Single-component reaction-type polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, applied in the field of polyurethane hot-melt adhesive, can solve the problems of insufficient high and low temperature resistance and chemical pollution resistance, achieve good low temperature flexibility, improve high and low temperature resistance, and weaken the interaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The composition of embodiment 1-4 and comparative example 1 sees the following table:

[0043] Component / part

A

B

C

D

E

F

G

H

Example 1

55

13

0.5

10

6

1

1

0

Example 2

60

17

0.35

6

12

3

2

0

Example 3

40

12

0.65

15

10

2

3

0

Example 4

50

15

0.5

12

8

2

5

0

Example 5

50

15

0.5

12

8

2

5

2

Comparative example 1

50

15

0.5

12

8

2

0

0

Comparative example 2

50

15

0.5

12

8

2

0

2

[0044] In the table above: A stands for polyol, B stands for polyisocyanate, C stands for catalyst, D stands for chain extender, E stands for tackifying resin, F stands for latent curing agent, G stands for plasticizer, H stands for vinyl unsaturated mono body.

[0045] In Examples 1-5 and Comparative Examples 1-2, the polyester polyol is XCP-3000H commerci...

Embodiment 6

[0051] Embodiment 6-10 is based on embodiment 5, difference is, the polyester polyol of embodiment 6 is polyethylene adipate diol, polyisocyanate is toluene diisocyanate, and catalyst is dimethylethanolamine; Embodiment 7 The plasticizer is dioctyl phthalate; the ethylenically unsaturated monomer of embodiment 8 is 1,2-dimethyl-3-(1-methylvinyl) cyclopentanol, the ethylene of embodiment 9 The base unsaturated monomer is 1,2-epoxy-4-vinylcyclohexane.

[0052] In the preparation process, the end point of the reaction between the polypolyol and the polyisocyanate is controlled so that the isocyanate content reaches 2.4%.

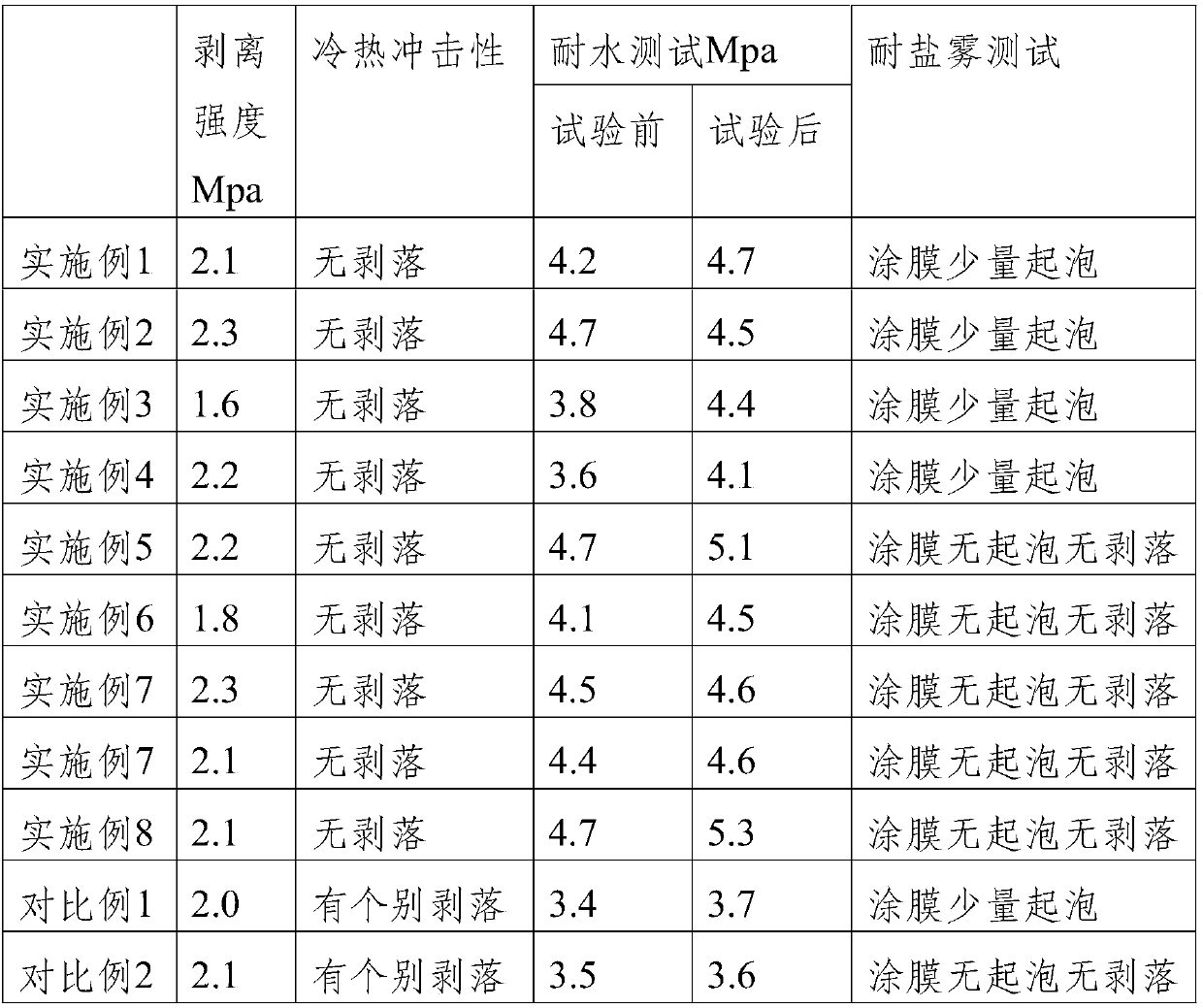

[0053] Peel strength (GB / T2791-95), thermal shock (ASTM D-746-40~80 ℃, 15 days), water resistance test ( 85°C 85% test before and after 1000 hours of shear strength) and salt spray resistance test (500 hours salt spray box sodium chloride 5%, test temperature 45°C), the test results are shown in the following table:

[0054]

Embodiment 8

[0056] In Example 8, the shear strength of the hot-melt adhesive coating film in the water resistance test increased significantly, indicating that the epoxy group in the 1,2-epoxy-4-vinylcyclohexane also played the role of a hydrolysis stabilizer to prevent ester bond Fracture and degradation of polymers. Therefore, preferred ethylenically unsaturated monomers are 1,2-epoxy-4-vinylcyclohexane and 1,2,8,9-bisepoxy-4-vinylcyclohexane with epoxy groups alkene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com