A kind of micro-nano fiber membrane containing high-density amine groups and its centrifugal spinning preparation method and application

A technology of micro-nano fiber and centrifugal spinning, which is applied in the direction of dry-cleaning fiber products, rayon manufacturing, textiles and paper making, etc. It can solve the problems of high voltage and complicated process of electrospinning, and achieve the improvement of adsorption capacity and adsorption speed, Simplified preparation process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

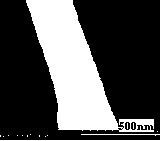

Image

Examples

Embodiment 1

[0032] Use 1wt% NaOH aqueous solution to adjust the pH value of 10ml of pure water to 9, use phenol red as a virtual template of bisphenol A, add 0.05g of phenol red, stir to dissolve, add 0.60g of polyvinylamine with a molecular weight of 300,000, stir to dissolve and prepare Spinning dope, filtered, debubbled, equipped to obtain 0.5wt% phenol red, 10wt% polyvinylamine mixed spinning dope. The mixture of ethanol and glutaraldehyde cross-linking agent is used as the coagulation liquid, and the concentration of glutaraldehyde to ethanol is 0.5%, and then the spinning solution is poured into a container with micropores at the bottom that can rotate at high speed. The diameter is 0.2mm, the rotation speed of the container is 12000rpm, and the centrifugal wet spinning is adopted. The spinning liquid is thrown out from the micropores at the bottom of the container and forms a micro-nano fiber film in the mixed coagulation liquid, and then 0.5mol / L NaOH solution elutes the phenol re...

Embodiment 2

[0035] Use 1wt% ethylenediamine aqueous solution to adjust the pH value of 10ml of pure water to 12, use phenol red as a bisphenol A virtual template, add 0.15g of phenol red, stir to dissolve, add 1.50g of polyethyleneimine with a molecular weight of 70,000, Stir and dissolve to form a spinning solution, filter, remove air bubbles, and prepare to obtain a mixed spinning solution of 1.5wt% phenol red and 10wt% polyethyleneimine. The mixed solution of ethanol and glutaraldehyde cross-linking agent is used as the coagulation solution, and the concentration of glutaraldehyde to ethanol is 3%, and then the spinning solution is poured into a container with micropores at the bottom that can rotate at high speed. The diameter is 2mm, the rotation speed of the container is 5000rpm, and the centrifugal wet spinning is adopted. The spinning liquid is thrown out from the micropores at the bottom of the container and forms a micro-nano fiber film in the mixed coagulation liquid, and then 3...

Embodiment 3

[0038] Use 1wt% triethylenetetramine aqueous solution to adjust the pH value of 10ml pure water to 10, use phenol red as a bisphenol A virtual template, add 0.10g phenol red, stir to dissolve, add 1.00g polyethyleneimine with a molecular weight of 10,000 , stirring and dissolving to form a spinning solution, filtering, removing air bubbles, and preparing to obtain a mixed spinning solution of 1.0wt% phenol red and 10wt% polyethyleneimine. A mixture of methanol and glutaraldehyde cross-linking agent is used as the coagulation liquid, wherein the concentration of glutaraldehyde to methanol is 2.5%, and then the spinning solution is poured into a container with micropores at the bottom that can rotate at high speed. The diameter is 1.4mm, and the rotation speed of the container is 8000rpm. Centrifugal wet spinning is adopted. The spinning liquid is thrown out from the micropores at the bottom of the container and forms a micro-nano fiber film in the mixed coagulation liquid, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com