Patents

Literature

92 results about "Dipropylene Glycol Dibenzoate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

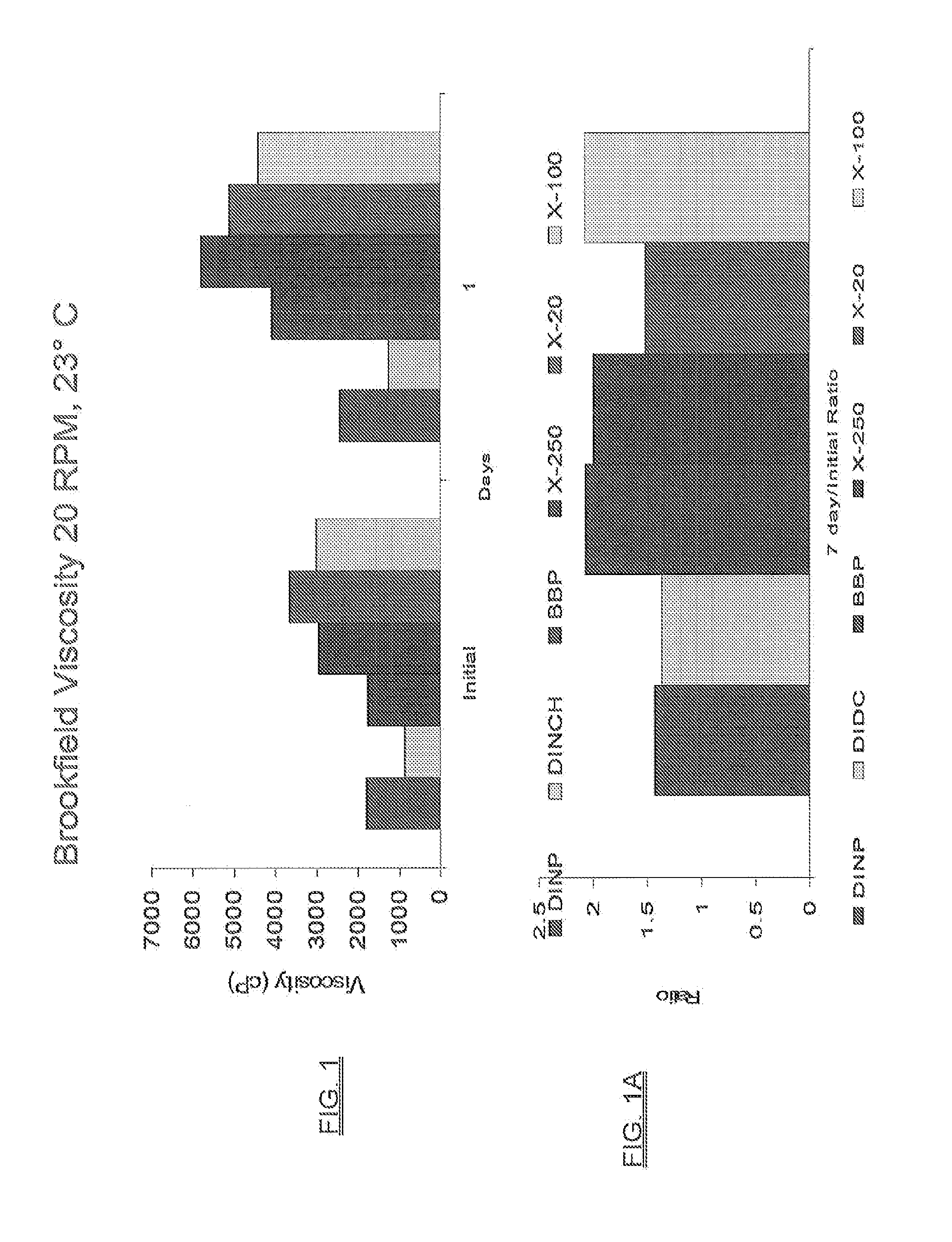

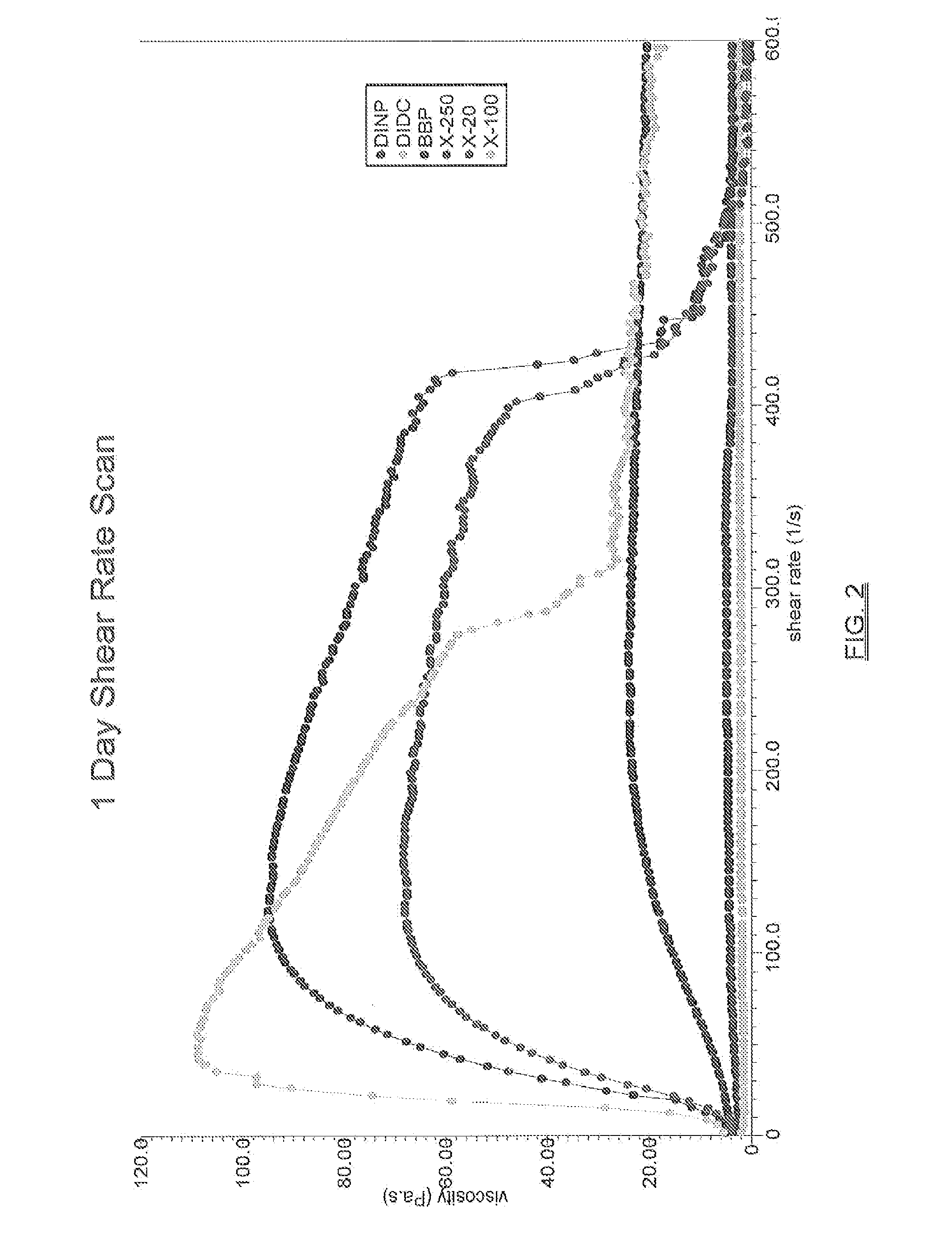

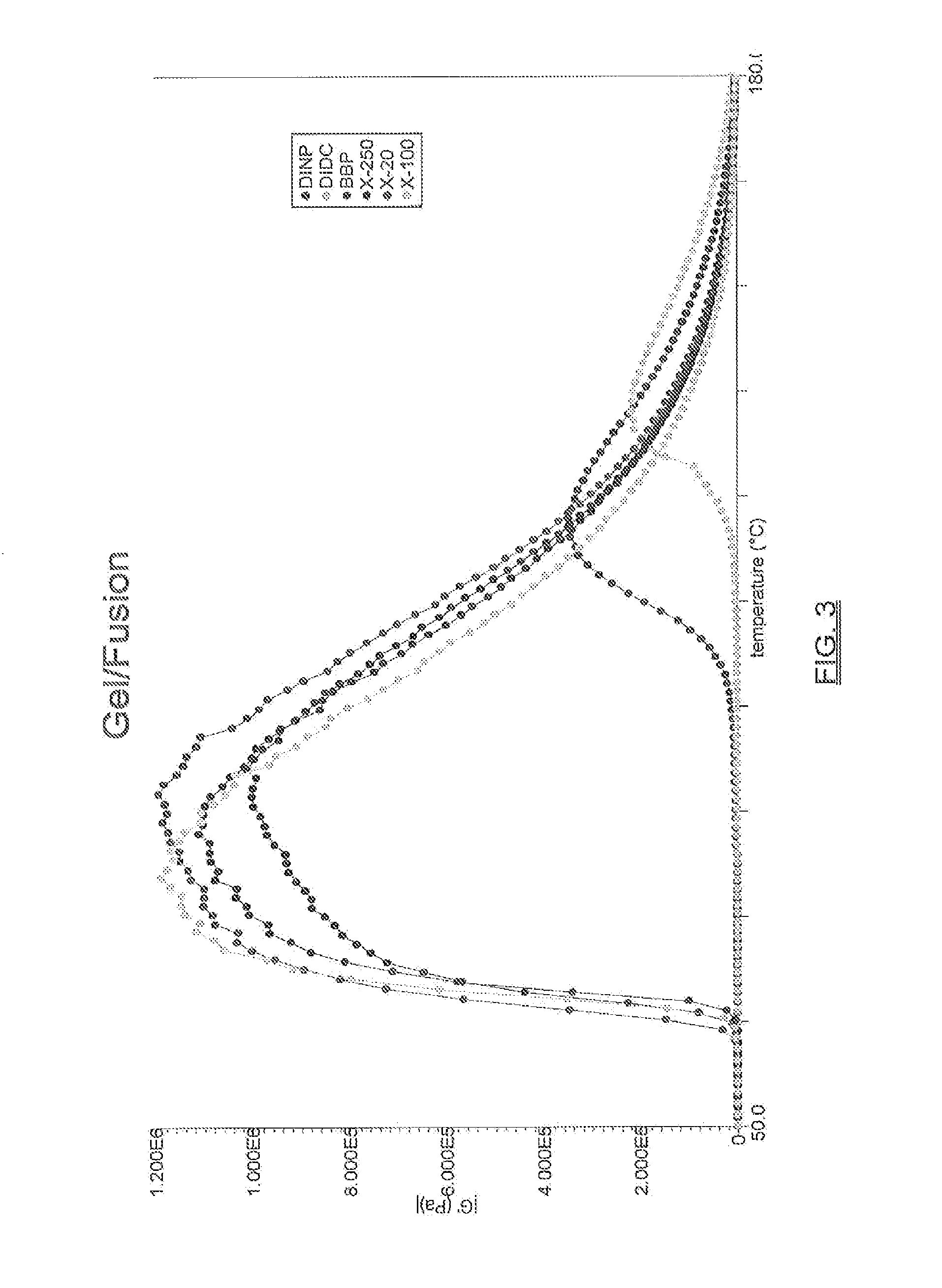

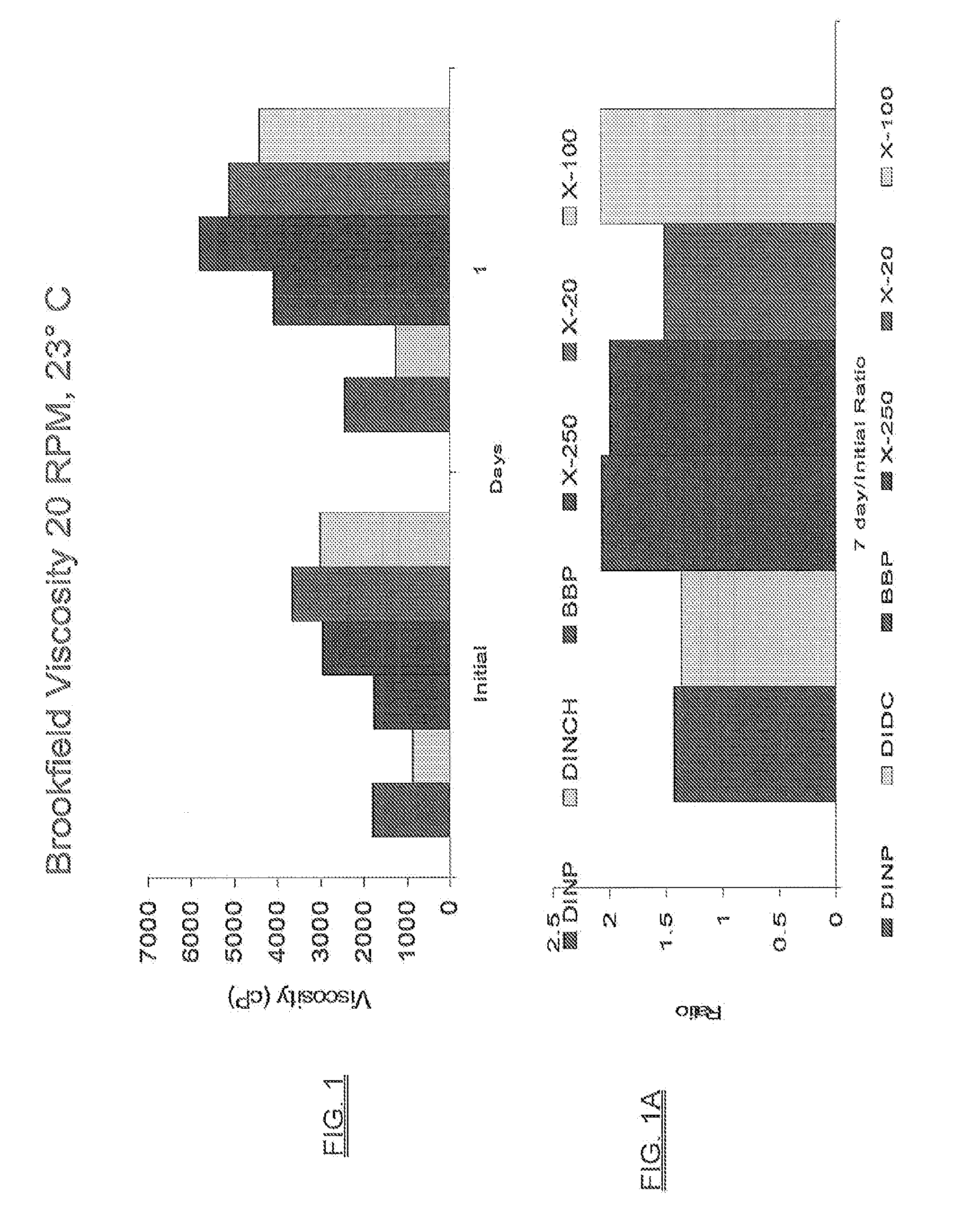

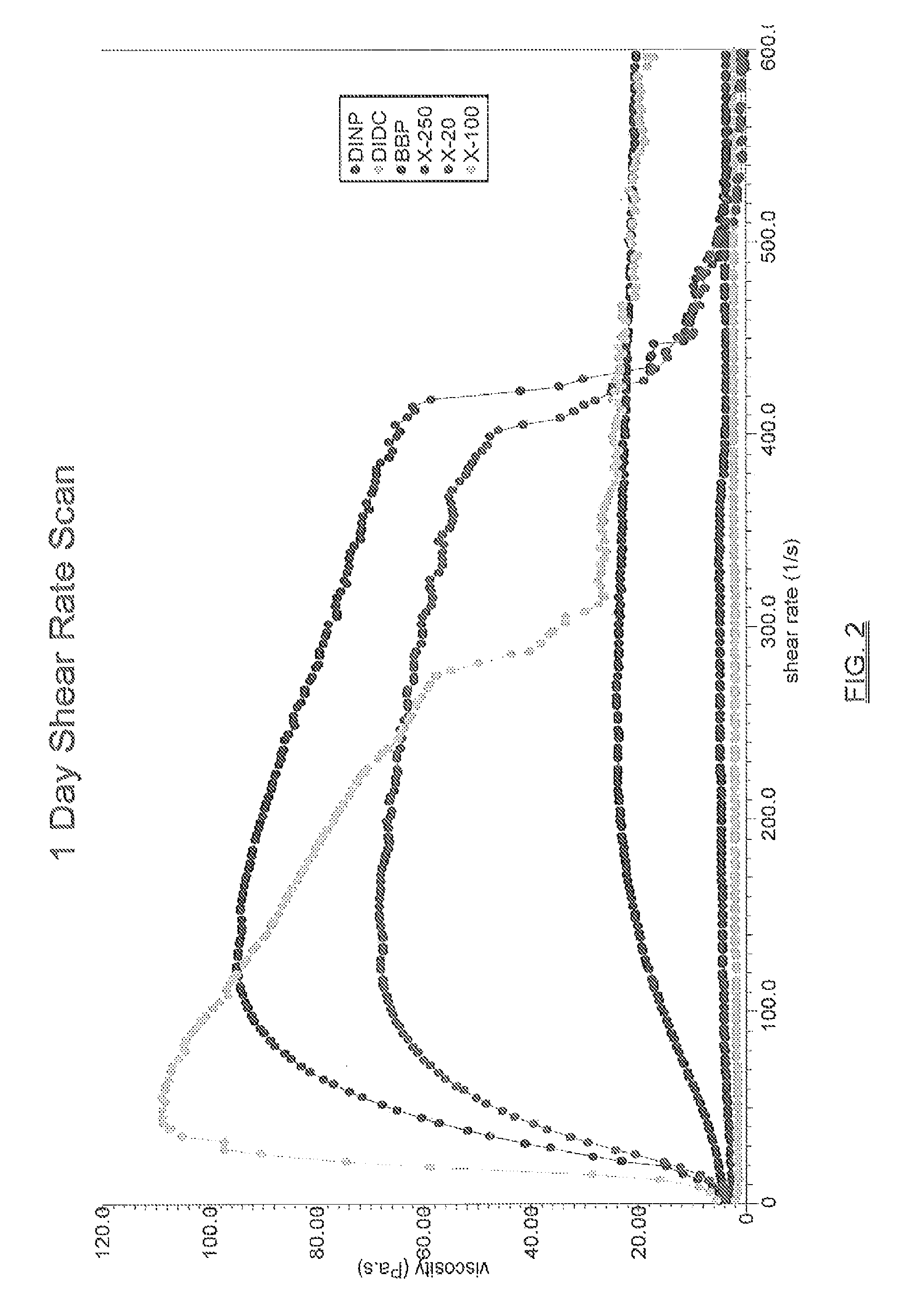

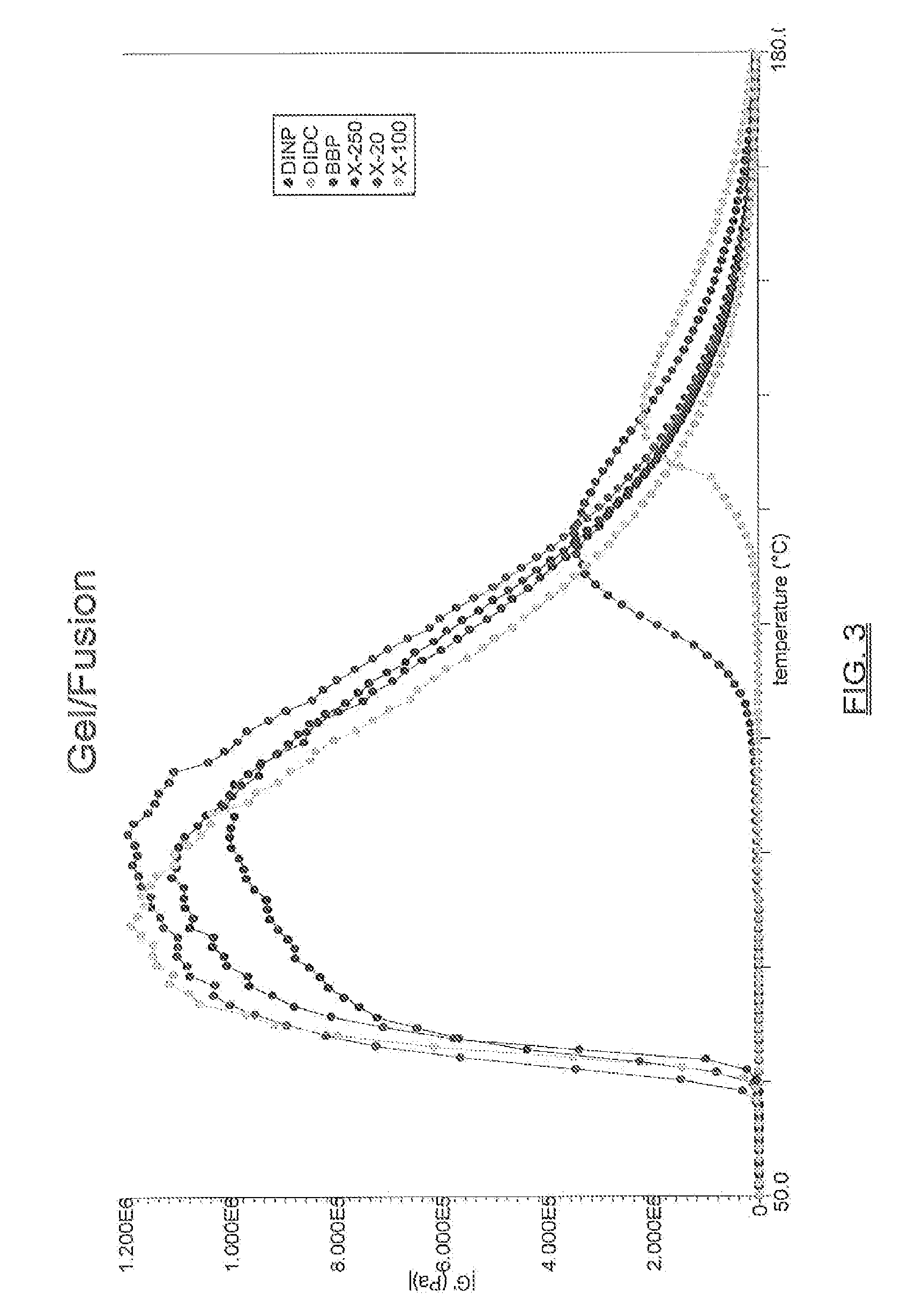

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

PVC gloves production method using non-o-benzene plasticiser

The invention provides a PVC glove production method by using a non-o-benzene plasticizer. The method is mainly used on the improvement of the materials that are used. The materials that are used are as follows: 100 portions of PVC powder, 20 to 40 portions of dipropylene glycol dibenzoate, 10 to 15 portions of epoxidized soybean oil, 10 to 35 portions of diethylene glycol dibenzoate, 5 to 20 portions of C8-C12 higher fatty alcohol benzoic ether, 1.5 to 3 portions of calcium-zinc stabilizer as well as 20 to 35 portions of viscosity reducer. The PVC gloves produced by the PVC glove production method by using a non-o-benzene plasticizer provided by the invention has the advantages of no poison, environment protection, better quality and lower cost.

