Preparation method of super-soft cable and external coating material of super-soft cable

An ultra-soft, over-clad technology, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problems of narrow cable laying space, large cable bending radius, insufficient flexibility, etc., to ensure mixing effect, improved electrical performance, easy dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

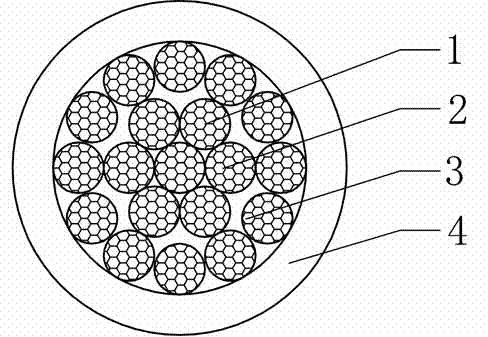

[0039] Embodiment: An ultra-flexible cable, comprising: a conductive wire core 2 twisted by 7 to 61 groups of strands 1 and its outer covering material, characterized in that: the strands 1 are made of several tinned Copper wire 3 is twisted, and the conductive wire core 2 is covered with super soft high-strength silicone rubber 4 as insulation. The material components and content by weight percentage of high-strength silicone rubber 4 are:

[0040] Methyl vinyl silicone rubber 32~43%

[0041] Precipitated silica 21~28%

[0042] Calcium carbonate 12~16%

[0044] Chlorinated paraffin 2.5~5%

[0045] Magnesium hydroxide 2.5~4%

[0046] Antiaging agent N-cumene-N′-phenyl-p-phenylenediamine 0.5~2.5%

[0047] Hydroxy silicone oil 3~4%

[0048] Hydrogen silicone oil 0.4~0.8%

[0049] Dioctyl phthalate 1~2%

[0050]Surfactant γ-mercaptopropyltrioxysilane 0.2~0.5%

[0051] Silane coupling agent KH-560 0.1~10%

[0052] Double 2,5 vulcanizing agent 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com