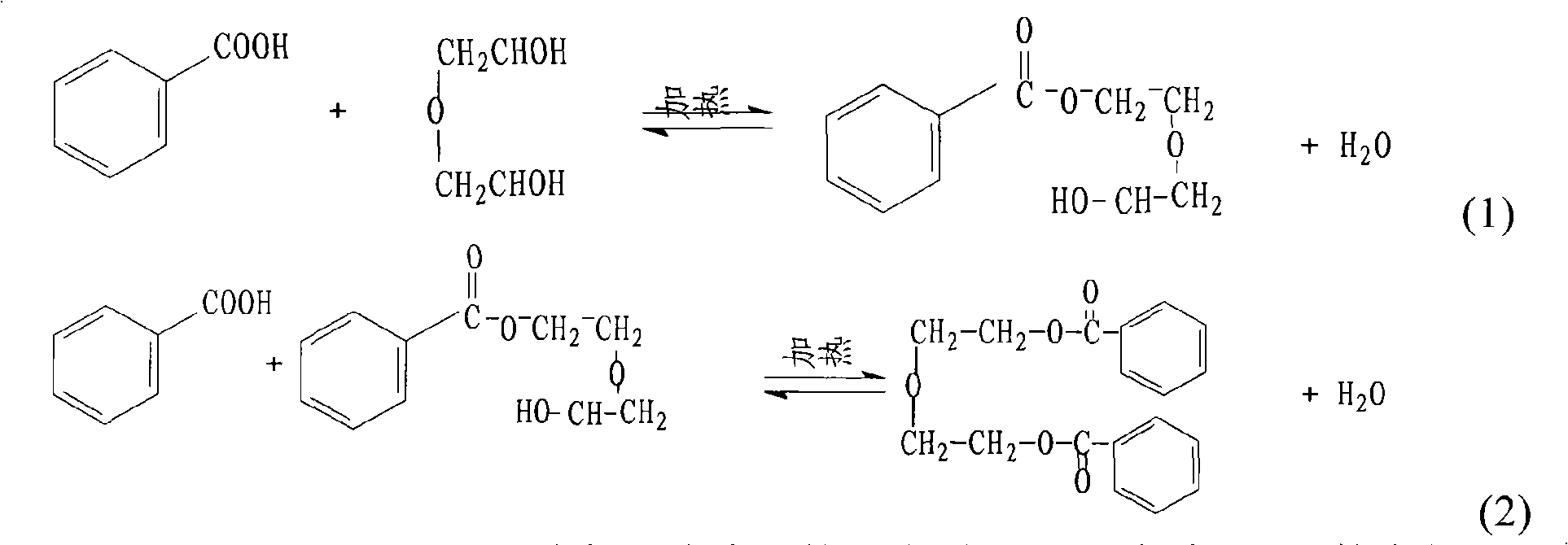

Preparation method of diethylene glycol dibenzoate

InactiveCN101407461ASmooth responseHigh yieldOrganic compound preparationCarboxylic acid esters preparationBenzoic acidReaction temperature

The invention discloses a method for preparing diethylene glycol dibenzoate ester, which relates to a process for preparing diethylene glycol dibenzoate ester (DEDB) which functions as a plasticizer of organic chemical products. First, benzyl acid and diglycol with the weight ratio of 2: 1-1.1 are taken; then, protonic acid is taken as a catalyst, which has a weight 0.01-0.02 time of the overall weight of benzyl acid and diglycol; then, benzyl acid and diglycol are put into a reactor to be stirred and heated up to 90-200 DEG C, and the catalyst is added; then saturated hydrocarbons is added as a water-carrying agent, and the temperature is adjusted to 90-160 DEG C with heat preservation for 6-16h until the reaction is fully conducted; at the temperature, the water-carrying agent is vacuumed and removed to get a crude product of diethylene glycol dibenzoate ester; finally, alkali is added for neutralization to remove the catalyst; then, decolorization and leaching are carried out in sequence to get diethylene glycol dibenzoate ester. The method for preparing diethylene glycol dibenzoate ester has the advantages that as the saturated hydrocarbons water-carrying agent is used, under the catalysis of protonic acid, the reaction temperature is effectively lowered, thus inhibiting production of side products; the conversion rate reaches 98 percent; the yield coefficient is high; the cost of the product is low; and the method has strong industrial production value.

Owner:EAST CHINA NORMAL UNIV

Method for producing elasticizer diethylene glycol dibenzoate

InactiveCN101492372ASafe and stable process operationLow costOrganic compound preparationCarboxylic acid esters preparationActivated carbonBenzoic acid

The invention relates to a production method of a plasticizing agent, in particular to a production method of the plasticizing agent of DEDB. The invention is achieved as follows: taking acidum benzoicum and diglycol as the raw materials, adding a compound catalyst, adopting a solvent-free method and completing the reaction at a special temperature. The material formula comprises (by weight): the acidum benzoicum: 66.5 to 68.5 percent; the diglycol: 31.5 to 33.5 percent; the compound catalyst: 0.05 to 0.08 percent (by total feed capacity); activated carbon: 0.1 to 0.15 percent (by total feed capacity); and diatomite: 0.1 to 0.15 percent (by total feed capacity). The invention is achieved by taking the acidum benzoicum and the diglycol as the raw materials, adding the compound catalyst, adopting the solvent-free method and completing the reaction at a special temperature, thus shortening the reaction time and increasing the yield rate of finished products.

Owner:无锡双象新材料有限公司

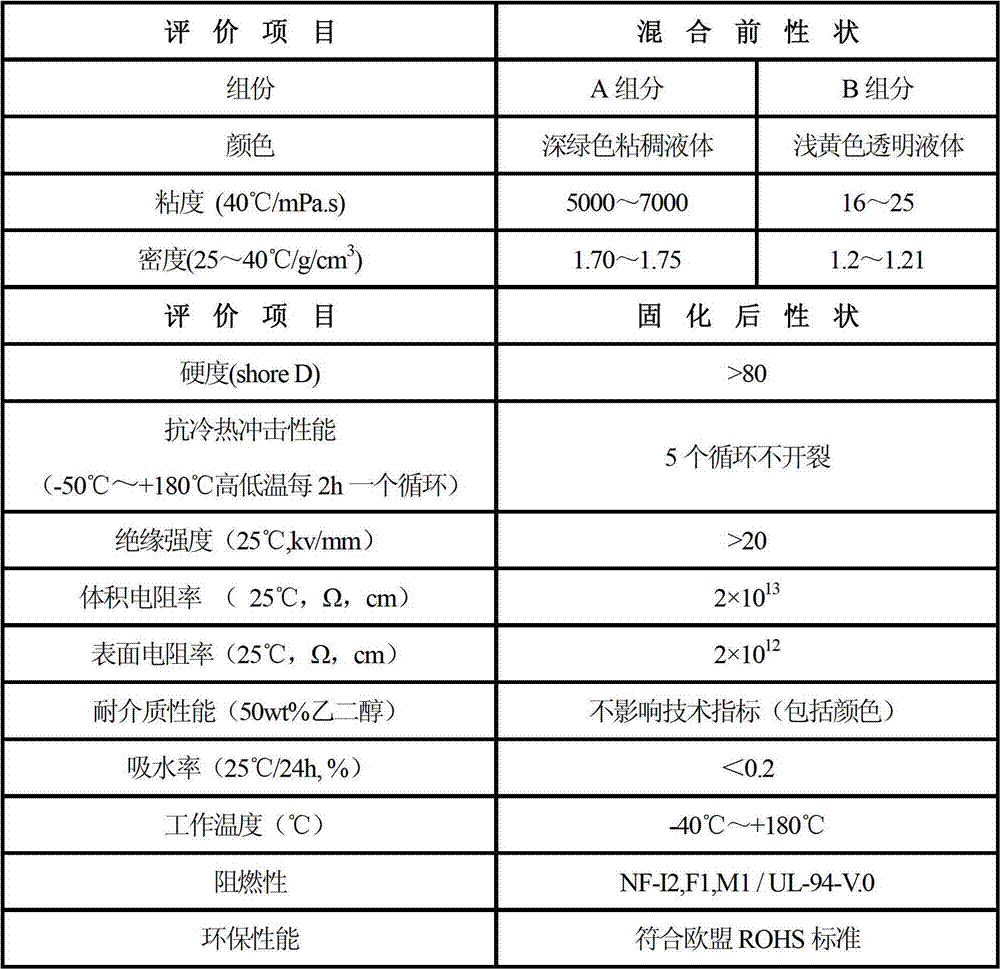

Flame-retardant encapsulating material and preparation method thereof

The invention relates to the field of encapsulation of electronic component, in particular relates to a flame-retardant encapsulating material applicable to electronic and electric product and a preparation method of the flame-retardant encapsulating material, solving the problems of the prior art that the fire-proofing and flame retardant performance is poor, and relatively high flame-retardant rating cannot be obtained. The material comprises a component A and a component B; in percentage by weight, the component A comprises base stock bisphenol-A epoxy resin, fire retardant, diluent diethylene glycol dibenzoate, flexibilizer dioctyl phthalate, pigment, organic silicon defoaming agent and filler silica micropowder; the component B comprises curing agent phthalic anhydride or methyl tetrahydrophthalic anhydride, curing agent eleostearate anhydride, and accelerator 2, 4, 6-tri(dimethylamino methyl) phenol; before the flame-retardant encapsulating material is used, the component A is pre-heated in an oven and then uniformly agitated in an up-to-bottom way; and the component A and the component B are uniformly mixed, so as to obtain flame-retardant encapsulating material; and then the encapsulating can be carried out. The flame-retardant encapsulating material provided by the invention is mainly applicable to insulating packaging of various electronic components such as power engine, rail transit, war industry, spaceflight, car and power.

