A kind of titanium alloy composite material coated with composite coating and its preparation method and application

A technology of composite coating and composite materials, which is applied in the fields of dental implants, medical science, and dentistry, to achieve the effects of improving wear resistance and corrosion resistance, fine grains, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

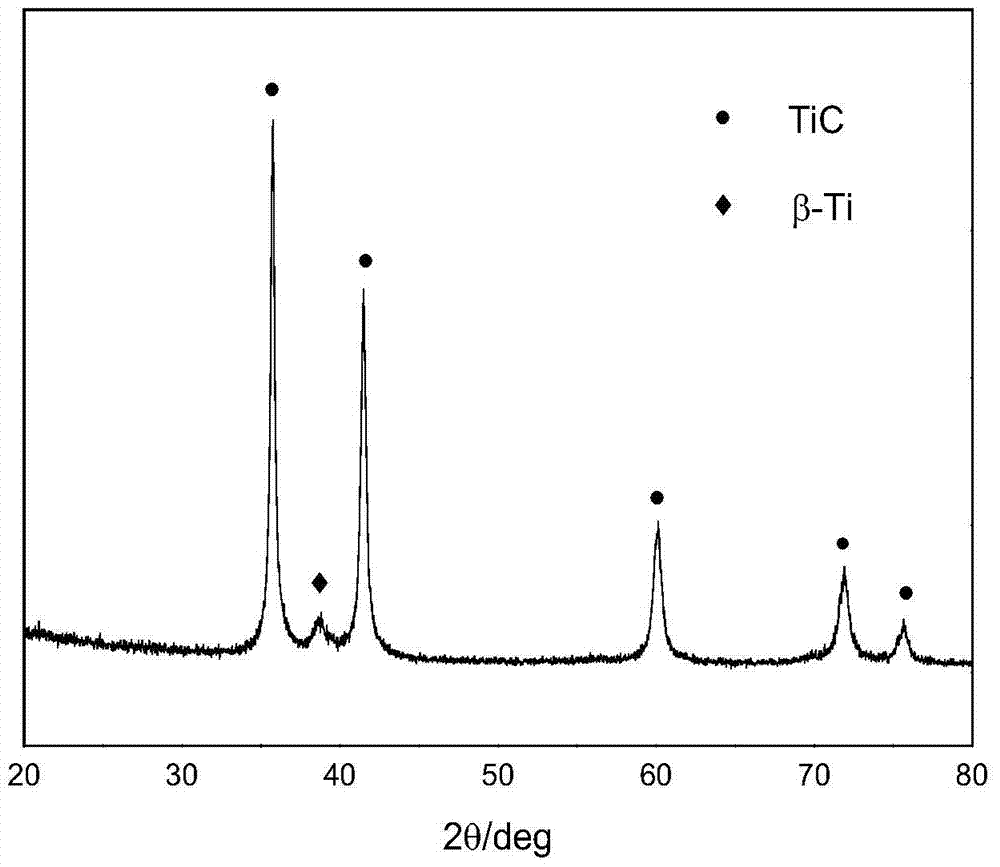

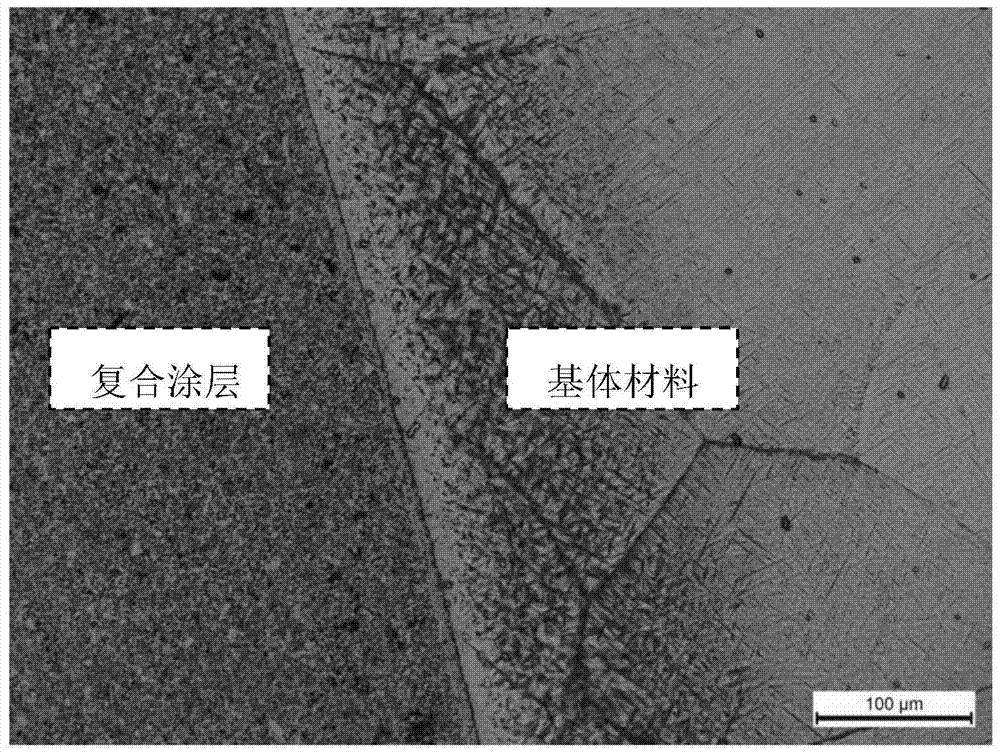

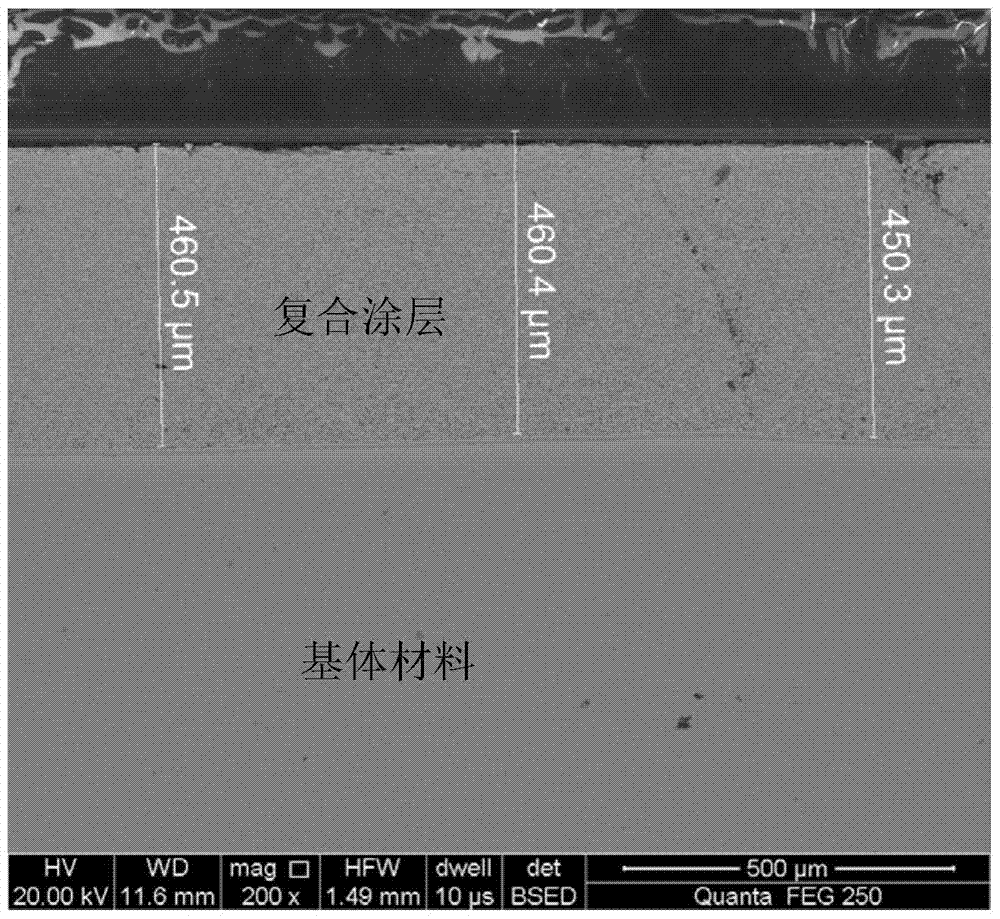

Embodiment 1

[0028] Reclaiming according to the following weight percentage: 89% titanium, niobium, tantalum and zirconium metal powder, 10% carbon nanotubes, 1% stearic acid, wherein stearic acid is used as a control agent to prevent cold welding during ball milling . The mass percentage of titanium, niobium, tantalum and zirconium element powder is Nb30%, Ta5%, Zr7%, Ti58%, the average particle size of titanium, niobium, tantalum and zirconium metal powder is 30-150 μm, the diameter of carbon nanotube is 20-30nm, and the length is 10- 30μm, the purity is greater than 95%.

[0029] The components weighed according to the above formula were placed in a ball mill jar, the ball-to-material ratio was 20:1, and the material of the grinding balls used was 201 stainless steel. In order to prevent the carbon nanotubes with low density from being sucked away in the vacuum, the carbon nanotubes are placed at the bottom of the ball mill jar, and then titanium, niobium, tantalum and zirconium elemen...

Embodiment 2

