Flame retardant polyurethane resin and preparation method thereof and flame retardant polyurethane conformal coating

A polyurethane resin and conformal coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of low moisture resistance and voltage resistance performance, high temperature and high humidity environment, and coatings that cannot meet the requirements. , to achieve the effect of good hydrophobicity and voltage resistance, convenient operation and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

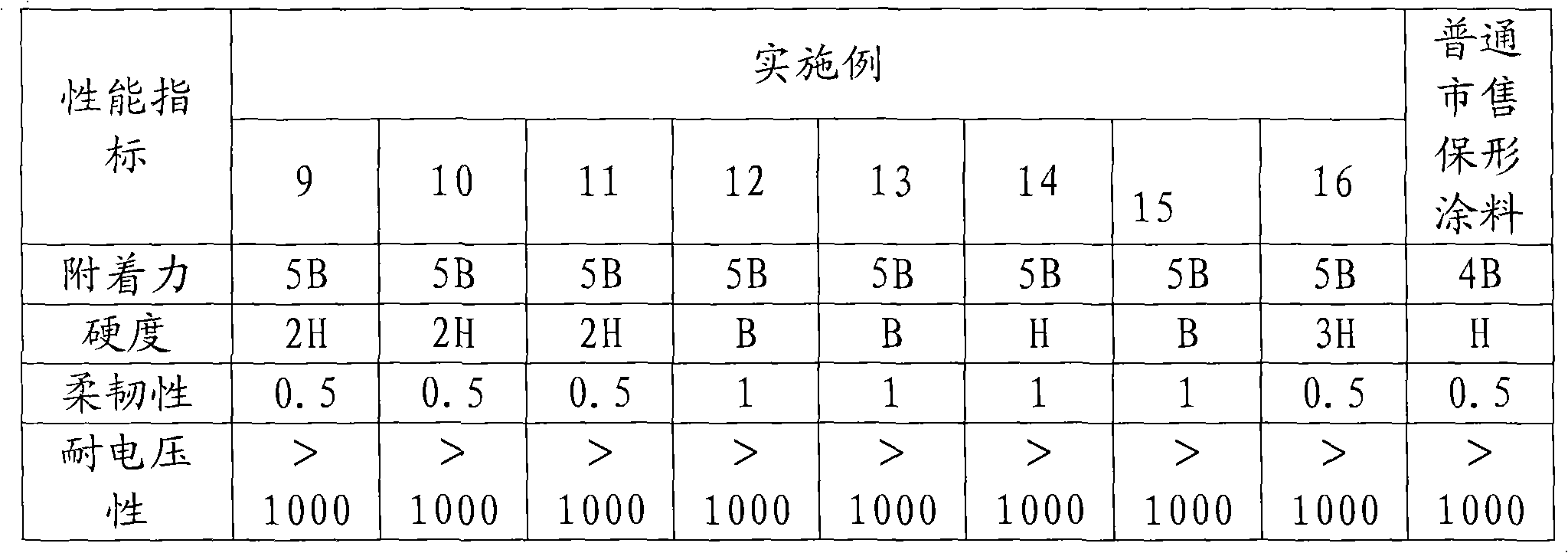

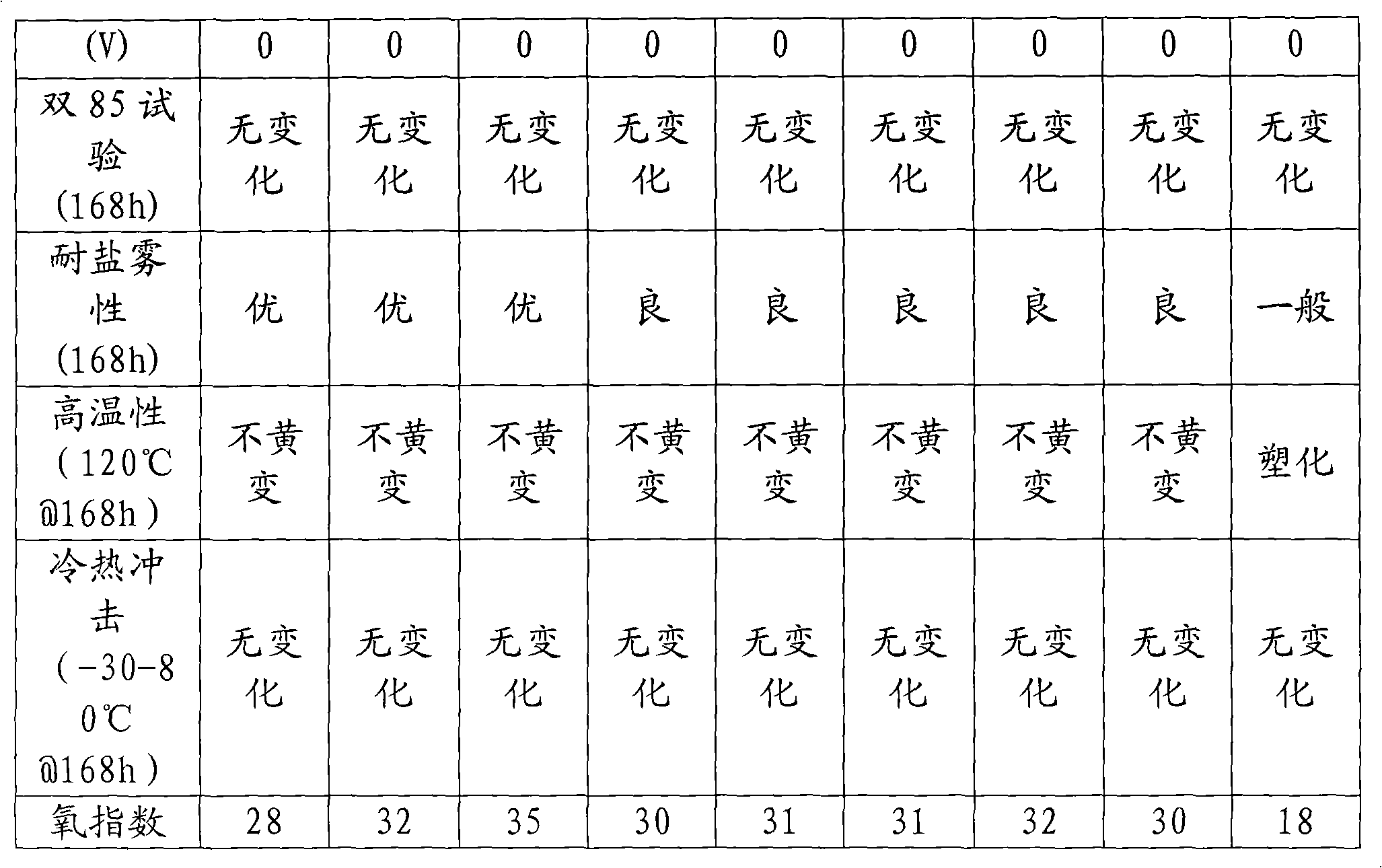

Examples

Embodiment 1

[0040] Add 93.2g of castor oil, 13.4g of trimethylolpropane, 0.19g of calcium naphthenate into a 500mL three-necked flask, protect it with nitrogen, heat to make the system homogeneous, then start stirring, and raise the temperature to 240°C for 1.5 hours , measure alcohol tolerance (85% ethanol solution, 1:4 transparent is qualified), cool down to 160°C, add 20g of xylene to azeotrope with water, until no water is taken out, cool down to 60°C.

[0041] Under the protection of nitrogen, add metered 146.45g of xylene and 26.65g of tris(dipropylene glycol) phosphite, stir evenly, drop 167.58g of TDI (toluene diisocyanate) into the polymerization system, after dropping, keep warm for 2 hours , add 0.28g of catalyst DBTL (dibutyltin dilaurate), raise the temperature to 75°C, and keep warm for reaction; after 2.5 hours, take a sample to test the NCO content.

Embodiment 2

