High-strength and high-temperature resistance EVA composite material and preparation method thereof

A composite material, high temperature resistance technology, applied in the field of modified EVA material and its preparation, can solve the problems of limited application scope, mechanical strength and high temperature resistance can not meet the needs of the market, etc., achieve high mechanical strength, improve thermal stability, etc. and mechanical properties, the effect of excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

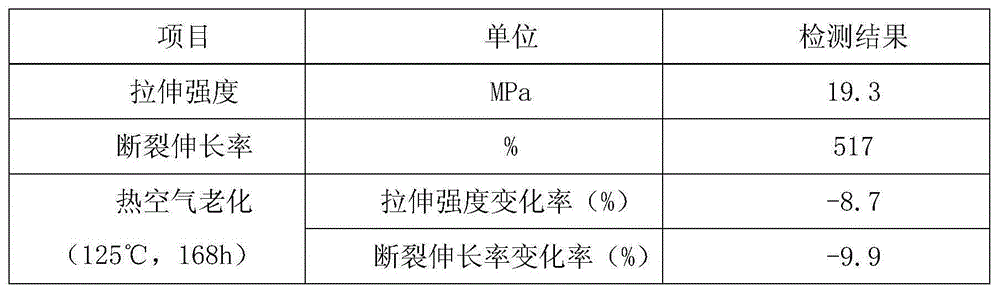

Examples

Embodiment

[0013] A high-strength and high-temperature-resistant EVA composite material, made of the following raw materials by weight (kg): ethylene-vinyl acetate copolymer 40, brominated isobutylene-p-methylstyrene copolymer 25, polybenzimidazole imide 20 , Nano palygorskite 16, polyphenylquinoxaline 18, epoxidized EPDM rubber 12, colloidal graphite powder 18, zinc sorbate 3, artificial stone polishing waste powder 32, dipropylene glycol dibenzoate 16 , stannous chloride 2.5, calcium stearate 2, barium stearate 1.5.

[0014] A preparation method of high-strength and high-temperature-resistant EVA composite material, comprising the following steps:

[0015] (1) Add brominated isobutylene-p-methylstyrene copolymer, epoxidized EPDM rubber, colloidal graphite powder, and calcium stearate into a high-speed mixer and stir until the material temperature reaches 70-80°C , stop stirring, let stand, cool to normal temperature, and discharge to obtain mixture A;

[0016] (2) Add polybenzimidazo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com