Polyolefin insulated cable material used for rail transit vehicle and preparation method thereof

A technology for rail transit vehicles and cable materials, used in insulators, circuits, electrical components, etc., can solve problems such as poor mechanical properties, poor aging resistance, and poor weather resistance, and achieve excellent weather resistance, high mechanical strength, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

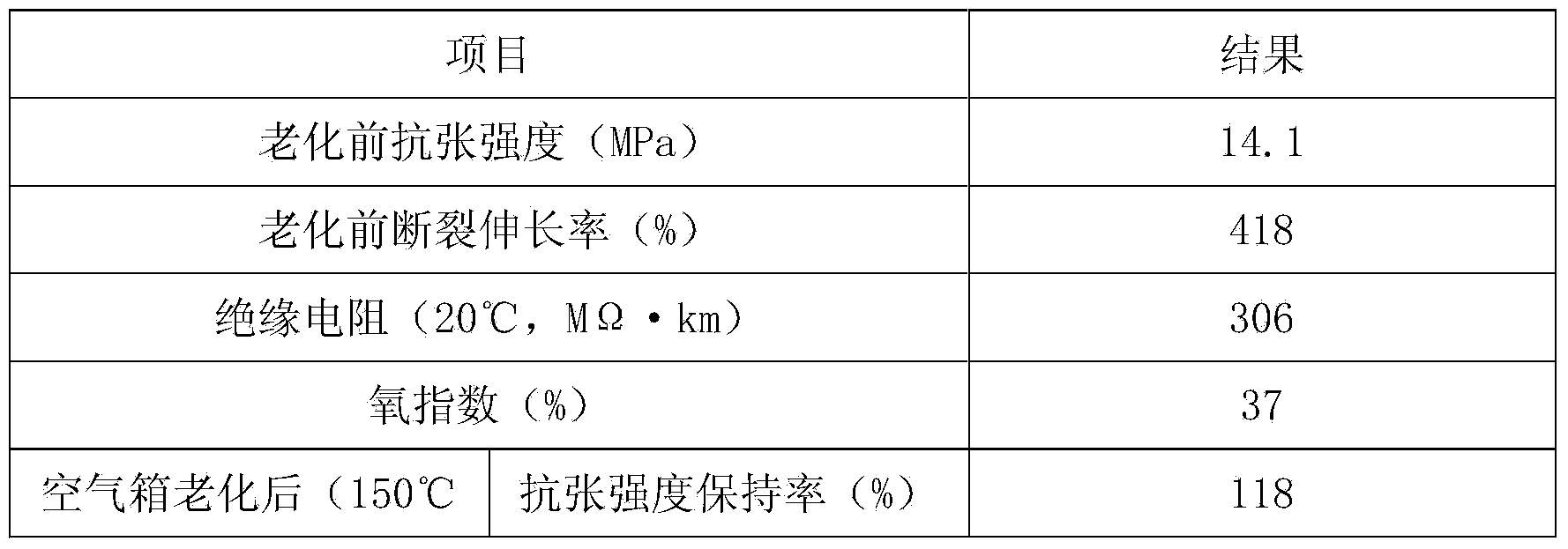

Examples

Embodiment Construction

[0013] A polyolefin insulated cable material for rail transit vehicles, made of the following raw materials in parts by weight: high-density polyethylene 60, ethylene-octene copolymer 20, poly-4-methyl-1-pentene 20, dipropylene glycol di Benzoate 15, Behenamide 5, Microcrystalline Paraffin 4, Zinc Stearate 2.5, Lanthanum Stearate 1.5, Epoxy Linseed Oil 8, Isomalt 3, Dibenzoylmethane 4, Organic Mongolia Soil removal 18, brucite powder 12, nano-spherical silica 26, hexabromocyclododecane 18, calcium phosphomolybdate 15, pentaerythritol polyphosphate melamine salt 10, three (3,5-di-tert-butyl- 4-Hydroxybenzyl) isocyanurate 3, dioctadecyl thiodipropionate 2, modified stone powder 12;

[0014] The preparation method of the modified stone powder is as follows: (1) Weigh coke gemstones, volcanic stones, and attapulgite at a weight ratio of 5:3:2, mix them uniformly, calcinate at 760°C for 2 hours, cool naturally to room temperature, pulverize, and sieve , stand-by; (2) getting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com