Thermal shrinkage type fiber reinforced concrete

A fiber reinforced concrete technology, applied in the direction of fiber cutting, fiber treatment, fiber chemical characteristics, etc., can solve the problems of unsuitable concrete materials, low shrinkage strength, and difficult to disperse, and achieves low cost, high shrinkage rate, and improved mechanical properties. and the effect of rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

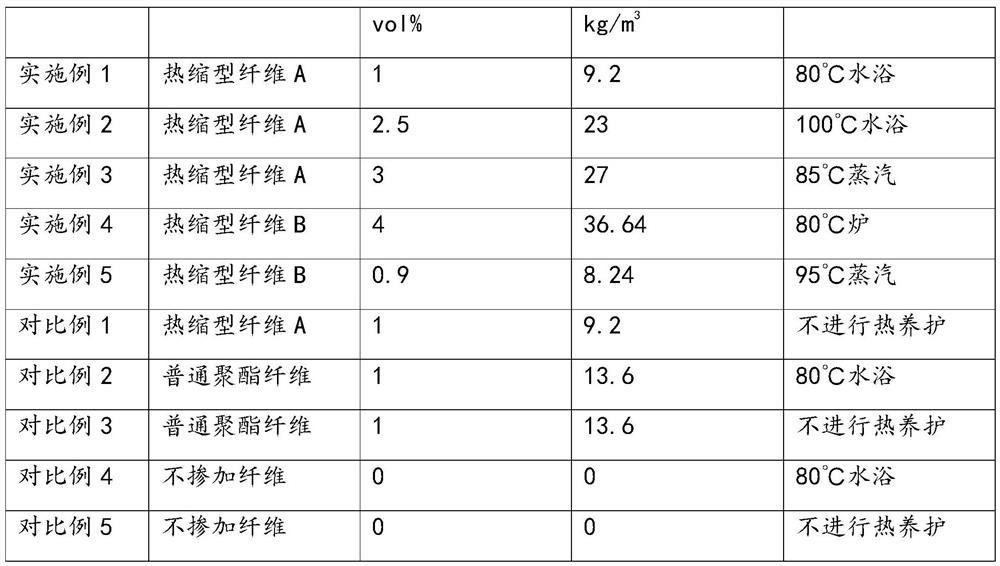

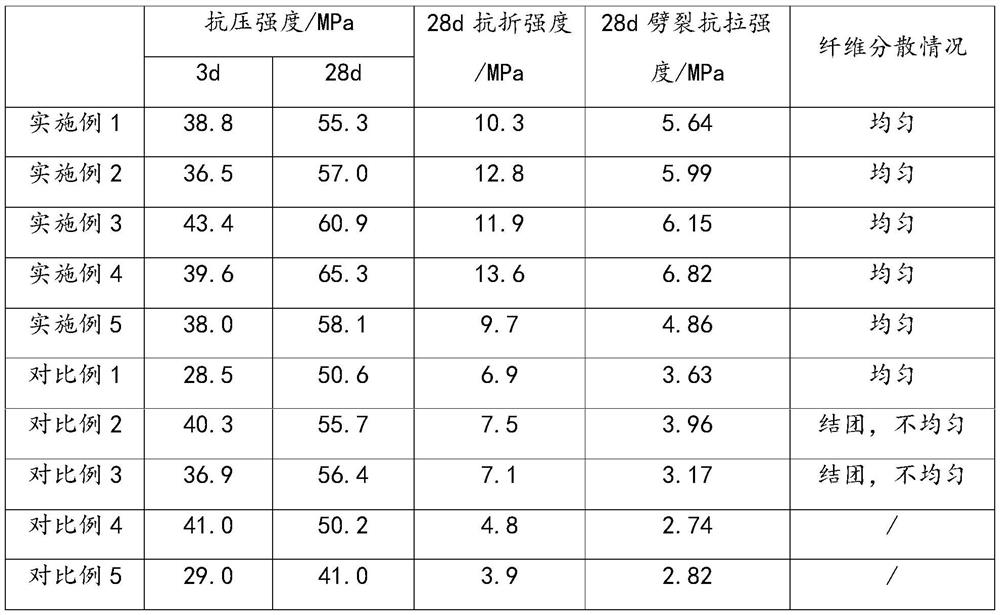

Embodiment 1

[0035] First prepare heat-shrinkable fiber A according to the following steps:

[0036] Choose 100 parts by weight of high-shrinkage polyester chips, 20 parts by weight of SiC whiskers, 3 parts by weight of triethylhexyl phosphoric acid, 2 parts by weight of zinc dialkyl dithiophosphate and 4.5 parts by weight of silane coupling agent , mixed to obtain raw materials. Dry the raw materials in a vacuum drying oven at 60°C for 12 hours, put them into a twin-screw extruder for blending and melt extrusion, and cool the raw fibers extruded from the extrusion port at a temperature of 10-20°C. Traction stretching, stretching 8 times, cooling at a temperature of 10-20°C; then performing a second stretching at a temperature of 110-115°C, stretching 1 time, to obtain heat-shrinkable fiber A, and cutting into lengths of 9mm chopped fibers with a fiber diameter of 0.15mm. The performance of the obtained heat-shrinkable fiber A: its density is 920kg / m 3 , The tensile strength at break is...

Embodiment 2

[0040] Using the heat-shrinkable fiber A in Example 1 to prepare concrete, the concrete mix ratio and curing method are the same as in Example 1, the difference is that the volume content of the heat-shrinkable fiber A is 2.5%, and the temperature of the water bath curing is 100°C .

Embodiment 3

[0042] The heat-shrinkable fiber A in Example 1 is used to prepare concrete, the concrete mix ratio is the same as that of Example 1, and the volumetric content of the heat-shrinkable fiber A is 3%. After the concrete is poured and shaped, it is cured in a standard curing environment for 24 hours, then placed in a steam curing box, heated at a rate of 15°C / h, maintained at a constant temperature of 85°C for 3 hours, and then cooled to 20°C at a rate of 10°C / h. Finally, put them in a standard conservation environment and preserve them for 28 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com