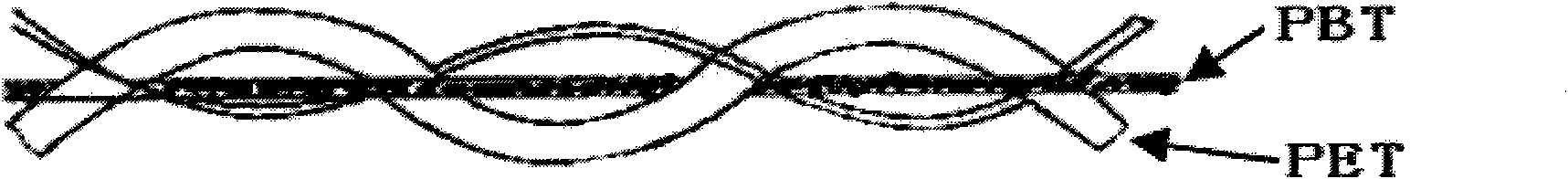

Novel production method of vehicular ATY (Air Texturing Yarn) elastic fiber

A technology of elastic fiber and production method, which is applied in the field of production of new ATY elastic fiber for vehicles, and can solve the problems of poor resilience of ATY space-changing yarn, insufficient warp and weft extension of fabrics, and inability to fully meet the needs of vehicle seat fabrics, etc. , to achieve the effect of simple production process route and improved resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