Owner:大连宝津科技发展有限公司 +1

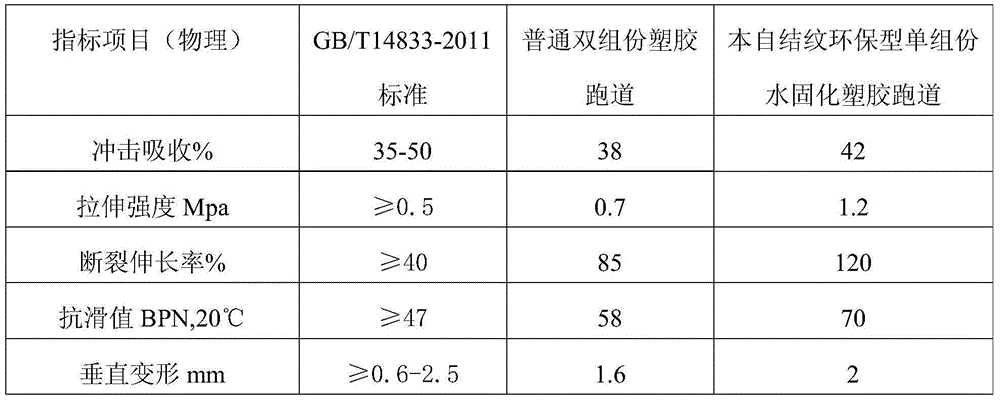

Environment-friendly type one-component water-cured lines-self-forming plastic track material and preparation method thereof

The invention relates to an environment-friendly type one-component water-cured lines-self-forming plastic track material and its preparation method. The track material contains the following raw materials, by weight, 30-50 parts of bifunctional polyether polyol, 30-50 parts of tri-functional polyether polyol, 30-50 parts of diethylene glycol dibenzoate, 30-40 parts of epoxidized soybean oil, 20-30 parts of methyl diphenylene diisocyanate, 1-5 parts of pigment, 60-80 parts of powdered steatile, 10-20 parts of a stabilizer, 1-5 parts of a rheological agent, 0.5-3 parts of calcium oxide and 1-3 parts of white carbon black. The track material is environmentally friendly, can be prepared in advance, is stored in a barrel after being prepared and is directly used at a construction site. According to the invention, the problem that bi-component materials need to be weighed and blended on site and must be uniformly stirred is minimized; three links which are most likely to get wrong during the construction process are avoided; construction process is simplified; and construction efficiency is enhanced.

Owner:蔡晓明

Preparation method of plasticizer diethylene glycol dibenzoate

InactiveCN103086891AImprove conversion rateGood choiceOrganic compound preparationCarboxylic acid esters preparationBenzoic acidReflux

The invention relates to a preparation method of a plasticizer, particularly a preparation method of a plasticizer diethylene glycol dibenzoate, which comprises the following steps: heating benzoic acid and diethylene glycol until the benzoic acid is dissolved, adding a catalyst to carry out reflux reaction, starting a vacuum pump, heating to 200-220 DEG C, keeping the temperature to react under reduced pressure, and stopping the reaction when no water is distilled out, thereby obtaining a diethylene glycol dibenzoate crude product; and cooling the obtained diethylene glycol dibenzoate crude product, neutralizing with an Na2CO3 water solution to remove excessive benzoic acid, washing, separating out the ester layer, and dehydrating by vacuum distillation to obtain a colorless transparent oil liquid which is the plasticizer diethylene glycol dibenzoate product. The technique is simple, does not use any water-carrying agent, continuously distils out water in the reaction under negative pressure, breaks the chemical equilibrium of the esterification reaction, shortens the reaction time, greatly enhances the benzoic acid conversion rate, has the advantages of high esterification rate (up to higher than 98%), favorable catalyst selectivity, fewer side reactions, light product color and no need of activated carbon for decolorization, and is suitable for industrial production and environment-friendly.

Owner:XIAMEN UNIV

Liquid rubber modified epoxidized natural rubber cable material

InactiveCN104610622AHigh strengthImprove aging resistanceRubber insulatorsPolymer sciencePolystyrene

The invention discloses a liquid rubber modified epoxidized natural rubber cable material. The liquid rubber modified epoxidized natural rubber cable material comprises raw materials in parts by weight as follows: 80-95 parts of epoxidized natural rubber, 5-20 parts of carboxyl-terminated liquid nitrile rubber, 5-15 parts of modified starch, 2-8 parts of ultrafine acrylate rubber powder, 3-8 parts of polystyrene thermoplastic elastomer, 10-25 parts of silica, 8-35 parts of modified diatomite, 15-27 parts of tetrapod-shaped zinc oxide whiskers, 1-2.5 parts of zinc oxide, 0.8-1.3 parts of sorbic acid, 2-4 parts of stearic acid, 1-2.6 parts of sulfur, 2-2.9 parts of dicumul peroxide, 1-3.5 parts of diallyl phthalate, 2-3.5 parts of diethylene glycol dibenzoate, 2-5 parts of calcium stearate, 2-5 parts of an accelerant, 2-5 parts of an anti-aging agent and 3-7 parts of a coupling agent. The liquid rubber modified epoxidized natural rubber cable material has high strength, good anti-aging performance and long service life.

Owner:无为县茂林电缆材料有限公司

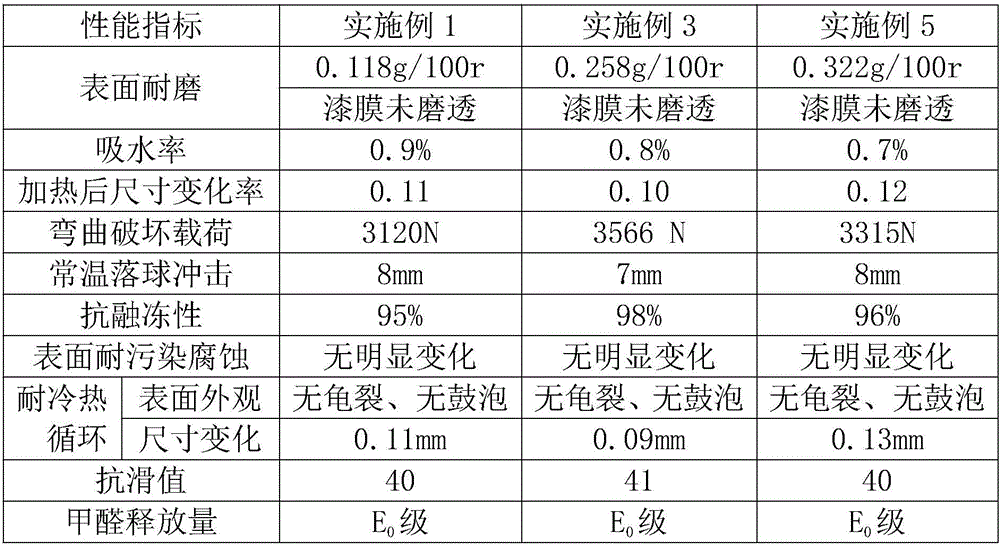

Wear-resistant wood-plastic profile and preparation method thereof

The invention belongs to the technical field of building materials and especially relates to a wear-resistant wood-plastic profile and a preparation method thereof. The wear-resistant wood-plastic profile is prepared from the following raw materials (by weight): 20-60 parts of walnut shell flour, 10-26 parts of peanut shell powder, 20-40 parts of polyethylene, 5-12 parts of glyceryl triacetate, 5-10 parts of silicone powder, 3-8 parts of polytetrafluoroethylene powder, 4-9 parts of di-n-butyl phosphate, 3-7 parts of cyclohexane dicarboxylate, 3-8 parts of diethylene glycol dibenzoate, 2-7 parts of tetramethyl divinyl disiloxane, 1-5 parts of vinyl trichlorosilane, 2-8 parts of 1,3-dimethyl-6-semicarbazide pyrimidine, 3-8 parts of alkyl glycoside, 1-5 parts of 1-vinyl imidazole and 1-6 parts of dialkyl diphenylamine. The invention also provides a preparation method of the wear-resistant wood-plastic profile. The wear-resistant wood-plastic profile has characteristics of aesthetic property, high wear resistance, waterproofness and skid resistance, durability and corrosion resistance, no release of formaldehyde and the like. In addition, the preparation technology is simple.

