Cold-resistant PVC sheath material for cable and preparation method thereof

A sheath material and cold-resistant technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of poor cold resistance, easy brittleness and cracking, and affect the performance of cables, and achieve the effect of broad application prospects and excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

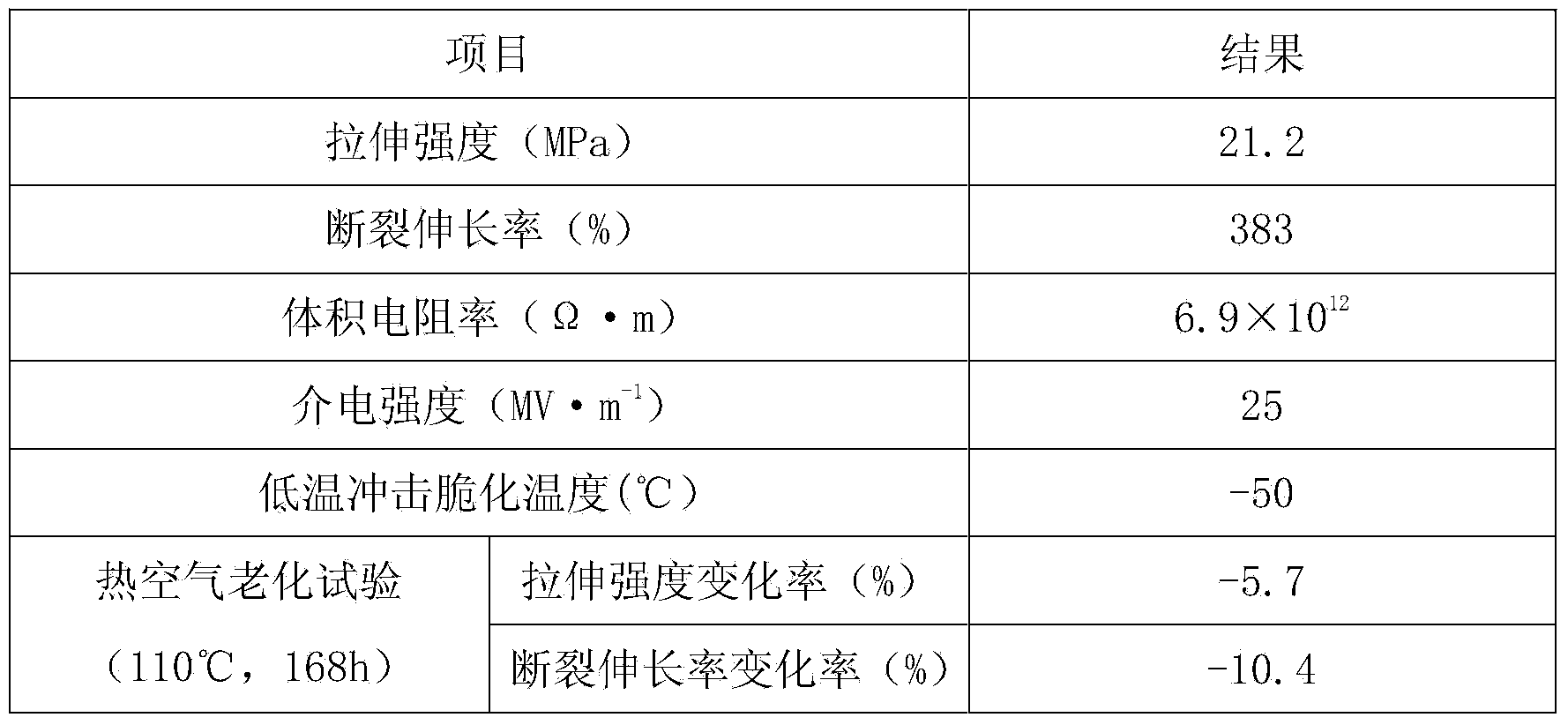

Examples

Embodiment Construction

[0010] A cold-resistant PVC sheathing material for cables, made of the following raw materials (kg): SG-4 type polyvinyl chloride 80, chlorosulfonated polyethylene 20, neoprene 15, epoxy tetrahydrophthalic acid Dioctyl Ester 12, Diisobutyl Nylonate 8, ACR5, Ethylene Bis Stearic Acid Amide 2, Dipropylene Glycol Dibenzoate 10, Antioxidant 2461, Decabromodiphenyl Ether 12, Polyphosphoric Acid Ammonium 6, dibasic lead phosphite 1, tribasic lead sulfate 1.5, barium stearate 2, epoxy soybean oil 6, titanium dioxide 4, acetylene carbon black 25, calcined loess 8, activated calcium carbonate 12, composite filler 5;

[0011] The preparation method of the composite filler is as follows: a. Take bentonite, barite, and monazite in a weight ratio of 5:4:3, then add 2% coal powder and 1.5% activated carbon by weight of bentonite, and mix them uniformly at 550°C Calcined for 4 hours, cooled to room temperature, crushed to a particle size below 15 μm, then added water to beat to make a slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com