Wear-resistant wood-plastic profile and preparation method thereof

A technology of wood-plastic profiles and walnut shell powder, which is applied in the field of building materials, can solve problems such as low requirements for skid resistance and aesthetics, affect consumers' use, and poor wear resistance, and achieve improved aesthetics, shortened preparation cycle, and high The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

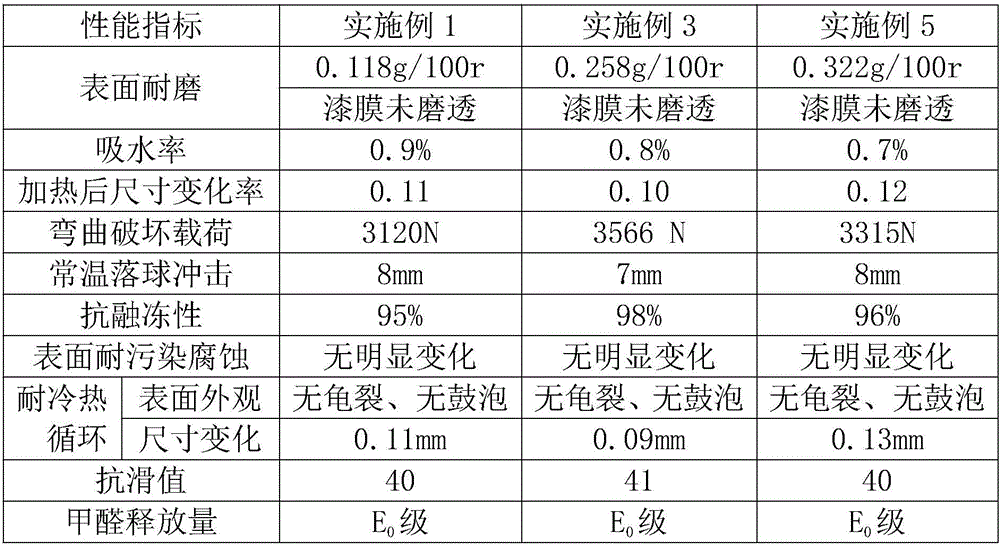

Examples

Embodiment 1

[0022] Wear-resistant wood-plastic profiles are made from the following raw materials by weight: 60 parts of walnut shell powder (particle size is 120 mesh), 26 parts of peanut shell powder (particle size is 100 mesh), 20 parts of polyethylene, triacetin 12 parts, 5 parts silicone powder, 8 parts polytetrafluoroethylene powder, 4 parts di-n-butyl phosphite, 7 parts cyclohexane dicarboxylate, 3 parts diethylene glycol dibenzoate, tetramethyl benzene 7 parts of divinyldisiloxane, 1 part of vinyltrichlorosilane, 2 parts of 1,3-dimethyl-6-aminouracil, 8 parts of alkyl glycosides, 1 part of 1-vinylimidazole, dioxane 1 part of diphenylamine.

[0023] The preparation method of wear-resistant wood-plastic profiles includes the following preparation steps: putting walnut shell powder and peanut shell powder into a mixer, heating at 80° C. for 8 minutes, and then adding alkyl glycosides, 1,3-dimethyl-6 -Semi-uracil, di-n-butyl phosphite, dialkyldiphenylamine and 1-vinylimidazole were m...

Embodiment 2

[0025] The wear-resistant wood-plastic profile is made from the following raw materials by weight: 50 parts of walnut shell powder (particle size is 130 mesh), 22 parts of peanut shell powder (particle size is 110 mesh), 25 parts of polyethylene, triacetin 10 parts, 6 parts silicone powder, 7 parts polytetrafluoroethylene powder, 5 parts di-n-butyl phosphite, 6 parts cyclohexane dicarboxylate, 4 parts diethylene glycol dibenzoate, tetramethyl benzene 6 parts of divinyldisiloxane, 2 parts of vinyltrichlorosilane, 3 parts of 1,3-dimethyl-6-aminouracil, 6 parts of alkyl glycosides, 2 parts of 1-vinylimidazole, dioxane 2 parts of diphenylamine.

[0026] The preparation method of wear-resistant wood-plastic profiles includes the following preparation steps: putting walnut shell powder and peanut shell powder into a mixer, heating at 85° C. for 5 minutes, and then adding alkyl glycosides, 1,3-dimethyl-6 -Semi-uracil, di-n-butyl phosphite, dialkyldiphenylamine and 1-vinylimidazole w...

Embodiment 3

[0028] Wear-resistant wood-plastic profiles are made from the following raw materials by weight: 40 parts of walnut shell powder (particle size is 140 meshes), 18 parts of peanut shell powder (particle size is 120 meshes), 30 parts of polyethylene, glycerol triacetate 8 parts, 8 parts silicone powder, 5 parts polytetrafluoroethylene powder, 6 parts di-n-butyl phosphite, 5 parts cyclohexane dicarboxylate, 5 parts diethylene glycol dibenzoate, tetramethyl benzene 5 parts of divinyldisiloxane, 3 parts of vinyltrichlorosilane, 5 parts of 1,3-dimethyl-6-aminouracil, 5 parts of alkyl glycosides, 3 parts of 1-vinylimidazole, dioxane 3 parts of base diphenylamine.

[0029] The preparation method of wear-resistant wood-plastic profiles includes the following preparation steps: putting walnut shell powder and peanut shell powder into a mixer, heating at 90° C. for 6 minutes, and then adding alkyl glycosides, 1,3-dimethyl-6 -Semi-uracil, di-n-butyl phosphite, dialkyldiphenylamine and 1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com