Lightweight heat-resistant flame-retardant modified PVC resin compound-mixed cable material and preparation method thereof

A PVC resin and cable material technology, applied in the direction of insulating cables, plastic/resin/wax insulators, cables, etc., can solve the problems of scratch resistance, poor flame retardancy, resistance to humidity, cold and heat, etc., and achieve excellent heat resistance Effects of improved flame retardancy, dispersibility and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

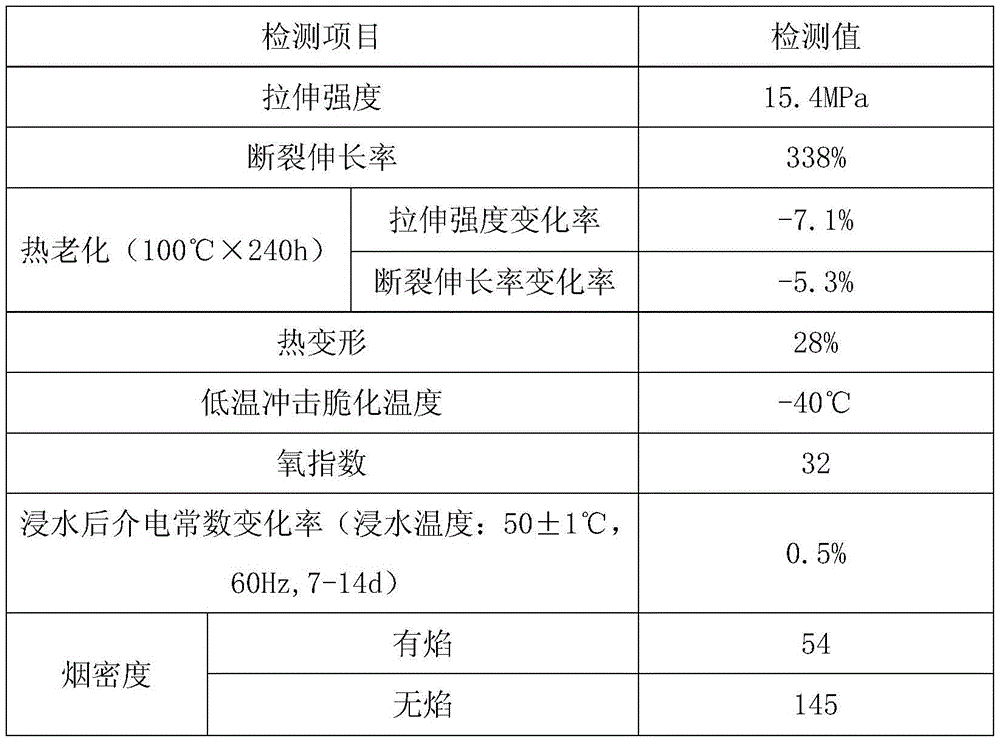

Examples

Embodiment

[0012] The cable material of this embodiment is made of the following raw materials in parts by weight: PVC resin 60, ethylene-vinyl acetate copolymer 38, tromarin 0.02, expandable graphite 15, polytetramethylene glycol ether 6, silicic acid Aluminum 22, oleic acid 3, hexamethyldiazasilane 4, cotton pulp 30, zinc stearate 4, diethylene glycol dibenzoate 16, color masterbatch 10, additive 3.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: polypropylene adipate 4, octyltin maleate 2, calcium zinc stabilizer 4, 600 mesh attapulgite powder 18, sodium metasilicate 2, three Sodium polyphosphate 4, the preparation method is: first dissolve sodium metasilicate in water to prepare an aqueous solution with a concentration of 6%, then put it into attapulgite, soak for 12 hours and then filter, dry and dehydrate the filtrate and mix it with other remaining materials , Grind and disperse for 40 minutes to obtain the auxiliary agent.

[0014] Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com