A halogen-free flame-retardant heat-shrinkable busbar sleeve and its preparation method

A heat-shrinkable busbar sleeve and color masterbatch technology are applied in the field of halogen-free flame retardant heat-shrinkable busbar sleeve and its preparation, which can solve construction difficulties, short service life, and flame retardant performance of the busbar heat-shrinkable sleeve. It can achieve the effects of good drip resistance, low smoke generation, and outstanding high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also proposes a method for preparing the above-mentioned halogen-free flame-retardant heat-shrinkable busbar sleeve, which includes the following steps:

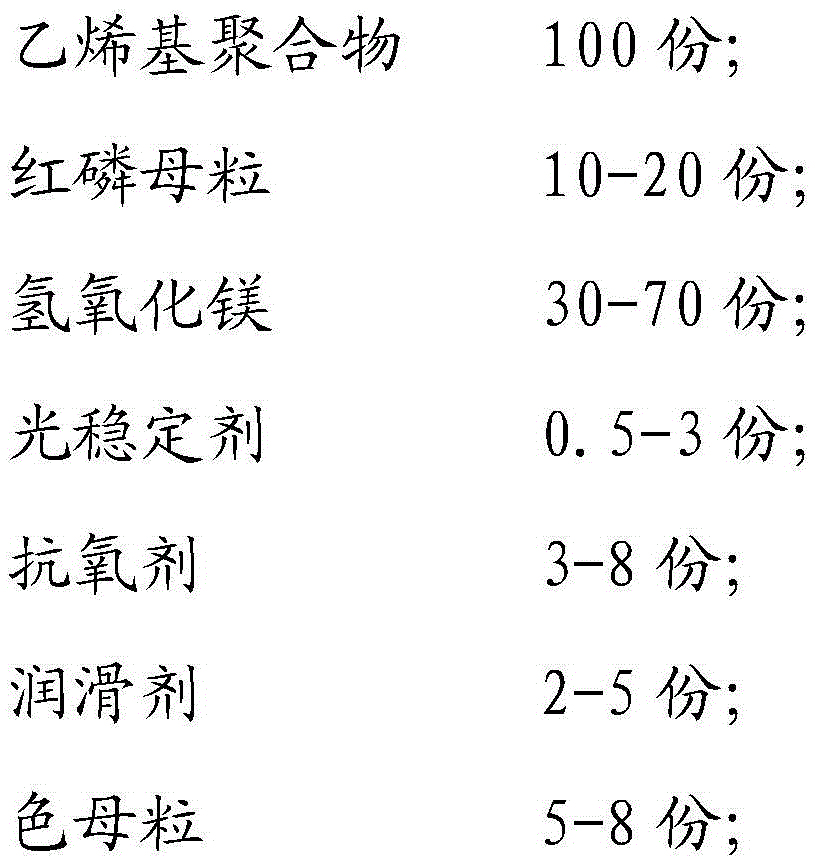

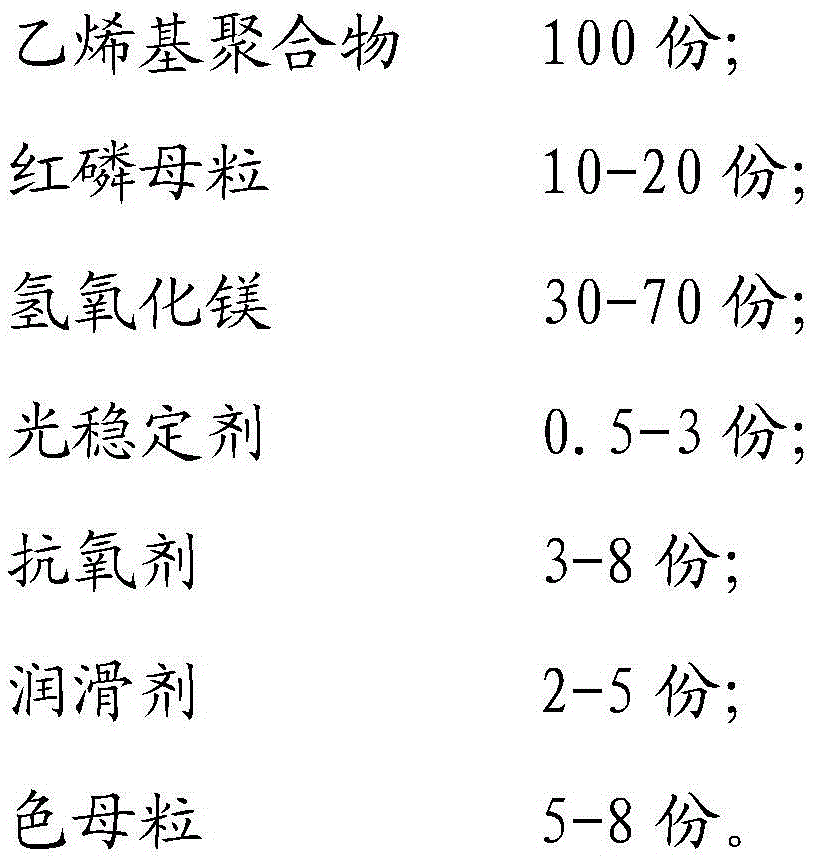

[0038] Step 1: Weigh 100 parts of vinyl polymer, 10-20 parts of red phosphorus masterbatch, 30-70 parts of magnesium hydroxide, 0.5-3 parts of light stabilizer, 3-8 parts of antioxidant, and 2 parts of lubricant -5 parts, 5-8 parts of color masterbatch;

[0039] Step 2: After mixing and granulating with an internal mixer or a parallel twin-screw extruder, extrude into a pipe with a single-screw extruder;

[0040] Step 3: The pipe is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the pipe after radiation cross-linking is expanded 2-4 times at a temperature of 85-135°C.

preparation Embodiment 1

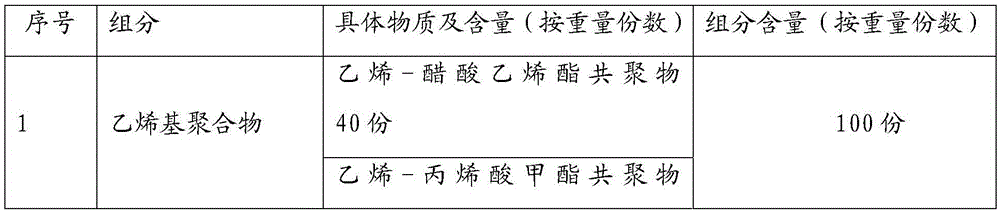

[0042] Weigh the components according to the weights listed in the table below.

[0043]

[0044]

