A plastic plasticizing method and device based on co2 laser

A laser and plastic technology, applied in the field of plastic plasticization based on CO2 laser, can solve the problems of inability to achieve micro-plasticization effect, limitation of lap welding of engineering plastics, inability to penetrate plastic materials, etc., and achieve easy micro-plasticization and plasticization. Short curing time and good plasticizing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

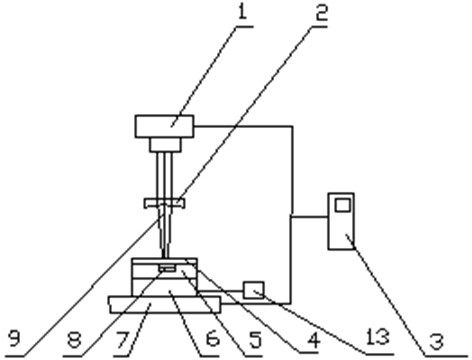

[0026] Take the plasticization of a nylon PA12 sample with a diameter of 6mm, a thickness of 1mm, and a mass of about 30mg as an example.

[0027] First prepare a plastic sample with a diameter of 6 mm and a thickness of 1 mm, which is punched from a sheet, dried in an oven and preheated.

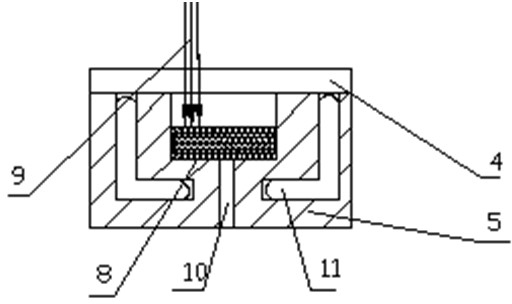

[0028] The control system sets the temperature control value, the heating thermostat 11 starts to work, heats the plasticizing device and keeps the temperature near the melting point of nylon PA12 at 215-235 degrees Celsius.

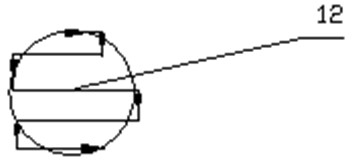

[0029] Laser parameter adjustment. Open CO 2 The laser, which outputs light energy with a wavelength of 10.6 microns, adjusts the laser beam regulator to adjust the diameter of the laser beam spot to 1mm, and the controller controls the laser to output laser energy to 5mJ.

[0030] Put the plastic sample into a plasticizing cylinder at a temperature of 215-235 degrees Celsius, and cover with a constraining layer, which is K9 glass.

[0031] Adjust the laser...

Embodiment 2

[0034] Take nylon PA66 particles with a diameter of 2mm and a thickness of 1mm, the number of particles is 10, and the mass is about 500mg.

[0035] First prepare a plastic sample with a diameter of 2 mm and a thickness of 1 mm. The number of particles is 10 and the mass is about 500 mg. The plastic is die-cut from masterbatch particles or sheets, and is dried and preheated in an oven.

[0036] The control system sets the temperature control value, the heating thermostat 11 starts to work, heats the plasticizing device and keeps the temperature near the melting point of nylon PA66 at 225-240 degrees Celsius.

[0037] Laser parameter adjustment. Open CO2 The laser, which outputs light energy with a wavelength of 10.6 microns, adjusts the laser beam regulator to adjust the diameter of the laser beam spot to 2mm, and the controller controls the laser to output laser energy to 3mJ.

[0038] Put the plastic sample into a plasticizing cylinder at a temperature of 225-240 degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com