Owner:GUILIN SHUKANG BUILDING MATERIAL

Lightweight heat-resistant flame-retardant modified PVC resin compound-mixed cable material and preparation method thereof

InactiveCN105482296AGood dispersionGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesAluminum silicateStearic acid

The invention relates to a cable material, in particular to a lightweight heat-resistant flame-retardant modified PVC resin compound-mixed cable material and a preparation method thereof. The cable material is prepared from, by weight, 55-65 parts of PVC resin, 30-40 parts of an ethylene-vinyl acetate copolymer, 0.01-0.02 part of tourmaline, 10-15 parts of expandable graphite, 5-8 parts of polytetra methylene ether glycol, 15-22 parts of aluminum silicate, 3-4 parts of eleostearic acid, 3-4 parts of hexamethyldisilazane, 22-30 parts of cotton pulp, 2-4 parts of zinc stearate, 14-18 parts of diethylene glycol dibenzoate, 8-10 parts of color master batch and 2-3 parts of an additive. The PVC resin and the ethylene-vinyl acetate copolymer are blended to serve as a resin base material, the cotton pulp subjected to modification treatment serves as a filler, and through the combination with the additive and other auxiliary raw materials for improving the machining performance and effect, the cable material can show more excellent heat-resistant flame-retardant performance than a traditional PVC resin when being used.

Owner:ZHONGGUAN CABLE CO LTD

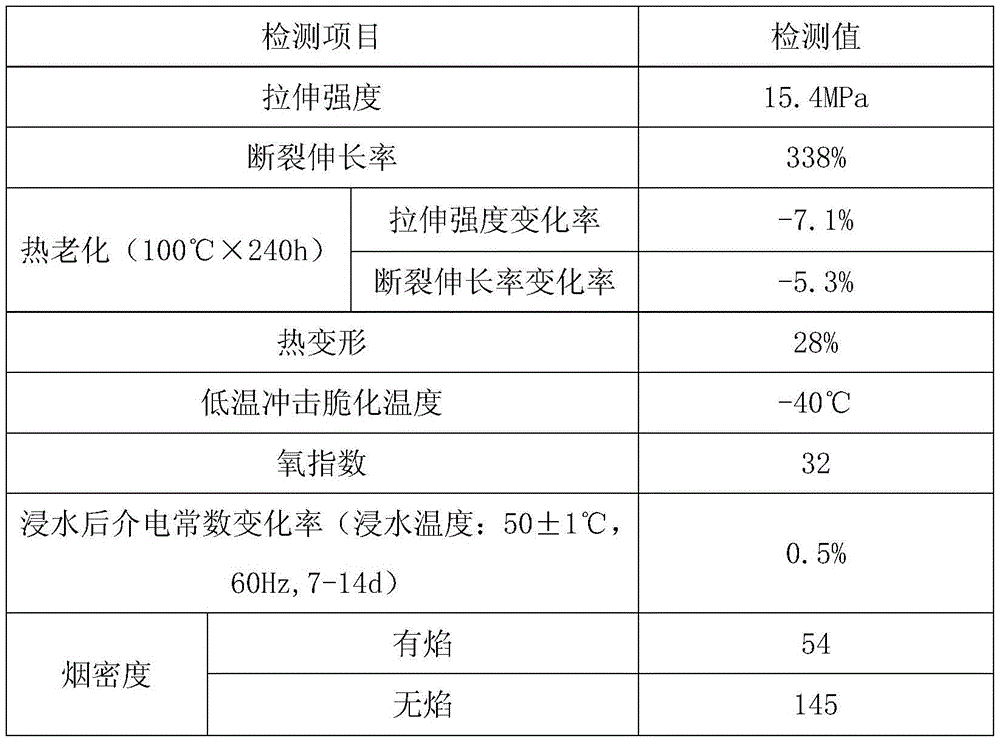

Nitrile rubber material for high-performance engine

InactiveCN103865125AImprove high temperature resistanceGood tear-off performancePolymer sciencePolyvinyl chloride

The invention discloses a nitrile rubber material for a high-performance engine. The nitrile rubber material comprises the following raw materials in parts by weight: 70-100 parts of nitrile rubber 3604, 20-30 parts of ethylene propylene diene monomer, 4-10 parts of organic silicon modified acrylate, 4-6 parts of polyvinyl chloride resin, 0.8-1.3 parts of stearic acid, 1.5-2.5 parts of paraffin, 40-60 parts of carbon black N550, 15-30 parts of zinc oxide whiskers, 8-12 parts of coupling agent KH-550, 13-17 parts of high styrene, 0.7-1.3 parts of trihydroxymethylaminomethane, 1.5-2.1 parts of dicumyl peroxide, 0.5-0.8 part of N,N-diphenyl-phenylene diamine, 0.3-0.5 part of antiager MB, 0.7-1 part of trimethylol-propane trimethacrylate, 1-2 parts of triallyl isocyanurate, 3-8 parts of magnesium hydrate, 1-3 parts of antimonous oxide, 8-13 parts of diethylene glycol dibenzoate and 0.5-1 part of accelerant TMTD. The nitrile rubber material for the high-performance engine disclosed by the invention is excellent in oil resistance, excellent in high temperature resistance, and good in wear-resisting property, warping strength and breaking performance, can be applied to preparation of various sealing materials inside the engines, and is long in service life.

Owner:ANHUI SHENGDONG CHEM

Single-component reaction-type polyurethane hot melt adhesive and preparation method thereof

ActiveCN109666441AHigh plasticizing efficiencyReduce volatilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPrepolymerHot-melt adhesive

The invention discloses single-component reaction-type polyurethane hot melt adhesive. The single-component reaction-type polyurethane hot melt adhesive is prepared from the following raw materials: polyurethane prepolymer, a chain extender, tackifying resin, a latent curing agent and filler, wherein the polyurethane prepolymer is formed by polymerizing polyalcohol with a molecular weight of 500 to 3000, polyisocyanate and a catalyst; and the raw material composition also comprises a plasticizer, wherein the plasticizer is dioctyl phthalate and / or diethylene glycol dibenzoate. The components of the single-component reaction-type polyurethane hot melt adhesive of the invention are mixed with plasticizers, the plasticizers are dioctyl phthalate and / or diethylene glycol dibenzoate, the two substances have high plasticizing efficiency for the polyurethane and low volatility and have good low-temperature flexibility; and by adding the plasticizers, the interaction between polymer macromolecular chains can be weakened, the elasticity and flexibility of the polymer materials of the polyurethane hot melt adhesive can be improved, and the high-temperature and low-temperature resistance of the hot melt adhesive can be improved.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Preparation method of diethylene glycol dibenzoate

InactiveCN102816068ASafe and stable process operationLow costOrganic compound preparationCarboxylic acid esters preparationBenzoic acidActivated carbon

The invention discloses a preparation method of diethylene glycol dibenzoate. Benzoic acid and diethylene glycol are used as raw materials, and a composite catalyst employed is a mixture of tetraisopropyl titanate and a solid titanium base compound. The method comprises steps of: adding by weight 66.5-68.5 parts of benzoic acid and 31.5-33.5 parts of diethylene glycol in a reaction kettle; heating; after complete dissolving of benzoic acid, adding 0.05-0.08 part of the composite catalyst; insulating at a temperature of 190-210 DEG C for 4-6 h to achieve complete reaction; after the reaction, removing alcohol by reducing temperature and pressure to obtain crude diethylene glycol dibenzoate; adding 0.1-0.15 part of diatomite and 0.1-0.15 part of activated carbon; and decolorizing and filtering to obtain the diethylene glycol dibenzoate finished product. The preparation method provided by the invention has characteristics of safe and stable technical operation, low cost, no environmental pollution, short reaction time and high yield of finished product.

