Stress activity fiber film and preparation method thereof

A technology of active fibers and fiber membranes, applied in the field of biomedical materials, to achieve the effects of promoting functional coordination, ensuring biocompatibility, good piezoelectric effect and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

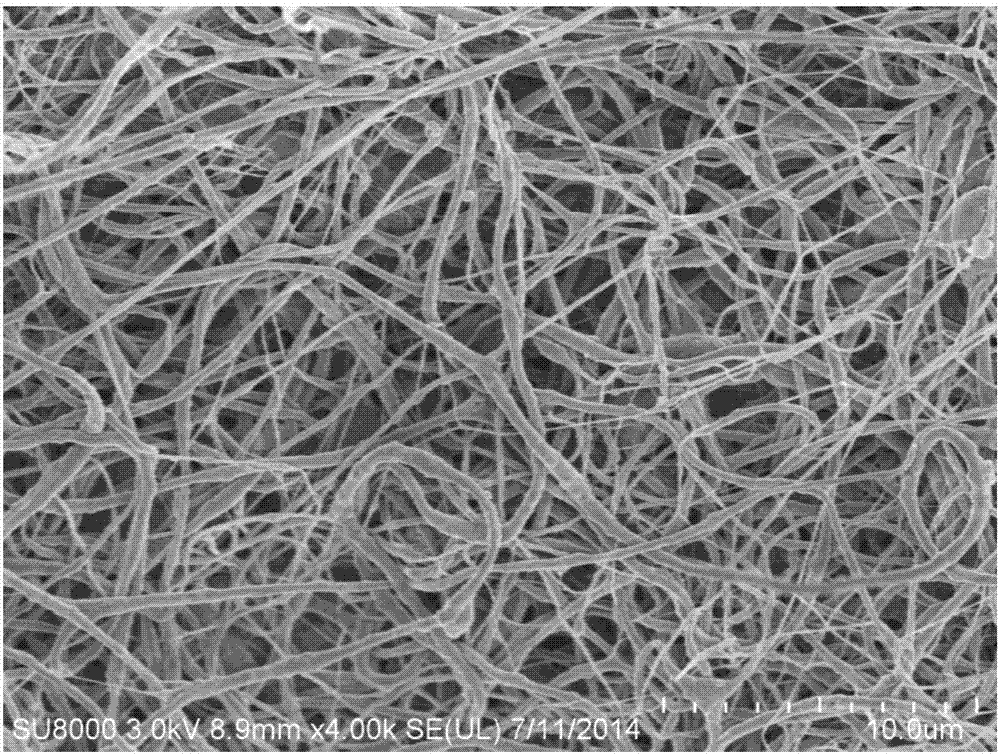

Image

Examples

preparation example Construction

[0027] A method for preparing a stress-activated fiber membrane, comprising preparing a silk fibroin solution or a silk fibroin powder dispersion, a medical polymer synthetic material solution, and a polyvinylidene fluoride solution, characterized in that: the stress-activated The preparation method of sex fiber film is carried out as follows:

[0028]a. Take the prepared silk fibroin solution or silk fibroin powder dispersion with a diameter less than 500nm and mix it with the medical polymer synthetic material solution to obtain a uniform and stable mixed solution or suspension, and suck it into the electrospinning machine Spinning liquid tube, wherein the mass ratio of silk fibroin and medical polymer synthetic material is 1 / 20~1 / 1, the total solute mass concentration of silk fibroin and medical polymer synthetic material is 7wt%~15wt%, take configuration A good concentration is 7wt%-15wt% polyvinylidene fluoride solution sucked into another spinning solution tube for elect...

Embodiment 1

[0039] a. taking hexafluoroisopropanol as a solvent and a silk fibroin solution with a mass concentration of 5wt%, and N,N-dimethylformamide as a solvent with a mass concentration of 20% polyurethane (PU) solution to mix to obtain silk fibroin The mass ratio with the medical polymer synthetic material polyurethane (PU) is 1 / 20, the total solute mass concentration of silk fibroin and the medical polymer synthetic material polyurethane (PU) is a mixed solution of 7wt%, and the mixed solution is sucked into the electrospinning The spinning liquid tube used is to suck the polyvinylidene fluoride solution with N,N-dimethylformamide as the solvent concentration of 7wt% into the spinning liquid tube for electrospinning.

[0040] b. Build the electrospinning device, use the rotating roller as the collection plate, and place two sets of electrospinning push pumps and corresponding high-voltage power supplies on the left and right sides of the rotating roller and on the reciprocating mov...

Embodiment 2

[0044] a. with hexafluoroisopropanol as a solvent, a mass concentration of 10wt% silk fibroin solution, and dimethylacetamide as a solvent mass concentration of 10wt% polycaprolactone (PCL) solution mixed to obtain silk fibroin and The mass ratio of medical polymer synthetic material polycaprolactone (PCL) is 1 / 10, and the total solute mass concentration of silk fibroin and medical polymer synthetic material polycaprolactone (PCL) is a mixed solution of 10wt%, and The mixed solution was sucked into the spinning liquid pipe for electrospinning, and the polyvinylidene fluoride solution with dimethylacetamide as the solvent concentration of 10 wt% was sucked into the spinning liquid pipe for electrospinning.

[0045] b. Build the electrospinning device, use the rotating roller as the collection plate, and place two sets of electrospinning push pumps and corresponding high-voltage power supplies on the left and right sides of the rotating roller and on the reciprocating moving tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com