High-modulus bituminous concrete additive

An asphalt concrete and additive technology, applied in the field of asphalt pavement materials, can solve the problems of low-temperature cracks on the pavement, unfavorable popularization and application, and single product performance, so as to maintain the balance of natural landscape and ecological environment, low price, and water stability. and the effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In the proportioning of the present embodiment, with 1.11kg as 1 part, the parts by weight of each component of the raw materials used are:

[0020] 68 parts of waste polyethylene

[0021] 10 parts polypropylene

[0022] 5 parts ethyl acetate

[0023] Dioctyl phthalate and 19 tert-dodecyl mercaptan are mixed in a mass ratio of 1:2 1 part

[0024] Preparation method: After mixing the above components evenly at room temperature, put them into a twin-screw extruder, control the blending temperature at 170°C when starting up, extrude semi-finished cylindrical strips, cool in a cooling water tank, enter a pelletizer, and cut evenly Granules with a length of 3 to 5 mm are obtained to obtain the product of the present invention.

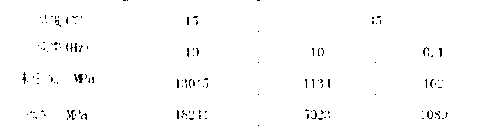

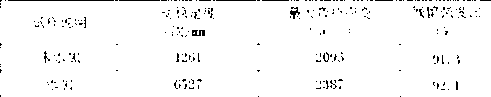

[0025] The main detection indicators of the high modulus asphalt concrete additive prepared in this example are shown in Table 1.

[0026] Table 1 Inspection results of high modulus additive products

[0027] project Test conditions...

Embodiment 2

[0036] In the proportioning of the present embodiment, with 0.87kg as 1 part, the parts by weight of each component of the raw materials used are:

[0037] 90 parts of waste polyethylene

[0038] Polypropylene 18 parts

[0039] 6 parts ethyl acetate

[0040] Mix 1 part of diisobutyl phthalate and isooctyl 3-mercaptopropionate at a mass ratio of 1:3

[0041] Its preparation method is identical with embodiment 1. After testing, after adding the high modulus additive of the present invention, the dynamic modulus, dynamic stability, failure strain, residual strength ratio, and fatigue performance index of the asphalt mixture are compared with the test results without adding the product of the present invention. The indicators have been greatly improved.

Embodiment 3

[0043] In the proportioning of the present embodiment, with 0.80kg as 1 part, the parts by weight of each component of the raw materials used are:

[0044] Waste polyethylene 89 parts

[0045] Polypropylene 27 parts

[0046] 8 parts ethyl acetate

[0047] Diethylene glycol dibenzoate and ethyl mercaptan are mixed in a mass ratio of 1:4 1 part

[0048] Its preparation method is identical with embodiment 1. After testing, after adding the high modulus additive of the present invention, the dynamic modulus, dynamic stability, failure strain, residual strength ratio, and fatigue performance index of the asphalt mixture are compared with the test results without adding the product of the present invention. The indicators have been greatly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com