Owner:PLASTIC LIGHT CHEM IND LIMITED

Dibenzoate plasticizers/coalescent blends for low VOC coatings

ActiveUS20130274395A1Reduce volatilityGood performance benefit in glossNon-macromolecular adhesive additivesInksEmulsionDiethylene glycol

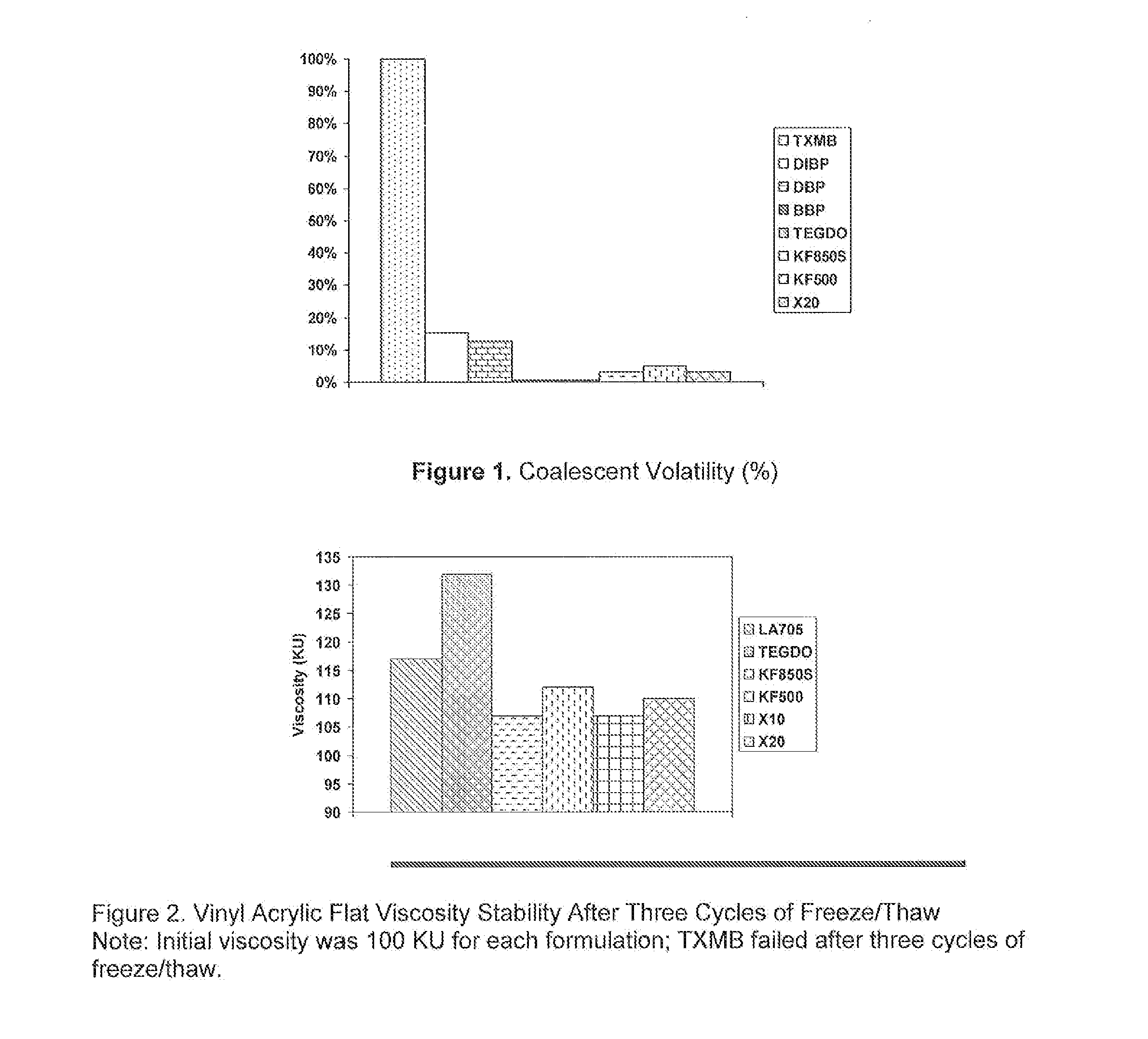

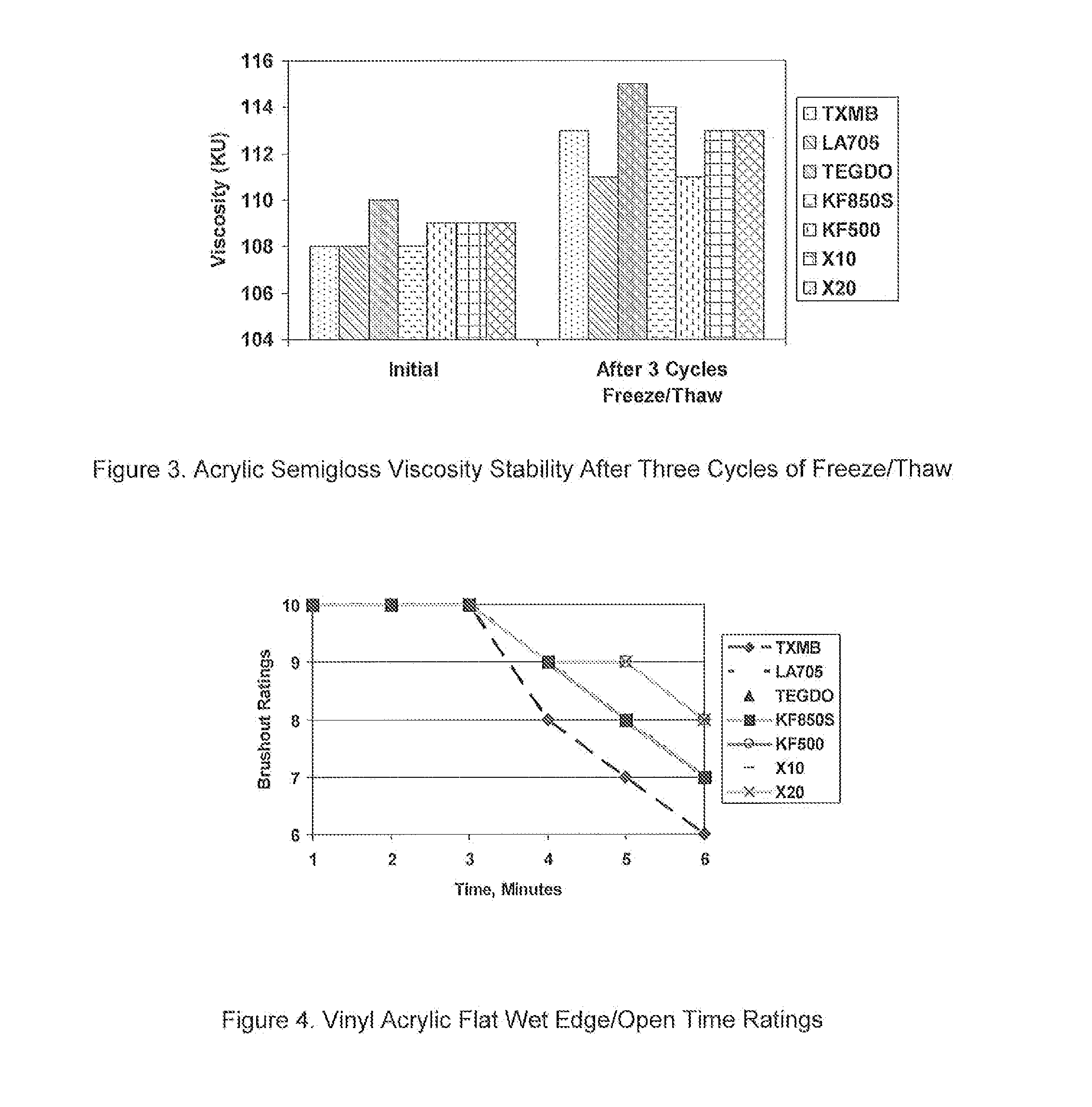

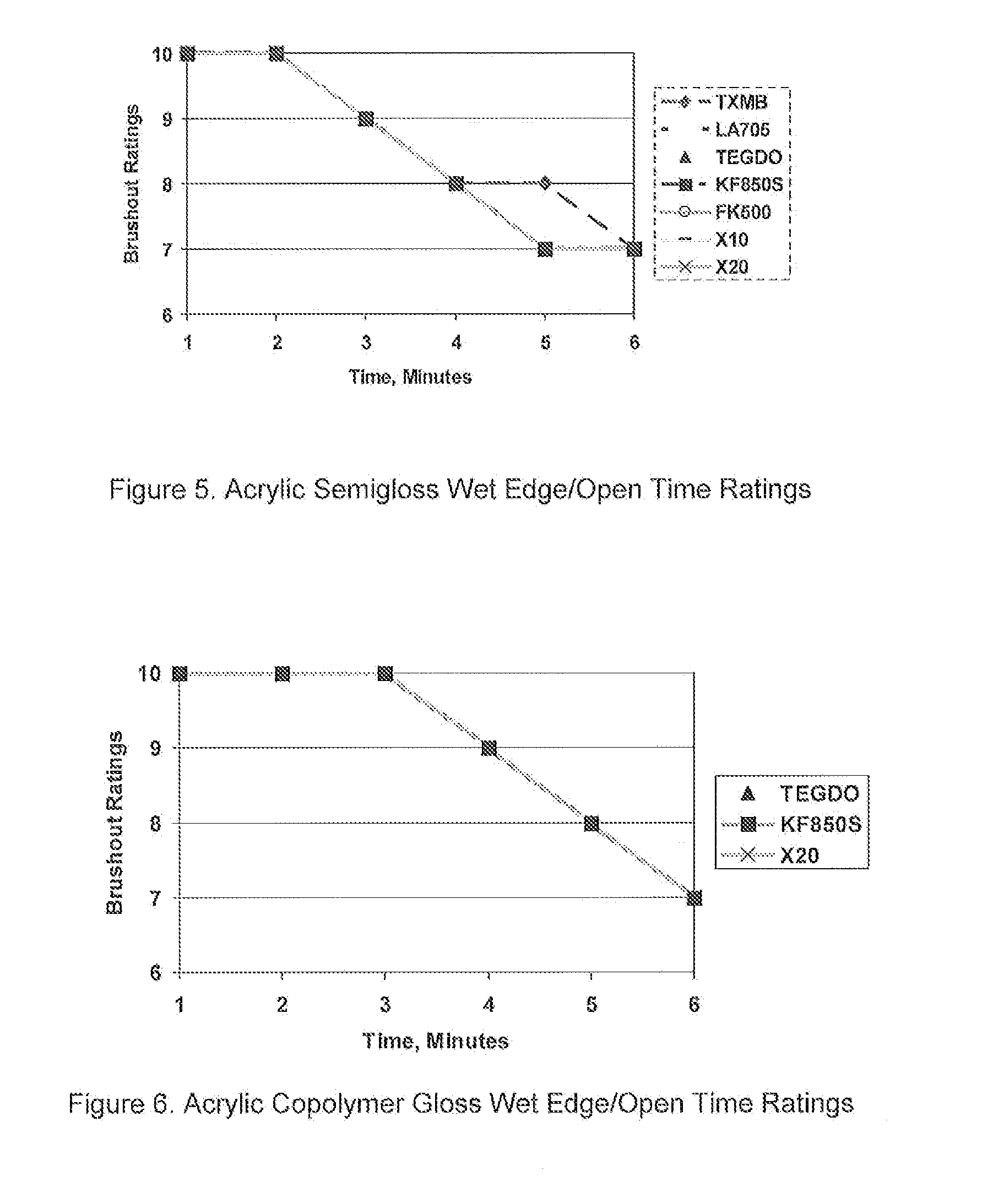

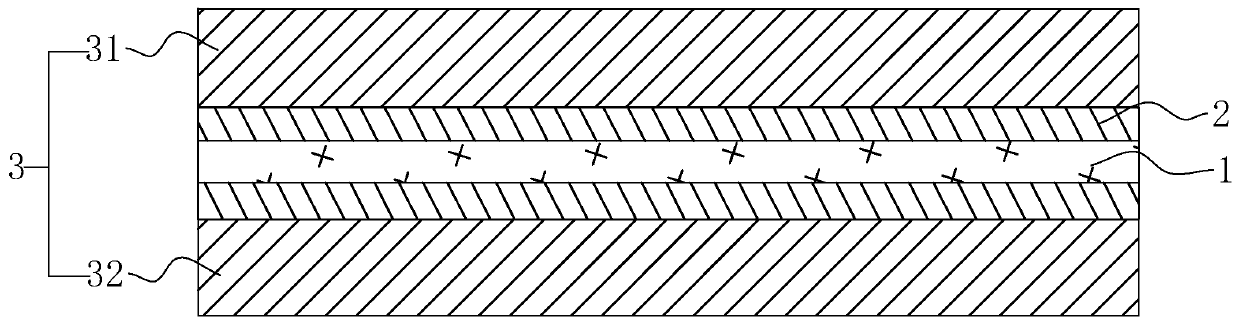

A novel, low volatility, non-phthalate plasticizer / coalescent blend for use in paints and other polymeric coatings comprises a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate. The triblend when used in a paint or other coatings achieves a low VOC paint or coating having stable viscosity after three freeze / thaw cycles and equivalent or superior wet edge / open time ratings, gloss ratings, scrub resistance and block resistance when compared to traditional coalescents, including without limitation high VOC coalescents, low VOC non-dibenzoate coalescents and other dibenzoate blends. The triblend may be used as a substitute or alternative coalescent in latex and acrylic emulsion coatings, among others, to achieve a lower VOC content without sacrificing performance properties.

