High resilience silicon rubber material and preparation method thereof

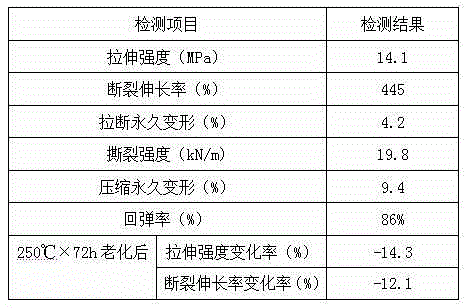

A silicone rubber, high resilience technology, applied in the field of silicone rubber, can solve the problem that the resilience performance of silicone rubber cannot meet special requirements, etc., and achieve the effects of low compression set, good aging resistance, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A high-resilience silicone rubber material, made of the following weight (kg): methyl vinyl silicone rubber 120, fumed silica 70, hydroxyl silicone oil 15, stearic acid 0.25, hydrogen silicone oil 0.8, tetramethyl Divinyl disiloxane 1.5, dipropylene glycol dibenzoate 12, bisbenzotriazole 0.4, alkylphenol disulfide 4, 1,4-bis-tert-butylperoxycumene 2.5, chalk Powder 8, jute short fiber 5, bispentamethylene thiuram tetrasulfide 1.5, 2-thiol methylbenzimidazole 0.8, additive 4.5;

[0011] The preparation method of the auxiliary agent is as follows: a, take the raw materials of the following weight (kg): rosin pentaerythritol ester 6, 4,5-epoxycyclohexane-1,2-diglycidyl dicarboxylate 3, zirconium fluoride 8. Thiophosphoric acid triphenyl isocyanate 3,4,4'-biphenyl diphenol 1.5, triisopropanolamine ring borate 4.5, methyl 2,2-dithienyl glycolate 2.5, bone cement powder 6 , tungsten carbide 8, decyl tetradecyl cetyl stearate 4, 2-(4-morpholino dithio) benzothiazole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com