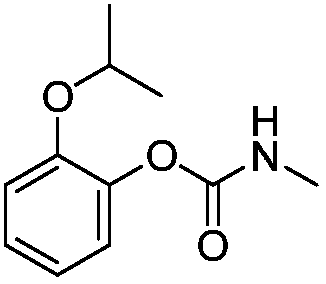

Purifying method of propoxur

A purification method, propoxur technology, applied in chemical instruments and methods, organic chemistry, preparation of organic compounds, etc., can solve problems such as difficult to achieve purification effect, unpleasant special smell, etc., achieve white color, avoid decomposition, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 214.4g propoxur (97.5%) and 8.5g petroleum ether into a 500mL three-neck flask with cooling tube, thermometer and stirring, stir and heat to 95°C until completely melted, and control the temperature of the system to slowly drop to 85°C (cooling rate 0.1°C / min) and maintained for 1 h, standing still for crystallization. A small amount of yellow liquid appeared in the kettle floating above the white solid, which was removed from the system. The white solid was heated and melted and sliced to obtain 205.2 g of white, odorless propoxur (liquid chromatography, external standard) with a content of 99.3% and a yield of 97.5%. The mass of the yellow liquid removed from the system was 15.8 g, which was analyzed as a 32.5% solution of propoxur in petroleum ether, in which 1,2-diisopropoxybenzene and 1-isopropoxy-2-methoxybenzene were also dissolved. 6g of petroleum ether can be recovered by simple distillation, and the remaining oily residue after distillation can be inci...

Embodiment 2

[0030] Add 214.4g propoxur (97.5%) and 6g petroleum ether into a 500mL three-neck flask with cooling tube, thermometer and stirring, stir and heat to 100°C until completely melted, and control the temperature of the system to slowly drop to 90°C (cooling rate 0.1°C / min ) and maintain 1h, static crystallization. A small amount of yellow liquid appeared in the kettle floating above the white solid, which was removed from the system. The white solid was heated and melted and sliced to obtain 206.5 g of white, odorless propoxur (liquid chromatography, external standard) with a content of 99.1% and a yield of 97.9%. The mass of the yellow liquid removed from the system was 12.0 g, which was analyzed to be a 36.2% solution of propoxur in petroleum ether, in which 1,2-diisopropoxybenzene and 1-isopropoxy-2-methoxybenzene were also dissolved. 3g of petroleum ether can be recovered by simple distillation, and the remaining oily residue after distillation can be incinerated.

Embodiment 3

[0032] Add 214.4g of propoxur (97.5%) and 4.2g of petroleum ether into a 500mL three-neck flask with a cooling tube, thermometer, and stirring, stir and heat to 100°C until completely melted, and control the temperature of the system to slowly drop to 85°C (cooling rate 0.1°C / min) and maintained for 2h, standing still for crystallization. A small amount of yellow liquid appeared in the kettle floating above the white solid, which was removed from the system. The white solid was heated and melted and sliced to obtain 208.2 g of 98.8% white, odorless propoxur (liquid chromatography, external standard), with a yield of 98.4%. The mass of the yellow liquid removed from the system was 8.4 g, which was analyzed as a 39.5% solution of propoxur in petroleum ether, in which 1,2-diisopropoxybenzene and 1-isopropoxy-2-methoxybenzene were also dissolved. 2g of petroleum ether can be recovered by simple distillation, and the remaining oily residue after distillation can be incinerated....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com