Owner:郑建明

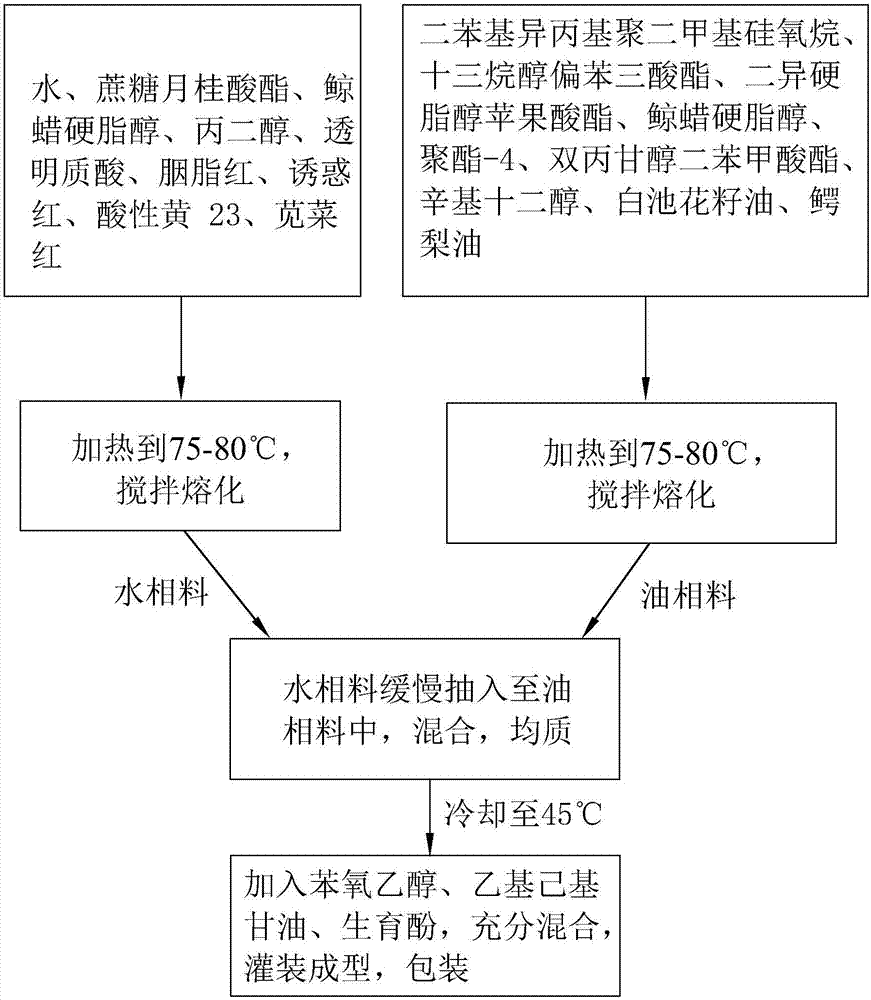

Cup sticking prevention lip gloss with maintenance function

InactiveCN107184432AEvenly dispersedFully moisturizedCosmetic preparationsMake-upPolyesterMeadowfoam seed oil

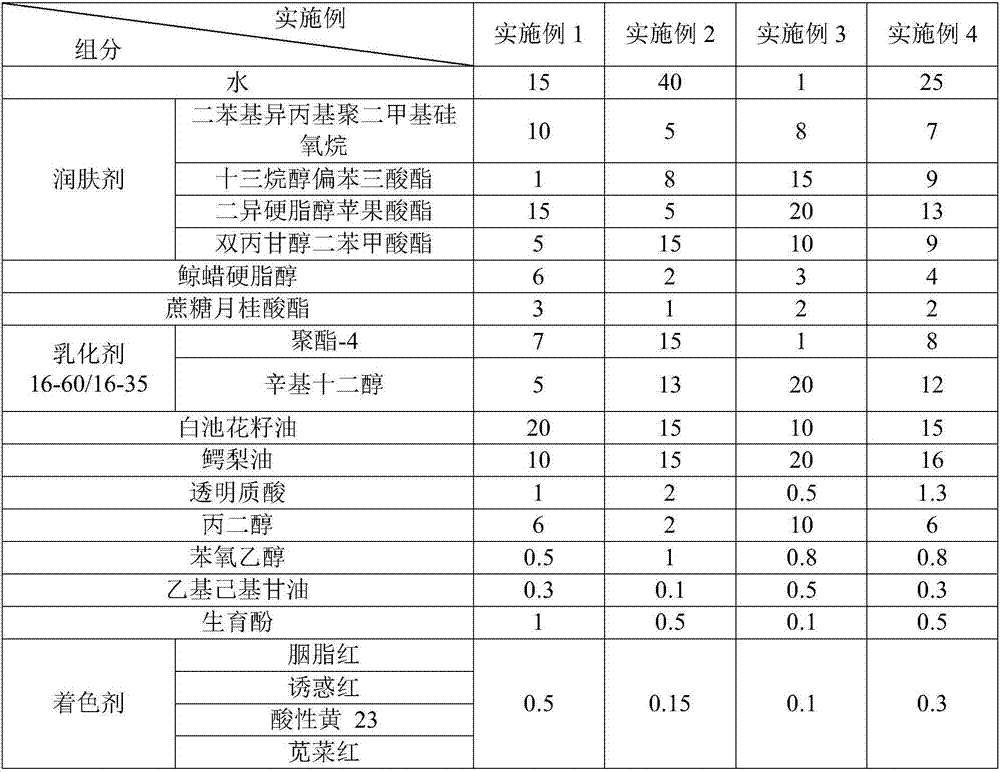

The invention discloses cup sticking prevention lip gloss with a maintenance function. The lip gloss comprises, by weight, 1-40 parts of water, 2-6 parts of cetostearyl alcohol, 10-20 parts of meadowfoam seed oil, 10-20 parts of avocado oil, 1-3 parts of sucrose laurate, 2-10 parts of propylene glycol, 0.5-2 parts of hyaluronic acid, 0.5-1 part of phenoxyethanol, 0.1-0.5 part of ethylhexylglycerin, 0.1-1 part of tocopherol, 16-60 parts of emollient, 6-35 parts of emulsifying agents and 0.1-0.5 part of coloring agents. The emollient comprises at least two of diphenyl isopropyl polydimethyl siloxane, tridecyl trimellitate, diisostearyl malate and dipropylene glycol dibenzoate; the emulsifying agents comprise at least one of polyester-4 and octyldodecanol; the coloring agents comprise at least three of carmine, allura red, acid yellow 23 and amaranth. The lip gloss has the maintenance functions of preserving moisture, moisturizing skin and the like and does not easily fade.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

Cold-resistant PVC sheath material for cable and preparation method thereof

InactiveCN103524930AHigh tensile strengthStrong impact resistanceInsulated cablesInsulated conductorsEpoxyPolyvinyl chloride

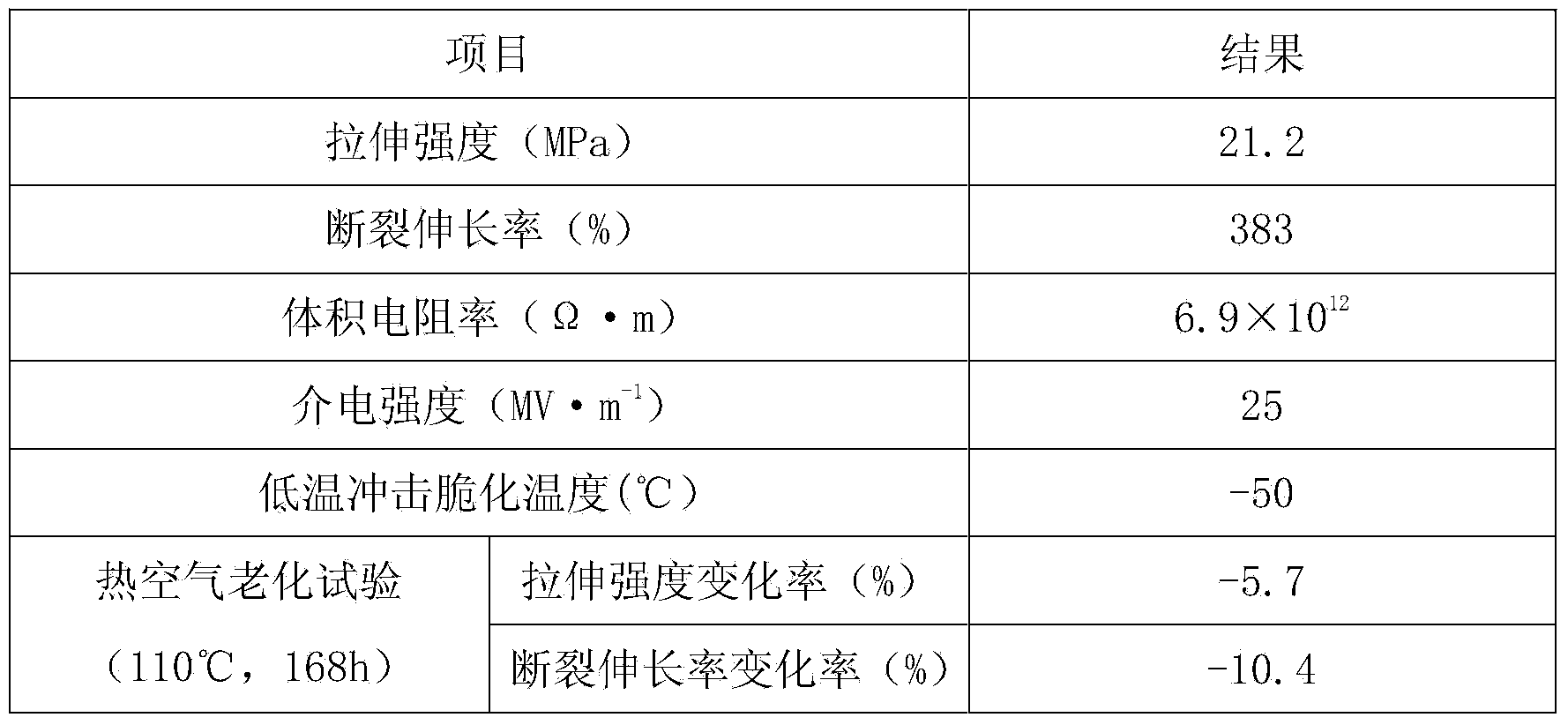

The invention discloses a cold-resistant PVC sheath material for a cable and a preparation method thereof. The sheath material comprises the following raw materials in parts by weight: 75-95 of SG-4 type polyvinyl chloride, 15-25 of chlorosulfonated polyethylene, 10-15 of chloroprene rubber, 10-15 of dioctyl epoxy tetrahydrophthalate, 5-10 of di-isobutyl adipate, 4-7 of ACR, 2-3 of N,N'-ethylene hisstearamide, 8-12 of dipropylene glycol dibenzoate, 1-1.5 of an antioxidant 246, 10-15 of decabromodiphenyl oxide, 5-10 of ammonium polyphosphate, 1-2 of dibasic lead phosphite, 1-2 of tribasic lead sulfate, 2-3 of barium stearate, 4-8 of epoxidized soybean oil, 3-6 of titanium dioxide, 20-30 of acetylene carbon black, 5-10 of calcined loess, 10-15 of active calcium carbonate, and 4-6 of a composite filler. The sheath material has high cold resistance, has the low temperature impacting brittleness temperature of up to -50 DEG C, also still maintains excellent tensile strength, impact resistance, abrasion resistance, aging resistance and the like under a low temperature condition, is durable in use, and has broad application prospects.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

Dibenzoate plasticizers/coalescent blends for low VOC coatings

ActiveUS20130274395A1Reduce volatilityGood performance benefit in glossNon-macromolecular adhesive additivesInksEmulsionDiethylene glycol

