Preparation method of antirust paint for power distribution cabinet

An anti-rust paint and power distribution cabinet technology, applied in the field of metal anti-rust paint, can solve the problems of poor weather resistance, easy to fall off, not suitable for complex, etc., to achieve excellent anti-rust and self-cleaning, not easy to peel off, wear resistance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

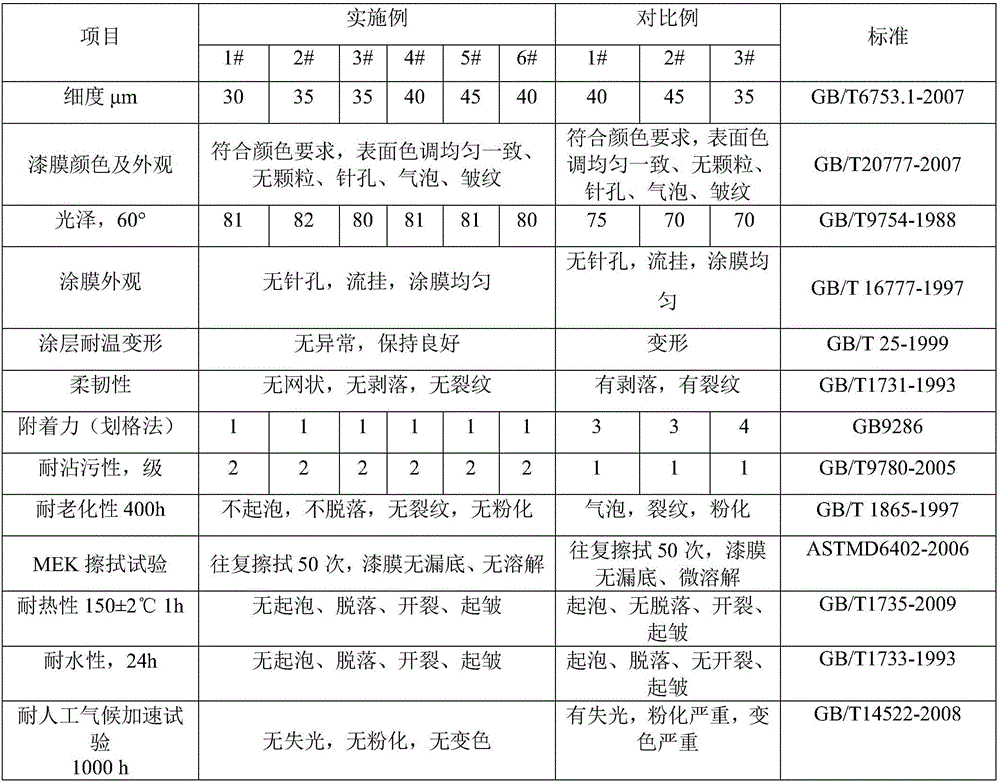

Examples

Embodiment 1

[0026] A preparation method for an antirust paint for a power distribution cabinet, comprising the following steps:

[0027] (1) Add chlorinated rubber, film-forming aids, fillers, paint film self-cleaning agent, and defoamer to ethyl acetate solution, heat to 40-50°C, ultrasonically disperse for 30-40min, and add phytic acid Esters and dipropylene glycol dibenzoate, under the condition of 600-800r / min, stir for 20-30min;

[0028] (2) Raise the temperature in step (1) to 50-60°C, add modified alkyd resin, fluorocarbon resin, and glass resin, and stir for 40-50 minutes at a speed of 600-1000 r / min;

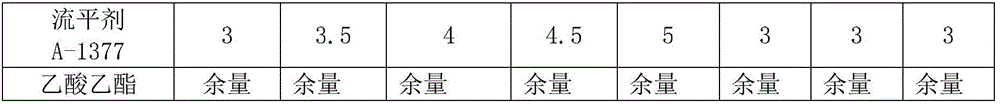

[0029] (3) Add leveling agent, stir and disperse for 10-20 minutes under the condition of 600-800r / min speed; mix evenly, add to the grinder to grind and disperse evenly, filter to get the material with a fineness of 30-45μm, and pack it ;

[0030] Among them, the composition of each component is calculated in parts by weight: phytate 5-10 parts, dipropylene glycol dibenzoate 3-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com