Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

A technology for anti-ultraviolet and instrumentation cables, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc. It can solve the problems that the cables cannot meet the anti-ultraviolet requirements, do not have anti-ultraviolet aging performance, and have short service life, etc., and achieve excellent anti-seawater Excellent corrosion resistance, UV light aging resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

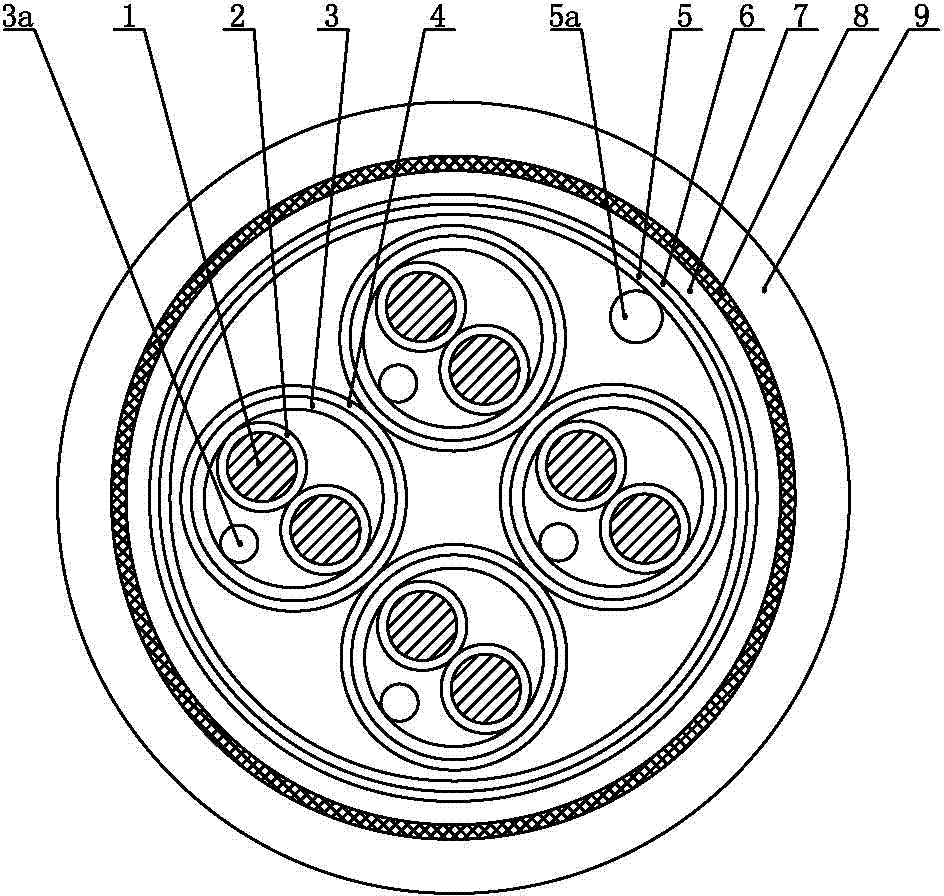

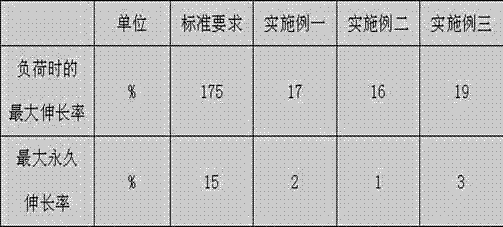

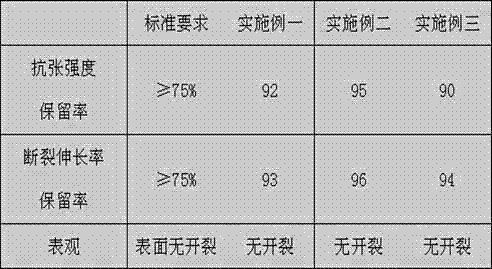

[0021] Such as figure 1 As shown, the whitening and anti-ultraviolet marine double-shielded instrument cable of the present invention is manufactured according to the following steps: extruding and whitening the anti-ultraviolet ethylene-propylene rubber insulation layer 2 on the outer periphery of a 0.35mm tinned annealed stranded copper conductor 1 to form an insulated wire core , the insulated wire cores are twisted in pairs to form a pair of twisted wires, the twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; in each pair of twisted wires The outer circumference of the pair is wrapped around the core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward. The inner side of the core copper foil polyester composite tape shielding layer 3 is provided with a core tinned stranded copper wire drain wire 3a, and the core Tinned stranded copper wire drainage wire 3a r...

Embodiment 2

[0027] The whitening and anti-ultraviolet marine double-shielded instrument cable of the present invention is manufactured according to the following steps: extrude and pack the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 1.25 mm to form an insulating core, and an insulating wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; on the outer circumference of each pair of twisted wires Wrapped wire core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward, the inner side of the wire core copper foil polyester composite tape shielding layer 3 is provided with a core tinned stranded copper wire drainage wire 3a, the wire core is tinned stranded The combined copper wire drainage wire 3a runs thr...

Embodiment 3

[0033] The whitening and anti-ultraviolet marine double-shielded instrument cable of the present invention is manufactured according to the following steps: extrude and pack the whitening and anti-ultraviolet ethylene-propylene rubber insulation layer 2 on the outer periphery of a tinned annealed stranded copper conductor 1 of 2.5 mm to form an insulating core, and an insulating wire The cores are twisted in pairs to form a pair of twisted wires. The twisted pitch of each pair of twisted wires is not greater than 120mm and all pairs of twisted wires use different twisted pitches; on the outer circumference of each pair of twisted wires Wrapped wire core copper foil polyester composite tape shielding layer 3 and the copper foil faces inward, the inner side of the wire core copper foil polyester composite tape shielding layer 3 is provided with a core tinned stranded copper wire drainage wire 3a, the wire core is tinned stranded The combined copper wire drainage wire 3a runs thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com