Preparation method of terylene low temperature dyeing carrier composition

A low-temperature dyeing and composition technology, which is applied in the directions of dyeing, textile and papermaking, etc., can solve the problems of high cost of polyester low-temperature carrier composition, pollute the environment, and difficult to remove, and achieve low cost, high color fastness, and easy removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

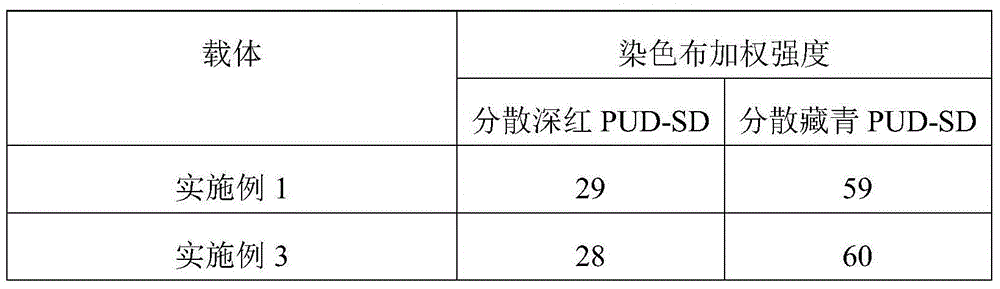

Embodiment 1

[0020] First, the weight fraction is 50 parts of ethyl benzoate, the weight fraction is 30 parts of N-n-butyl phthalimide, the weight fraction is 15 parts of tristyrylphenol polyoxyethylene ether, and the weight fraction is 5 parts of ethylene glycol Mix alcohol and phenylene ether, then raise the temperature to 60°C and stir for 1 hour, then cool down to 40°C and discharge.

Embodiment 2

[0022] First, the weight fraction is 20 parts of methyl cinnamate, the weight fraction is 40 parts of N-isopropyl phthalimide, the weight fraction is 20 parts of castor oil polyoxyethylene ether (EL-40), and the weight fraction is 10 parts of isomeric tridecyl alcohol polyoxyethylene ether (n EO =9), the weight fraction is 10 parts of ethylene glycol monobutyl ether and mixed, then, the temperature is raised to 65°C and stirred for 1 hour, and then the temperature is lowered to 45°C, and the material is discharged.

Embodiment 3

[0024] First, the weight fraction is 60 parts of phthalimide, the weight fraction is 20 parts of N-isopropyl phthalimide, the weight fraction is 15 parts of tristyrylphenol polyoxyethylene ether, the weight fraction Mix 5 parts of isopropanol, then raise the temperature to 70°C and stir for 1 hour, then cool down to 45°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com