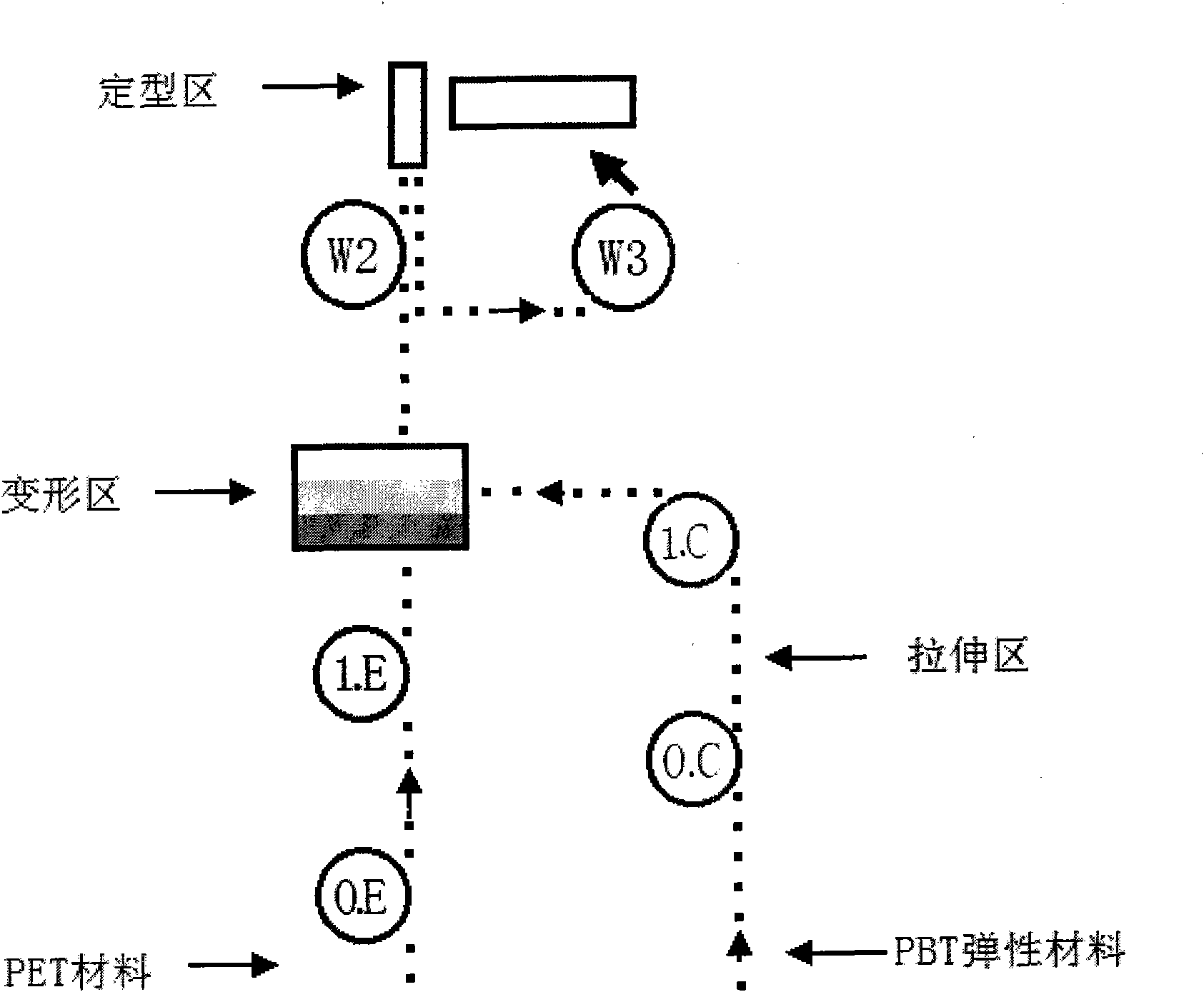

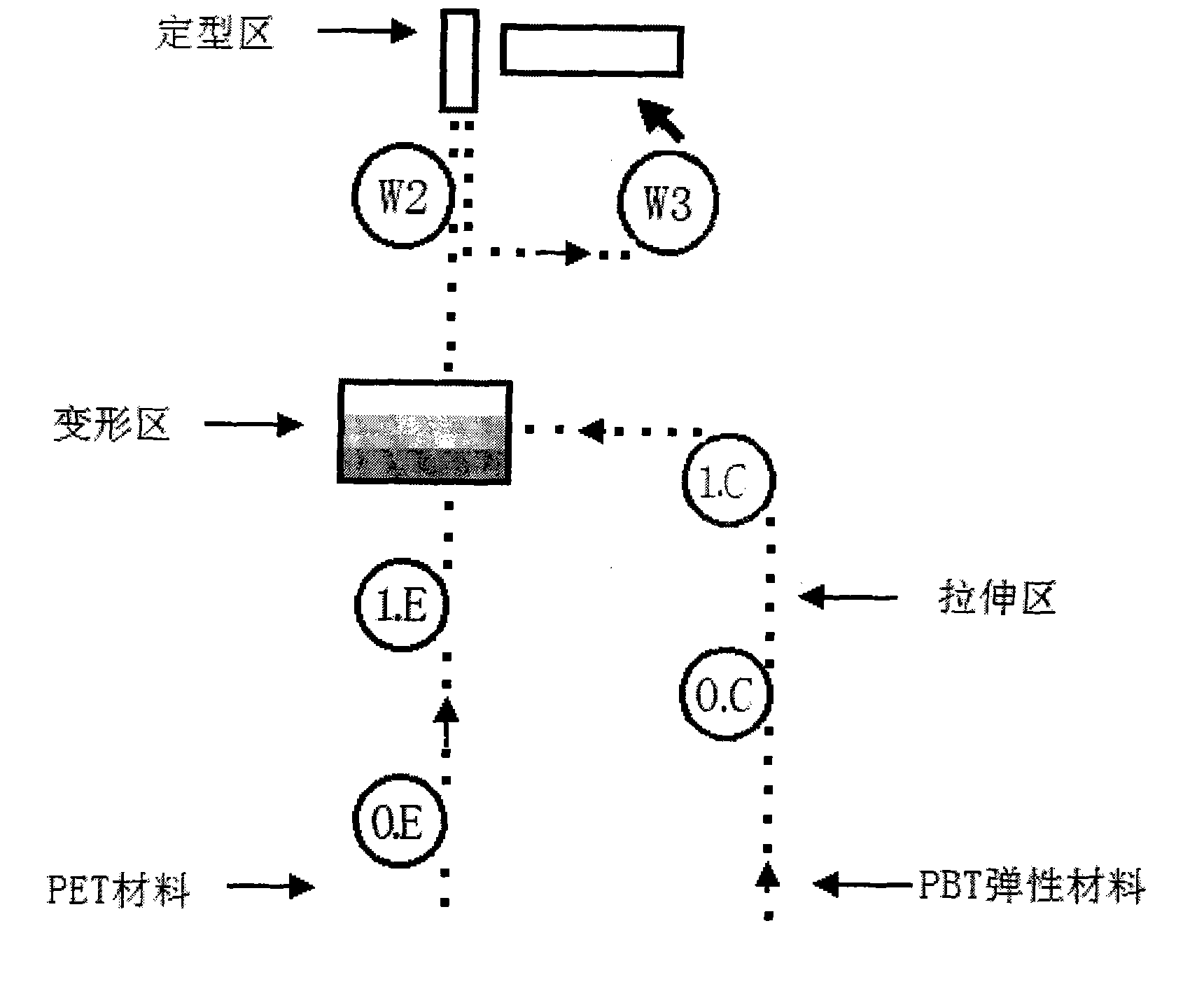

[0010] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0011] Such as figure 2 The process diagram shown is a production method of a new type of ATY elastic fiber for vehicles. First, POY is drawn to form a PET material, and POY is drawn to form a PBT elastic material; then the PET material and the PBT elastic material are preheated, and the PBT The elastic material is the core filament, and the PET material is the outer skin, which is air-deformed and entangled to form an air-textured yarn; finally, the air-textured yarn is shaped and wound. Oiling process can also be carried out before winding.

[0012] By implanting high-elastic PBT materials and intertwining and coating, the resilience of ATY yarns of craft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com