Halogen-free flame-retardant adhesion-proof heat-shrinkable bush and preparation method thereof

A heat-shrinkable sleeve and anti-sticking technology, which is applied in the field of halogen-free flame retardant and anti-sticking heat-shrinkable sleeve and its preparation, can solve the problems of short service life and poor flame retardant performance of the heat-shrinkable sleeve, and achieves high resistance to The effect of good dripping performance, good anti-sticking performance and low smoke emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

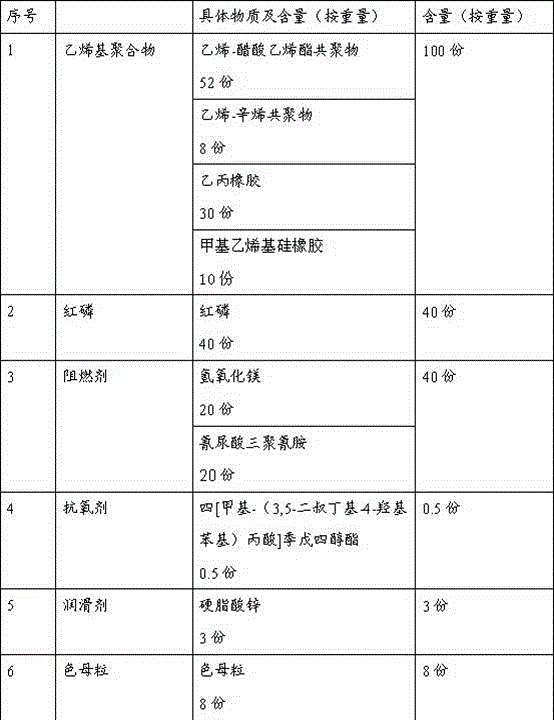

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned halogen-free flame-retardant anti-sticking heat-shrinkable sleeve includes the following steps:

[0041] Step 1: Take vinyl polymer by weight, 100 parts; red phosphorus, 20-40 parts; flame retardant, 50-80 parts; antioxidant, 0.5-3 parts; lubricant, 0.5-3 parts; Masterbatch, 5~8 parts;

[0042] Step 2: After mixing and granulating with an internal mixer or a parallel twin-screw extruder, extrude into a pipe with a single-screw extruder;

[0043] Step 3: The pipe is cross-linked by cobalt 60 or electron accelerator 50-160KGy radiation, and the pipe after radiation cross-linking is expanded 2-4 times at a temperature of 85-135°C.

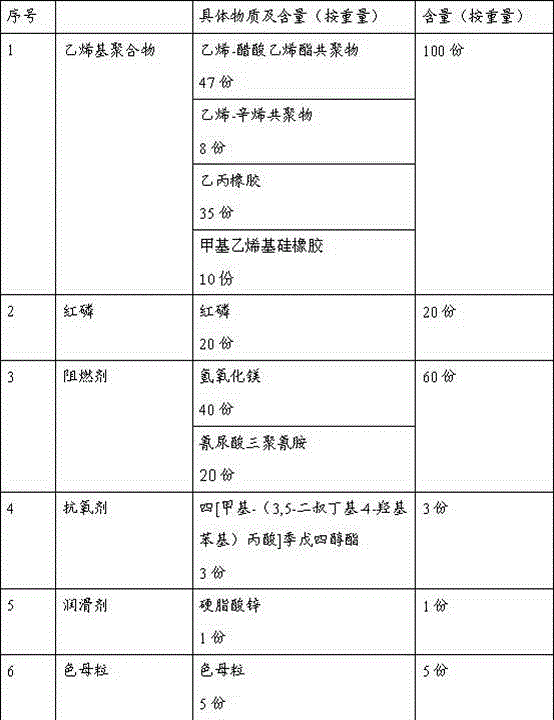

preparation Embodiment 1

[0045] Weigh each according to the weight listed in the table below.

[0046]

[0047] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0048] The pipe is cross-linked by cobalt 60 radiation at 50KGy, and the cross-linked pipe expands 2.5 times at a temperature of 135°C to obtain a halogen-free flame-retardant anti-sticking heat-shrinkable sleeve, and its properties are as follows.

[0049] Flame retardancy: passed the vw-1 flame retardancy test.

[0050] The tensile strength is 13.7MPa, and the elongation at break is 440.32%.

[0051] Halogen-free flame-retardant anti-adhesive heat-shrinkable sleeves for automotive steel pipes are limited and side-by-side. After shrinking and cooling to room temperature, they are separated by two opposite forces. The surface of the heat-shrinkable sleeve has no indentation, no deformation, and no stickiness.

[0052] After aging at 158℃ / 300h, the ten...

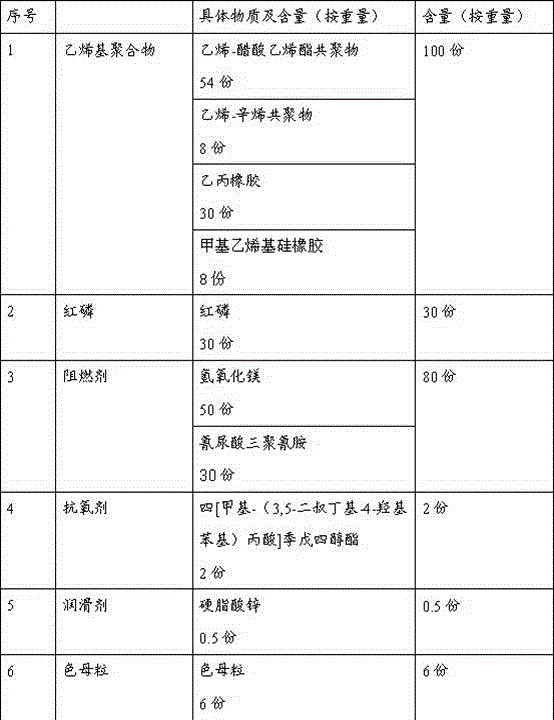

preparation Embodiment 2

[0055]

[0056] The above-mentioned materials are mixed and granulated by an internal mixer, and then extruded into pipes by a single-screw extruder.

[0057] The pipe is cross-linked by cobalt 60 radiation at 50KGy, and the cross-linked pipe expands 2.5 times at a temperature of 135°C to obtain a halogen-free flame-retardant anti-sticking heat-shrinkable sleeve, and its properties are as follows.

[0058] Flame retardancy: passed the vw-1 flame retardancy test.

[0059] The tensile strength is 16.83MPa, and the elongation at break is 471.50%.

[0060] Halogen-free flame-retardant anti-adhesive heat-shrinkable sleeves for automotive steel pipes are limited and side-by-side. After shrinking and cooling to room temperature, they are separated by two opposite forces. The surface of the heat-shrinkable sleeve has no indentation, no deformation, and no stickiness.

[0061] After aging at 158℃ / 300h, the tensile strength is 9.43MPa, and the elongation at break is 230.75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com