Owner:EMERALD KALAMA CHEM

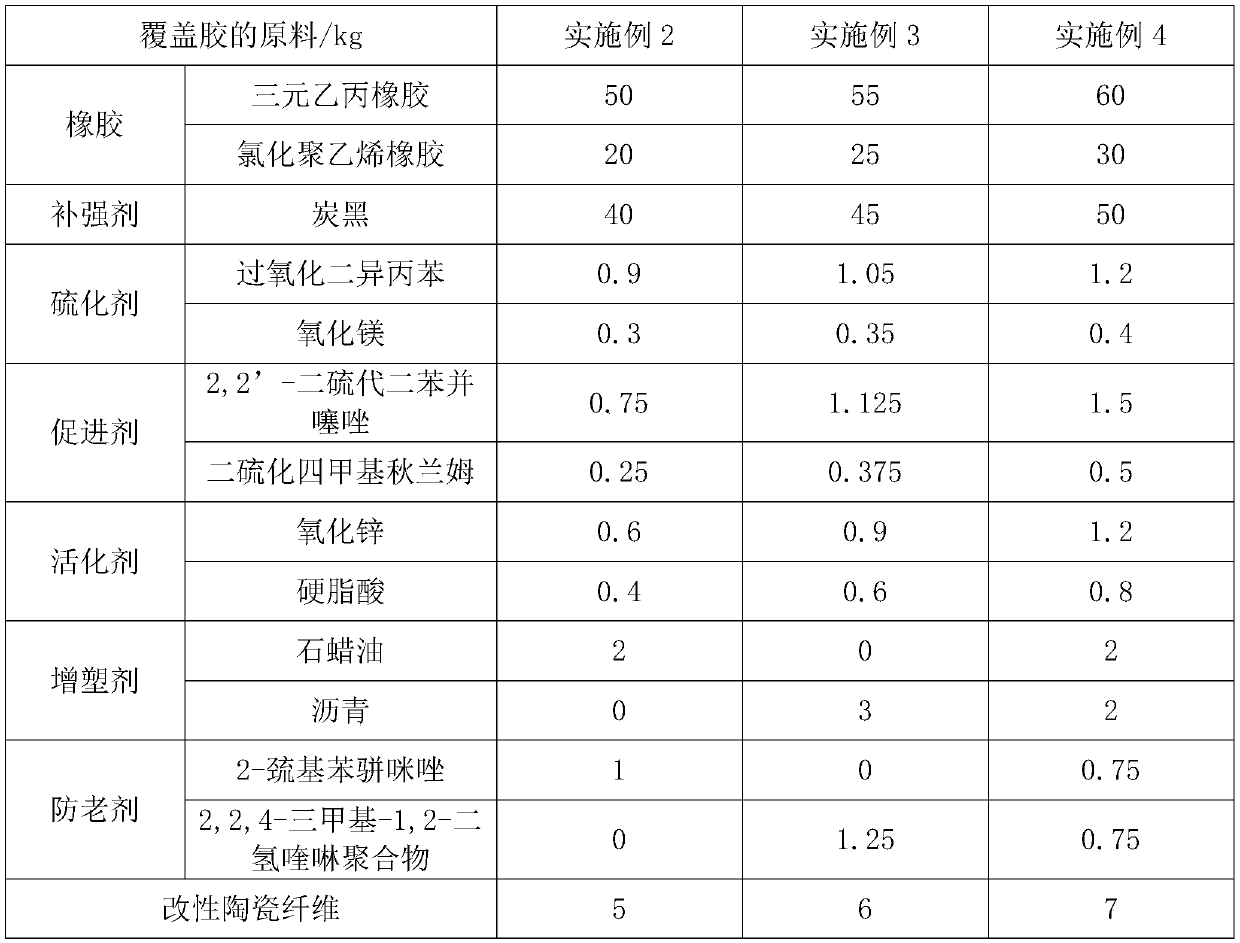

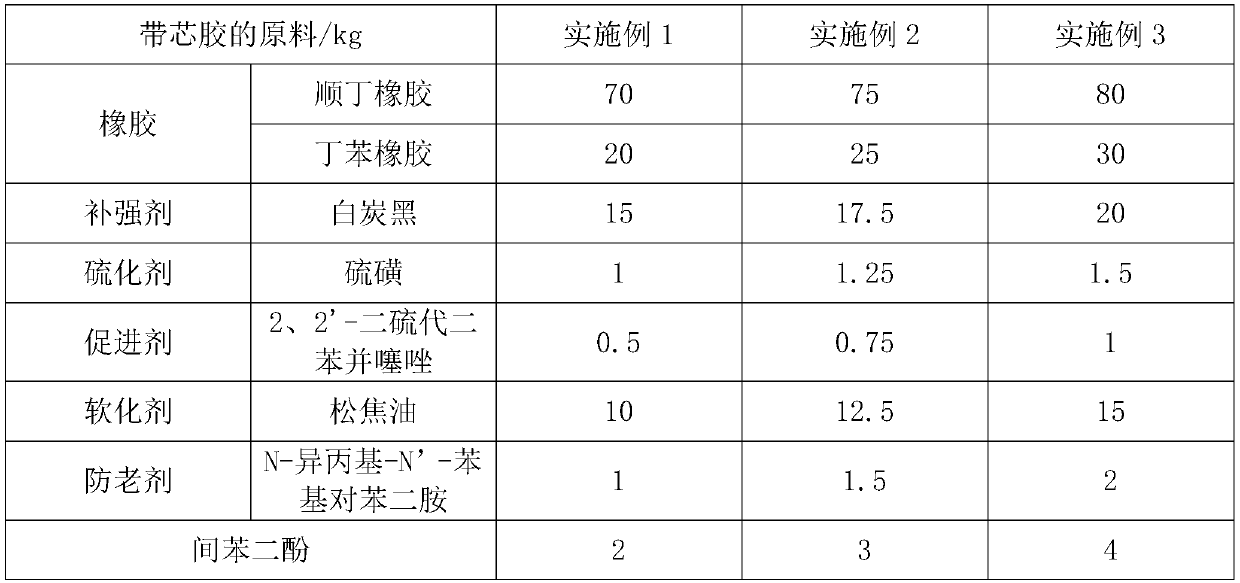

Heat-resisting conveying belt special for large junk and preparation process of heat-resisting conveying belt

InactiveCN109809106AImprove heat resistanceHigh bonding strengthConveyorsSynthetic resin layered productsFiberPolyethylene glycol

The invention discloses a heat-resisting conveying belt special for a large junk and a preparation process of the heat-resisting conveying belt. According to the technical scheme, the heat-resisting conveying belt special for the large junk comprises a belt core, belt core rubber and coverage rubber. The coverage rubber comprises upper coverage rubber and lower coverage rubber. The coverage rubberis formed by polymerizing raw materials which include EPDM, chlorinated polyethylene rubber, carbon black, modified ceramic fibers, a vulcanizing agent, an accelerant, an activation agent, a plasticizer and an anti-aging agent. Ceramic fibers are immersed into impregnation liquid formed by polyethylene glycol, imvite, glycerol ester of rosin, a silane coupling agent, BMDPM and diethylene glycol dibenzoate, and the modified ceramic fibers are obtained through modification treatment. The bonding strength of the modified ceramic fibers is high, the bonding force of the modified ceramic fibers and rubber can be improved, the defect that the bonding strength of EPDM and the belt core is low can be overcome, heat resistance of the conveying belt is improved, and meanwhile the interlayer bondingstrength of EPDM and the belt core is improved.

Owner:青岛环球输送带有限公司

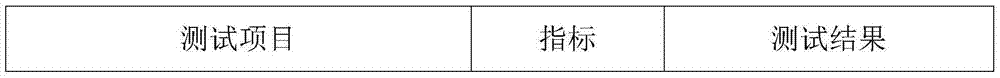

Mouse-proof optical cable rubber sleeve

InactiveCN105802233AExtended retention timeGuaranteed anti-rodent effectFibre mechanical structuresPolymer sciencePolyethylene glycol

The invention discloses a mouse-proof optical cable rubber sleeve. The mouse-proof optical cable rubber sleeve is composed of an insulating layer on the innermost layer, a sandwiched layer in the middle and a protection layer on the outermost layer, wherein the insulating layer is prepared from ethylene propylene diene monomer, silicon rubber, stearic acid, polyethylene glycol PEG4000, white carbon black, carbon black N568, carbon black N765, light calcium carbonate and paraffin oil 2280; the sandwiched layer is prepared from natural rubber, polyurethane rubber, mustard, chili, ground pepper, carbon black N550, carbon black N774, a plasticizer DEDB (Diethylene Glycol Dibenzoate), an anti-ageing agent A, a vulcanizing agent, diatomite, an accelerant TMTD (Tetramethylthiuram Disulfide) and gas-phase white carbon black; the protection layer is prepared from the ethylene propylene diene monomer, butyl rubber, fluorous rubber, chloroprene rubber, carbon black N660, carbon black N539, the accelerant TMTD, magnesium oxide and modified talcum powder. The mustard, the chili and the pepper, which have spicy and stimulating smells, are added into the sandwiched layer, so that oral mucosa and gustatory nerves of mice are strongly stimulated, and the mice reject eating, and furthermore, the mouse-proof optical cable rubber sleeve can prevent the mice from biting.

Owner:韩静静

High-modulus bituminous concrete additive

The invention belongs to the technical field of bituminous road material and relates to a high-modulus bituminous concrete additive. The high-modulus bituminous concrete additive is composed of the following materials by mass: 60-90 parts of waste polyethylene, 10-30 parts of polypropylene, 5-10 parts of ethyl acetate and 0.5-1.5 parts of additive, wherein the additive is prepared by mixing a plasticizer and a modifier according to the mass ratio of 1:(2-4), wherein the plasticizer is dioctyl phthalate, diisobutyl phthalate or diethylene glycol dibenzoate, and the modifier is 19-tert-lauryl mercaptan, isooctyl 3-mercaptopropionate, ethanethio or dodecanethiol. The additive provided by the invention is convenient to use, low in cost and stable in performance, and the track prevention performance, the low temperature anti-cracking performance, the water stability and the anti-fatigue performance of the bituminous mixture are improved. Meanwhile, the waste plastic can be effectively recycled, the advantage of ecological environmental protection is achieved, the resource waste is directly reduced, the natural landscape and the ecological environment balance are greatly kept, and good social and environmental benefits are obtained.