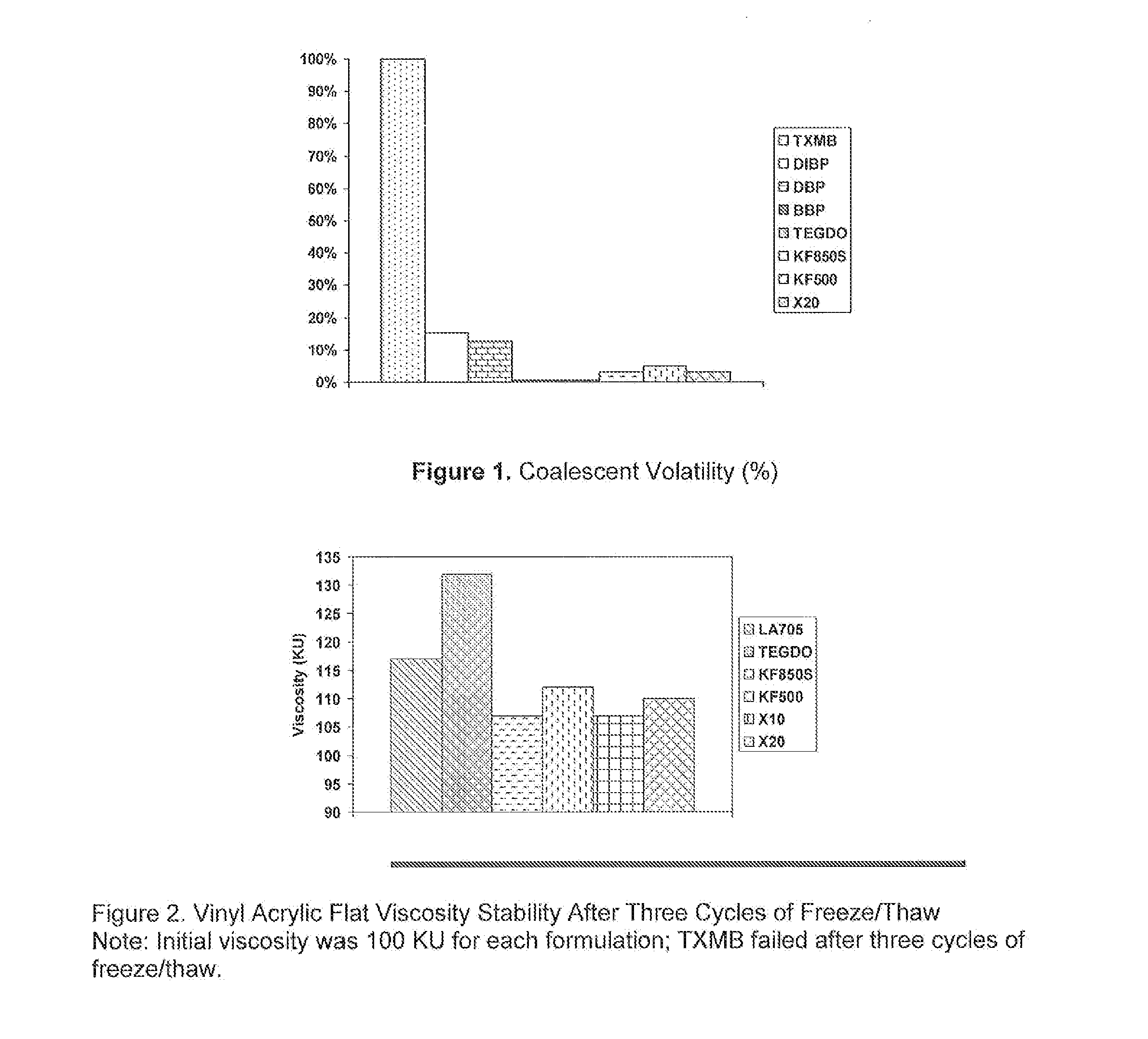

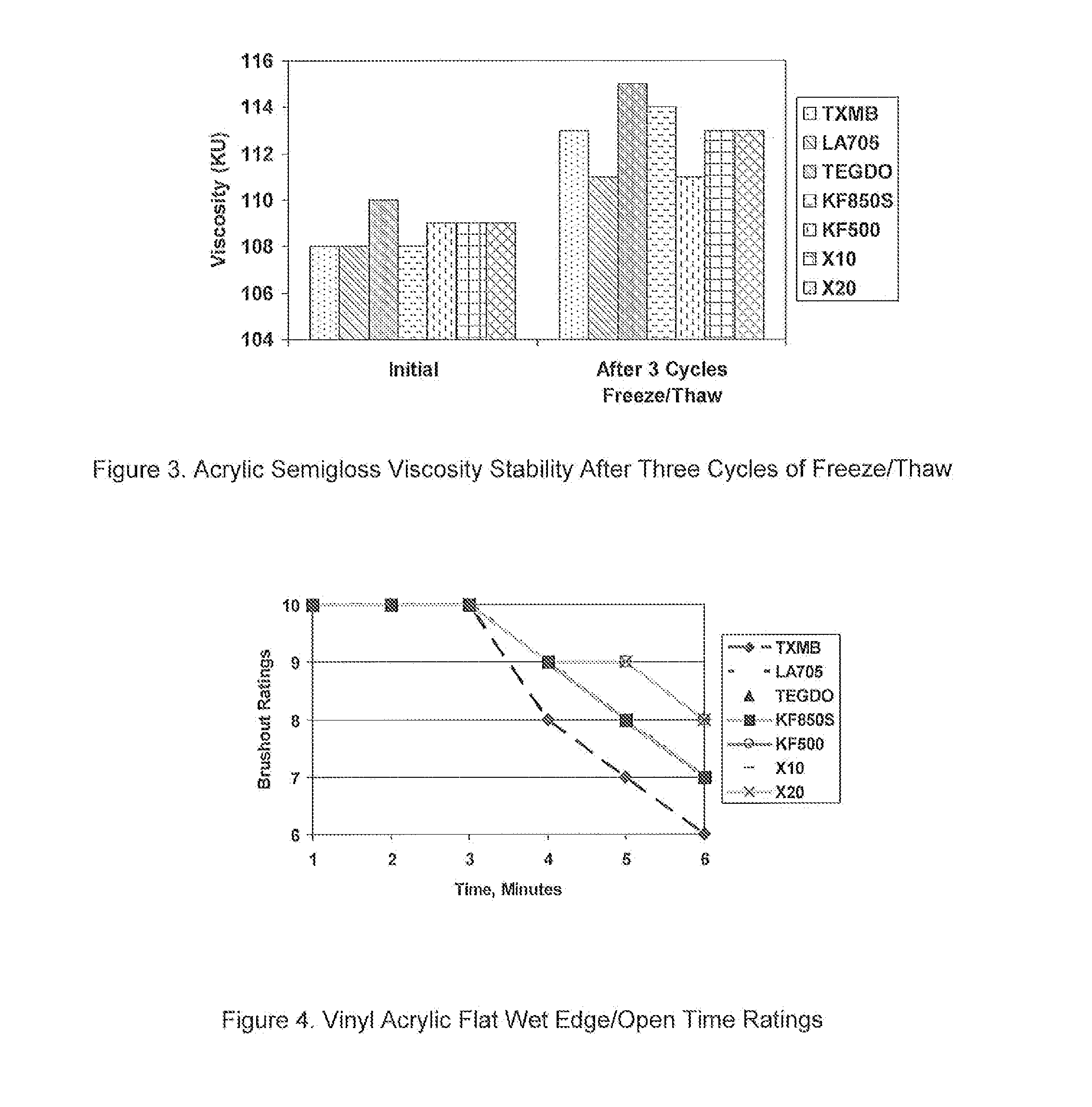

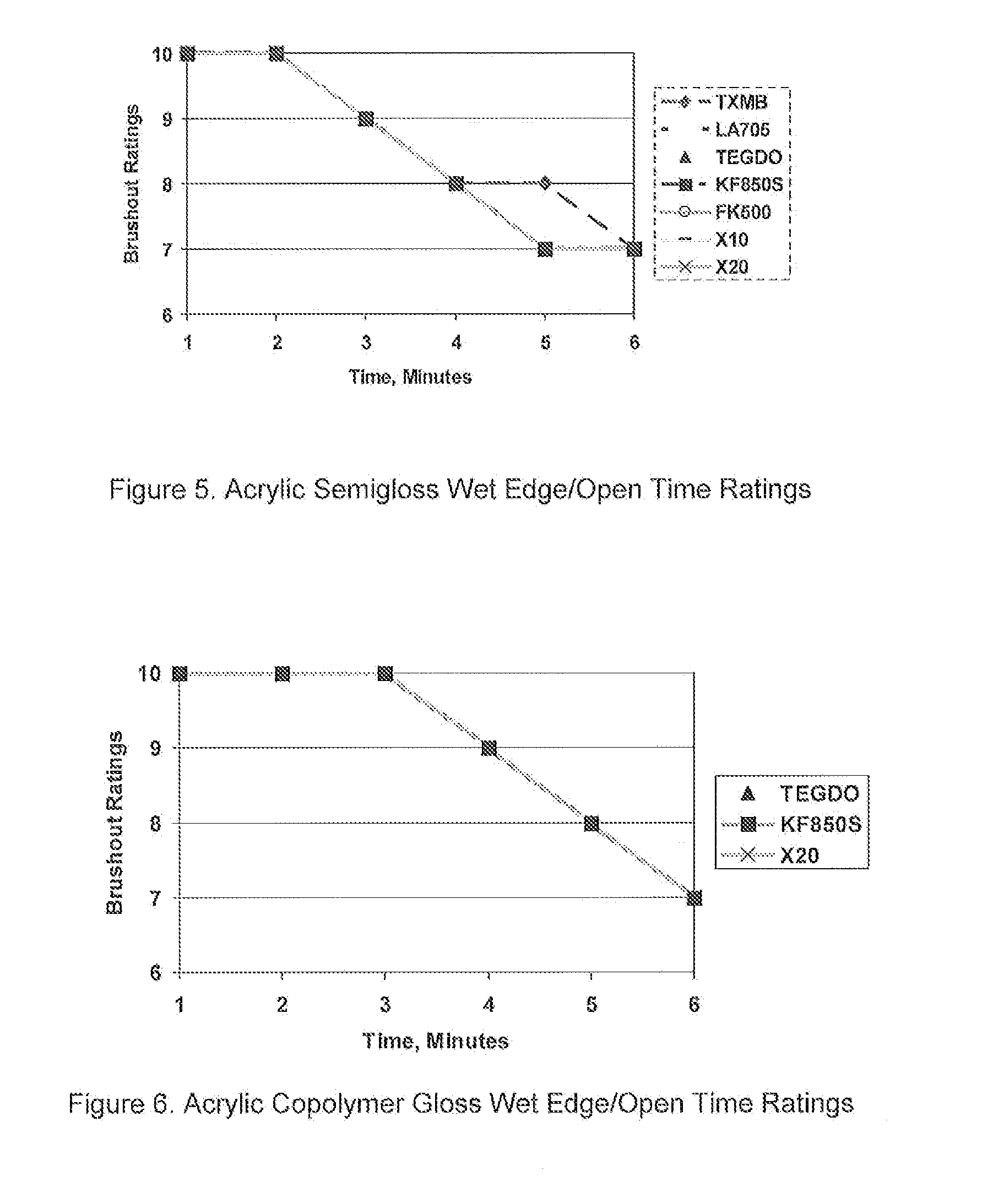

A novel, low volatility, non-phthalate plasticizer / coalescent blend for use in paints and other polymeric coatings comprises a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate. The triblend when used in a paint or other coatings achieves a low VOC paint or coating having stable viscosity after three freeze / thaw cycles and equivalent or superior wet edge / open time ratings, gloss ratings, scrub resistance and block resistance when compared to traditional coalescents, including without limitation high VOC coalescents, low VOC non-dibenzoate coalescents and other dibenzoate blends. The triblend may be used as a substitute or alternative coalescent in latex and acrylic emulsion coatings, among others, to achieve a lower VOC content without sacrificing performance properties.

Owner:EMERALD KALAMA CHEM

Preparation method of elastic disposable PVC (polyvinyl chloride) gloves

The invention discloses a preparation method of elastic disposable PVC (polyvinyl chloride) gloves. Each PVC glove comprises the following raw materials in parts by weight: 100 parts of PVC paste resin, 20-22 parts of dipropylene glycol dibenzoate, 26-28 parts of dioctyl terephthalate, 18-22 parts of fatty acid triglyceride, 1-2 parts of phosphate, 1.5-2.5 parts of acrylate, 0.5-1.5 parts of dihydric alcohol, 0.9-1.3 parts of a calcium-zinc complex heat stabilizer and 17-19 parts of a viscosity reducer. The preparation method comprises the following steps: (1) preparing the raw materials; (2) defoaming in vacuum; (3) preparing the glove by soaking a hand model in defoamed paste and baking, wherein the online temperature of the hand model before demoulding is 90-92 DEG C, the online temperature of the hand model before the soaking of the paste is 90-92 DEG C, the online temperature of the hand model before the soaking of wet powder is 135-137 DEG C, and the online temperature of a wet powder tank is 60-62 DEG C.

