Mouse-proof optical cable rubber sleeve

A technology of rubber sleeves and optical cables, applied in optics, light guides, optical components, etc., can solve problems such as difficult line maintenance, optical cables being bitten by rodents, and unsatisfactory anti-rat effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

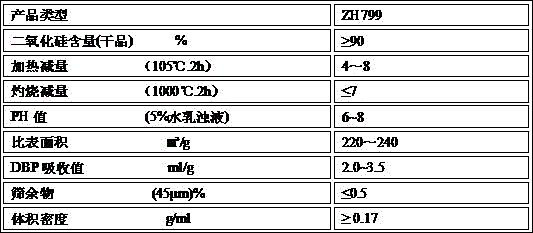

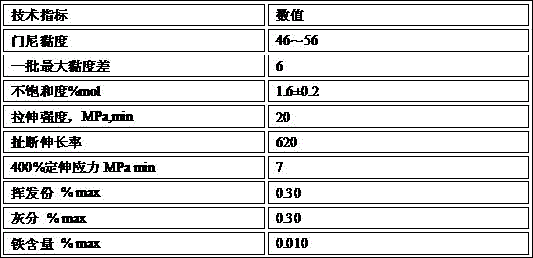

Method used

Image

Examples

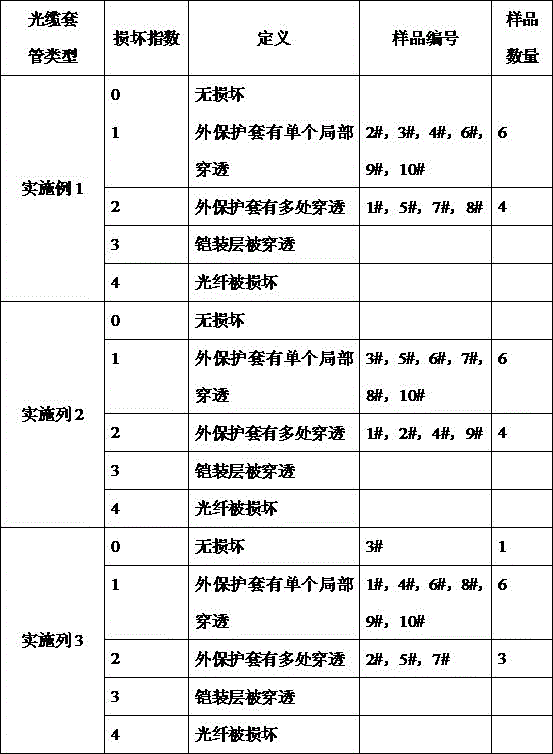

example 1

[0043] A rat-proof optical cable rubber sleeve, which is composed of an innermost insulating layer, a middle sandwich layer and an outermost protective layer,

[0044] The insulating layer is made of the following raw materials in parts by weight: EPDM rubber, 40; silicone rubber, 45; stearic acid, 4; polyethylene glycol PEG4000, 0.3; white carbon black, 14; carbon black N568, 18; carbon black N765, 16; light calcium carbonate, 25; paraffin oil 2280, 25;

[0045] The sandwich layer is made of the following raw materials in parts by weight: natural rubber, 70; polyurethane rubber, 20; mustard, 8; pepper, 5; pepper, 5; carbon black N550, 35; carbon black N774, 20; Plasticizer DEDB, 10; Antiaging agent A, 3; Vulcanizing agent, 2; Diatomaceous earth, 20; Accelerator TMTD, 1; Fumed silica, 12;

[0046] The protective layer is made of the following raw materials in parts by weight: EPDM rubber, 20; butyl rubber, 30; fluorine rubber, 30; neoprene rubber, 15; carbon black N660, 25; c...

example 2

[0059] A rat-proof optical cable rubber sleeve, which is composed of an innermost insulating layer, a middle sandwich layer and an outermost protective layer,

[0060] The insulating layer is made of the following raw materials in parts by weight: EPDM rubber, 50; silicone rubber, 55; stearic acid, 6; polyethylene glycol PEG4000, 0.5; white carbon black, 16; carbon black N568, 20; carbon black N765, 18; light calcium carbonate, 30; paraffin oil 2280, 35;

[0061] The sandwich layer is made of the following raw materials in parts by weight: natural rubber, 80; polyurethane rubber, 30; mustard, 10; pepper, 8; pepper, 8; carbon black N550, 45; carbon black N774, 30; Plasticizer DEDB, 15; Antiaging agent A, 5; Vulcanizing agent, 2; Diatomaceous earth, 40; Accelerator TMTD, 2; Fumed silica, 16;

[0062] The protective layer is made of the following raw materials in parts by weight: EPDM rubber, 25; butyl rubber, 40; fluorine rubber, 40; neoprene rubber, 20; carbon black N660, 30; ...

example 3

[0075] A rat-proof optical cable rubber sleeve, which is composed of an innermost insulating layer, a middle sandwich layer and an outermost protective layer,

[0076] The insulating layer is made of the following raw materials in parts by weight: EPDM rubber, 45; silicone rubber, 50; stearic acid, 5; polyethylene glycol PEG4000, 0.4; white carbon black, 15; carbon black N568, 18; carbon black N765, 17; light calcium carbonate, 26; paraffin oil 2280, 30;

[0077] The sandwich layer is made of the following raw materials in parts by weight: natural rubber, 75; polyurethane rubber, 25; mustard, 9; pepper, 7; pepper, 7; carbon black N550, 40; carbon black N774, 25; Plasticizer DEDB, 12; Antiaging agent A, 4; Vulcanizing agent, 2; Diatomaceous earth, 30; Accelerator TMTD, 2; Fumed silica, 15;

[0078] The protective layer is made of the following raw materials in parts by weight: EPDM rubber, 22; butyl rubber, 30; fluorine rubber, 30; neoprene rubber, 18; carbon black N660, 25; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com