Owner:辽宁省交通科学研究院有限责任公司

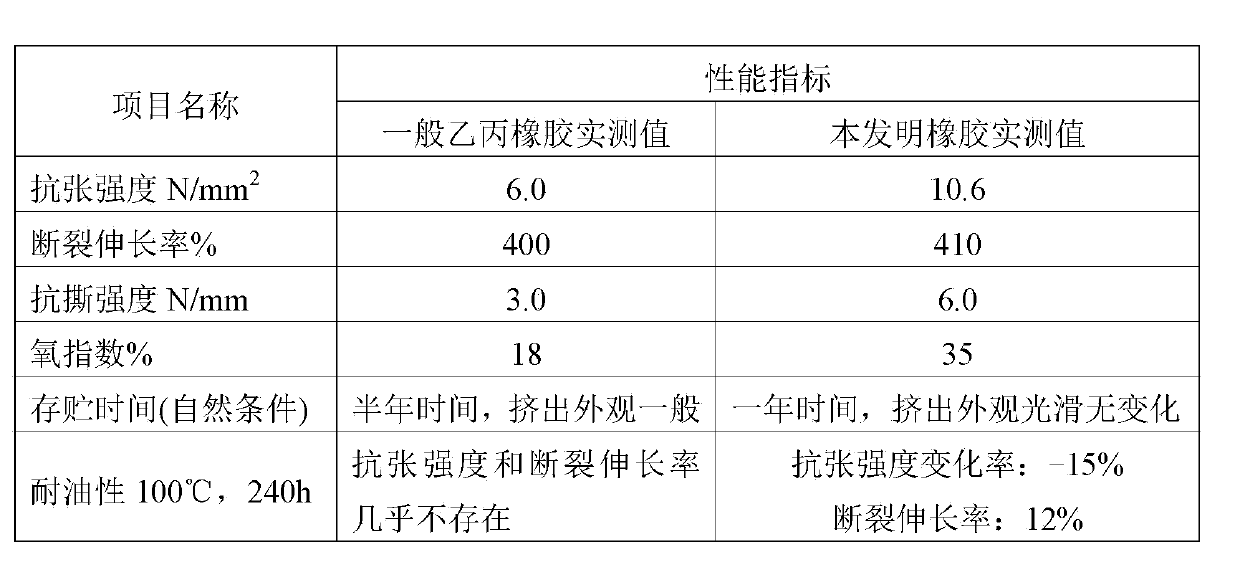

Anti-aging high-flame-retardant ethylene propylene diene monomer rubber pipe

The invention discloses an anti-aging high-flame-retardant ethylene propylene diene monomer rubber pipe comprising the raw materials: ethylene propylene diene monomer, polyvinyl chloride, chlorinated polyethylene, zinc oxide, stearic acid, bromo-octyl-phenolic curing resin, dicumyl peroxide, modified nano-silicon dioxide, attapulgite, expandable graphite, polyacrylonitrile fiber, cerous phosphate, pentaerythritol, ammonium polyphosphate, an anti-aging agent MC, an anti-aging agent MB, zinc nitrilotiracetate, calcium nitrilotiracetate, an accelerant, diethylene glycol dibenzoate, tricresyl phosphate, and a silane coupling agent. The anti-aging high-flame-retardant ethylene propylene diene monomer rubber pipe disclosed by the invention has the advantages of high strength, excellent anti-aging and flame-retardant property and long service life.

Owner:安徽都邦电器有限公司

High performance crosslinked elastomeric insulation material

InactiveCN103396615AImprove flame retardant performanceExtended storage timePlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a high performance crosslinked elastomeric insulation material, which is composed of the following raw materials by weight part: 90-100 of chlorinated polyethylene CPE135B, 3-5 of a curing agent DCBP, 2-4 of triallyl isocyanurate, 8-15 of magnesium oxide, 100-110 of 1250-mesh talcum powder, 10-15 of precipitated white carbon black, 10-15 of kaolin, 2-3 of polypropylene adipate, 3-4 of bisphenol A phosphite, 1-2 of dibutyltin dilaurate, 1-2 of dibasic lead phosphite, 15-20 of chlorinated paraffin 52, 4-6 of ethylene bis stearamide, 2-4 of hydrated zinc borate, 8-10 of diethylene glycol dibenzoate, 50-55 of light calcium carbonate, 1-2 of an antiager AW, and 10-15 of an auxiliary filler. The insulation material produced in the invention has good oil resistance, high strength, strong tear resistance, good flame retardance, and superior overall performance.

Owner:安徽龙庵电缆集团有限公司

Production technique of diethylene glycol dibenzoate

InactiveCN103012152ALight colorHigh whitenessOrganic compound preparationCarboxylic acid esters preparationBenzoic acidVegetable oil

The invention discloses a production technique of diethylene glycol dibenzoate, which comprises the following steps: putting benzoic acid, diethylene glycol and catalyst into a reactor to carry out esterification reaction, neutralizing the synthesized crude product, washing with water, stripping, decolorizing, and carrying out pressure filtration to obtain the finished product. The invention is characterized in that a vegetable oil plasticizer, which accounts for 10-30% of the finished product, is added to the decolorization product, and after the vegetable oil plasticizer and the decolorization product are evenly mixed, pressure filtration is carried out on the mixture; the weight ratio of the benzoic acid to the diethylene glycol is (1.8-2.5):1; and the catalyst accounts for 0.5-0.8% of the total amount of the benzoic acid and the diethylene glycol. Compared with the prior art, the invention lowers the production cost and reduces the environmental pollution; and oxidation technique and low-cost low-color-number vegetable oil plasticizer are added to the after-treatment process to obtain the light-color low-cost low-freezing-point diethylene glycol dibenzoate, thereby further widening the application range of the product.

Owner:CENXI XIANGSHENG CHEM CO LTD

Preparation method of solid acid catalyst and application of catalyst to synthetic reaction of diethylene glycol dibenzoate (DEDB)

ActiveCN102172533APhysical/chemical process catalystsOrganic compound preparationCooking & bakingSolid acid

The invention discloses a SO4<2-> / ZrO2 / SiO2 solid acid catalyst for synthesizing DEDB (Diethylene Glycol Dibenzoate). A preparation method of the solid acid catalyst comprises the following steps of: adding zirconium oxide into a sodium silicate aqueous solution; stirring, preserving heat and drying; soaking in a NH4HSO4 or (NH4)2SO4 aqueous solution; drying; soaking a solid with sulfuric acid, boric acid or phosphoric acid; and baking at the temperature of 450-600 DEG C and cooling to obtain the solid acid catalyst. In the DEDB synthesis process, procedures such as neutralizing, water washing, decoloring and the like are eliminated, the yield of DEDB reaches 98.6 percent, and the esterification rate reaches 99.5 percent.