Owner:WUXI XINYA SAFETY PROD

Environmentally-friendly quick-drying waterproof veneering glue

InactiveCN103289610AImprove water resistanceFast dryingMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistancePolymer science

The invention relates to an environmentally-friendly quick-drying waterproof veneering glue which is prepared through the following steps of: adding all of 625-635 parts by weight of intermediate material into a reaction kettle, and then adding 208-220 parts by weight of polyvinyl alcohol aqueous solution; adding 12.5-14.0 parts by weight of functional additive DB, 12.5-14.0 parts by weight of DPGDB (dipropylene glycol dibenzoate) and 12.5-14.0 parts by weight of water into the reaction kettle; adding 83-88 parts by weight of starch into the reaction kettle, stirring for 1 hour so that the mixture reacts completely; when the temperature of the materials in the reaction kettle is reduced to be less than 37 DEG C, adding 16.0-16.5 parts by weight of sodium p-methylbenzene sulfonic acid; adding a sterilizing agent and a defoaming agent; filtering by a filter screen of 60 meshes and emptying to obtain the environmentally-friendly quick-drying waterproof veneering glue. The invention aims at providing the environmentally-friendly quick-drying waterproof veneering glue which is environmentally-friendly, good in water resistance performance, high in drying speed and high in adhesive strength and meets the standards.

Owner:河北霖江木业有限公司

One-component laminating glue

InactiveCN103275655AEasy to useFast constructionMonocarboxylic acid ester polymer adhesivesTO-18Polyvinyl alcohol

The invention relates to a one-component laminating glue which comprises the following components in parts by weight: 900 to 945 parts of intermediate material, 25 to 30 parts of polyvinyl alcohol aqueous solution PVA-H2O with the weight percent concentration of 17%, 10 to 15 parts of AlCl3, 0.5 to 1.2 parts of mineral oil defoamer 691, 12 to 18 parts of multifunctional additive DB and 8 to 12 parts of plasticizer DPGDB (Dipropylene Glycol Dibenzoate), wherein the one-component laminating glue is formed by mixing all the components. The one-component laminating glue is very convenient to use, rapid in construction speed and low in cost. In addition, for the one-component laminating glue, the quality is further guaranteed; the heat-resistant performance is improved obviously; the service life and the open period are prolonged; and the one-component laminating glue generates little pollution to the environment.

Owner:河北霖江木业有限公司

Polyurethane anticorrosive thermal-insulation paint and preparation method thereof

InactiveCN104761993AReduce volatilityReduce dosageAntifouling/underwater paintsPaints with biocidesThermal insulationSolvent

The invention relates to a polyurethane anticorrosive thermal-insulation paint and a preparation method thereof. The paint comprises a polyurethane prepolymer, diacetone acrylamide, dipropanediol dibenzoate, an aluminate coupling agent LS-822, a dispersing agent triethanolamine, rutile titanium white, a defoaming agent OP-10, kaolin, a mixed solvent, expanded perlite and a preservative. The preparation method comprises the following steps: adding 2.4kg of 55-85 vol% ethanol into every kilo of diacetone acrylamide, dissolving, mixing with the polyurethane prepolymer in a reaction kettle, reacting at 80-140 DEG C for 1-2 hours, and adding the aluminate coupling agent LS-822 and dispersing agent triethanolamine; and continuing reacting for 3-5 hours, adding the dipropanediol dibenzoate, rutile titanium white, defoaming agent OP-10, kaolin, mixed solvent, expanded perlite and preservative, and evenly mixing to obtain the polyurethane anticorrosive thermal-insulation paint product.

Owner:莫明鑫

Antibacterial flame retardant polyurethane pouring sealant

InactiveCN105482764AAccelerated corrosionImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAluminium hydroxideCarbon nanotube

The invention discloses an antibacterial flame retardant polyurethane pouring sealant. The pouring sealant comprises the following raw materials: polyether polyol, hexamethylene diisocyanate, methyl cyclohexyl diisocyanate, a catalyst, nano-zinc oxide, nano-titania, nano aluminium hydroxide, organically modified montmorillonite, carbon nanotubes, cetyltrimethyl ammonium chloride, nano-silver, bamboo charcoal powder, quaternary ammonium salt, tricresyl phosphate, dipropylene glycol dibenzoate, dipropylene glycol phthalate, 8-hydroxyquinolinone, vinyl-terminated silicone oil and a vinyltriethoxysilane-platinum complex. The antibacterial flame retardant polyurethane pouring sealant provided by the invention has excellent antibacterial properties, good flame retardant property, high bonding strength and long service life.

Owner:ANHUI ANDA HUATAI NEW MATERIALS CO LTD

Blends of dibenzoate plasticizers

ActiveUS9193843B2Low viscosityImprove featuresNon-macromolecular adhesive additivesSpecial tyresElastomerAdhesive

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

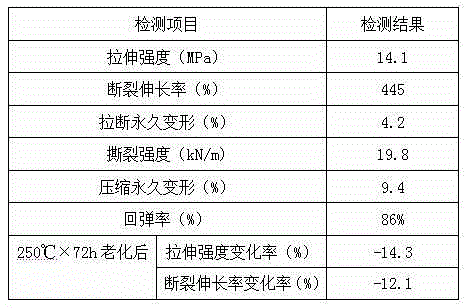

High resilience silicon rubber material and preparation method thereof

The invention discloses a high resilience silicon rubber material and a preparation method thereof. The material consists of the following raw materials by weight: 100-150 parts of methyl vinyl silicone rubber, 60-90 parts of fumed silica, 10-20 parts of hydroxy silicone oil, 0.2-0.3 part of stearic acid, 0.5-1 part of hydrogen-containing silicone oil, 1-2 parts of divinyl tetramethyl disiloxane, 10-15 parts of dipropylene glycol dibenzoate, 0.3-0.6 part of bitertanol, 3-5 parts of alkylphenate disulfide, 2-3 parts of 1,4-bis(1-(tert-butylperoxy)-1-methylethyl)-benzene, 5-10 parts of chalk, 4-6 parts of jute fibers, 1-2 parts of dipentamethylenethiuram tetrasulfide, 0.5-1 part of methyl-2-mercaptobenzimidazole, and 3-6 parts of an auxiliary agent. The silicone rubber material provided by the invention of has high resilience performance, low compression permanent deformation, good mechanical properties, good aging resistance, high temperature resistance, fatigue resistance and corrosion resistance, and can meet the special requirements of some products on the market and broaden the scope of application of silicone rubber materials.

Owner:天长市荣盛有机硅科技有限公司

Wearproof antifouling two-component polyurethane paint and preparation method thereof

InactiveCN106854412AImprove wear resistanceGood antifoulingAntifouling/underwater paintsPaints with biocidesPolymer scienceWater resistant

The invention discloses a wearproof antifouling two-component polyurethane paint and a preparation method thereof. The wearproof antifouling two-component polyurethane paint is prepared from the following raw materials by weight: 70-80 parts of polypropylene oxide glycol, 140-150 parts of hexamethylene diisocyanate, 4-6 parts of sorbitol, 2-4 parts of ethanolamine, 7-9 parts of acrylic ester, 5-6 parts of dipropylene glycol dibenzoate, and 2-3 parts of tert-butyl peroxypivalate, etc. According to the invention, polyurethane, acrylic ester and the like are adopted for cooperation to serve as film-forming matters, so that the wearproof antifouling two-component polyurethane paint has good film-forming characteristics. The added sub-white corundum fine powder, white graphite, aluminum titanate and other raw materials can be evenly and stably dispersed in the paint under the action of polypropylene glycol and sodium methylene dinaphthalene sulfonate to enhance the wear resistance of the paint. The added dipropylene glycol dibenzoate, perfluorooctyl triethoxysilane and other raw materials can improve the antifouling and water resistant performance of the paint.

Owner:汤子宁

Low-hardness polyurethane elastomer material

The invention discloses a low-hardness polyurethane elastomer material which is prepared from the following materials in parts by weight: 1-3 parts of hydroxypropyl methyl cellulose, 2 parts of fatty alcohol-polyoxyethylene ether, 45 parts of diethylene glycol dibenzoate, 2 parts of trimethylolpropane, 180 parts of polyester polyol, 0.2 part of stannous octoate, 8 parts of triisopropanolamine, 7 parts of dibutyl phthalate, 31 parts of butyl benzyl phthalate, 18 parts of dipropylene glycol dibenzoate, 3 parts of glycerol, 68 parts of toluene diisocynate, 0.4 part of tin dibutyl dicaprylate, 11 parts of di-n-octyl phthalate, 5 parts of triethanolamine, 0.3 part of bismuth isocaprylate, 40 parts of filler, 0.1 part of bismuth carboxylate, 23 parts of dimethoxyethyl phthalate, 13 parts of diethyl phthalate, 7 parts of diethanol amine, 2 parts of an organic silicon de-foaming agent, 0.5 part of dibutyltin dilaurate and 4 parts of trimethylol ethane. The low-hardness polyurethane elastomer material disclosed by the invention has good mechanical performance, good solvent resistance and good cutting processing performance.

Owner:CHANGSHU YONGLI CHEM

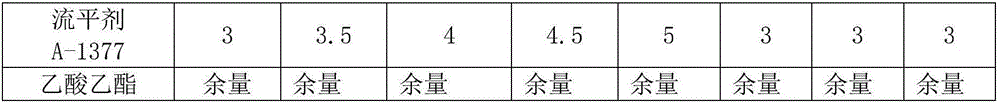

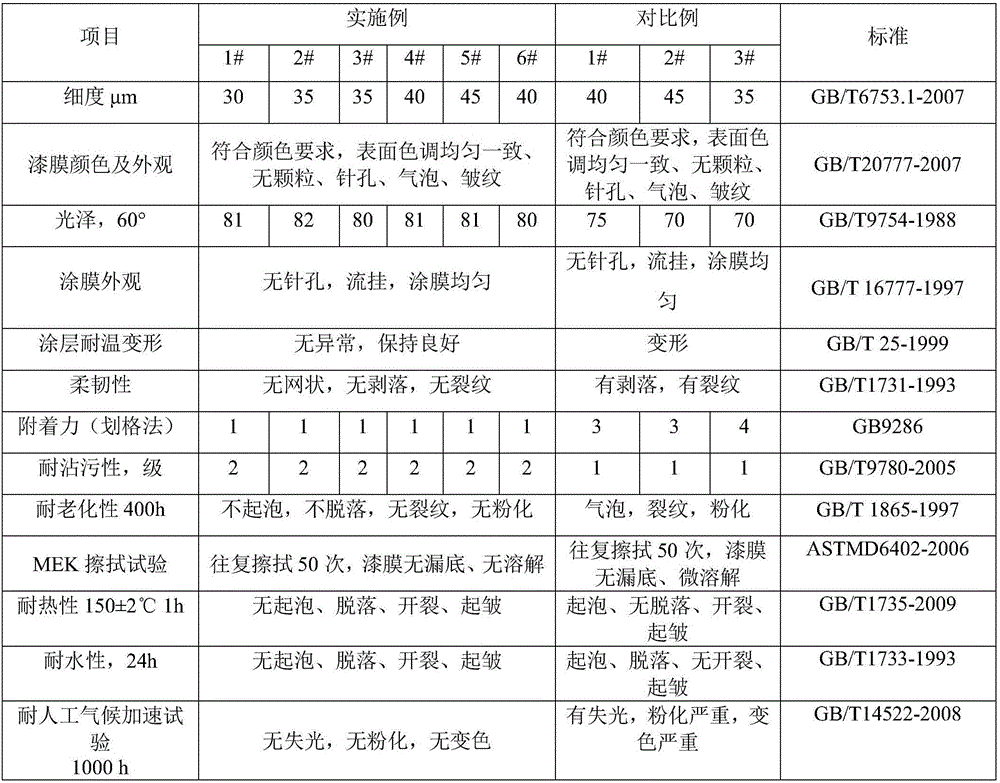

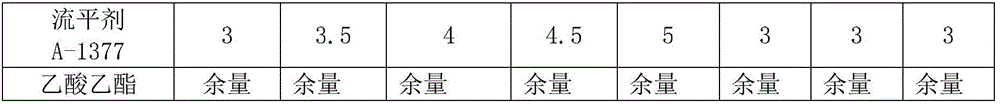

Anticorrosive paint for electric power distribution cabinet

InactiveCN106085158AImprove adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesEthyl acetateChemistry

The invention relates to anticorrosive paint for metal, in particular to anticorrosive paint for an electric power distribution cabinet. The anticorrosive paint is prepared from the following components in parts by weight: 5-10 parts of inositol hexaphosphoric acid, 3-5 parts of dipropylene glycol dibenzoate, 1-3 parts of chlorinated rubber, 20-25 parts of modified alkyd resin, 15-20 parts of a filming addition agent, 15-20 parts of a filling, 10-15 parts of fluorocarbon resin, 5-10 parts of glass resin, 1-3 parts of a paint film self-cleaning agent, 1-3 parts of an antifoaming agent, 3-5 parts of a flatting agent and the balance of ethyl acetate. The prepared anticorrosive paint disclosed by the invention is broad in application range, high in adhesive force, good in weather resistance, high in hardness after being solidified, good in abrasion resistance, free from discoloring, wrinkling and stripping, resistant to sunshine and rain, and good in decorative performance, has excellent antirust and self-cleaning effects, and is simple in preparation method, low in cost, and suitable for mass production.

