Bus bar heat-shrinkable tube and preparation method thereof

A heat-shrinkable tube and busbar technology, applied in the field of heat-shrinkable tube and its preparation, can solve the problems of difficult construction, poor insulation performance, short service life, etc., and achieve excellent corrosion resistance, good flame retardant performance, high and low temperature resistance. Superior effect of aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The preparation method for preparing the above-mentioned busbar heat shrinkable tube includes the following steps:

[0058] Step 1: Weigh 60-80 parts of basic resin, 20-40 parts of ethylene-propylene rubber, 5-8 parts of dimethyl silicone oil, 40-70 parts of flame retardant, 4-10 parts of antioxidant, nano-montmorillonite 2-4 parts of soil, 2-5 parts of lubricant, 4-8 parts of masterbatch;

[0059] Step 2: After mixing and granulating with an internal mixer or a parallel twin-screw extruder, extrude into a pipe with a single-screw extruder;

[0060] Step 3: Treat the outer surface of the extruded pipe with infrared light with a wavelength of 700nm-1600nm at a distance of 5-10cm from the die of the extruder;

[0061] Step 4: The tube is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the tube after radiation cross-linking is expanded 2-4 times at a temperature of 85-135°C.

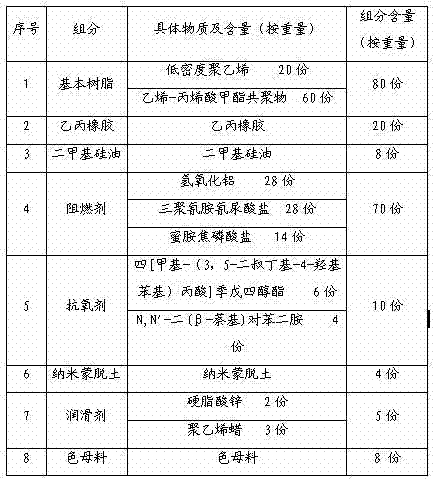

preparation Embodiment 1

[0063] The various components were weighed according to the weights listed in the table below.

[0064] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0065] The outer surface of the extruded pipe is treated with infrared light with a wavelength of 700-1600nm at a distance of 5-10cm from the die of the extruder.

[0066] The tube is cross-linked by cobalt 60 or electron accelerator 50KGy radiation, and the tube after radiation cross-linking is expanded 2.5 times at a temperature of 95°C to obtain a busbar heat-shrinkable tube, and its properties are as follows.

[0067] Flame retardant: passed the IEC60332 flame retardant test.

[0068] The tensile strength is 12.6MPa, and the elongation at break is 645%.

[0069] After 120°C / 168h aging and -55°C / 4h low temperature treatment, the power frequency withstand voltage test and lightning impact test passed.

[0070] After the heat-shrinkabl...

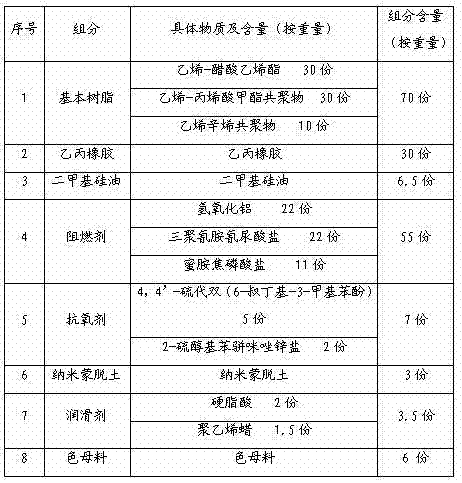

preparation Embodiment 2

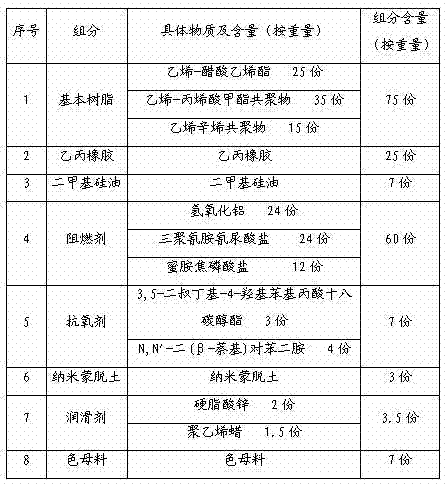

[0073] The various components were weighed according to the weights listed in the table below.

[0074]

[0075] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0076] The outer surface of the extruded pipe is treated with infrared light with a wavelength of 700-1600nm at a distance of 5-10cm from the die of the extruder.

[0077] The tube is cross-linked by cobalt 60 or electron accelerator 160KGy radiation, and the tube after radiation cross-linking is expanded 2.5 times at a temperature of 105°C to obtain a busbar heat-shrinkable tube, and its properties are as follows:

[0078] Flame retardant: passed the IEC60332 flame retardant test.

[0079] The tensile strength is 14.7MPa, and the elongation at break is 528%.

[0080] After 120°C / 168h aging and -55°C / 4h low temperature treatment, the power frequency withstand voltage test and lightning impact test passed.

[0081] After the he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com