Elevator system with lightweight glass plates

A glass plate and equipment technology, applied in the field of elevator equipment, can solve the problems of heavy glass components, unsightly connectors, and cost, and achieve the effect of reducing motion energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

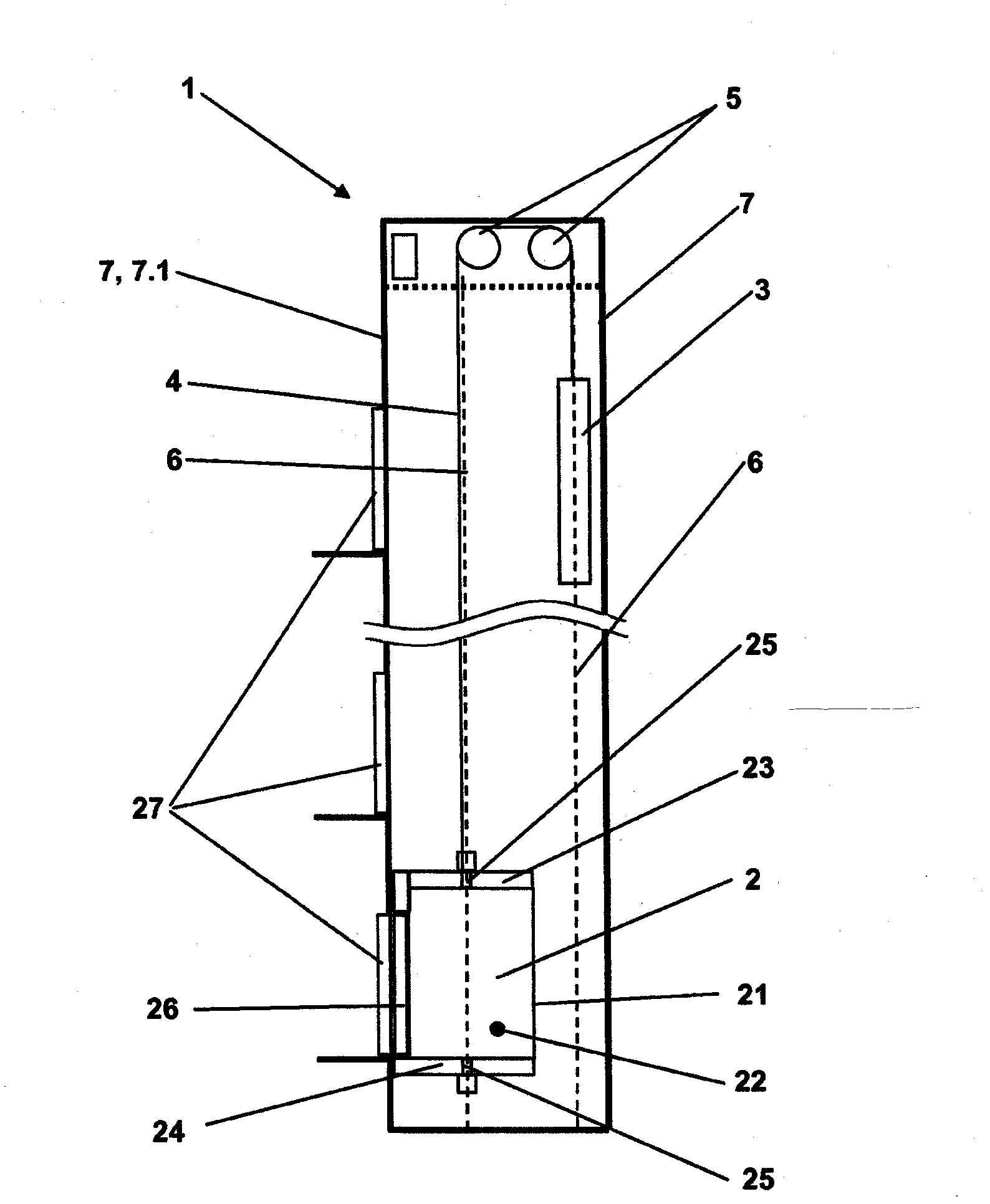

[0052] figure 1 A possible general structure diagram of an elevator is shown in . The elevator 1 or elevator system comprises at least one elevator car 2 , a drive 5 , a counterweight 3 and also a support device 4 . The drive device 5 drives the support device 4 and thus moves the elevator car 2 and counterweight 3 in the opposite direction. The car 2 is designed to accommodate people and / or goods and to transport it between floors of a building. The car 2 and the counterweight 3 are guided by means of guides 6 . The elevator is built in a shaft, wherein the shaft is essentially defined by the travel space, which itself is defined by the travel path of the car 2 and the counterweight 3 . It contains safe spaces and spacing in all cases.

[0053] The shaft is delimited by shaft walls 7 . The shaft wall 7 can optionally be produced partly or completely from the lightweight glass panes according to the invention, from other building materials or from a mixture of any desired...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com