Owner:仪征恒运电器有限公司

High-strength and high-temperature resistance EVA composite material and preparation method thereof

InactiveCN105237863AHigh mechanical strengthImprove high temperature resistancePalygorskiteTemperature resistance

The invention discloses a high-strength and high-temperature resistance EVA composite material and a preparation method thereof. The composite material is prepared from, by weight, 35-45 parts of ethylene-vinyl acetate copolymer, 18-33 parts of brominated isobutene-p-methylstyrene copolymer, 15-25 parts of poly(benzimidazole-imide), 12-18 parts of nanometer palygorskite, 14-22 parts of polyphenylquinoxaline, 10-15 parts of epoxidized ethylene propylene diene rubber, 15-20 parts of colloidal graphite powder, 2-4 parts of zinc sorbate, 23-37 parts of artificial stone polishing waste powder, 14-19 parts of dipropylene glycol dibenzoate, 2-3 parts of stannous chloride, 1.5-2.5 parts of calcium stearate and 1-2 parts of barium stearate. The composite material prepared in the invention has excellent mechanical strength, high temperature resistance and weatherability, and still maintains high mechanical strength after long-term working in high temperature environment.

Owner:CHUZHOU YOUSHENG HIGH POLYMER MATERIAL

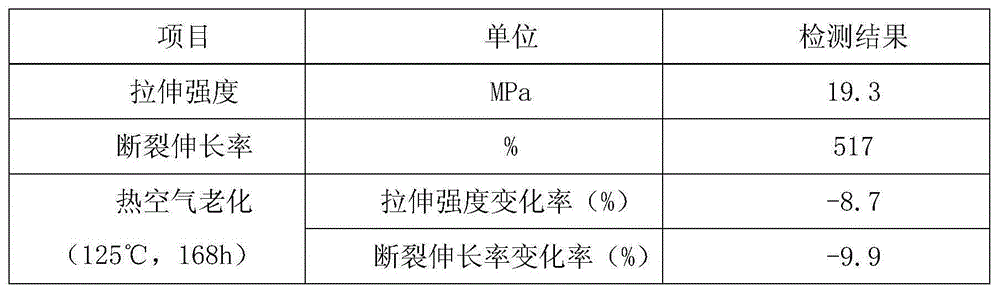

Heat aging resistant polyvinyl chloride pipe and preparation method thereof

The invention discloses a heat aging resistant polyvinyl chloride pipe and a preparation method thereof. The heat aging resistant polyvinyl chloride pipe is prepared from the following raw materials in parts by weight: 35-55 parts of SG-5 PVC resin, 25-45 parts of polyamideimide, 1.5-2.5 parts of a cadmium-barium-zinc compound stabilizer, 4-6 parts of E wax, 2.5-4.5 parts of tert-dodecylmercaptan, 6-9 parts of ethylhexyl thioglycolate, 15-20 parts of brominated polystyrene, 10-15 parts of poly-4-methyl-1-amylene, 3-5 parts of glyceryl monostearate, 10-15 parts of flint clay powder, 3-6 parts of beryllium oxide, 5-10 parts of asbestos powder, 7-11 parts of phosphate tri(xylene) ester, 2-3 parts of mannitol, 4-8 parts of trimethylsilyl crotonate, 2.5-4.5 parts of cobalt boroacylate, 1.5-2.5 cadmium ricinoleate, 1-2 parts of lead ricinoleate, 10-15 parts of dipropylene glycol dibenzoate, 8-12 parts of trimethyl citrate and 15-20 parts of composite nanometer powder. The PVC pipe disclosed by the invention is excellent in heat aging resistance, still can keep high tensile strength and elongation at break at a high temperature, has excellent abrasive resistance, chemical resistance and environmental crack resistance, and is durable and wide in application prospect.

Owner:六安市协诚车辆配件有限公司

Environment-friendly waterborne polyurethane adhesive for artificial leather and preparation method of environment-friendly waterborne polyurethane adhesive

InactiveCN106189994AHigh viscosityImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyethylene glycolIsophorone diisocyanate

The invention discloses an environment-friendly waterborne polyurethane adhesive for artificial leather and a preparation method of the environment-friendly waterborne polyurethane adhesive. The environment-friendly waterborne polyurethane adhesive is prepared from the following raw materials in parts by weight: 120 to 130 parts of polyethylene glycol adipate, 22 to 26 parts of isophorone diisocyanate, 15 to 19 parts of hexamethylene diisocyanate, 5 to 7 parts of dipropylene glycol dibenzoate, 3 to 5 parts of p-phenylenediamine, 5 to 7 parts of ammonium ethoxylaurate, 4 to 5 parts of anilmomethyl triethoxy silane, 3 to 5 parts of stannous octoate, 6 to 8 parts of ammonium dihexenoate, 4 to 5 parts of butylene glycol, 4 to 6 parts of diisooctyl phenyl phosphite, 5 to 7 parts of ammonium dihydrogen phosphate, 2 to 4 parts of magnesium stearate and the like. When the adhesive disclosed by the invention is used, moisture in the air and on the surface of an adhered material or the adhered material contains substances including active hydrogen and the like, the adhesive is reacted with the substances to form chemical bonds including a urea bond, a hydrogen bond and the like, so that a binding effect is realized. Raw materials including magnesite, edible seaweed powder, chitosan acrylate and the like are added, so that the binding property of polyurethane is improved, the shrinkage stress and the thermal stress are reduced, the stability on thermal damages is enhanced and the viscosity of the adhesive is enhanced. The environment-friendly waterborne polyurethane adhesive has the advantages of no toxin and environment friendliness and meets the national requirements of China.

Owner:张枫浩

Multifunctional antibiosis coating layer for children's intelligence development toys

InactiveCN105925038AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsNitrocellulosePhosphate

The invention relates to a multifunctional antibiosis coating layer for children's intelligence development toys. The multifunctional antibiosis coating layer comprises an acrylonitrile-butadiene-styrene copolymer, para-tert-octylphenol fomaldehyde resin, nitrocellulose plastic, an ethylene-vinyl acetate copolymer, ammonium polyphosphate, trioctyl phosphate, hexahydrophthalic anhydride, glass fiber powder, molybdenum disulfide powder, silica powder, wollastonite powder, andalusite powder, active zinc oxide, wooden fibers, dipropylene glycol methyl ether, benzotriazole, butanetriol, dipropylene glycol dibenzoate, di-n-octyltin dilaurate, iron naphthenate, xanthan gum, butyl methacrylate, polyamide, aluminum dihydrogen phosphate, tributyl phosphate, trioctyl trimellitate, hydroxymethyl cellulose, hydroabietyl alcohol, nitrocellulose and fatty alcohol polyether amide. The multifunctional antibiosis coating layer has the advantages of superior flame retardation, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:梁方英

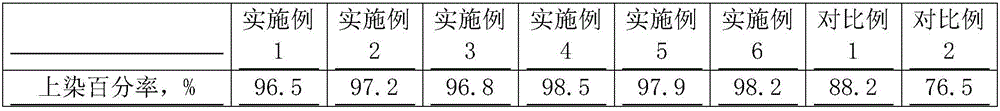

Permeation type dyeing auxiliary for dyeing aramid fiber and preparation method of permeation type dyeing auxiliary

The invention discloses a permeation type dyeing auxiliary for dyeing aramid fiber. The permeation type dyeing auxiliary comprises the following components in parts by weight: 5-12 parts of malic acid, 5-10 parts of sodium acetate, 6-11 parts of cysteine, 2-6 parts of guar gum, 10-15 parts of sodium alginate, 3-7 parts of dipropylene glycol dibenzoate, 2-4 parts of castor oil polyoxyethylene ether, 1-2 parts of a pH adjusting agent, 2-3 parts of an emulsifier and 10-15 parts of deionized water. The invention further discloses a preparation method of the permeation type dyeing auxiliary. By adopting the permeation type dyeing auxiliary for dyeing aramid fiber, the dyeing rate of aramid fiber can be effectively increased, the problem that the aramid fiber is hard to dye is solved, the dyeing effect is good, the fiber structure of aramid fiber is not damaged, and the dyed fiber is soft and comfortable, bright in color and good in gloss. The preparation method is simple and the cost is low.

Owner:厦门谢田守望新材料有限公司

Corrosion-resistant insulated cable material and preparation method thereof

InactiveCN107141765AExtended service lifeImprove wear resistanceRubber insulatorsYarnHigh resistance

The invention discloses a corrosion-resistant insulated cable material and a preparation method thereof. The corrosion-resistant insulated cable material comprises the following raw materials in parts by weight: 70-90 parts of polyurethane rubber, 1-20 parts of a mica powder, 6-12 parts of nylon, 10-15 parts of alkali-free glass fiber yarn, 5-10 parts of dipropylene glycol dibenzoate, 5-10 parts of HRB-6 resin, 7-13 parts of magnesium hydroxide, 4-8 parts of aluminum hydroxide, 2-3 parts of tert-butyl peroxybenzoate, 1.5-2 parts of zinc oxide, 2-3 parts of stearic acid, 3-6 parts of chlorinated paraffin, 15-20 parts of fumed silica, 10-15 parts of nano attapulgite, 10-15 parts of precipitated barium sulfate, 1.5-2.5 parts of an antioxidant, 2-3 parts of an anti-aging agent TPPD, 3-6 parts of composite fillers, 1-2 parts of an accelerator ZDMC and 1-2 parts of an accelerator CZ. The cable material provided and prepared in the invention has high wear resistance, also has high heat resistance, high flame retardancy, high aging resistance, high oil resistance, high flexure resistance, high impact resistance and high tear resistance, is durable in use, and can fully meet performance requirements of modern wires and cables.

