Method for producing elasticizer diethylene glycol dibenzoate

A technology of diethylene glycol dibenzoate and production method, which is applied in the production field of plasticizer diethylene glycol dibenzoate, can solve the problems of toluene environmental pollution, complex production process, equipment corrosion, etc., and achieve resistance Good pollution, safe and stable process operation, good light denaturation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

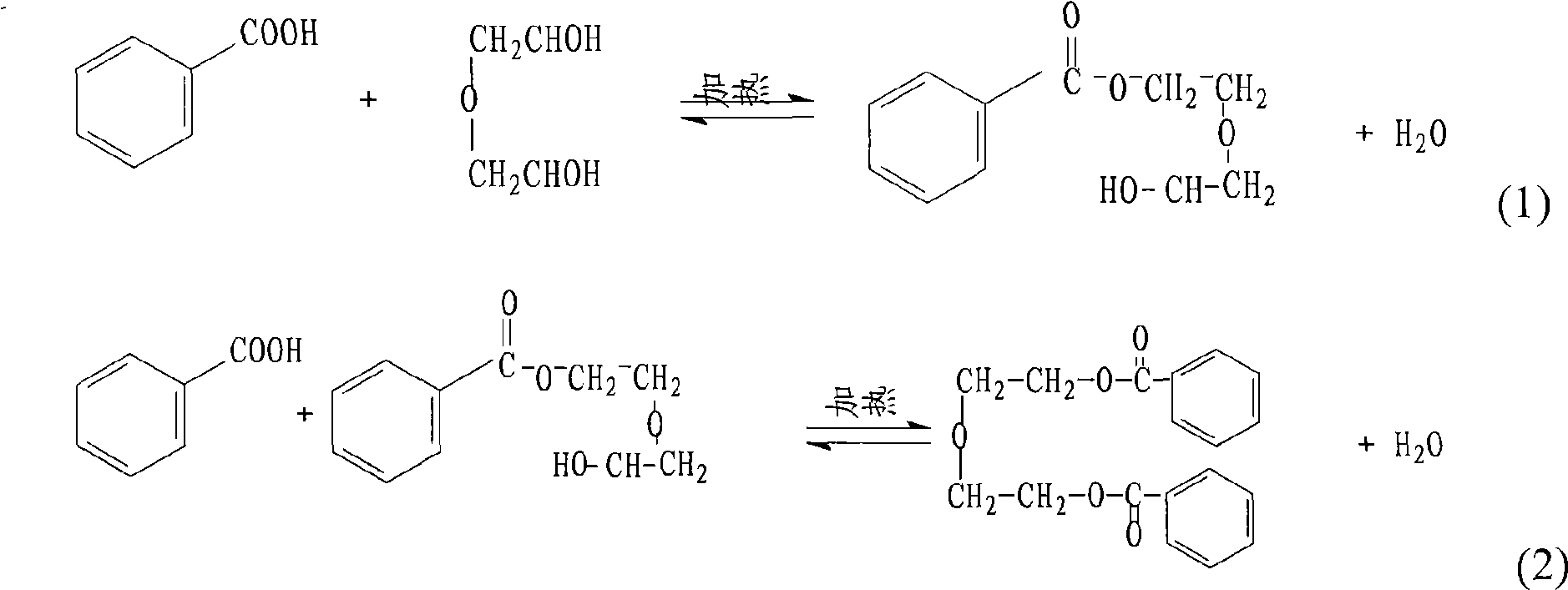

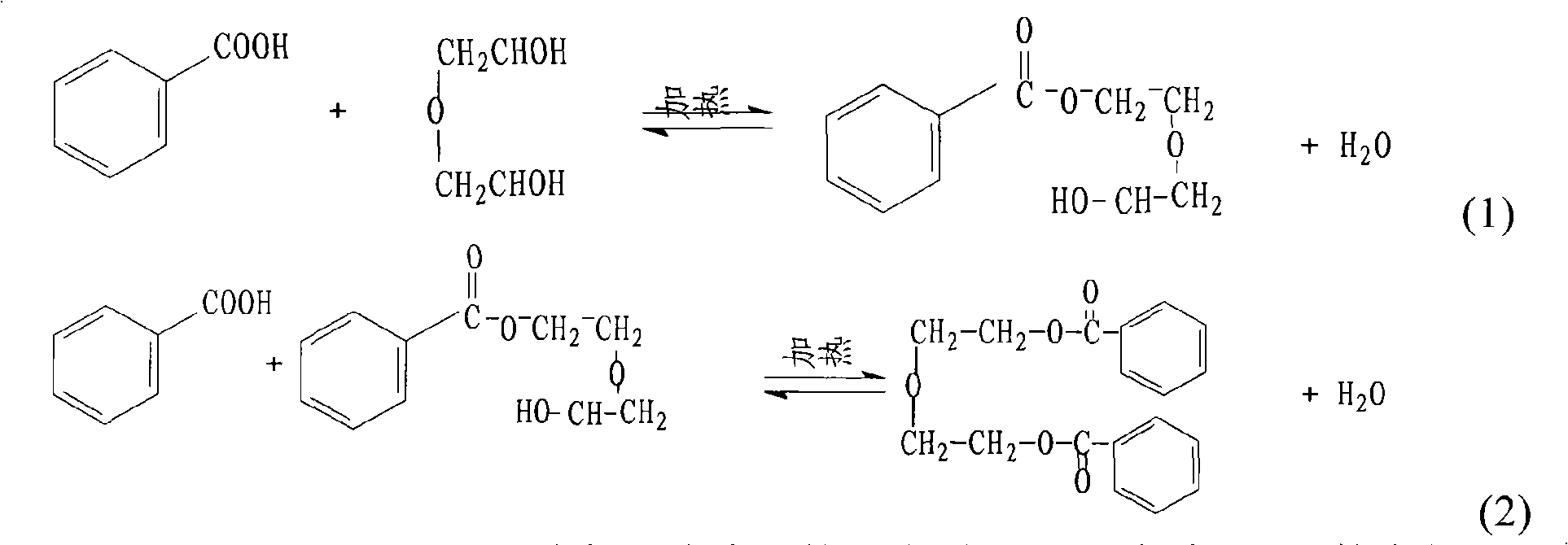

Method used

Image

Examples

Embodiment 1

[0020] at 30m 3 Drop into 13300kg of benzoic acid and 6700kg of diethylene glycol in a stainless steel reactor, and heat up (hot oil temperature 220°C-250°C). All the benzoic acid is dissolved, start the stirring, add the composite catalyst tetraisopropyl titanate and 10kg of solid titanium-based compound, continue to heat up to 190°C-210°C, and keep it warm for 4-6 hours to complete the reaction. Then lower the temperature to 190±2°C, dealcoholize under reduced pressure (vacuum degree≤-0.095Mpa) to obtain crude DEDB. Add 20kg of diatomaceous earth and 25kg of activated carbon, and obtain DEDB through traditional decolorization and filtration methods.

Embodiment 2

