Heat aging resistant polyvinyl chloride pipe and preparation method thereof

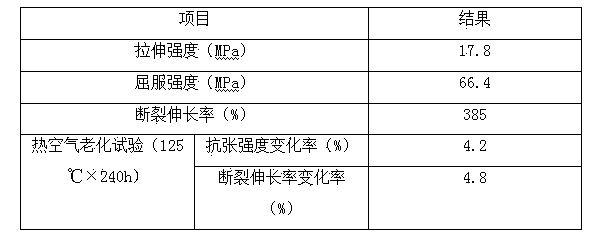

A polyvinyl chloride, heat-resistant aging technology, applied in the field of PVC materials and its preparation, can solve the problems of poor thermal stability, aging resistance, reduced service life, and deterioration of mechanical properties, and achieve excellent heat aging resistance and excellent wear resistance properties, high tensile strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A heat-resistant aging polyvinyl chloride pipe is made of the following raw materials in weight (kg): SG-5 type PVC resin 45, polyamideimide 35, barium cadmium zinc composite stabilizer 2, E wax 5, tertiary ten Dialkyl mercaptan 3.5, Isooctyl thioglycolate 7, Brominated polystyrene 17, Poly-4-methyl-1-pentene 13, Glyceryl monostearate 4, Scorched gemstone powder 12, Beryllium oxide 4 , asbestos powder 8, tris (xylene) phosphate 9, mannitol 2.5, trimethylsilyl crotonate 6, boron acylate 3.5, cadmium ricinoleate 2, lead ricinoleate 1.5, dipropylene glycol two Paraben 12, trimethyl citrate 10, composite nanopowder 18;

[0015] The preparation method of the composite nanopowder is as follows: a. Weigh dolomite, celestite and medical stone in a ratio of 8:6:3 by weight, mix well, calcinate at 880° C. for 1 hour, cool to room temperature, pulverize, and sieve , stand-by, b, take 5 times the weight of the powder obtained in step a, the solid content is 40% of silica sol, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com