Owner:山东励仙电力工程有限公司

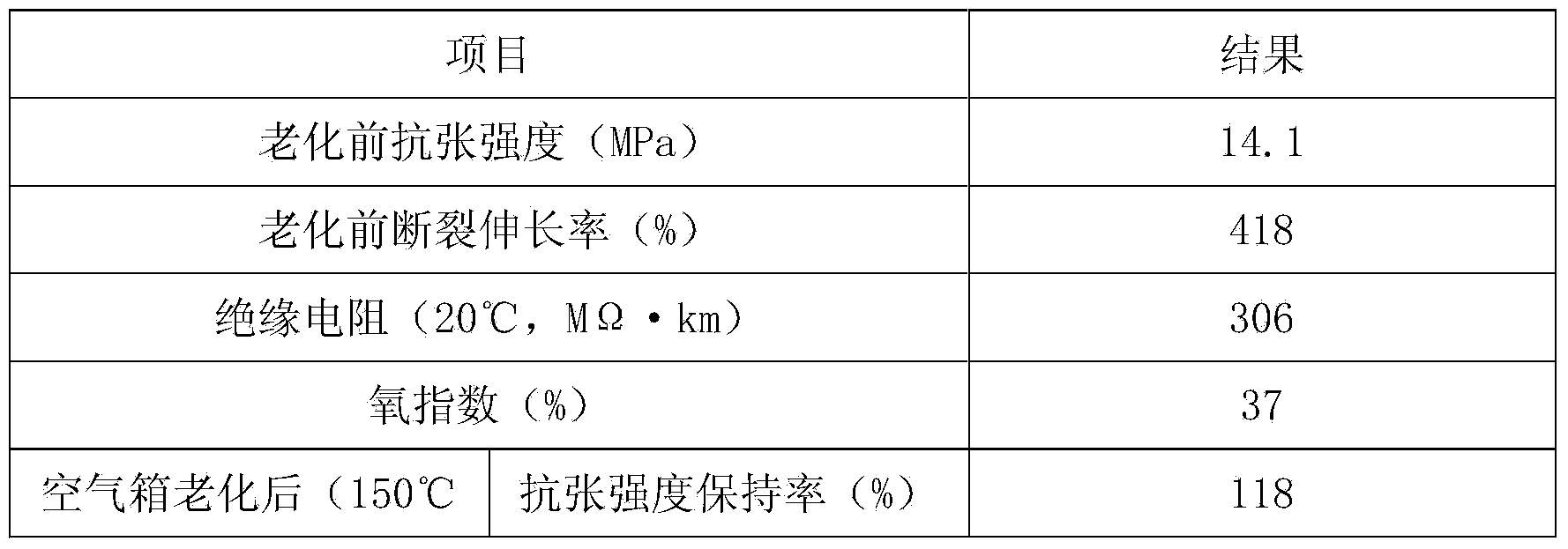

Polyolefin insulated cable material used for rail transit vehicle and preparation method thereof

The invention discloses polyolefin insulated cable material used for a rail transit vehicle and a preparation method thereof. The polyolefin insulated cable material is prepared by using the following raw materials by weight: 50-70 parts of high density polyethylene, 20-40 parts of ethylene-octylene copolymer, 15-25 parts of poly 4-methyl-1-pentene, 10-15 parts of dipropylene glycol dibenzoate, 4-6 parts of docosanamide, 3-5 parts of microcrystalline wax, 2-3 parts of zinc stearate, 1-2 parts of lanthanium stearate, 5-10 parts of epoxy linseed oil, 2-4 parts of isomaltitol, 3.5-4.5 parts of dibenzoyl methane, 15-20 parts of organic montmorillonite, 10-15 parts of brucite powder, 25-30 parts of nanometer spherical silica, 13-21 parts of hexabromocyclododecane, 11-19 parts of calcium phosphomolybdate, 10-15 parts of pentaerythritol polyphosphoric ester melamine, 2-4 parts of tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanurate, 1-3 parts of dioctadecyl thiodipropionate and 10-15 parts of modified stone powder. The cable material provided by the invention has high mechanical strength, excellent mechanical properties, excellent weather resistance, ageing resistance, temperature tolerance, fatigue resistance and fire resistance, is durable in use, is safe and reliable, and can meet cable-related requirements of the rail transit vehicle.

Owner:ANHUI KANGLIYA CO LTD

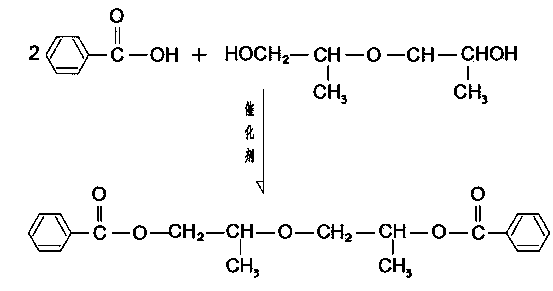

Synthetic method of dipropylene glycol dibenzoate

PendingCN106565471AHigh yieldReduce the color numberOrganic compound preparationCarboxylic acid esters preparationBenzoic acidPtru catalyst

A method for preparation of dipropylene glycol dibenzoate is disclosed. According to the method, a synthetic route of esterification-decoloration-washing-dehydration is adopted. benzoic acid and dipropylene glycol are used as raw materials; a stannous oxalate and basic zirconium carbonate binary complex catalyst is used; and an excessive amount of dipropylene glycol and nitrogen are used as a water carrying agent to reasonably control the temperature. Through decoloration, neutralization, washing and dehydration, the finished product dipropylene glycol dibenzoate is prepared. The synthetic method of the invention has advantages of simple process, short production period, high yield of the product, small colour number, etc. By the method, it is easy to realize industrialization.

Owner:HUBEI GREENHOME MATERIALS TECH INC

Method for efficiently producing dipropylene glycol dibenzoate

InactiveCN103739493AIncrease productivityGood compatibilityOrganic compound preparationCarboxylic acid esters preparationBenzoic acidSodium bisulfate

The invention relates to a method for efficiently producing dipropylene glycol dibenzoate. The method comprises the process flows of weighing benzoic acid and dipropylene glycol proportionally, and adding benzoic acid and dipropylene glycol as well as a catalyst sodium bisulfate into a reaction kettle for esterification; then, pumping to another neutralization kettle, adding a NaOH aqueous solution to neutralize, washing with water after layering, decoloring after layering, washing with water, drying, filtrating, and then, inspecting, thereby obtaining a finished product. According to the method, 4.5t of high-quality plasticizer or named DPDB can be produced in a reaction kettle with the volume of 5.5 cubic meters in a manner of taking stannous chloride as a catalyst.

Owner:广州正道环保新材料有限公司

Acid-base erosion-resistant arrester external protective coating

InactiveCN105111833AExtended service lifeErosion effect is goodConjugated diene hydrocarbon coatingsNatural rubber coatingsPolystyreneChlorinated paraffins

The invention relates to an acid-base erosion-resistant arrester external protective coating which is prepared from, by weight parts, 82-90 parts of natural rubber, 3-8 parts of methylol aliphatic amines, 2-4 parts of zinc stearate, 40-50 parts of nitrile rubber, 100-120 parts of ethylene propylene rubber, 2-7 parts of zinc oxide, 3-7 parts of magnesium oxide, 25-30 parts of butadiene-styrene rubber, 2-9 parts of chlorinated paraffin, 3-7 parts of methanol, 9-16 parts of dibutyl phthalate, 2-6 parts of polylactic acid, 9-15 parts of polystyrene, 4-5 parts of calcium naphthenate, 5-6 parts of titanium dioxide, 5-6 parts of zinc oxide, 35-45 parts of fluororubber, 1-2 parts of smoked sheet rubber, 12-14 parts of diethylene glycol dibenzoate, 7-11 parts of activated Calcium carbonate, 4-8 parts of cumarone, 6-9 parts of dipropylene glycol dibenzoate and 30-34 parts of aluminum nitride.

Owner:HEFEI HAICHANG ELECTRICAL TECH

Preparation method of antirust paint for power distribution cabinet

InactiveCN106010238AImprove adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesEthyl acetateUltrasonic dispersion

The invention relates to a preparation method of a metal antirust paint, and in particular, relates to the preparation method for the antirust paint for a power distribution cabinet, wherein the method comprises the following steps: (1) adding chlorinated rubber, a film-forming auxiliary agent, a filler, a paint film self-cleaning agent and a defoaming agent into an ethyl acetate solution, heating to 40-50 DEG C, carrying out ultrasonic dispersion, adding inositol hexaphosphate and dipropylene glycol dibenzoate, and stirring for 20-30 min; (2) rising the temperature to 50-60 DEG C, adding modified alkyd resin, fluorocarbon resin and glass resin, and stirring for 40-50 min; and (3) adding a leveling agent, stirring, and dispersing to obtain the antirust paint. The prepared antirust paint has the advantages of wide use scope, high adhesive force, excellent weatherability, high hardness after curing, good wear resistance, no discoloring, no wrinkling, difficult peeling, sun-scorching and rain-drenching resistance, good decoration, and excellent anti-rust and self-cleaning effects; and the preparation method is simple, low in cost, and suitable for mass production.

Owner:仪征恒运电器有限公司

Oxidation-resisting lubricating oil for civil use and preparation method thereof

InactiveCN107142143AImprove rust resistanceImprove wear resistanceLubricant compositionVegetable oilChemical reaction

The invention discloses oxidation-resisting lubricating oil for civil use, which is prepared from the following components in parts by weight: 10 to 30 parts of vegetable oil, 10 to 12 parts of triethanolamine oleate, 5 to 10 parts of alpha-olefin polymer, 10 to 15 parts of polypropylene glycol adipate, 5 to 10 parts of dipropylene glycol dibenzoate, 3 to 6 parts of chlorinated paraffin, 2 to 10 parts of organosiloxane, 3 to 8 parts of boric acid, 3 to 6 parts of anticreaming agent, 5 to 10 parts of triethanolamine, 1.5 to 7.5 parts of organic molybdenum, 3 to 6 parts of alkyl diphenylamine, and 0.3 to 2.5 parts of additive. The invention provides the oxidation-resisting lubricating oil for the civil use and a preparation method thereof, wherein the lubricating oil is excellent in anti-rust property, antioxidant resistance and abrasion resistance, has good foam inhibition and defoaming properties and good chemical inertness, and cannot have chemical reaction with defoamed medium under different pH values and different temperatures.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