[0032] The ingredients are formulated according to the following weight percentages: 89% of titanium, niobium, tantalum and zirconium metal powder, 10% of carbon nanotubes, and 1% of stearic acid, wherein stearic acid is used as a control agent to prevent cold welding during the ball milling process. The mass percentage of titanium, niobium, tantalum and zirconium element powder is Nb30%, Ta5%, Zr7%, Ti58%, the average particle size of titanium, niobium, tantalum and zirconium metal powder is 30-150 μm, the diameter of carbon nanotube is 20-30nm, and the length is 10- 30μm, the purity is greater than 95%.

[0033] Put the components weighed according to the above formula into a ball mill jar, the ball-to-material ratio is 30:1, and the material of the grinding balls used is 201 stainless steel. In order to prevent the carbon nanotubes with low density from being sucked away in the vacuum, the carbon nanotubes are placed at the bottom of the ball mill jar, and then titanium, ni...

Embodiment 3

[0036] Dosing according to the following weight percentage: 94% titanium niobium tantalum zirconium metal powder, 5% carbon nanotubes, 1% stearic acid, wherein stearic acid is used as a control agent to prevent the powder from contacting with the grinding ball during the ball milling process Or cold welding occurs between ball milling tanks. The mass percentage of titanium, niobium, tantalum and zirconium metal powder is Nb30%, Ta5%, Zr7%, Ti58%, the average particle size of titanium, niobium, tantalum and zirconium element powder is 30-150 μm, the diameter of carbon nanotube is 20-30nm, and the length is 10- 30μm, the purity is greater than 95%.

[0037] The components weighed according to the above formula were placed in a ball mill jar, the ball-to-material ratio was 20:1, and the material of the grinding balls used was 201 stainless steel. In order to prevent the carbon nanotubes with low density from being sucked away in the vacuum, the carbon nanotubes are placed at the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com