Owner:XILONG SCI CO LTD

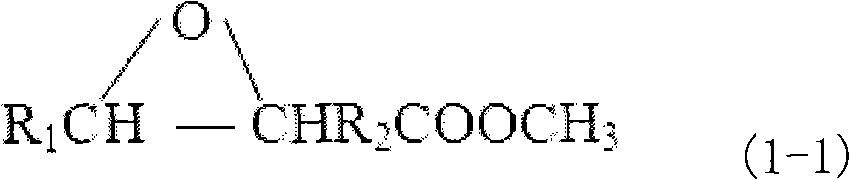

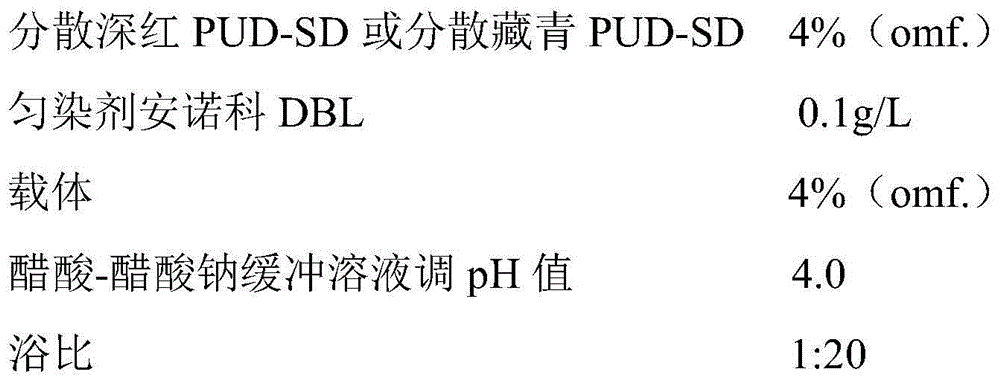

Preparation method of terylene low temperature dyeing carrier composition

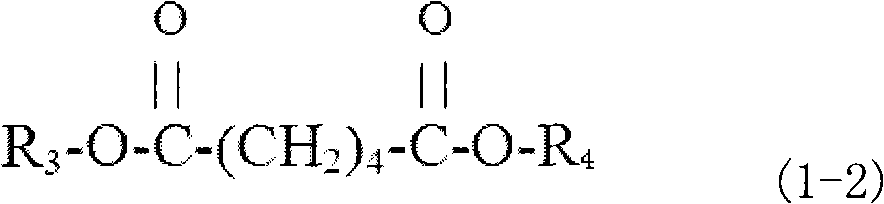

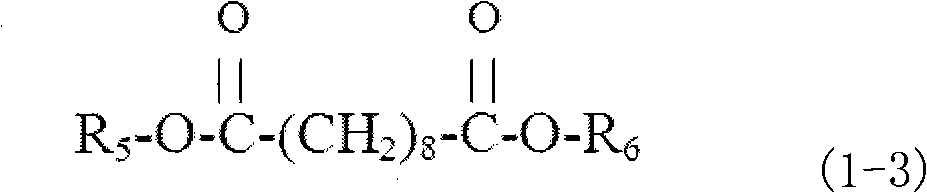

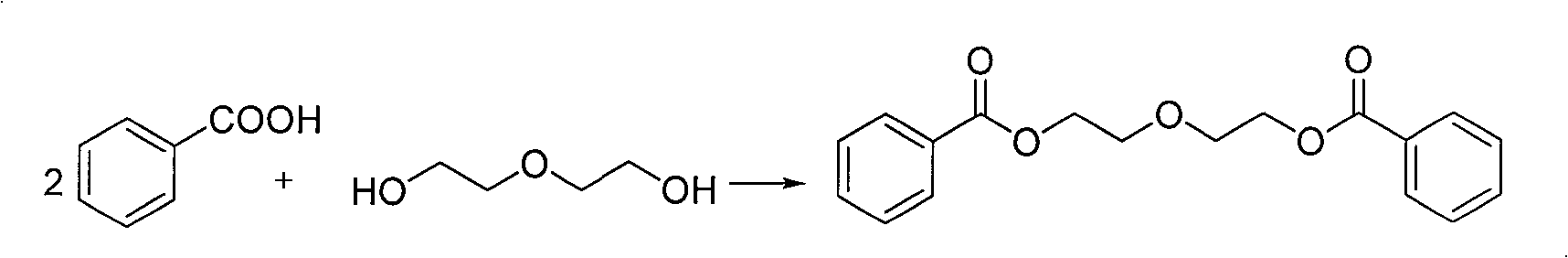

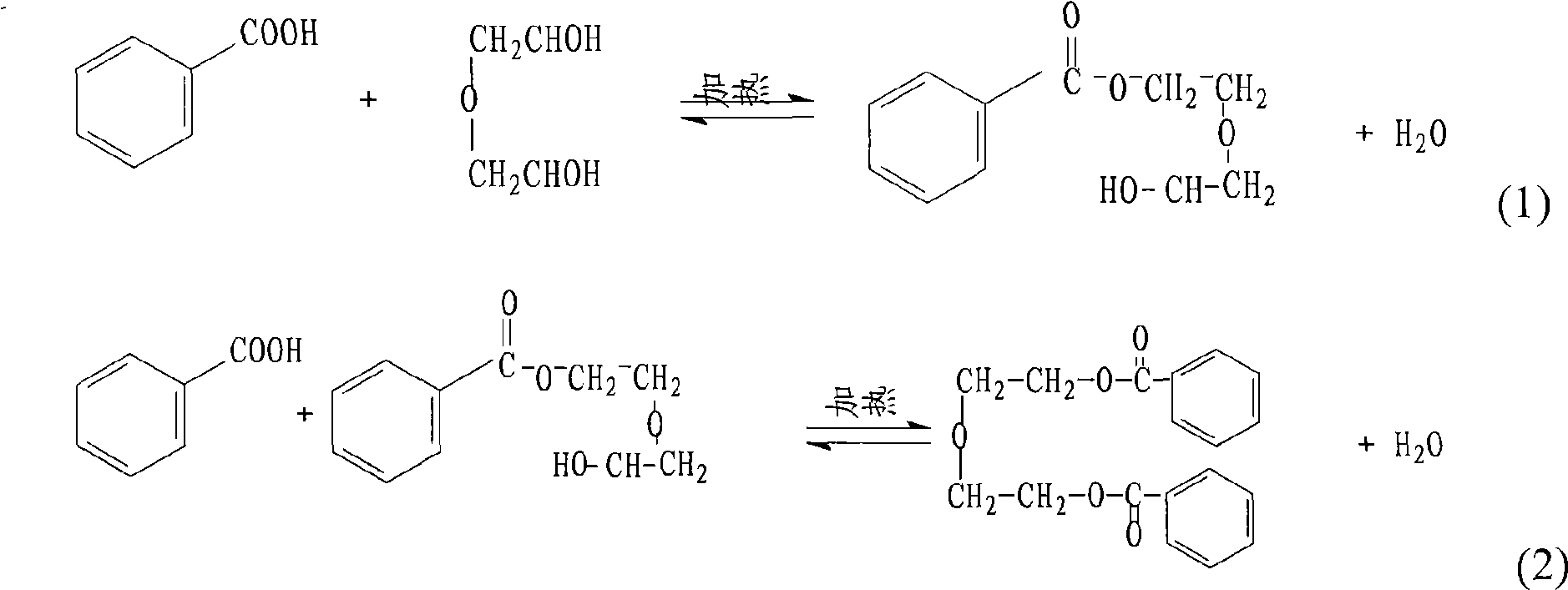

The invention discloses a preparation method of a terylene low temperature dyeing carrier composition. The method comprises a step of mixing aromatic compounds with a weight fraction of 50 to 90, non-ionic surfactant with a weight fraction of 5 to 40, and an organic solvent with a weight fraction of 4 to 20; wherein the aromatic compounds are more than one of compounds (A), compounds (B), compounds (C), and diethylene glycol dibenzoate, the structures of compounds (A), (B), and (C) are represented in the description, R1 represents a C1-C4 alkyl group or benzyl group, R2 represents a C1-C4 alkyl group, R3 represents a hydrogen atom or a C1-C4 alkyl group, the nonionic surfactant is polyoxyethylene ether, and the organic solvent is an alcohol solvent and / or an alcohol-ether solvent. The preparation method has the advantages of simple operation, cleanness, and environment-friendliness. The prepared terylene low temperature dyeing carrier composition has the advantages of low cost, easy removal, high color fastness, low toxicity, and environment-friendliness.

Owner:TONGXIANG LONGXIN PRINTING & DYEING

Flame-retardant foamed sheet

InactiveCN103571086AImprove flame retardant performanceLow densityAzodicarbonamideSODIUM DODECYL BENZENE SULFONATE

The invention discloses a flame-retardant foamed sheet which is characterized by being prepared from the following raw materials in parts by weight: 100 parts of SG-3PVC, 5-7 parts of light calcium carbonate, 10-14 parts of titanium dioxide, 4-5 parts of azodicarbonamide, 1.4-1.6 parts of hexamine, 2.8-3.2 parts of nanometer titania, 4-6 parts of precipitated barium sulphate, 1-2 parts of sodium dodecyl benzene sulfonate, 1-2 parts of dibutyltin dilaurate, 4-5 parts of diethylene glycol dibenzoate, 2-3 parts of zinc oxide, 1-2 parts of dicumyl peroxide and 6-8 parts of modified packing. The foamed sheet has an uncommon excellent flame-retardant effect, is low in density, light in weight, sound-insulated, heat-insulated, attractive in appearance and suitable for serving as a building material and is convenient and simple in raw material source, low in production cost and suitable for large-area popularization.

Owner:安徽玉龙新型建材有限公司

Magnetic polyethylene powder coating containing maleic anhydride grafted activated nano calcium carbonate and preparation method of polyethylene powder coating

InactiveCN104629519AImprove liquidityGood adhesionMagnetic paintsPowdery paintsElastomerEnvironmental resistance

The invention relates to a polyethylene powder coating and particularly relates to a magnetic polyethylene powder coating containing maleic anhydride grafted activated nano calcium carbonate and a preparation method of the polyethylene powder coating. The powder coating is prepared from the following raw materials in parts by weight: 6-10 parts of nano calcium carbonate, 2-3 parts of an aluminate coupling agent DL-411, 5-8 parts of diethylene glycol dibenzoate, 2-3 parts of polyethylene glycol, 12-16 parts of a polyurethane thermal elastomer, 2-3 parts of maleic anhydride, 1-2 parts of diethyl isopropyl benzene peroxide, 1-2 parts of nano spherical ferroferric oxide magnetic powder, 5-6 parts of pigments, 2-3 parts of an antioxidant and 40-50 parts of polyethylene. According to the coating prepared by the invention, nano calcium carbonate is activated by oxygen, and maleic anhydride is grafted on the surface of nano calcium carbonate, so that the binding force and compatibility of the raw materials and high molecular materials are improved; the doped nano spherical ferroferric oxide magnetic powder endows the material with uniform magnetism. The coating shows good flowability and adhesiveness, the strength and toughness of the sprayed coating are improved, and the coating is smooth and fine in surface, heat-resistant and stable, and has certain magnetism. The product is environmental-friendly and efficient and is excellent in coating effect.

Owner:WUHU BAOYI AMUSEMENT EQUIP

Environment-friendly method for preparing fluorine-containing polymer microporous film

ActiveCN103521092AImprove connectivityNo emissionsSemi-permeable membranesPolymer scienceCITRATE ESTER

The invention discloses an environment-friendly method for preparing a fluorine-containing polymer microporous film. The method comprises steps of mixing fluorine-containing polymer and diluents, wherein the diluents are one or more than two of citrate, p-phenyl trimellitate, and diethylene glycol dibenzoate; heating to dissolve, and defoaming to form uniform casting film liquid; processing, solidifying and molding through natural cooling or gel bath; extracting the diluents in the film holes through an extraction agent so as to obtain the fluorine-containing polymer microporous film; and separating and recycling the formed extraction agent or diluents mixture through rectification. Compared with the prior art, the method uses a thermally induced phase separation principle so as to prepare the fluorine-containing polymer microporous film which has a bicontinuous pore structure with uniform fracture surfaces, has controllable cortex structure, and has high connectivity and excellent mechanical property; on the other hand, in the process of preparing the film, environment-friendly diluents and the extraction agent or diluents are combined and used in rectification separating and recycling, so that no contaminants are discharged, and the method is environment-friendly and is economic and feasible.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com