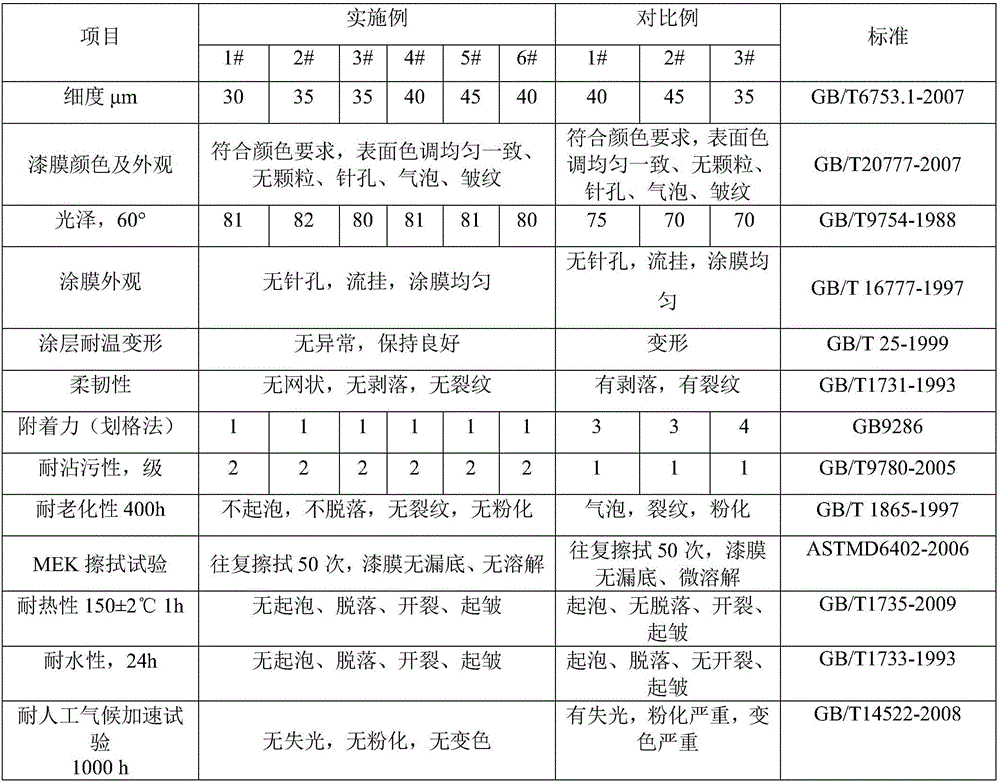

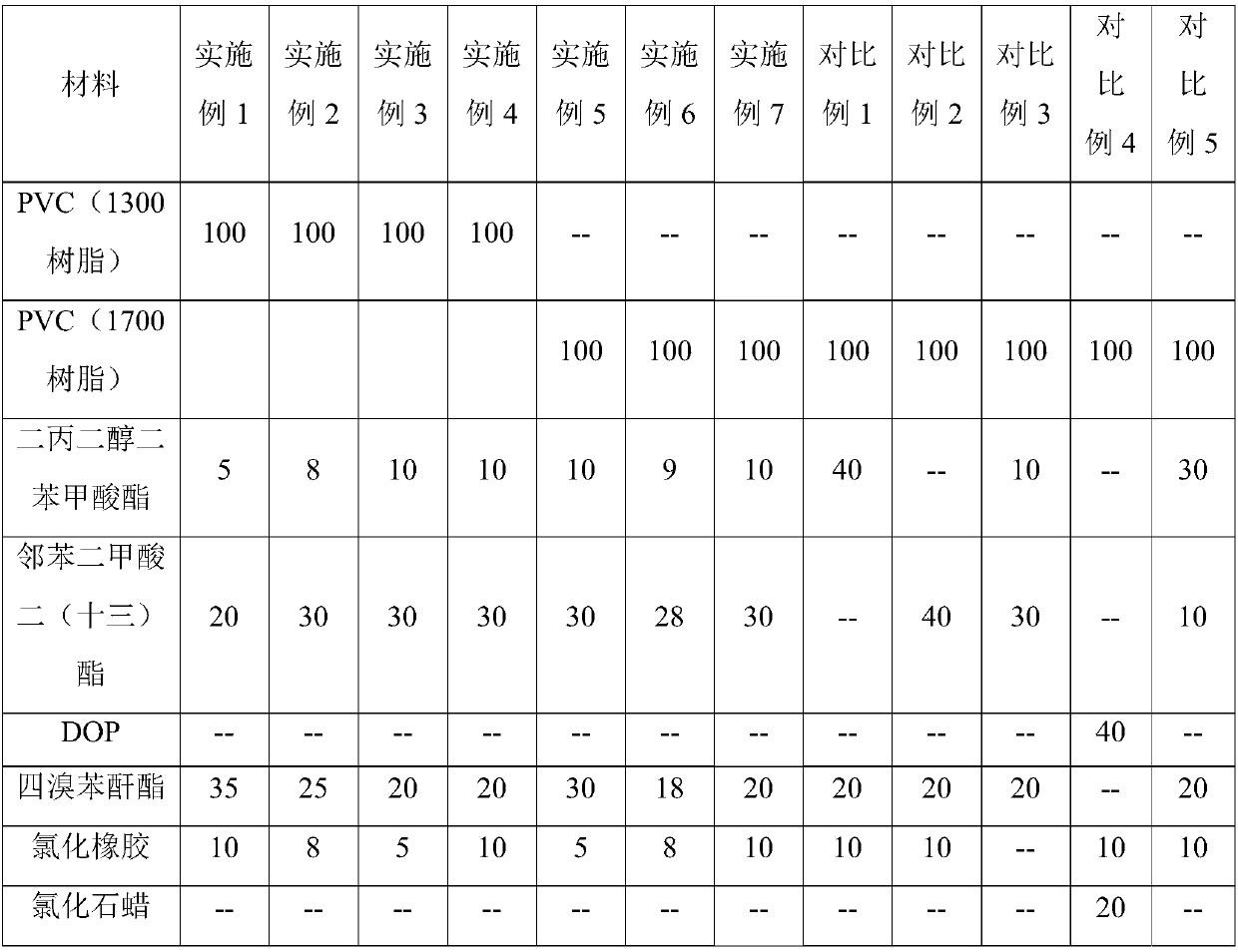

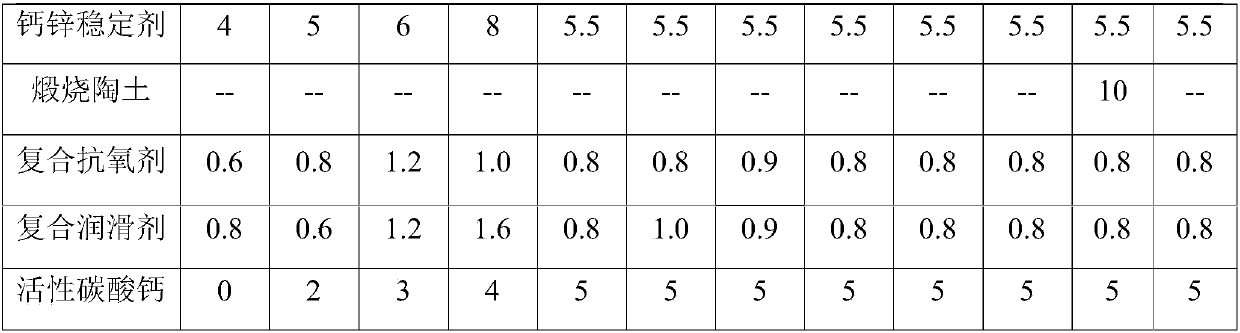

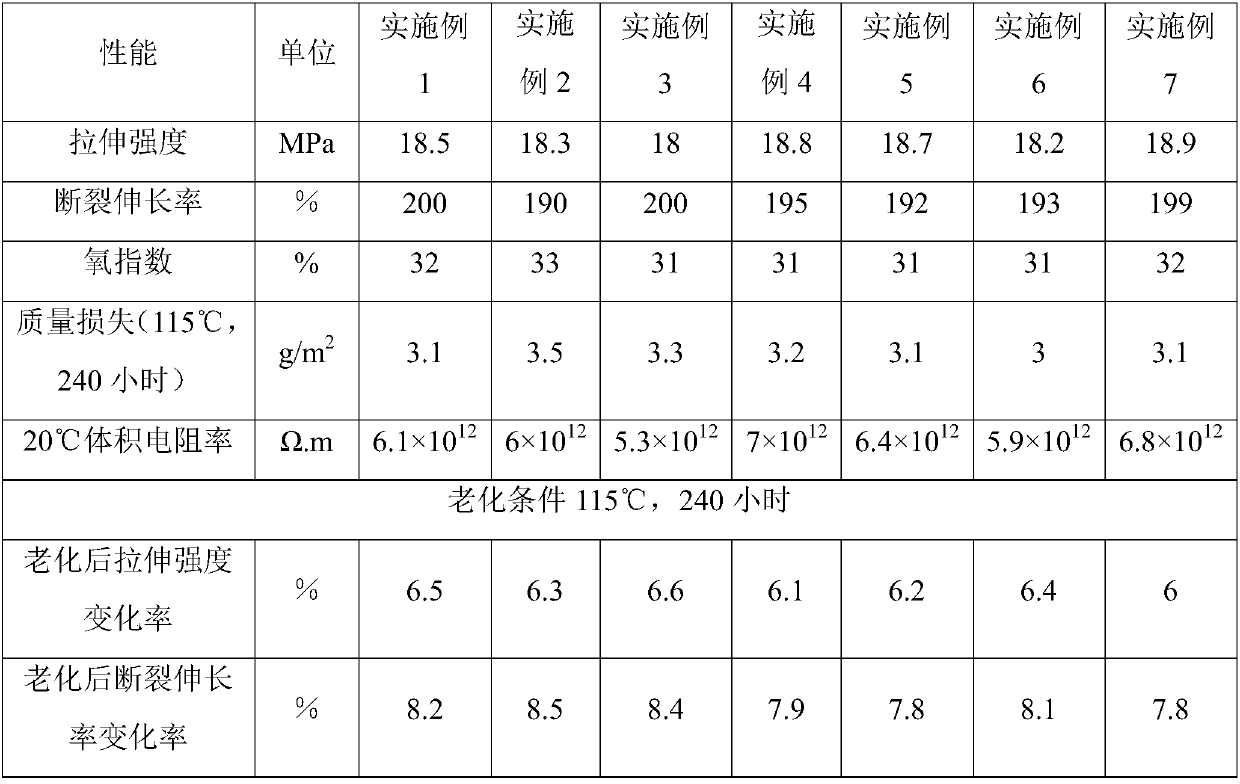

High-resistivity flame-retardant polyvinyl chloride composition for cable material

ActiveCN110760139AReduce leachingImprove flame retardant performancePlastic/resin/waxes insulatorsPolymer sciencePolyvinyl chloride

The invention relates to a high-resistivity flame-retardant polyvinyl chloride composition for a cable material, and belongs to the technical field of polyvinyl chloride modification. The high-resistivity flame-retardant PVC cable material composition provided by the invention includes the following raw materials in parts by weight: 100 parts of PVC resin, 30-50 parts of a special composite plasticizer, 15-35 parts of a flame-retardant plasticizer, 5-10 parts of powdered chlorinated rubber, 3-10 parts of a calcium zinc stabilizer, 0.5-1.2 parts of a composite antioxidant, 0.5-2 parts of a composite lubricant, and 0-5 parts of active calcium carbonate, wherein the special composite plasticizer is a mixture of dipropylene glycol dibenzoate and di(tridecyl)phthalate. The cable material prepared by using the high-resistivity flame-retardant polyvinyl chloride cable material composition provided by the invention has a high volume resistivity, and excellent flame retardancy, resistance to precipitation, and aging resistance.

Owner:CHINA PETROLEUM & CHEM CORP

Waterproof temperature-resistant modified polyphenyl ether material for automotive plastic part

The invention belongs to the field of high molecular materials and particularly relates to a waterproof temperature-resistant modified polyphenyl ether material for an automotive plastic part. The material is prepared from the following raw materials in parts by weight: 100 parts of polyphenyl ether, 12-15 parts of silicon carbide, 7-9 parts of aluminum oxide, 7-9 parts of dipropylene glycol dibenzoate, 3-5 parts of stearic acid, 2-3 parts of triallyl isocyanurate, 5-8 parts of barium sulfide, 3-5 parts of zinc sulfide, 5-8 parts of C5 petroleum resin, 1-2 parts of vinyl triethoxy silane, 1-2 parts of accelerant DM and 12-15 parts of assistant. The material provided by the invention combines the advantages of the raw materials such as polyphenyl ether and C5 petroleum resin and modifies the raw materials such as silicon carbide, so that the obtained material has good processing and mechanical performances. The prepared material prepared is great in strength, water-penetration and oil-penetration resistant, thermal-aging resistant, low-temperature impact resistant, good in electric insulating performance, and safe and reliable to use, and can be widely applied to preparing various automotive plastic parts.

Owner:安徽省中日农业环保科技有限公司

Multi-fiber composite wear-resistant anti-microbial woven fabric and manufacturing method for same

InactiveCN105155092AImprove spinnabilityImprove spinning qualityConjugated cellulose/protein artificial filamentsWoven fabricsFiberWear resistant

The invention discloses a multi-fiber composite wear-resistant anti-microbial woven fabric. The multi-fiber composite wear-resistant anti-microbial woven fabric is composed of warp yarns and weft yarns which are woven by an air-jet loom. The raw materials of the warp yarns and the weft yarns are made from the following components, by weight, 30 to 33 parts of polypropylene, 20 to 25 parts of down feather, 23 to 26 parts of terylene, 24 to 28 parts of chicken feather, 16 to 19 parts of shengma fiber, 13 to 17 parts of acetate rayon, 2 to 4 parts of bentonite, 0.3 to 0.5 part of zinc oxide, 0.7 to 0.9 part of nanometer zirconia powder, 3 to 6 parts of mercaptoacetic acid, 7 to 10 parts of n-Propyl acrylate, 6 to 9 parts of dipropylene glycol dibenzoate, 3 to 5 parts of ginger, 2 to 4 parts of burdock, 85 to 95 parts of 1-butyl-3-methylimidazolium acetate, 90 to 110 parts of 1- allyl-3-methylimidazolium bromide, a proper amount of water, and 5 to 8 parts of auxiliary agent. The multi-fiber composite wear-resistant anti-microbial woven fabric can be used for automotive trims, and is stiff and smooth in appearance and fashionable.

Owner:安徽省中日农业环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com