Preparation method and product of adipate epoxy plasticizer

A technology of epoxy plasticizer and adipate, which is applied in the preparation of adipate epoxy plasticizer, in the field of plasticizers, can solve the problem that it is difficult to meet the requirements of diversification, the type of plasticizer is single, and the preparation Complicated process and other issues, to achieve the effect of increasing heat resistance, low raw material cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

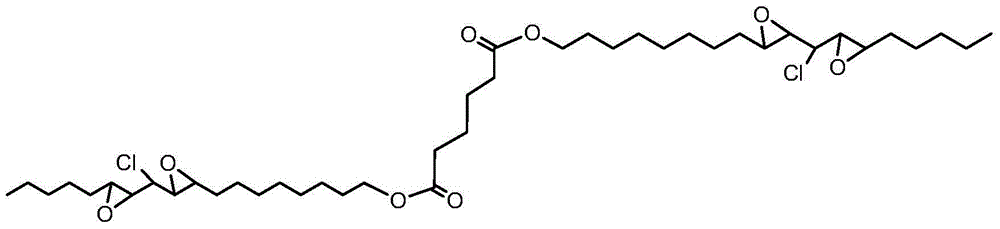

Image

Examples

Embodiment 1

[0043] Dissolve azobenzene in 100ml of n-heptane / n-butanol mixed solvent, the volume ratio of mixed solvent n-heptane / n-butanol is 10:1, and the concentration is 1×10 -6 mol / L solution, and then sonicated for 30 min.

[0044] At room temperature, add the prepared sodium aluminate aqueous solution with a mass percentage concentration of 5% dropwise with a dropper, add it to saturation and end when it is not turbid (about 9g), and continue to ultrasonically vibrate for 30min after adding to accelerate. The micelles are formed, and the micelle structure is stabilized, and then the ultrasonic reaction is continued for 1 hour while carbon dioxide is introduced into it.

[0045] Add concentrated sulfuric acid (the amount of added sulfuric acid is 16% of the soapstock weight) dropwise to the raw vegetable oil residue, control the pH of the solution in the range of about 2-3, stir for 3h, use ethanol as an extractant to extract the fatty acid, and the amount of ethanol About 500 mL, ...

Embodiment 2

[0050] Dissolve azobenzene in 100ml of n-heptane / n-butanol mixed solvent, the volume ratio of mixed solvent n-heptane / n-butanol is 10:1, and the concentration is 2×10 -5 mol / L solution, and then sonicated for 30 min.

[0051] At room temperature, add the prepared sodium aluminate aqueous solution with a mass percentage concentration of 7% dropwise with a dropper, add it to saturation and end when it is not turbid (about 6g), and continue to ultrasonically vibrate for 45min after the addition to accelerate. The micelles are formed and the micelle structure is stabilized, and then the ultrasonic reaction is continued for 2 hours while carbon dioxide is introduced into it.

[0052] Add concentrated sulfuric acid (the amount of added sulfuric acid is 16% of the soapstock weight) dropwise to the raw vegetable oil residue, control the pH of the solution in the range of about 2-3, stir for 3h, use ethanol as an extractant to extract the fatty acid, and the amount of ethanol About 50...

Embodiment 3

[0057] Dissolve azobenzene in 100ml of n-heptane / n-butanol mixed solvent, the molar ratio of mixed solvent n-heptane / n-butanol is 10:1, and the mass percentage concentration is 6×10 -4 mol / L solution, and then sonicated for 30 min. At room temperature, add the prepared sodium aluminate aqueous solution with a concentration of 10% dropwise with a dropper, add it to saturation and end when it is not turbid (about 6g), and continue to ultrasonically shake for 60min after the addition to accelerate the micelles. The micelle structure is formed and stabilized, and then the ultrasonic reaction is continued for 3 hours while carbon dioxide is introduced into it, and the reaction temperature is 60° C. The desired catalyst-reverse micelle nano-alumina catalyst can be obtained.

[0058] Add concentrated sulfuric acid (the amount of added sulfuric acid is 16% of the soapstock weight) dropwise to the raw vegetable oil residue, control the pH of the solution in the range of about 2-3, stir...

PUM

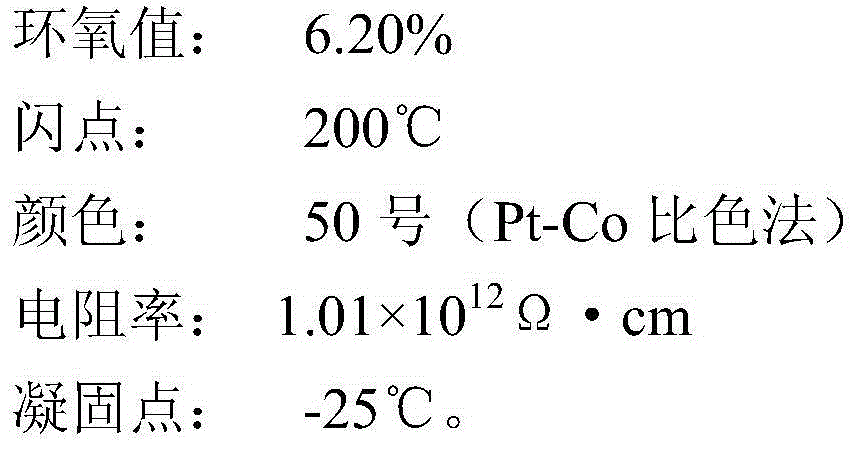

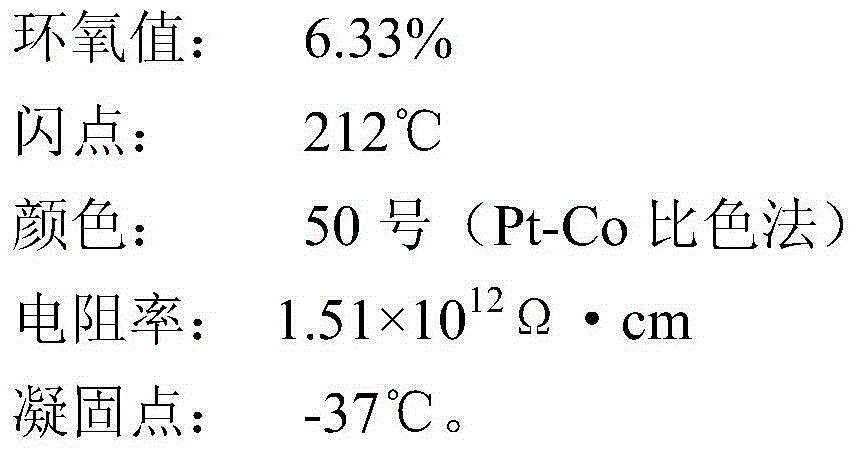

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com