Permeation type dyeing auxiliary for dyeing aramid fiber and preparation method of permeation type dyeing auxiliary

A technology of penetrating and dyeing aids, applied in the field of penetrating dyeing aids, can solve the problems of difficult dyeing of aramid fiber, and achieve the effect of easy dyeing and fiber protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

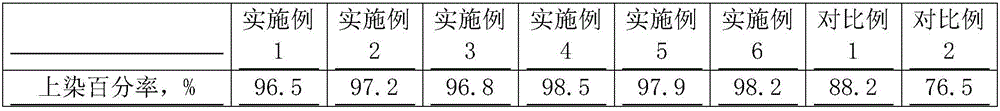

Examples

Embodiment 1

[0042] A kind of penetrating dyeing aid for aramid fiber dyeing, in parts by weight, comprises the following components:

[0043] 5 parts of malic acid, 5 parts of sodium acetate,

[0044] 6 parts cysteine, 2 parts guar gum,

[0045] 10 parts of sodium alginate, 3 parts of dipropylene glycol dibenzoate,

[0046] 2 parts of castor oil polyoxyethylene ether, 1 part of pH regulator,

[0047] 2 parts of emulsifier, 10 parts of deionized water.

[0048] Its preparation method comprises the following steps:

[0049] (1) Mix and stir malic acid, sodium acetate, cysteine, sodium alginate and deionized water evenly to obtain mixed solution A;

[0050] (2) Mix and stir guar gum, dipropylene glycol dibenzoate, castor oil polyoxyethylene ether and deionized water evenly, add an emulsifier, and ultrasonicate for 2 hours at a power of 500W to obtain a mixed solution B;

[0051] (3) Mix the mixed solution A obtained in step (1) and the mixed solution B obtained in step (2) uniformly, ad...

Embodiment 2

[0053] A kind of penetrating dyeing aid for aramid fiber dyeing, in parts by weight, comprises the following components:

[0054] 12 parts of malic acid, 10 parts of sodium acetate,

[0055] 11 parts of cysteine, 6 parts of guar gum,

[0056] 15 parts of sodium alginate, 7 parts of dipropylene glycol dibenzoate,

[0057] 4 parts of castor oil polyoxyethylene ether, 2 parts of pH regulator,

[0058] 3 parts of emulsifier, 15 parts of deionized water.

[0059] Its preparation method comprises the following steps:

[0060] (1) Mix and stir malic acid, sodium acetate, cysteine, sodium alginate and deionized water evenly to obtain mixed solution A;

[0061] (2) Mix and stir guar gum, dipropylene glycol dibenzoate, castor oil polyoxyethylene ether and deionized water evenly, add an emulsifier, and ultrasonicate for 3 hours at a power of 800W to obtain a mixed solution B;

[0062] (3) Mix the mixed solution A obtained in step (1) and the mixed solution B obtained in step (2) uni...

Embodiment 3

[0064] A kind of penetrating dyeing aid for aramid fiber dyeing, in parts by weight, comprises the following components:

[0065] 10 parts of malic acid, 8 parts of sodium acetate,

[0066] 7 parts of cysteine, 2-6 parts of guar gum,

[0067] 12 parts of sodium alginate, 5 parts of dipropylene glycol dibenzoate,

[0068] 3.5 parts of castor oil polyoxyethylene ether,

[0069] 1.5 parts of pH regulator, 2 parts of emulsifier, 15 parts of deionized water.

[0070] Its preparation method comprises the following steps:

[0071] (1) Mix and stir malic acid, sodium acetate, cysteine, sodium alginate and deionized water evenly to obtain mixed solution A;

[0072] (2) Mix and stir guar gum, dipropylene glycol dibenzoate, castor oil polyoxyethylene ether and deionized water evenly, add an emulsifier, and ultrasonicate for 2.2 hours at a power of 600W to obtain a mixed solution B;

[0073] (3) Mix the mixed solution A obtained in step (1) and the mixed solution B obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com