[0045] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0046] The pipe was cross-linked by cobalt 60 radiation at 50KGy, and the radiation cross-linked pipe was expanded by 2.5 times at a temperature of 95°C to obtain a busbar heat-shrinkable tube with the following properties.

[0047] Flame retardancy: passed the vw-1 flame retardancy test.

[0048] The tensile strength is 14.7MPa, and the elongation at break is 585%.

[0049] After the heat-shrinkable sleeve of the busbar is restricted to shrink, the V-shaped notch is cut and aged at 120°C / 168h, and the crack does not extend.

[0050] After aging at 150℃ / 1200h, the elongation at break is 421%.

[0051] After 120°C / 168h aging, and then -55°C / 4h low temperature treatment, the power frequency withstand voltage test and lightning impa...

preparation Embodiment 2

[0053] Weigh the components according to the weights listed in the table below.

[0054]

[0055] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0056] The tube was cross-linked by radiation at 160 KGy of an electron accelerator, and the tube after radiation cross-linking was expanded 2.5 times at a temperature of 110° C. to obtain a heat-shrinkable busbar tube with the following properties.

[0057] Flame retardancy: passed the vw-1 flame retardancy test.

[0058] The tensile strength is 18.3MPa, and the elongation at break is 537%.

[0059] After the heat-shrinkable sleeve of the busbar is restricted to shrink, the V-shaped notch is cut and aged at 120°C / 168h, and the crack does not extend.

[0060] After aging at 150℃ / 1200h, the elongation at break is 461%.

[0061] After 120°C / 168h aging, and then -55°C / 4h low temperature treatment, the power frequency withstand voltage test and li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com