Environment-friendly method for preparing fluorine-containing polymer microporous film

An environment-friendly and process technology, applied in the field of preparing fluorine-containing polymer microporous membranes, can solve the problems of complex post-treatment process, potential safety hazards, environmental pollution, etc., and achieve environmental friendliness, high penetration, and excellent mechanical properties. and the effect of separation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

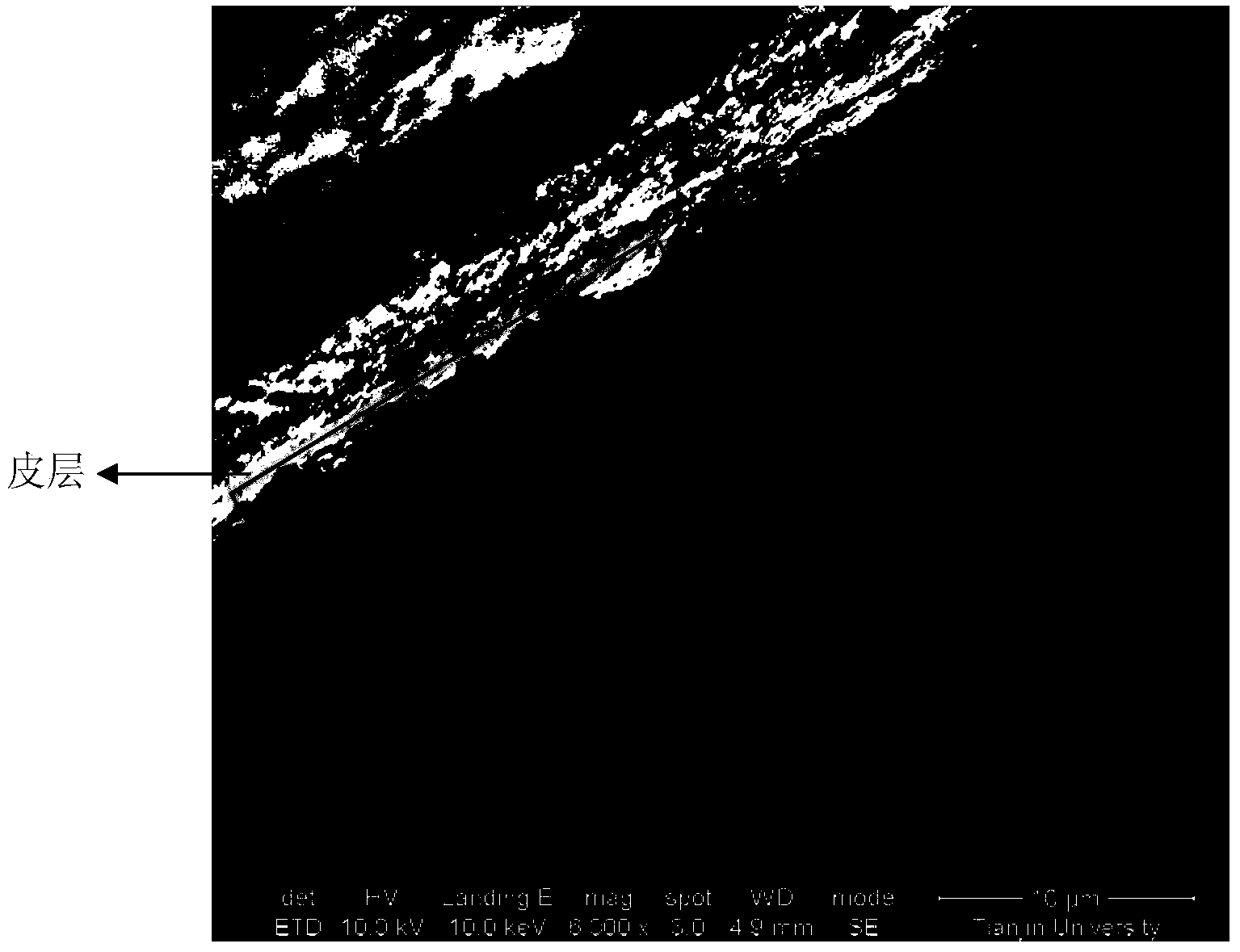

[0023] Add solid-liquid mixture A consisting of 60 g of vinylidene fluoride-hexafluoropropylene copolymer resin and 140 g of 140 g of acetyl triethyl citrate into a stirring tank and mix. Heated to 160°C in a stirred tank, with a stirring speed of 100r / min, under nitrogen protection, stirred at a temperature of 160°C for 7 hours, and left to defoam for 24 hours to form a uniform casting solution; pass the formed casting solution through a hollow The fiber membrane forming machine is processed and formed into a hollow fiber membrane primary membrane; the primary membrane is immersed in a gel bath composed of a mixed solution of acetyl triethyl citrate and ethanol at 8°C to solidify and form, wherein the ethanol is in the gel bath The mass percentage content in the hollow fiber membrane is 85%; ethanol is used as the extractant to extract the acetyl triethyl citrate in the hollow fiber membrane, and then dried at room temperature to obtain the vinylidene fluoride-hexafluoropropyl...

Embodiment 2

[0027]Add solid-liquid mixture A consisting of 60 g of vinylidene fluoride-hexafluoropropylene copolymer resin and 140 g of 140 g of acetyl triethyl citrate into a stirring tank and mix. Heat to 170°C in a stirred tank, the stirring speed is 120r / min, under nitrogen protection, stir at 170°C for 12 hours, stand for defoaming for 24 hours, and form a uniform casting solution; pass the casting solution through a hollow fiber film forming machine Processing and molding to make a hollow fiber membrane nascent membrane; immerse the nascent membrane in a gel bath composed of a mixed solution of acetyl triethyl citrate and n-butanol at 5°C to solidify and form, wherein n-butanol is in the gel bath The mass percent content is 30%; use n-butanol as the extractant to extract the acetyl triethyl citrate in the hollow fiber membrane, and then dry it at room temperature to obtain the vinylidene fluoride-hexafluoropropylene copolymer hollow fiber membrane ; The rectification process is used...

Embodiment 3

[0030] Add solid-liquid mixture A consisting of 40 g of polyvinylidene fluoride resin and 160 g of tri-n-hexyl citrate into a stirring tank and mix. Heat to 160°C in a stirred tank, the stirring speed is 90r / min, under nitrogen protection, stir at 160°C for 10 hours, stand for defoaming for 24 hours, and form a uniform casting solution; pass the casting solution through a hollow fiber film forming machine Processing and molding to make a hollow fiber membrane nascent membrane; immerse the nascent membrane in a gel bath composed of a mixed solution of tri-n-hexyl citrate and ethanol at 10°C to solidify and form, wherein the mass percentage of ethanol in the gel bath is 30% %; using ethanol as an extractant to extract the tri-n-hexyl citrate in the hollow fiber membrane, and then drying at room temperature to obtain a polyvinylidene fluoride hollow fiber membrane; using a rectification process to separate the mixture of ethanol and tri-n-hexyl citrate , recovery of ethanol and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Antenna | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com