[0022] at 30m 3 Drop into 13300kg of benzoic acid and 6700kg of diethylene glycol in a stainless steel reactor, and heat up (hot oil temperature 220°C-250°C). All the benzoic acid is dissolved, start stirring, add the composite catalyst tetraisopropyl titanate and 16 kg of solid titanium-based compound, continue to heat up to 190°C-210°C, and keep it warm for 4-6 hours to complete the reaction. Then lower the temperature to 190±2°C, dealcoholize under reduced pressure (vacuum degree≤-0.095Mpa) to obtain crude DEDB. Add 25kg of diatomaceous earth and 30kg of activated carbon, and obtain DEDB through traditional decolorization and filtration methods.

Embodiment 3

[0024] at 30m 3 Drop into 13400kg of benzoic acid and 6600kg of diethylene glycol in a stainless steel reactor, and heat up (hot oil temperature 220°C-250°C). All the benzoic acid is dissolved, start stirring, add the composite catalyst tetraisopropyl titanate and 14kg of solid titanium-based compound, continue to heat up to 190°C-210°C, and keep the temperature for 4-6 hours to complete the reaction. Then lower the temperature to 190±2°C, dealcoholize under reduced pressure (vacuum degree≤-0.095Mpa) to obtain crude DEDB. Add 20kg of diatomaceous earth and 25kg of activated carbon, and obtain DEDB through traditional decolorization and filtration methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com