[0043]Add 46.6g of castor oil, 6.7g of trimethylolpropane, 0.1g of cobalt naphthenate into a 500mL three-necked flask, protect it with nitrogen, heat the system to make the system homogeneous, then start stirring, and raise the temperature to 240°C for 1.5 hours , measure alcohol tolerance (85% ethanol solution, 1:4 transparent is qualified), cool down to 160°C, add 20% xylene to azeotrope with water, bring it out without water, and cool down to 60°C.

[0044] Under the protection of nitrogen, add metered 155.71g ethylene glycol ethyl ether acetate and 53.3g tris(dipropylene glycol) phosphite, stir evenly, drop 122.63g HDI (1,6-hexamethylene diisocyanate) into Polymerization system, after dripping, keep warm for 2 hours, add 1.8g of catalyst stannous octoate; raise the temperature to 75°C, keep warm for reaction; 2.5 hours later, take a sample to test the NCO content, when the NCO content is less than 7.89%, cool down, filter, pack, Instantly.

Embodiment 3

[0046] Add 46.6g of castor oil, 6.7g of trimethylolpropane, 0.1g of zinc naphthenate into a 500mL three-necked flask, protect it with nitrogen, heat the system to make the system homogeneous, then start stirring, and raise the temperature to 240°C for 1.5 hours , measure alcohol tolerance (85% ethanol solution, 1:4 transparent is qualified), cool down to 160°C, add 20% xylene to azeotrope with water, bring it out without water, and cool down to 60°C.

[0047] Under the protection of nitrogen, add metered 289.01g of butanone and 79.95g of tris(dipropylene glycol) phosphite, stir evenly, drop 155.76g of TDI into the polymerization system, after dropping, keep warm for 1-2 hours, add catalyst Dibutyltin di(dodecylsulfide) 1.5g; raise the temperature to 80°C, and keep it warm; take a sample after 2.5 hours to test the NCO content;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com