Isoprene rubber grafted maleic anhydride and preparation method thereof

A technology for grafting maleic anhydride and isoprene rubber, applied in the field of synthetic rubber, can solve the problems of increasing the industrialization process, reducing the industrialization process, increasing the difficulty of industrialization, etc., and achieves the effect of reducing the difficulty, reducing the process and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

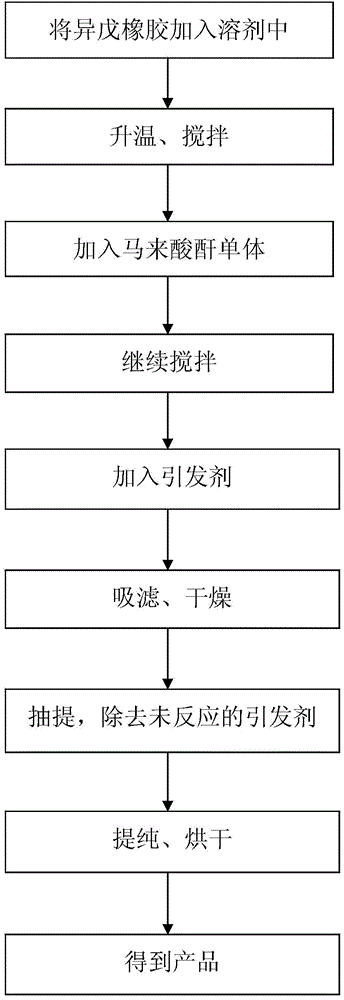

Image

Examples

preparation example Construction

[0059] The preparation method of isoprene rubber grafted maleic anhydride of the present invention only needs to mix each component in the solution according to the formula to obtain isoprene rubber grafted maleic anhydride, and endow isoprene rubber maleic anhydride with better grafting At the same time, the product has little peculiar smell, white color, environmental protection and safety, the preparation method is simple, the conditions are easy to control, the cost is low, the requirements for equipment are low, and it is suitable for industrial production.

[0060] The above-mentioned isoprene rubber is the isoprene rubber with a Mooney viscosity of 70-80 prepared by the rare earth catalyst independently developed by Jihua Research Institute as the graft base. Pentyl rubber grafted with maleic anhydride.

[0061] The above-mentioned initiator is preferably benzoyl peroxide (BPO), which comes from Tianjin Damao Chemical Reagent Factory. Benzoyl peroxide can decompose unde...

Embodiment 1

[0064] Add 5g of isoprene rubber and 100ml of toluene into a three-necked flask equipped with a thermometer, stirring paddle and thermometer, stir and heat to 70°C to fully dissolve the isoprene rubber in toluene, add 0.3g of maleic anhydride monomer, Stir at a medium speed, then add 0.2 g of initiator BPO, and continue stirring for 5 hours. After the reaction was finished, the product was precipitated with acetone, then suction-filtered with a Buchner funnel, and dried. The dried product was extracted in acetone for 3 hours with a Soxhlet extractor to remove unreacted monomers and initiators, and after purification, the product was vacuum-dried at 60°C to constant weight for later use to obtain the isoprene rubber graft branched maleic anhydride product.

Embodiment 2

[0066] Add 5g of isoprene rubber and 100ml of toluene into a three-necked flask equipped with a thermometer, stirring paddle and thermometer, stir and heat to 70°C to fully dissolve the isoprene rubber in toluene, add 0.5g of maleic anhydride monomer, Stir at a medium speed, then add 0.2 g of initiator BPO, and continue stirring for 5 hours. After the reaction was finished, the product was precipitated with acetone, then suction-filtered with a Buchner funnel, and dried. The dried product was extracted in acetone for 3 hours with a Soxhlet extractor to remove unreacted monomers and initiators, and after purification, the product was vacuum-dried at 60°C to constant weight for later use to obtain the isoprene rubber graft branched maleic anhydride product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com