Orientated nano fiber bionic nerve conduit and manufacturing method thereof

A technology of nanofibers and nerve conduits, which is applied in the field of nerve repair conduits and its production, can solve the problems of poor application effect and poor nerve regeneration effect, and achieve accelerated nerve regeneration speed, excellent tensile strength and shape maintenance ability, The effect of high fiber orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0045] The oriented nanofiber bionic nerve conduit of the present invention is made of oriented biodegradable nanofibers, the inner diameter of the nerve conduit is 0.5-5.0 mm, the outer diameter is 1.0-6.0 mm, and the inner and outer diameters can be adjusted according to needs; the degree of orientation ≥ 75%.

[0046] We take PLGA as an example, and adopt the spinning technology to make the nerve guide, the method is as follows:

[0047] Prepare the PLGA solution, connect the spinning device, adjust the spinning parameters such as the solution flow rate, voltage, roller speed, and receiving distance, and prepare a fiber film composed of uniaxially oriented nanofibers by roller stretching; the orientation direction of the nanofibers is In the axial direction, the fiber membrane is crimped to form a nerve fiber conduit, and the rolled nerve conduit can be fixedly connected by suturing or bonding.

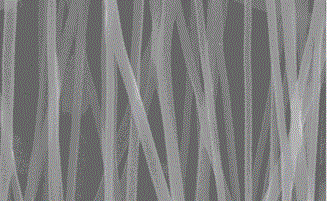

[0048] Under the acceleration voltage of 10kv, the fiber morphology was obser...

Embodiment approach 2

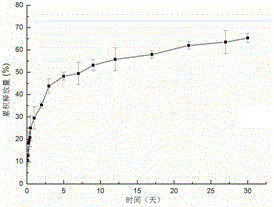

[0052] On the basis of Embodiment 1, the nanofibers that make up the bionic nerve guide of the present invention are hollow fibers, and the cavity is filled with biologically active substances such as nerve growth factor (NGF), such as proteins, drugs, etc., to form a shell, core structure.

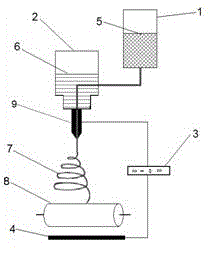

[0053] refer to figure 1 , taking the coaxial co-spinning electrospinning technology as an example, the manufacturing method of the oriented nanofiber bionic nerve guide of the present invention is as follows:

[0054] Prepare 8% concentration of PLGA solution as the shell solution 6; take 10 μg of NGF freeze-dried powder and dissolve it in phosphate buffered saline solution (PBS) with a pH value of 7.0~7.5, stir evenly to obtain the core solution 5 containing NGF; take two Syringes 1 and 2 absorb the shell solution and the core solution respectively, connect the coaxial electrospinning device, place the shell solution on the outer layer, and the core solution on the inner layer, adjust ...

Embodiment approach 3

[0067] On the basis of Embodiment 2, the core layer of the shell and core structural fibers constituting the bionic nerve guide of the present invention further includes polyethylene glycol.

[0068] Referring to the method described in Embodiment 2, the manufacturing method of the oriented nanofiber biomimetic nerve guide of the present invention is as follows:

[0069] Prepare 8% concentration of PLGA solution as the shell solution; take 10 μg of NGF freeze-dried powder and dissolve it in phosphate buffer solution (PBS) with a pH value of 7.2 to make NGF solution, add 400 mg of PEG to the NGF solution to make a concentration of 400 mg / ml of NGF / PEG solution as the core layer solution.

[0070] Take the syringe to absorb the core layer solution and the shell layer solution respectively, connect the coaxial electrospinning device, place the PLGA solution (shell layer solution) on the outer layer, and the NGF / PEG solution (core layer solution) on the inner layer, adjust the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com