Environment-friendly composite plasticizer and preparation method

A plasticizer and composite technology, applied in the field of chemical plasticizers and preparation, can solve the problems of poor resin compatibility, high molecular weight and molecular polarity, and low plasticizing performance.

Inactive Publication Date: 2011-03-30

浙江嘉澳环保科技股份有限公司

View PDF3 Cites 31 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, DEDB plasticizer has large molecular weight and molecular polarity, good compatibility with PVC resin, high plasticizing efficiency, good pollution resistance and durability, but its melting point is low, it is solid in winter, and it is inconvenient to use

DOTP is an isomer of DOP. Due to the difference in structure, it has better electrical resistance, heat resistance, extraction resistance, and migration resistance than DOP, but its plasticizing performance is lower than DOP.

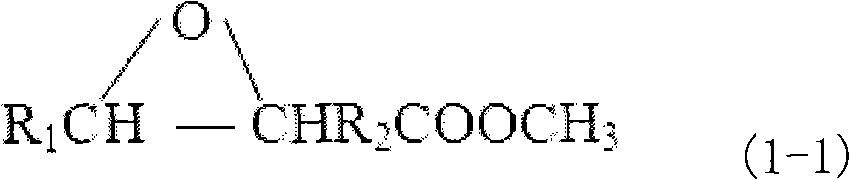

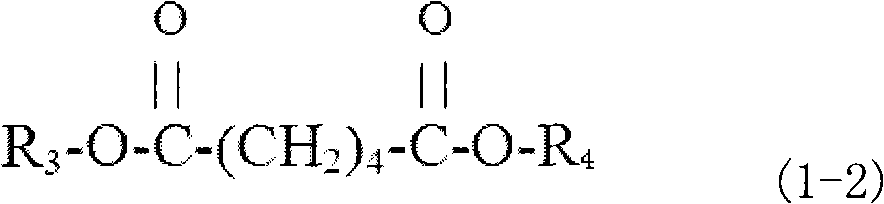

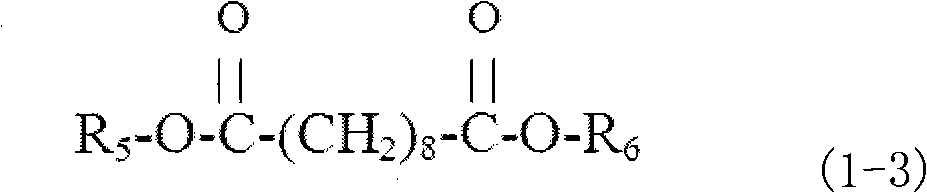

Other plasticizers such as epoxies, aliphatic polybasic esters, trimellitates, etc., all have their own unique properties, but they have not been widely used due to their poor compatibility with resins.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0051] 30 wt% of diethylene glycol dibenzoate and 70 wt% of bis(2-ethylhexyl) terephthalate were mixed to form a plasticizer.

Embodiment 2

[0053] A plasticizer composed of 50 wt% of dipropylene glycol dibenzoate and 50 wt% of bis(2-ethylhexyl) terephthalate.

Embodiment 3

[0055] A plasticizer composed of a mixture of 35% by weight of diethylene glycol dibenzoate and 30% of dipropylene glycol dibenzoate, and 35% by weight of bis(2-ethylhexyl) terephthalate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a plasticizer and a preparation method, in particular an environment-friendly composite plasticizer which is based on a diethylene glycol dibenzoate type plasticizer and di(2-ethylhexyl) terephthalate and can comprise epoxy compounds, adipate compounds, dicaprate compounds and trimellitate compounds. The environment-friendly composite plasticizer can be used as a main plasticizer of polyvinyl chloride resin and other resins. The invention also relates to a preparation method of the environment-friendly composite plasticizer and ingredients thereof, namely the diethylene glycol dibenzoate type plasticizer and the di(2-ethylhexyl) terephthalate. The environment-friendly composite plasticizer has the characteristics of high intermiscibility, plasticizing efficiency, cold resistance, heat resistance, pollution resistance, extraction resistance, migration, electric insulation, light and heat stability and the like, and is widely applied in plasticizing industry.

Description

technical field [0001] The invention relates to a chemical plasticizer and a preparation method, which can be used as an environment-friendly composite plasticizer as the main plasticizer of polyvinyl chloride (PVC) and other resins. technical background [0002] Plasticizers are the largest additives in the modern plastics industry, accounting for 60% of the total output of plastic additives. Among them, phthalates as plastic plasticizers account for more than 50% of the market share of plasticizers. Dioctyl phthalate (DOP), as the main plasticizer, was suspected of carcinogenicity by the National Cancer Institute (NCI), and its use was restricted. People are looking for and researching alternatives that are safer and perform better than DOP. Diethylene glycol dibenzoate (DEDB) and bis(2-ethylhexyl) terephthalate (DOTP) are the two most common environmentally friendly plasticizers, which can replace DOP as the main plasticizer , has the value of promotion and application....

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08K5/10C08K5/103C08K5/12C08K5/00C08K5/1515C08K5/11C08L27/06

Inventor 沈健章金富王艳涛沈海平

Owner 浙江嘉澳环保科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com